Patents

Literature

97results about How to "Achieve mechanical connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

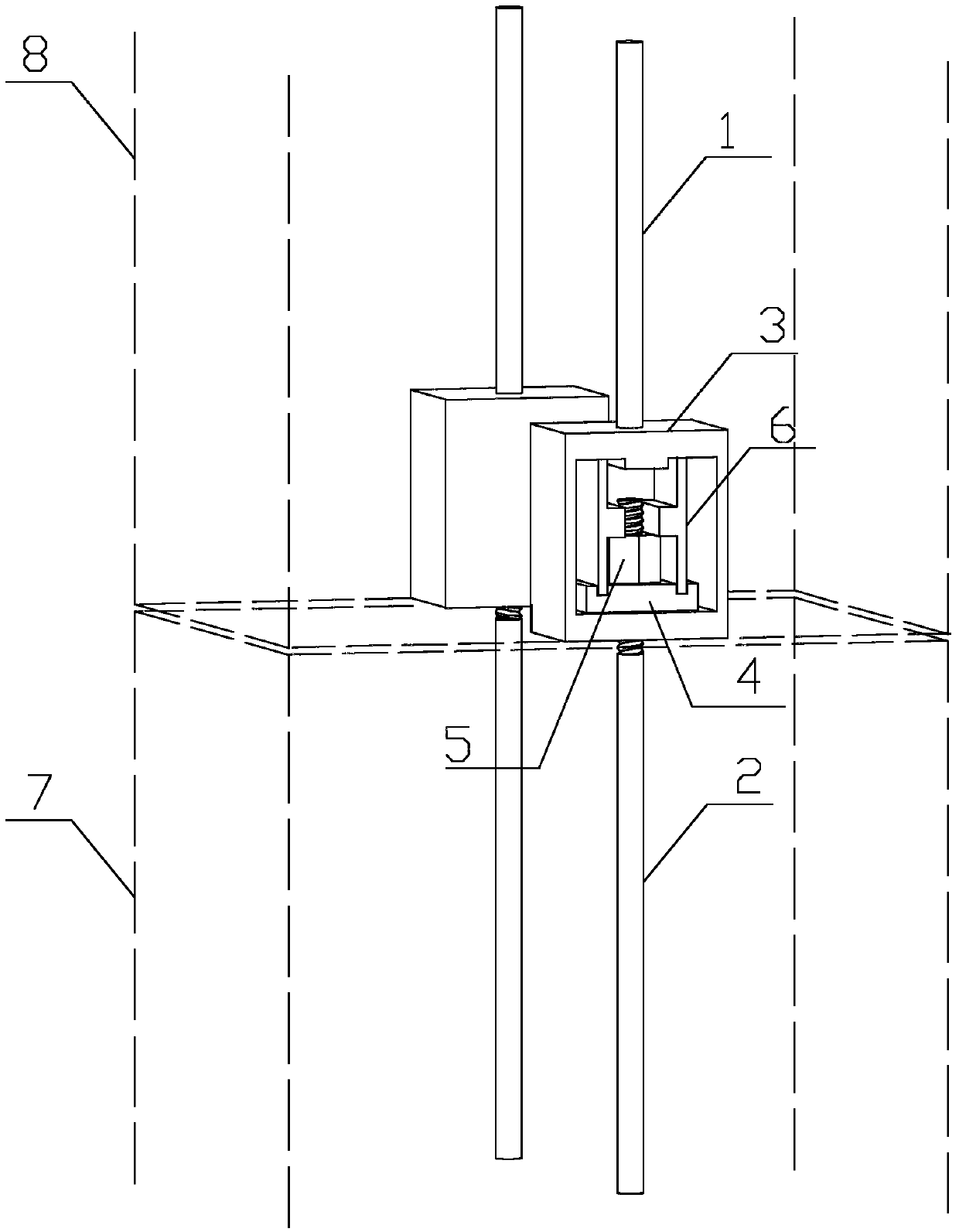

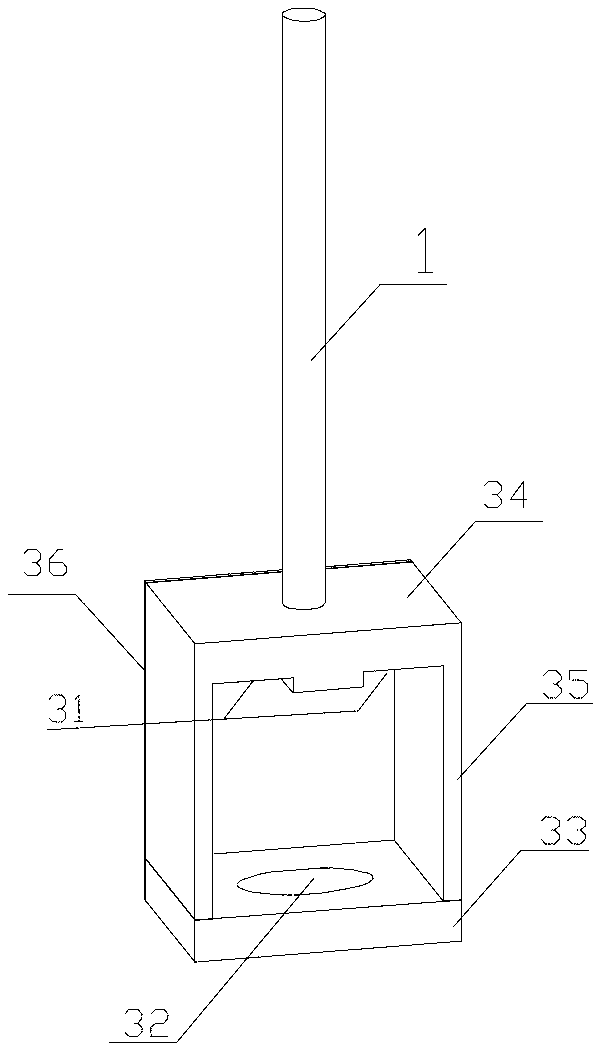

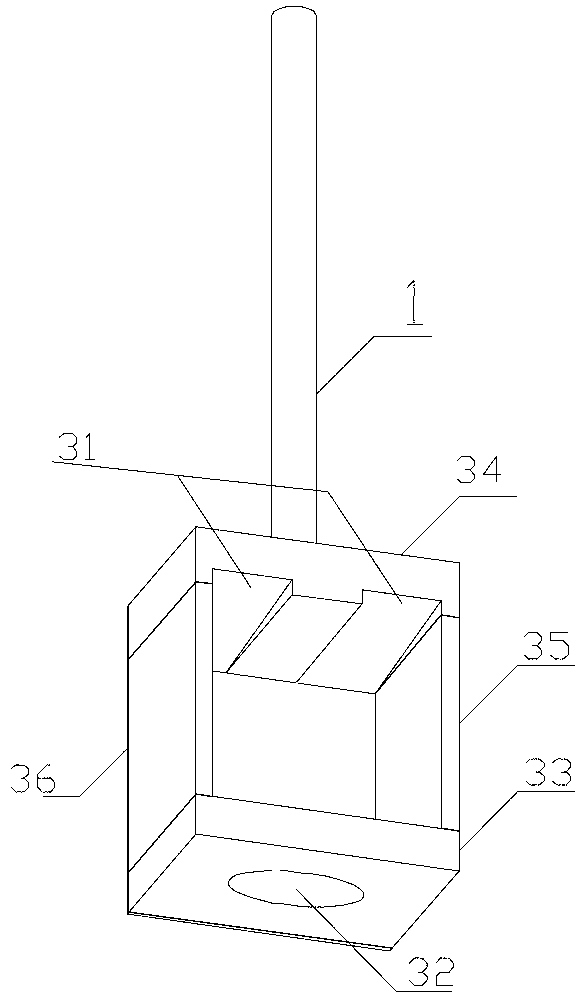

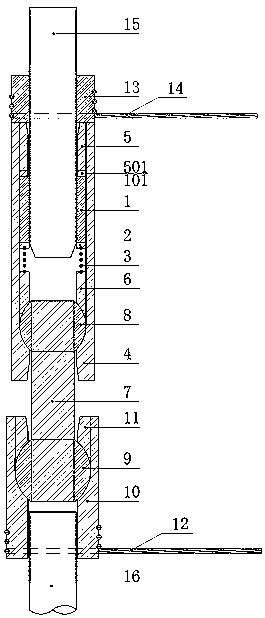

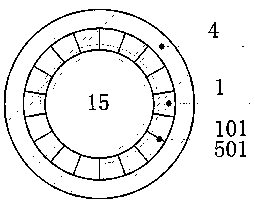

