High-fluidity concrete and preparation method thereof

A high-fluidity, concrete technology, applied in the field of concrete, special concrete, high-fluidity concrete and its preparation, can solve the problems of difficulty in meeting the fluidity and self-compacting requirements of steel shell immersed tubes, and achieve excellent overall fluidity, The effect of high concrete strength and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Formulating High Fluid Concrete

[0067] Concrete takes raw materials according to the following ratio per cubic meter:

[0068] Gravel 765.9kg / m 3 ; (The apparent density of gravel is 2700kg / m 3 )

[0069] River sand 863.6kg / m 3 ; (the apparent density of the river sand is 2640kg / m 3 , sand rate 53%)

[0070] Cement 286kg / m 3 ; (the cement apparent density is 3140kg / m 3 )

[0071] Fly ash 156kg / m 3 ; (the apparent density of fly ash is 2240kg / m 3 )

[0072] Mineral powder 78kg / m 3 ; (the apparent density of mineral powder is 2900kg / m 3 )

[0073] Water 171.6kg / m 3 ;

[0074] Admixture 5.2kg / m 3 , of which tackifier accounts for 8.0%, and the rest is water reducing agent.

[0075] Stir and mix evenly to obtain high fluidity concrete.

[0076] Table 1 High fluidity mix ratio

[0077]

[0078] Table 2 Workability of high fluidity concrete

[0079]

[0080]

[0081] Table 3 Other Properties of High Fluidity Concrete

[0082]

[0083] Acco...

Embodiment 2

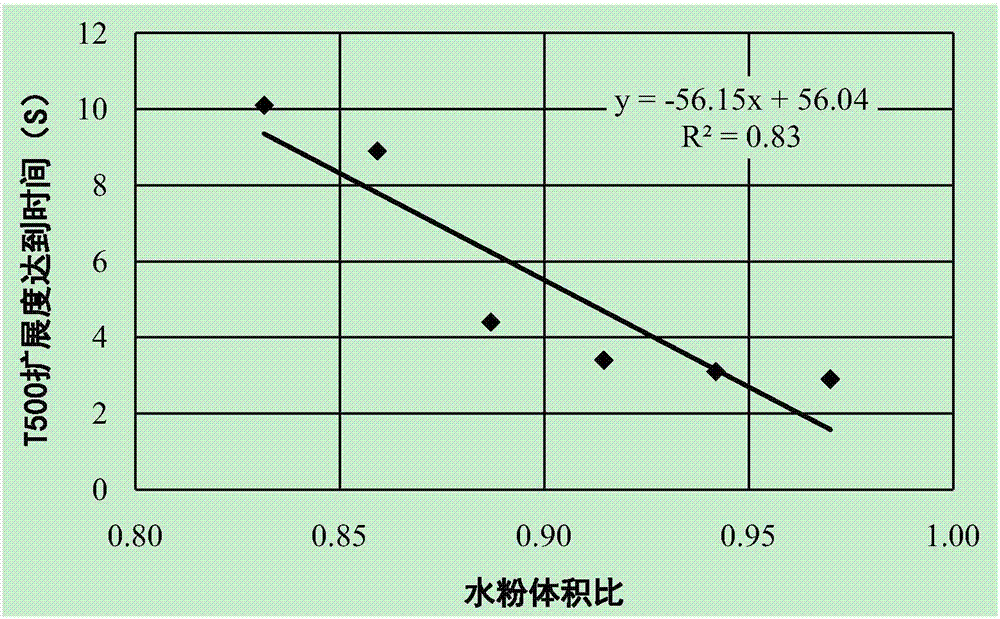

[0093] Concrete preparation: the volume ratio of water to powder is 0.83~0.97, and the amount of cementitious material is 520kg / m 3 , the cementitious material volume ratio is 48.5% cement + 37.1% fly ash + 14.4% mineral powder, the sand rate is 52% to 54%, the water-cement ratio is 0.30 to 0.35, and the amount of admixture is 0.8% to 1.2% (0.8% in admixture % is a tackifier). Prepare concrete to test its working performance (T 500 Expansion reached time, V-shaped funnel outflow time), water-powder volume ratio to T of high fluidity concrete 500 The degree of expansion has a significant effect, with results such as figure 1 As shown, as the water-powder volume ratio increases, T 500 The time decreases rapidly, the flow velocity increases, the fluidity increases, and the water-powder volume ratio increases to 0.89, T 500 The time drops below 5s.

