Method for preparing silicon quantum dot films through microwave annealing

A technology of microwave annealing and silicon quantum dots, which can be used in final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc. It can solve problems such as silicon quantum dots that have not yet been seen, and achieve lower crystallization temperature, faster separation, and lower costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Si / SiO x Preparation of multilayer films

[0025] Step 1. Substrate cleaning: A quartz plate with a thickness of 1mm is ultrasonically cleaned by deionized water, acetone, absolute ethanol and deionized water for 15 minutes;

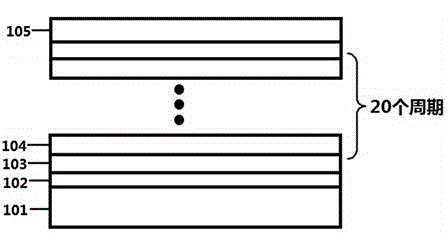

[0026] Step 2. Sputtering coating: prepare SiO on the quartz substrate by magnetron co-sputtering x / Si multilayer film. Background vacuum 5×10 -5 Pa, the substrate temperature is 300°C, the argon gas flow rate is 40sccm, the working pressure is 0.3Pa, the pulse power of the Si target is 100W, and the SiO is connected 2 The RF power of the target is 40W. Such as figure 1 As shown, a layer of SiO with a thickness of 10 nm is grown on the substrate 101 2 buffer layer 102, and then alternately grow a 5nm-thick silicon-rich silicon oxide layer 103 and a 5nm-thick silicon layer 104 (a total of 20 cycles), and finally grow a layer of 10nm-thick SiO 2 Capping layer 105;

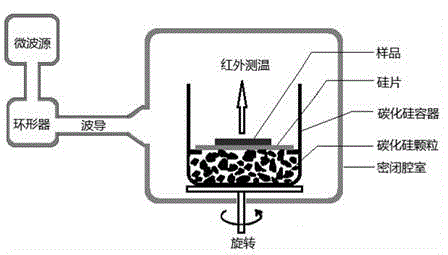

[0027] Microwave annealing crystallization process

[0028] Take out the s...

Embodiment 2

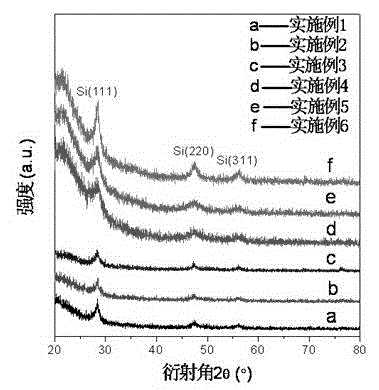

[0030] Similar to Example 1, the difference is that the annealing temperature is 800°C. The GIXRD test result of the silicon quantum dot obtained is as follows image 3 (b) shown.

Embodiment 3

[0032] Similar to Example 1, the difference is that the annealing temperature is 700°C. The GIXRD test result of the silicon quantum dot obtained is as follows image 3 (c) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com