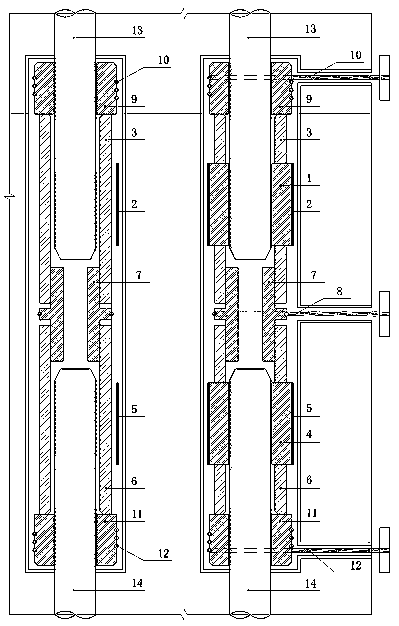

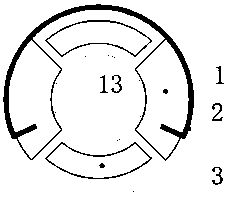

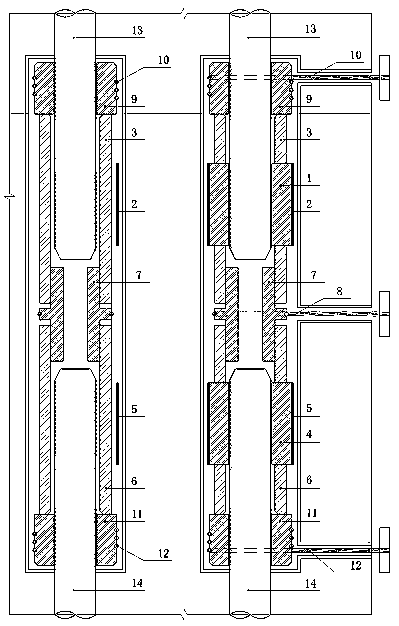

Connecting structure for vertical reinforcement bars of prefabricated wall parts

InactiveCN103132656ACapable of error adjustmentEasy to installBuilding reinforcementsEngineeringRebar

