Double-acting hydraulic retarder

A hydraulic retarder, double-acting technology, applied in the direction of hydraulic resistance brakes, brake types, mechanical equipment, etc., can solve the problems of increasing oil circulation, accidents, low transmission power, etc., and improve the braking response speed. , Improve the efficiency of braking, prolong the effect of heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

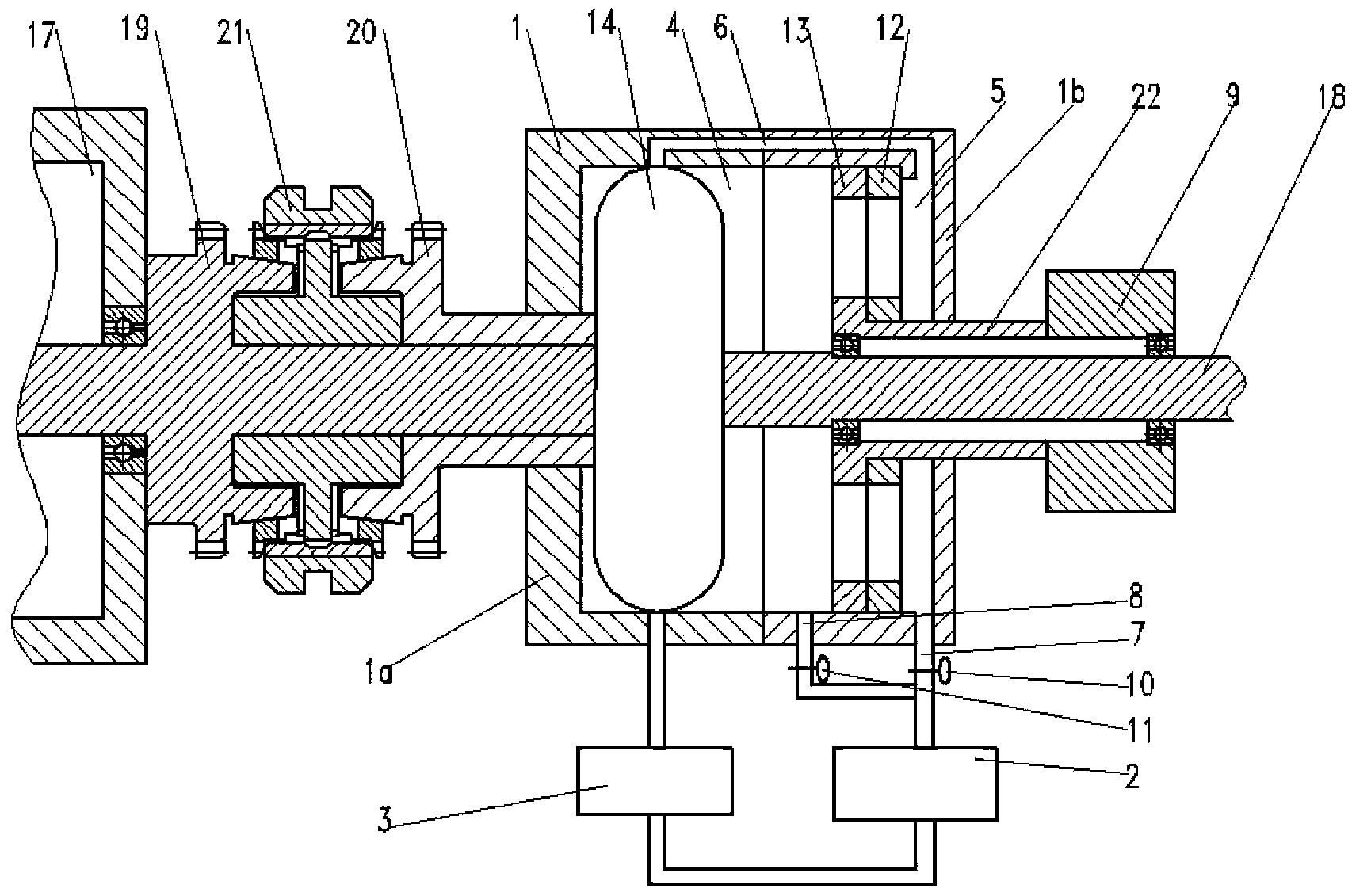

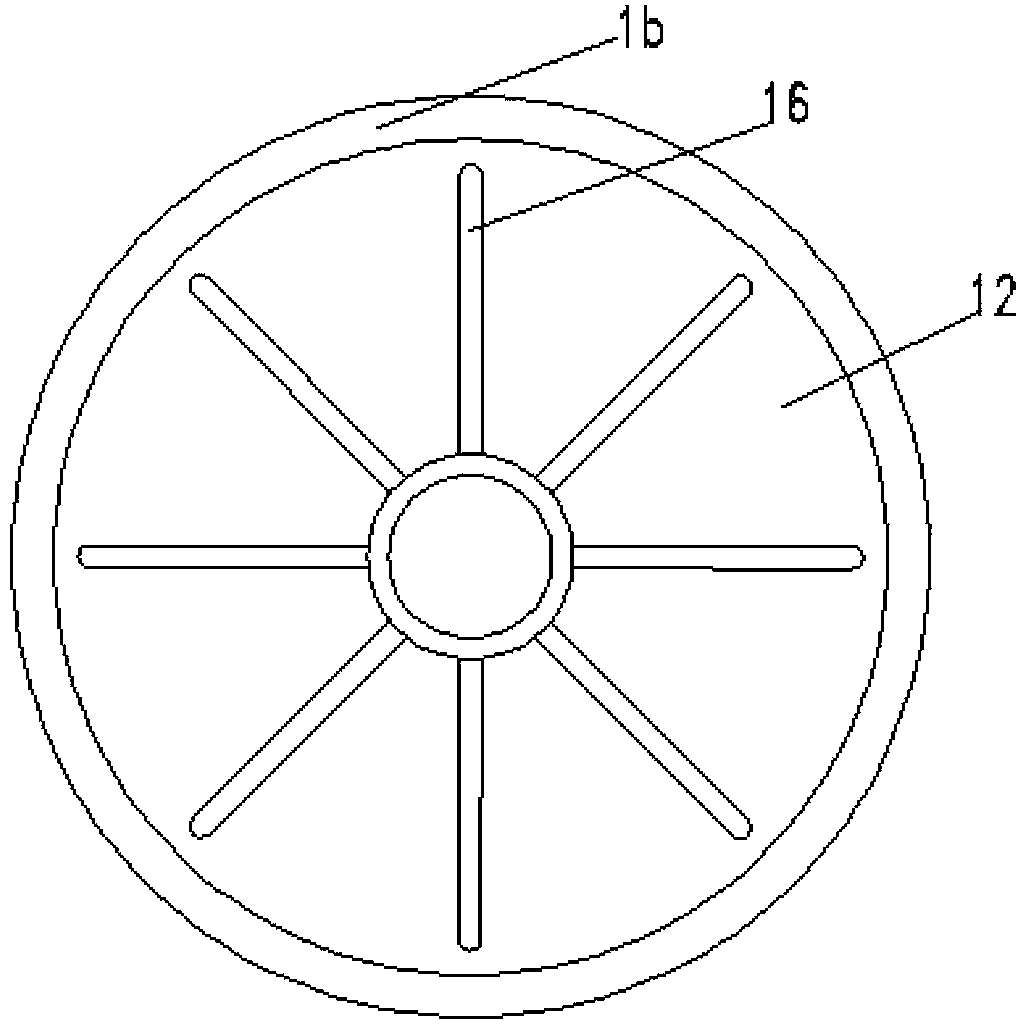

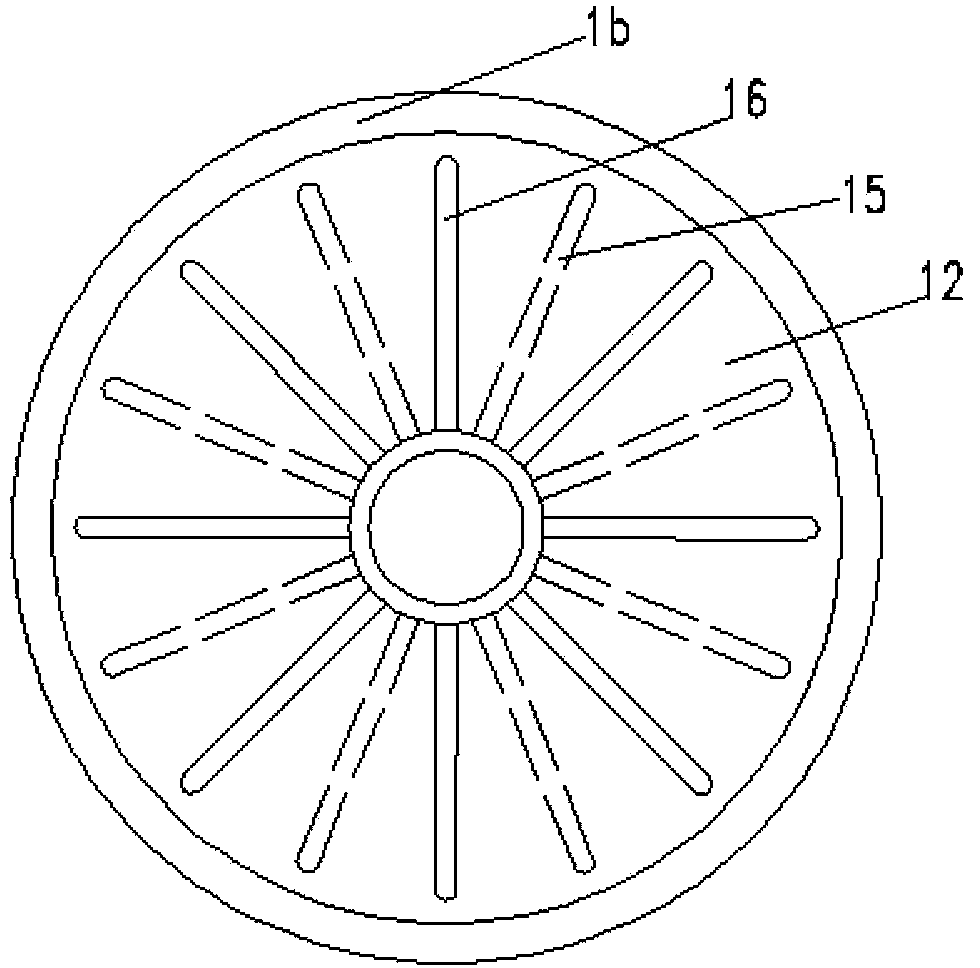

[0018] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a structural schematic diagram of the position relative to the fixed disk after the rotating disk rotates, image 3 It is a schematic structural diagram of the position relative to the fixed disk when the rotating disk is stationary, as shown in the figure: the double-acting hydraulic retarder of this embodiment includes a housing 1, a control system and a heat exchanger 2 communicating with the housing 1 and an oil tank 3, the inner cavity of the housing 1 is provided with an impeller 14 and a high-pressure fuel injection device for spraying oil to the impeller during high-speed braking, and the high-pressure fuel injection device separates the inner cavity of the housing into The vacuum working chamber 4 where the impeller works and the oil storage chamber 5 for storing high-pressure injection oil, the housing 1 is provided with an oil passage 6 communicating with the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com