Processing method of ready-to-eat kelp chips

A processing method and technology of kelp slices are applied in the processing field of green leisure instant kelp chips, which can solve the problems of restricting the development of kelp processing industry and unsatisfactory, and achieve the purpose of retaining flavor and nutrients, heating time is not long, and preventing oxidative deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

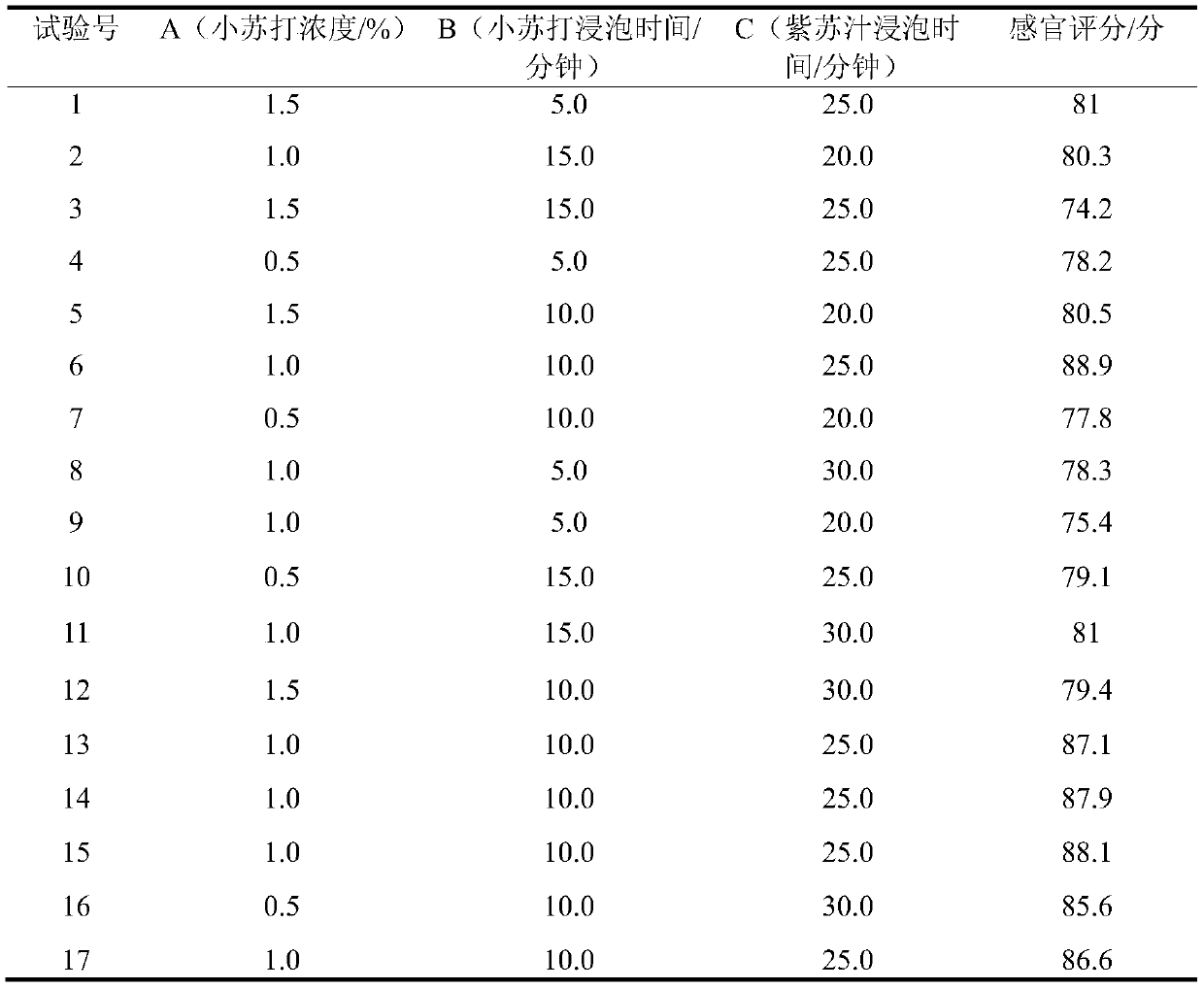

Embodiment 1

[0029] (1) Raw material selection: choose the salted dry kelp with uniform thickness and no excessive damage or mildew as raw material;

[0030] (2) Kelp pretreatment: salted dried kelp was dry-steamed for 30 minutes, then rinsed with clear water to remove sand and attached mucus on the kelp to obtain pretreated kelp;

[0031] (3) Soak hair to remove fishy smell: put the pretreated kelp in water containing 3% perilla juice and 1.5% cooking wine, soak at room temperature (25-30°C) for 25 minutes, and soak in perilla juice Remove the fishy smell and obtain the kelp after soaking;

[0032] (4) Baking soda soaking: Soak the kelp soaked in step (3) with a 1.0% sodium bicarbonate aqueous solution at room temperature for 10 minutes, then wash the kelp with clean water, cut the kelp into sheets of 3cm*3cm, and obtain kelp slices ;

[0033] (5) Seasoning and mixing: oyster sauce, sesame oil, and sugar are prepared in a mass ratio of 6:3:1 to prepare the sauce, and evenly spread on th...

Embodiment 2

[0039] (1) Raw material selection: choose the salted dry kelp with uniform thickness and no excessive damage or mildew as raw material;

[0040] (2) Kelp pretreatment: salted dried kelp was dry-steamed for 30 minutes, then rinsed with clear water to remove sand and attached mucus on the kelp to obtain pretreated kelp;

[0041] (3) Soak hair to remove fishy smell: put the kelp pretreated in step (2) into water containing 3% perilla juice and 1.5% cooking wine to soak for 30 minutes at room temperature, and remove the fishy smell by soaking in perilla juice to obtain Soaked kelp;

[0042] (4) Baking soda soaking: Soak the kelp soaked in step (3) with a 0.5% sodium bicarbonate aqueous solution at room temperature for 10 minutes, then wash the kelp with clean water, cut the kelp into sheets of 3cm*3cm, and obtain kelp slices ;

[0043] (5) Seasoning and mixing: oyster sauce, sesame oil, and sugar are prepared in a mass ratio of 6:3:1 to prepare a sauce, and evenly spread on the ...

Embodiment 3

[0047] (1) Raw material selection: choose the salted dry kelp with uniform thickness and no excessive damage or mildew as raw material;

[0048] (2) Kelp pretreatment: salted dried kelp was dry-steamed for 30 minutes, then rinsed with clear water to remove sand and attached mucus on the kelp to obtain pretreated kelp;

[0049] (3) Soak hair to remove fishy smell: soak the pretreated kelp in water containing 3% perilla juice and 1.5% cooking wine for 25 minutes, remove the fishy smell by soaking in perilla juice, and obtain kelp after soaking ;

[0050] (4) Baking soda soaking: soak the kelp after soaking with 1.2% sodium bicarbonate aqueous solution at room temperature for 10 minutes, then wash the kelp with clear water, cut the kelp into sheets of 3cm*3cm, and obtain the kelp slices;

[0051] (5) Seasoning and mixing: mix oyster sauce, sesame oil, and sugar with a mass ratio of 3:1:1 to make a sauce, and spread it evenly on the surface of the kelp slices;

[0052] (6) Air fry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com