Owner:SOUTHEAST UNIV

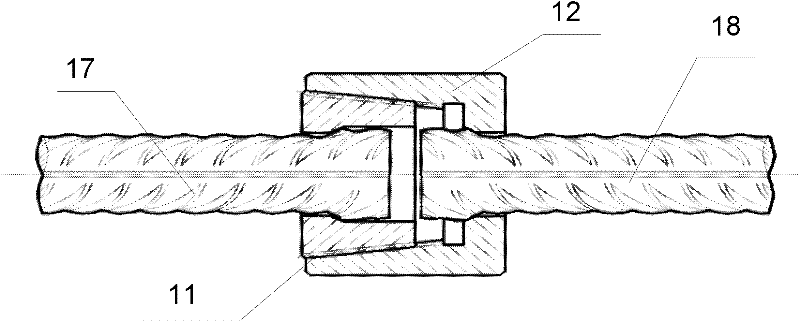

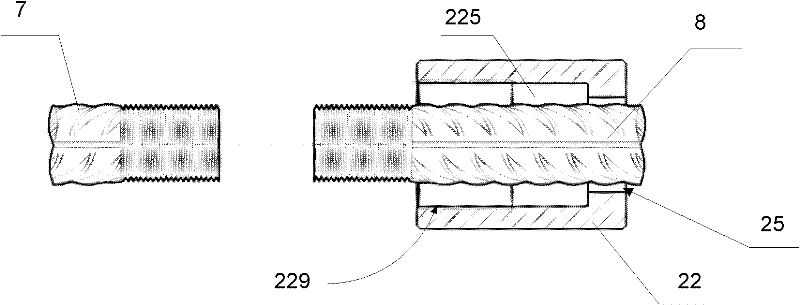

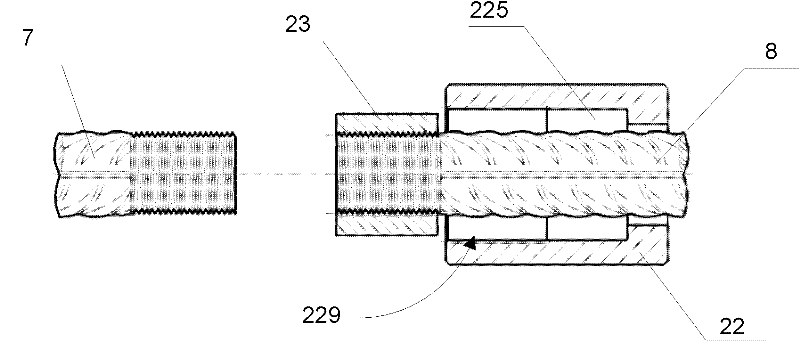

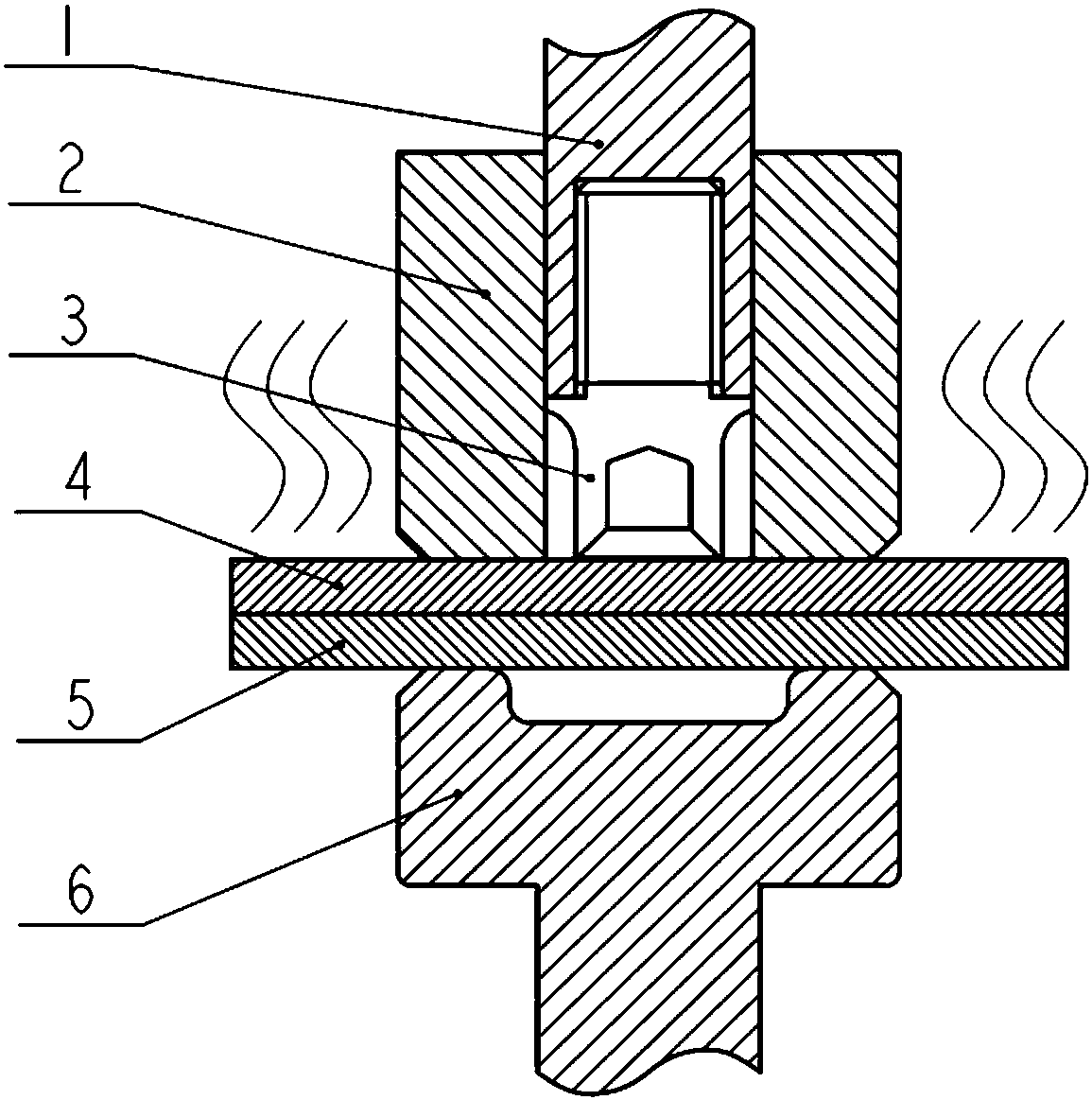

Adjustable steel bar thread connection device

InactiveCN102261167AAchieve mechanical connectionImprove replacement abilityBuilding reinforcementsArchitectural engineeringRebar

The invention discloses an adjustable steel bar threaded connection device, which comprises a first threaded sleeve, a second threaded sleeve and a joint; internal thread; the inner wall of the second threaded sleeve is provided with an internal thread for threaded connection with the end of the second steel bar, and the outer wall is provided with an external thread; the joint is a cavity with a cylindrical cavity at one end, and the cavity The bottom is provided with a hole with a diameter slightly larger than the outer diameter of the first steel bar, the inner diameter of the cavity is greater than or equal to the outer diameter of the first threaded sleeve, and the inner wall of the cavity near the outlet is provided with an outer wall thread for connecting with the second threaded sleeve. Connected internal thread. The adjustable steel bar threaded connection device of the present invention realizes the mechanical connection of two steel bars through the nested connection between the first threaded sleeve, the second threaded sleeve and the joint. The invention requires fewer parts, is simple to operate, and has strong replaceability, greatly reducing construction difficulty.

