Workpiece clamping device with oscillating drive and vacuum supporting functions and relevant vacuum clamp

A technology of swing drive and workpiece clamping, applied in positioning devices, metal processing machinery parts, clamping and other directions, can solve the problems of high structural cost and sealing, and achieve the effect of simple processing and precise processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

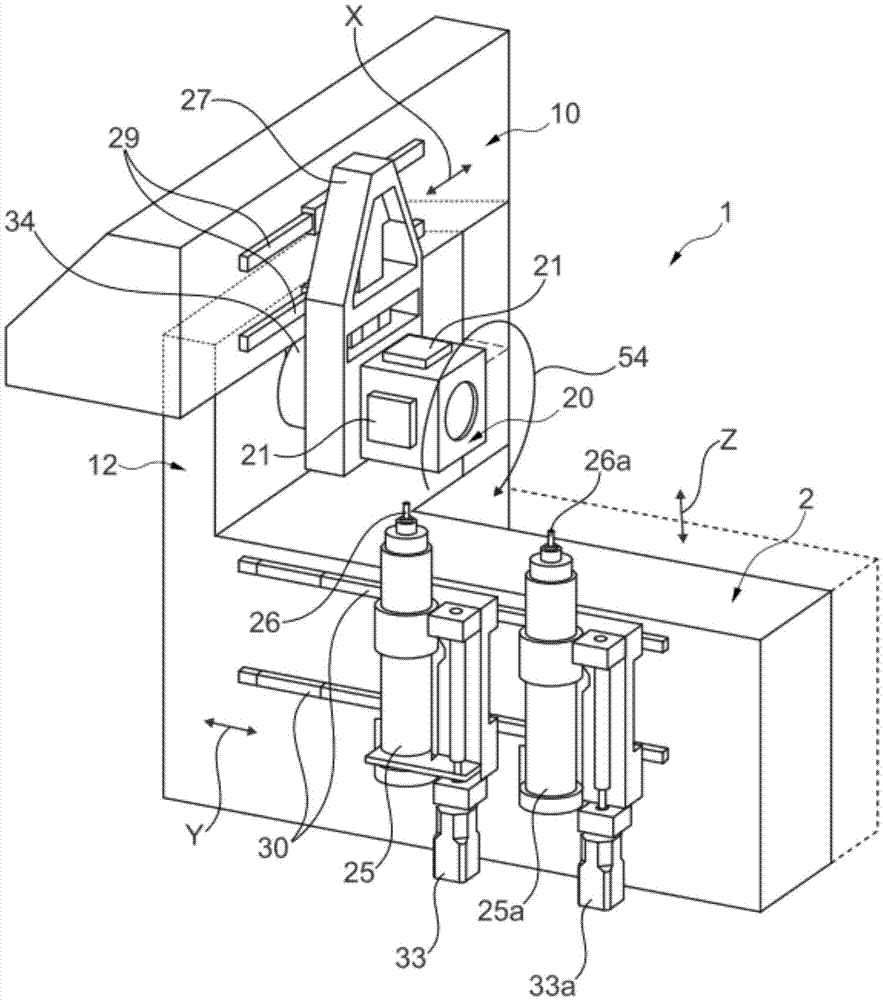

[0039] exist figure 1 The workpiece processing machine 1 is shown in perspective in the middle, which can be varied in various embodiments.

[0040] Only shown as a preferred exemplary embodiment is that the approximately square component 2 supports an L-shaped middle part 12 , on which the square upper part 10 rests, which is chamfered for weight-saving reasons.

[0041] On the front side of the base part 2 , in the region of the guide rail 30 , a carriage for the displacement drive of the two tool spindles 25 , 25 a arranged next to each other is formed. Each tool spindle 25 , 25 a is driven by a separate drive motor 33 , 33 a and accordingly there is a separate drive for the machining spindle 26 , 26 a. The guide rail 30 is oriented in the Y direction.