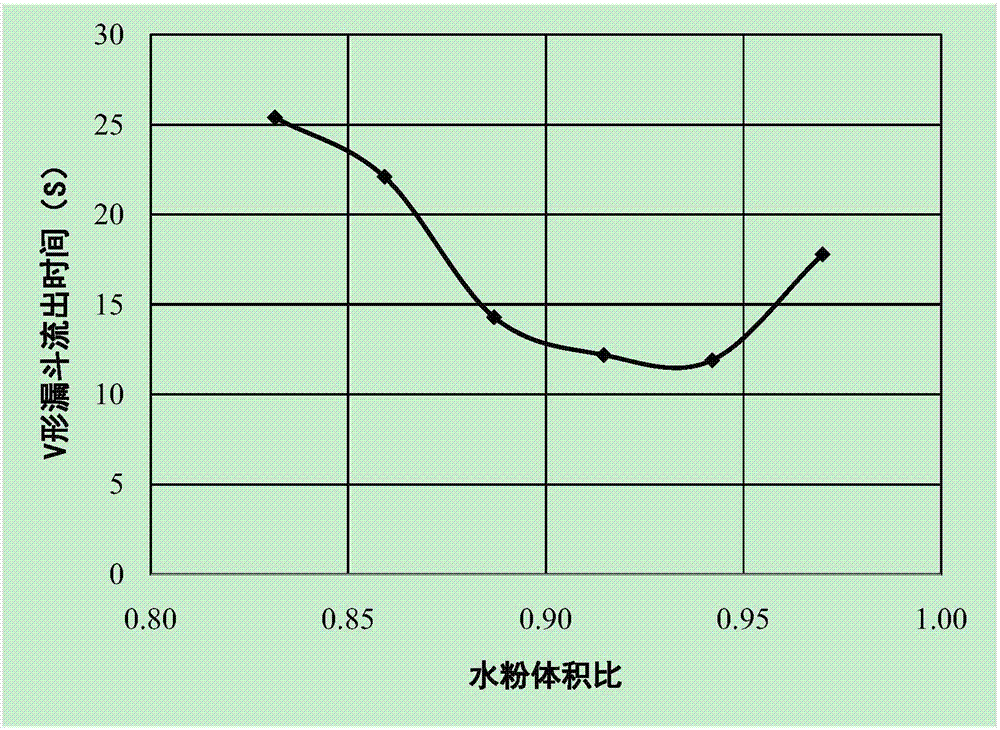

[0094] The water-powder volume ratio has a significant effect on the outflow time of the V-shaped funnel of high-fluidity concr...

Embodiment 3

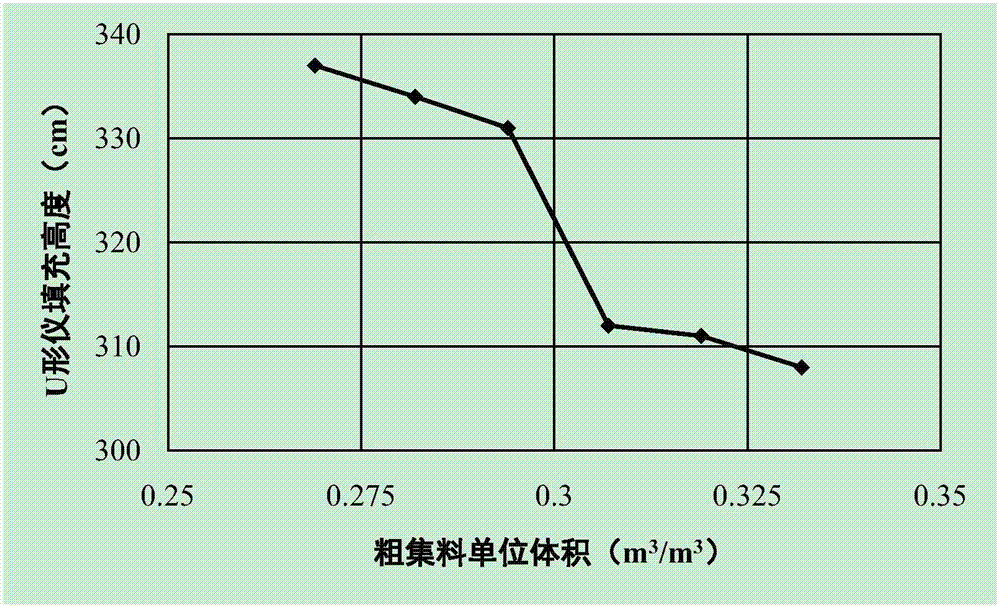

[0097] Concrete preparation: water-binder ratio 0.33, cementitious material dosage 520kg / m 3 , the cementitious material is 48.5% cement + 37.1% fly ash + 14.4% mineral powder by volume, and the unit volume of coarse aggregate is 0.26-0.33m 3 / m 3 , Admixture 0.9 ~ 1.1% (0.8% of admixture is tackifier).

[0098] The regular influence of the unit volume of coarse aggregate on the workability of high-flow concrete is mainly reflected in the package of concrete and the filling height of U-shaped instrument. The influence of the unit volume of coarse aggregate on the filling height of the U-shaped instrument is as follows: image 3 shown. As the unit volume of coarse aggregate decreases, the filling height of the U-shaped instrument gradually increases, and the concrete filling performance, segregation resistance and gap passability increase. When the unit volume of coarse aggregate decreases to 0.29m 3 / m 3 , the filling height rises to 331mm, and the filling height differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump spread | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com