Owner:CABR TECH CO LTD +1

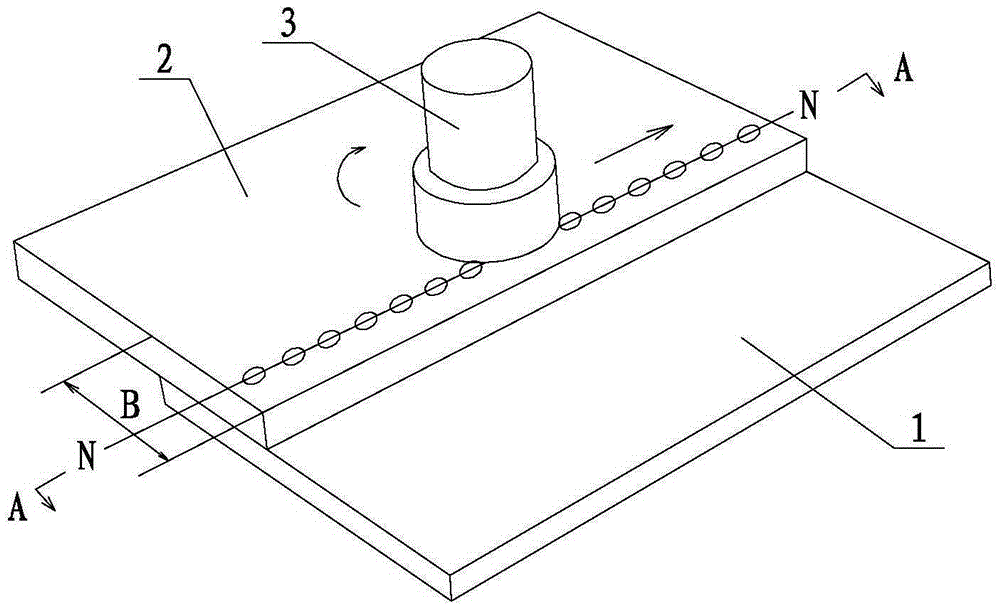

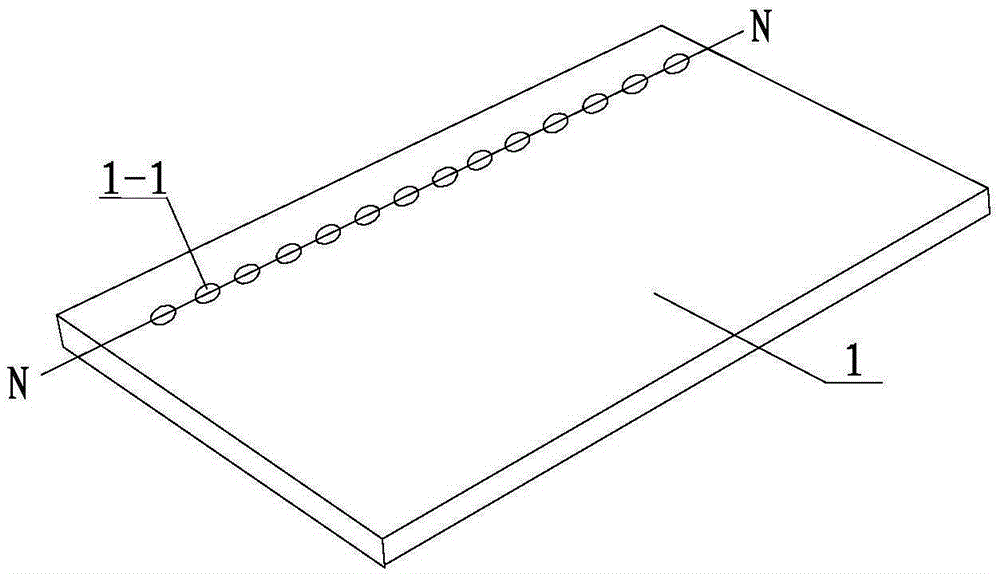

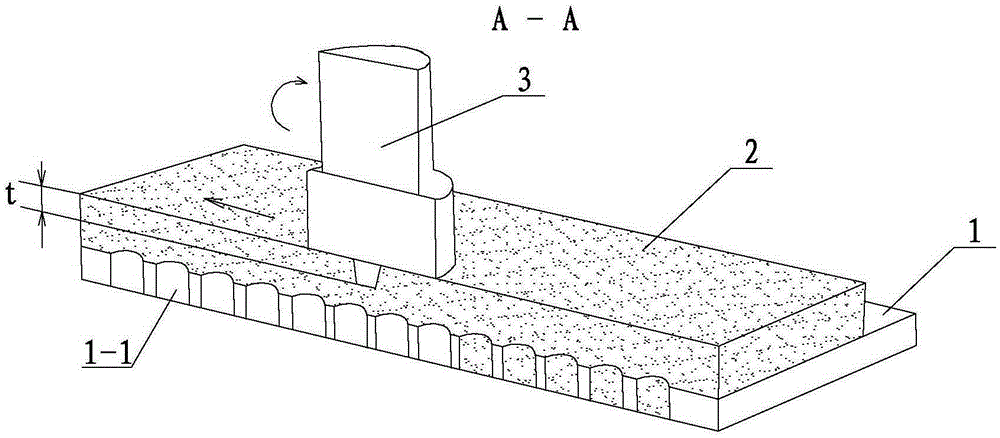

Aluminum/steel dissimilar material friction-stir lap joint method assisted by rivet type mechanical connection

InactiveCN105290608AReduce wearWeakening Effects of Weakening Carrying CapacityWelding/soldering/cutting articlesNon-electric welding apparatusLap jointDrill hole

Provided is an aluminum / steel dissimilar material friction-stir lap joint method assisted by rivet type mechanical connection. The lap join method aims at solving the problems that aluminum / steel dissimilar metals are prone to reaction to generate brittle intermetallic compounds in the existing connection process of brazing or fusion welding, and the bearing area of connectors is small and the bearing capacity of the aluminum / steel dissimilar connectors is weakened in the friction-stir-welding lap joint process. The method comprises the steps that (1) a row of pre-drilled holes are drilled in the lap joint width direction B of a steel plate along the longitudinal central line; (2) contact surfaces and the peripheral areas of the steel plate and an aluminum plate are cleaned up, and oxides on the surface of the steel plate and the surface of the aluminum plate are removed; (3) the surface of the steel plate and the surface of the aluminum plate are wiped with organic solvents or cleaning agents; and (4) the aluminum plate and the steel plate are fixed through a clamp, in the friction stir welding process, a stirring head and the aluminum plate rub, softened aluminum flows downwards, and then the pre-drilled holes in the steel plate are filled, so that a rivet type connecting structure is formed, and an aluminum / steel friction-stir lap joint connector which is strengthened through mechanical connection is obtained. The method is used for friction-stir lap joint of dissimilar materials.

