Preparation method of nano calcium fluoride for self-lubricating tool material

A tool material, calcium fluoride technology, applied in nanotechnology, calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., can solve the problem of not being able to prepare self-lubricating tool materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

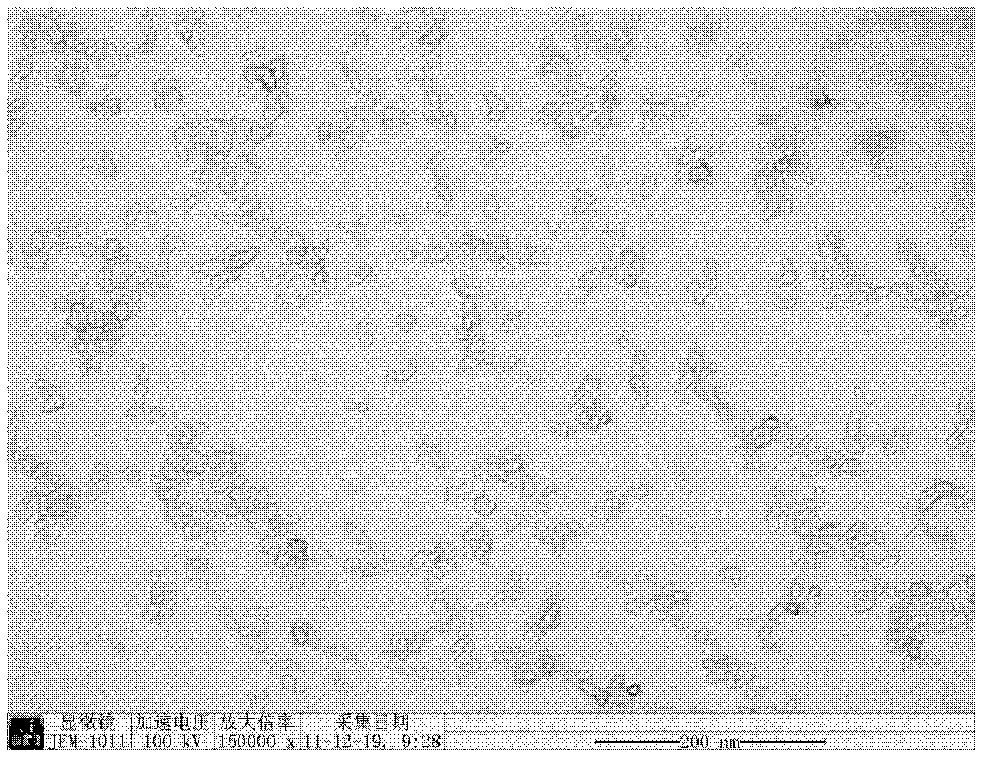

Image

Examples

Embodiment 1

[0027] Weigh 4.72g of calcium nitrate and 1.85g of ammonium fluoride according to the molar ratio of 1:2.5, put them into beakers respectively, add 10ml of distilled water and 10ml of absolute ethanol respectively, shake well and dissolve, and obtain the pre-prepared calcium nitrate and ammonium fluoride solution; weigh 0.8 g of PEG6000, add it to 200 ml of absolute ethanol, and ultrasonically disperse it for 20 minutes to completely dissolve it to obtain a composite solvent of polyethylene glycol and absolute ethanol. Divide the prepared composite solvent into two parts in equal amounts, add to the pre-prepared calcium nitrate and ammonium fluoride solutions respectively, stir magnetically for 60 minutes, and disperse ultrasonically for 20 minutes; the dispersed calcium nitrate solution and ammonium fluoride solution are obtained.

[0028] Under ultrasonic and stirring conditions, pour the dispersed calcium nitrate solution into the dispersed ammonium fluoride solution, and re...

Embodiment 2

[0031] Weigh 4.72g of calcium nitrate and 1.85g of ammonium fluoride according to the molar ratio of 1:2.5, put them into beakers respectively, add 8ml of distilled water and 10ml of absolute ethanol respectively, shake well and dissolve, and obtain the pre-prepared calcium nitrate and ammonium fluoride solution; weigh 0.9 g of PEG6000, add it to 250 ml of absolute ethanol, and ultrasonically disperse it for 10 minutes to completely dissolve it to obtain a composite solvent of polyethylene glycol and absolute ethanol. Divide the prepared composite solvent into two equal parts, add them to the pre-prepared calcium nitrate and ammonium fluoride solutions respectively, stir magnetically for 45 minutes, and disperse ultrasonically for 30 minutes; the dispersed solution containing calcium nitrate and ammonium fluoride The solution.

[0032] Under the conditions of ultrasound and stirring, pour the dispersed calcium nitrate solution into the dispersed ammonium fluoride solution and ...

Embodiment 3

[0035] Weigh 4.72g of calcium nitrate and 1.85g of ammonium fluoride according to the molar ratio of 1:2.5, respectively put them into beakers, add 10ml of distilled water and 15ml of absolute ethanol, shake well and dissolve, and obtain the pre-prepared calcium nitrate and ammonium fluoride solution; weigh 1.3 g of PEG6000, add it to 300 ml of absolute ethanol, and disperse it ultrasonically for 30 minutes to completely dissolve it to obtain a composite solvent of polyethylene glycol and absolute ethanol. Divide the prepared composite solvent into two equal parts, add to the pre-prepared calcium nitrate and ammonium fluoride solutions respectively, stir magnetically for 80 minutes, and disperse ultrasonically for 15 minutes; the dispersed calcium nitrate solution and ammonium fluoride solution are obtained.

[0036] Under ultrasonic and stirring conditions, pour the dispersed calcium nitrate solution into the dispersed ammonium fluoride solution, and react for 4.5 minutes. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com