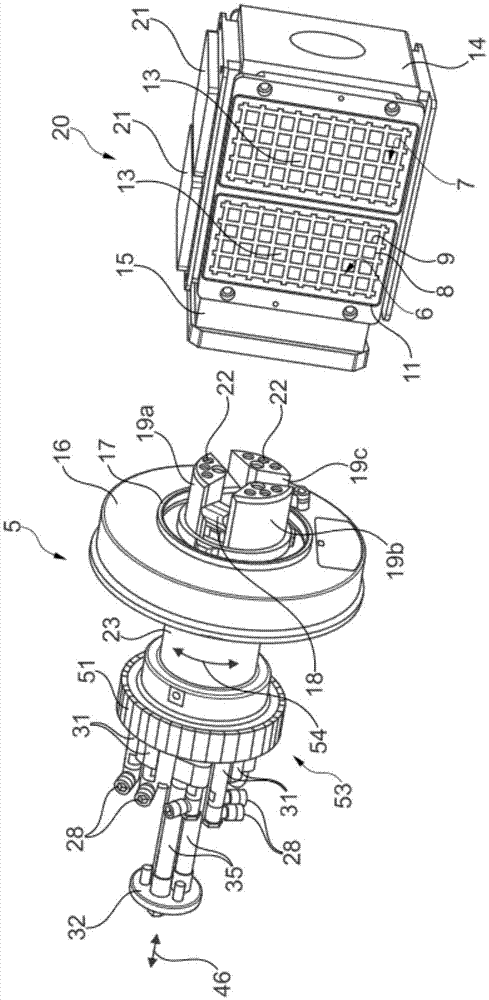

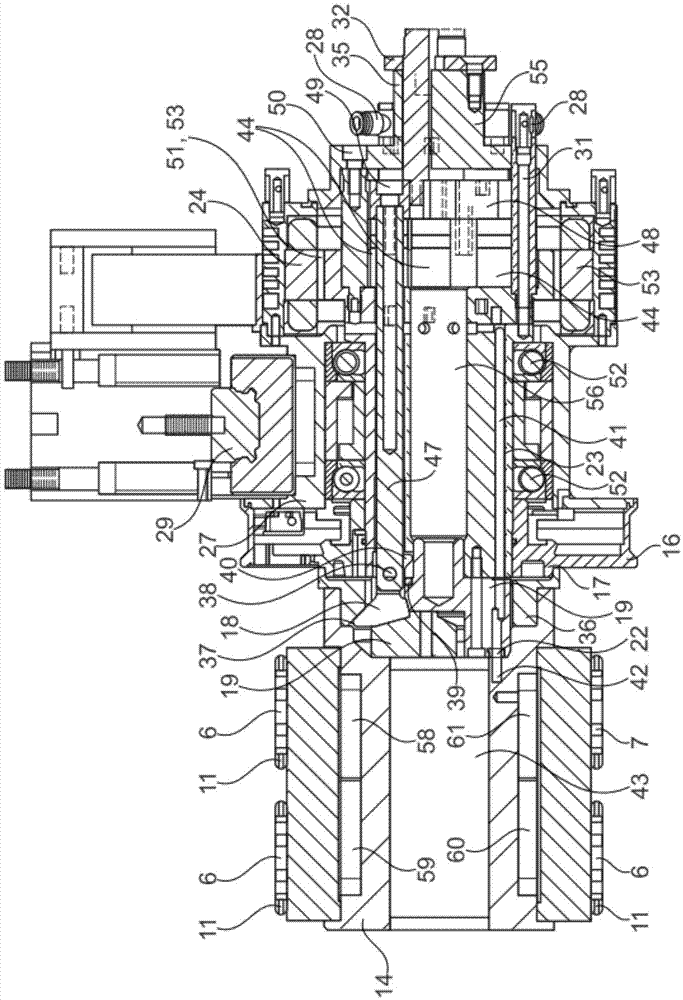

[0042] At the front side of the upper part 10 , an L-shaped beam 27 is arranged in the region of the guide rail 29 , at its lower free end a workpiece clamping device 20 according to the invention is arranged about the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com