Owner:HARBIN INST OF TECH

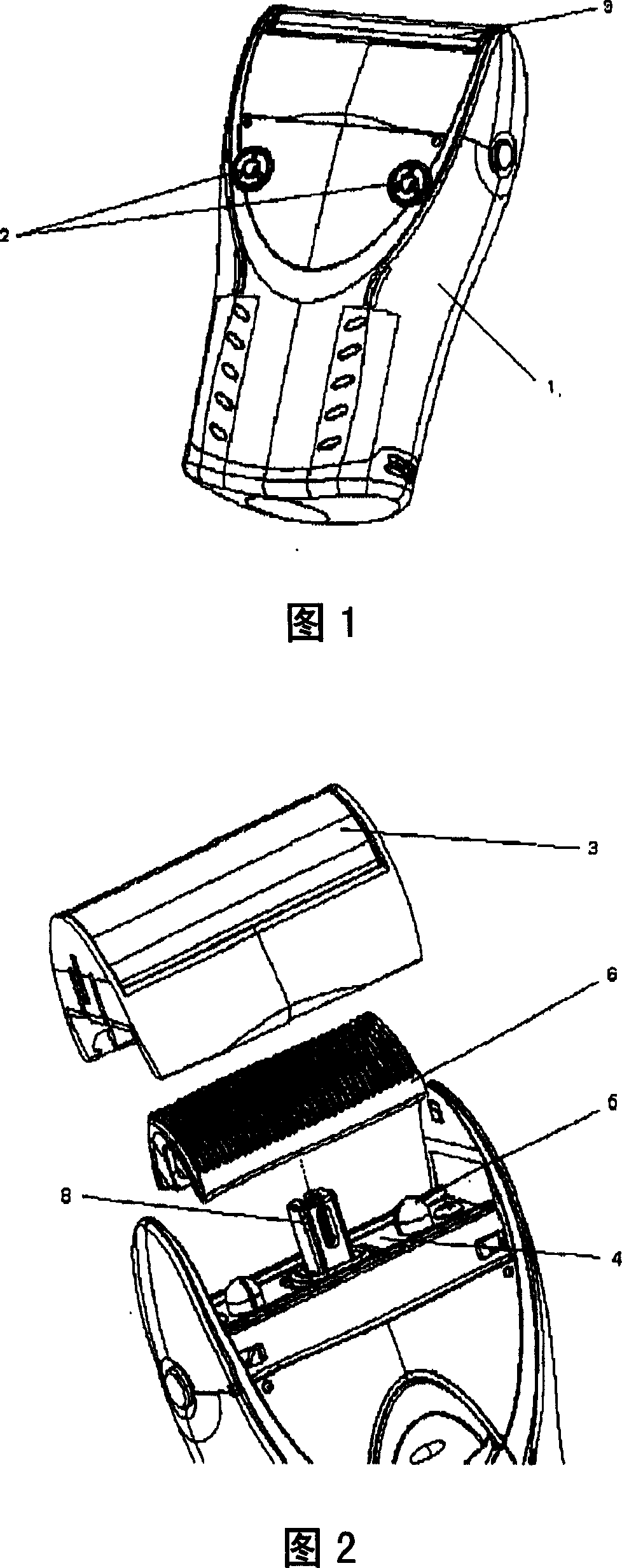

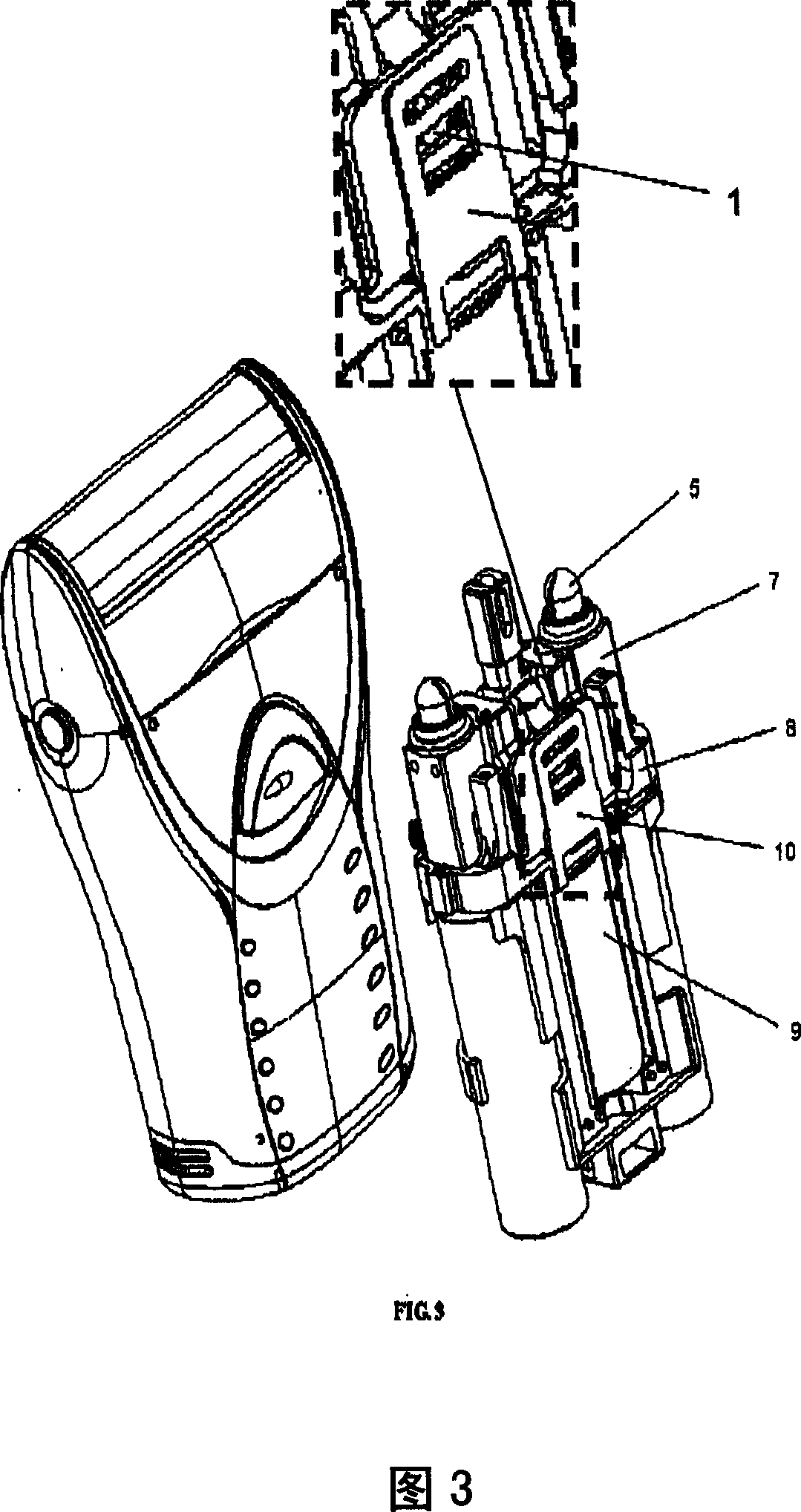

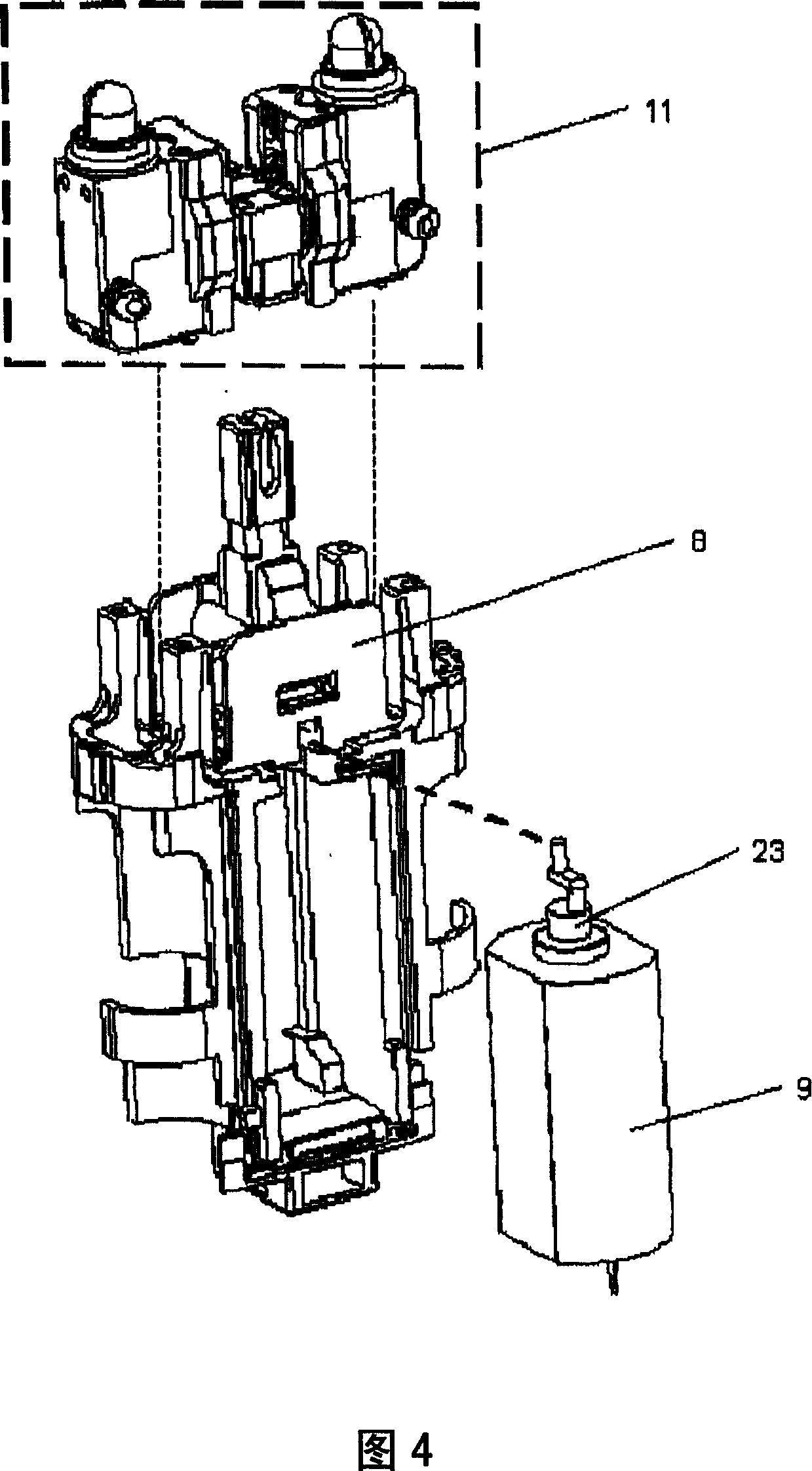

Electric shaver

InactiveCN1721146APrevent backflowAchieve mechanical connectionMetal working apparatusShaving accessoriesSpray nozzleEngineering

The present invention relates to electric shaver with shell, shaving system and motor; wherein, it also comprises cleaning pump set in shell and connected with motor output machine by rod, nozzle set on outlet of pump to spray and clean for shaving system; cleaning liquid inlet; controller to control and switch for pump by connection rod. This invention realizes inside-outside cleaning and improves cleaning efficiency.

