Carbon fiber oiling agent for dry spray wet spinning technology and preparation method thereof

A technology of dry jet wet spinning and carbon fiber, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., which can solve the problems of high content of polymerized monomers, increased emulsification difficulty, and poor protection of carbon fibers, etc. Good electrostatic effect and protect carbon fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the preparation of compound A

[0037] Add 2Kg of polyetheramine D400 (ammonia value 4.5mmol / g) and 19Kg of isopropanol to the reactor, stir, heat up to 85°C to 90°C, add 36Kg of epoxy-terminated silicone oil (molecular weight 10000) dropwise, add dropwise After reflux for 4 hours, the solvent was evaporated under reduced pressure, and finally the pressure was reduced to 133Pa, and the temperature was raised to 120°C to remove small molecules to obtain compound A-1 with a viscosity of 5600cp and an ammonia value of 0.22mmol / g.

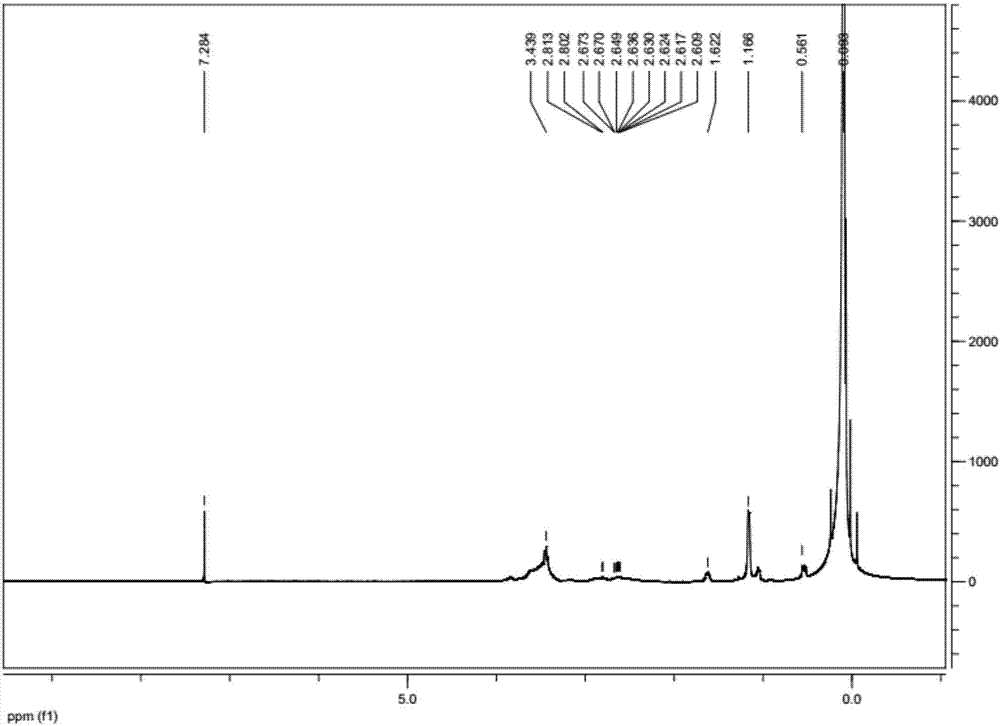

[0038] Compound A-1 H NMR spectrum such as figure 1 As shown, the solvent is CDCl 3 . Among them, the chemical shift δ=0.093 is the proton peak of the silicon methyl group, δ=0.526 is the proton peak of the methyl group connected with silicon, δ=1.166 is the proton peak of the methyl group in the polyoxypropylene link, and δ=1.622 is the proton peak of the methyl group connected with silicon. The proton peak of the methylene gro...

Embodiment 2

[0039] Embodiment 2, the preparation of compound A

[0040] Add 3Kg polyetheramine ED600 (ammonia value 3.1mmol / g) and 15Kg isopropanol to the reactor, stir, raise the temperature to 85°C-90°C, add 27.9Kg terminal epoxy silicone oil (molecular weight 7000) dropwise, and the dropwise addition is completed After reflux for 4 hours, the solvent was evaporated under reduced pressure, and finally the pressure was reduced to 133Pa, and the temperature was raised to 120°C to remove small molecules to obtain compound A-2 with a viscosity of 13000cp and an ammonia value of 0.28mmol / g.

[0041] The specific proportioning and composition of Examples 3-5 are shown in Table 1.

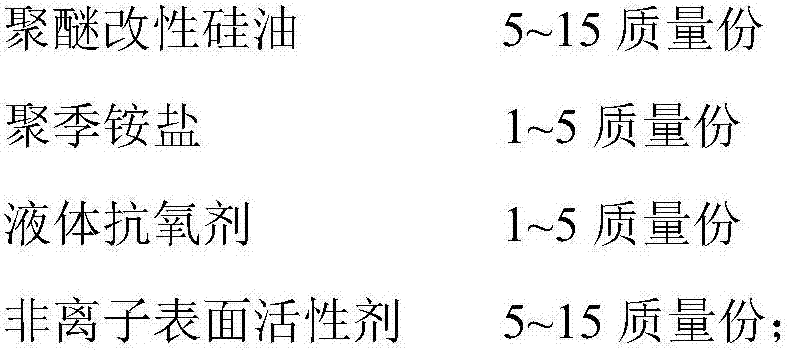

[0042] The specific proportioning and composition are shown in Table 1, and the preparation steps are as follows:

[0043] After mixing the materials, stir and drip water, neutralize with acetic acid to neutral after phase inversion, and finally obtain a stable emulsion with a particle size of 0.01 μm to 0.5 μm th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com