Owner:KWONNIE ELECTRICAL PRODS

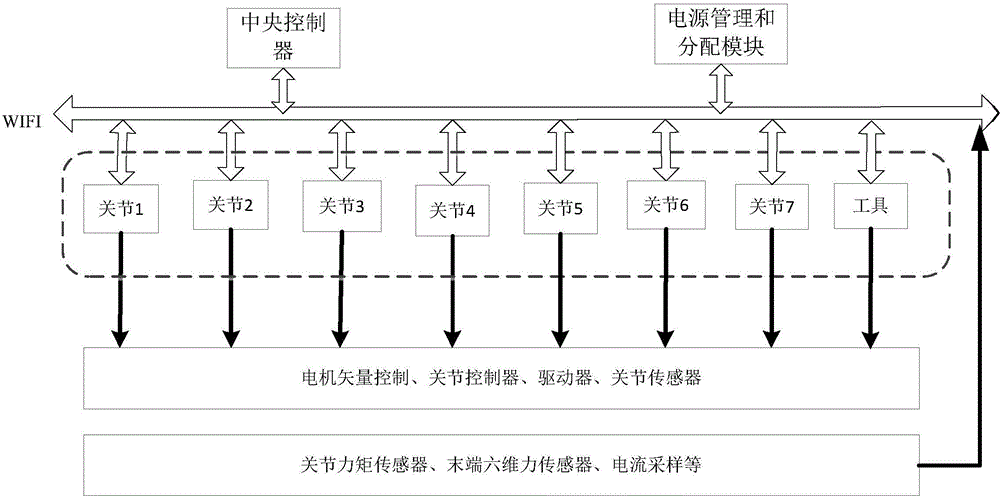

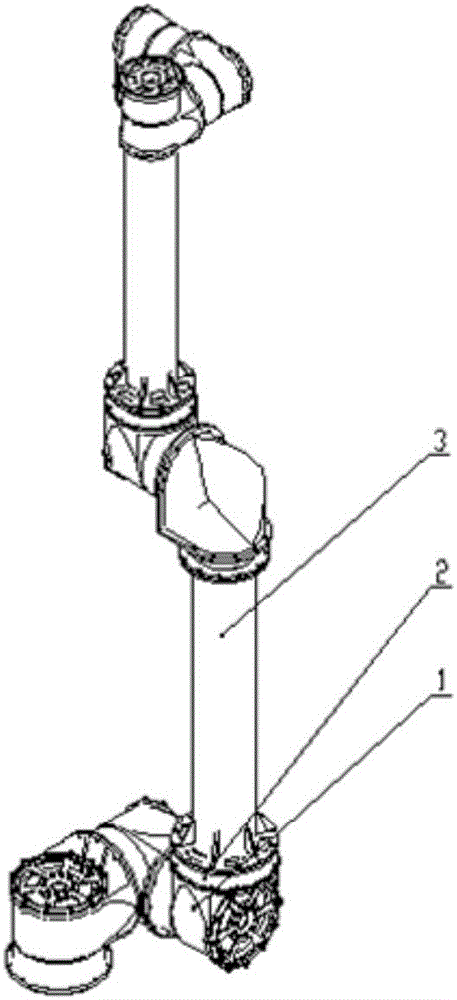

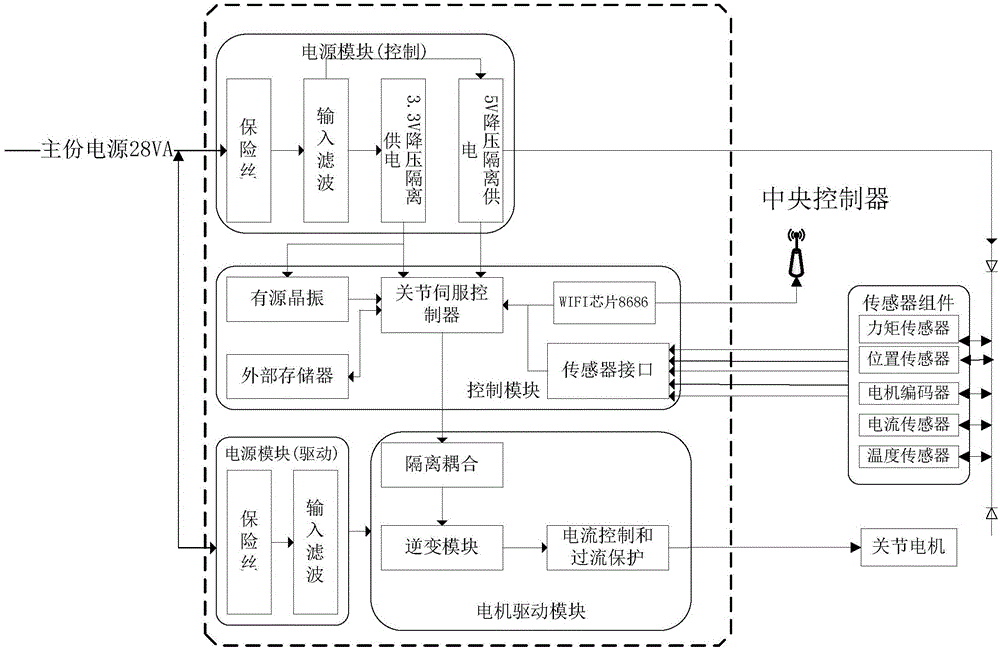

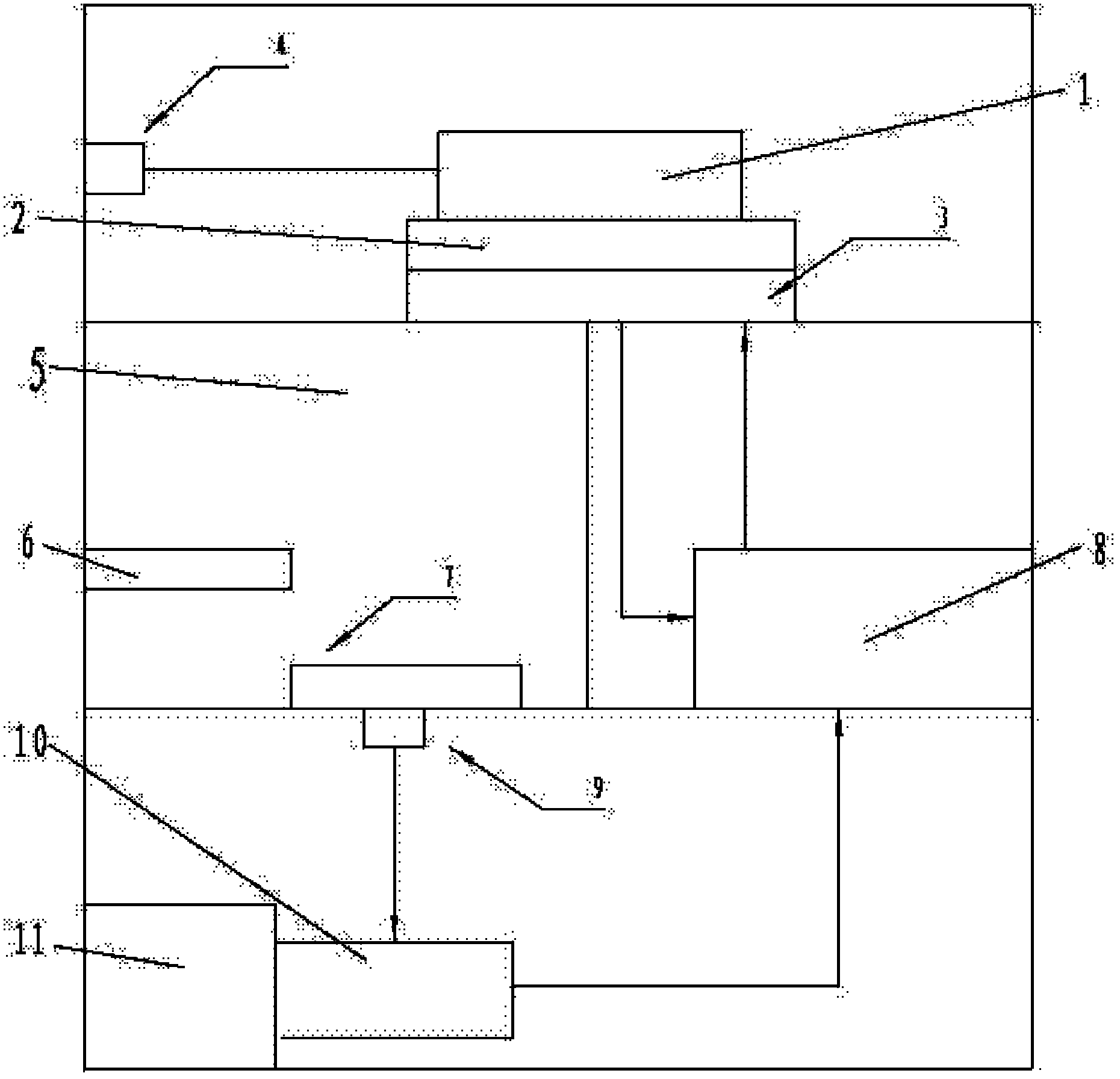

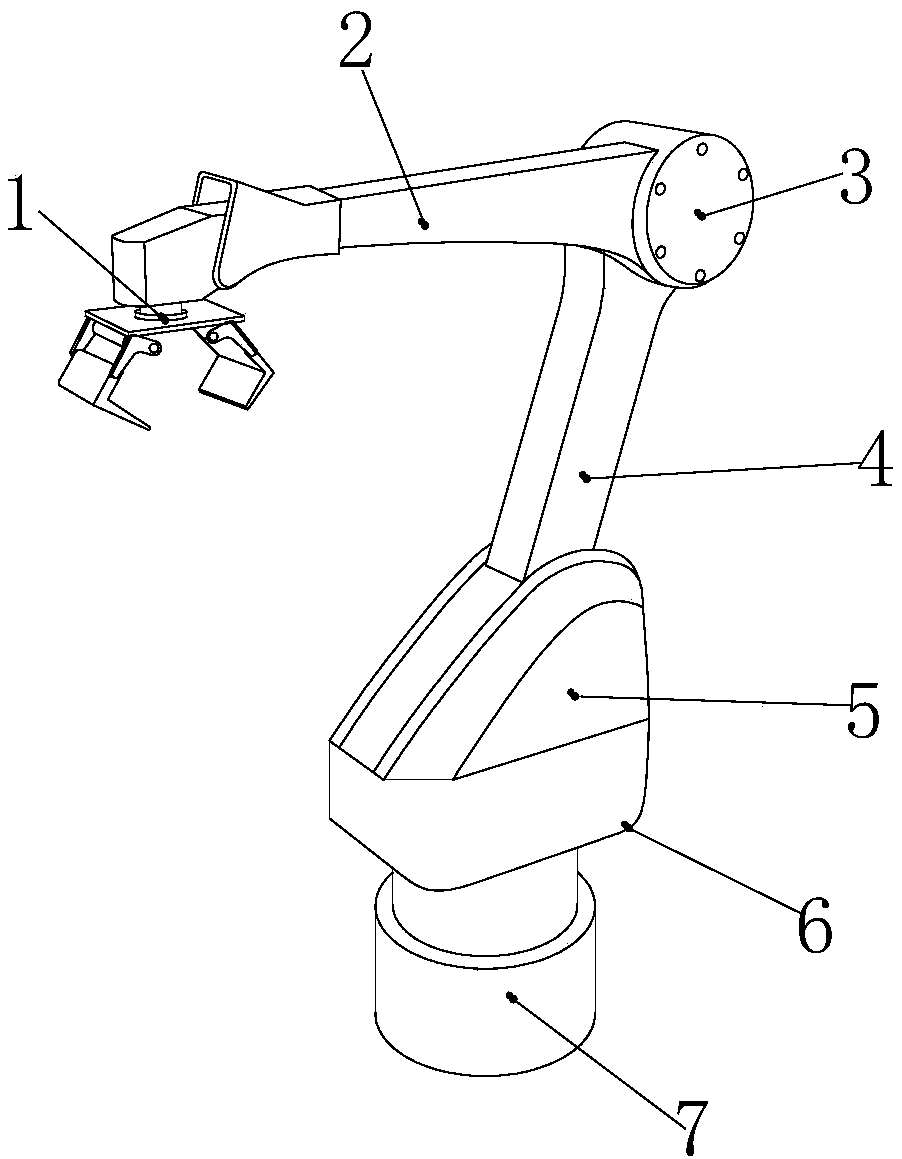

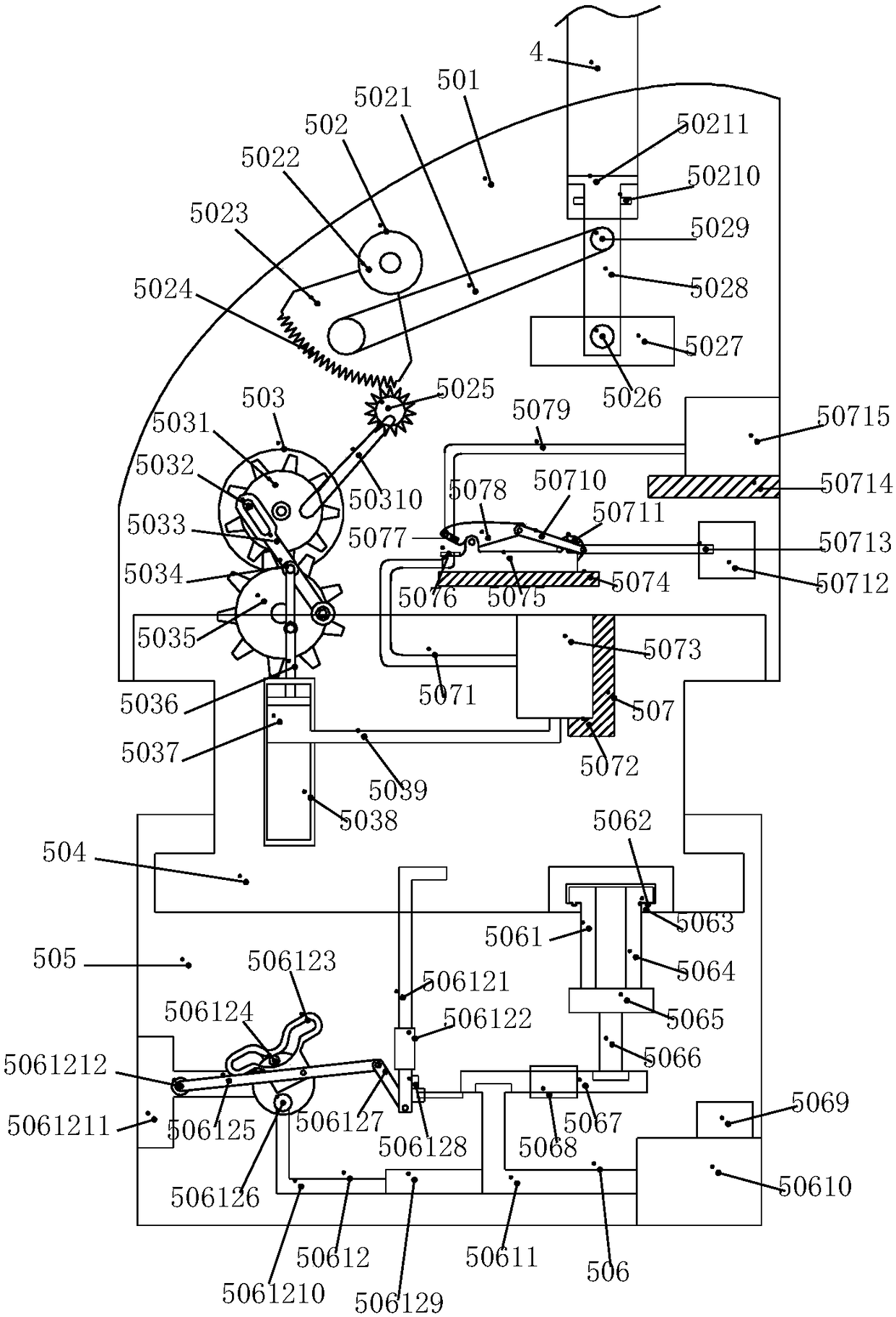

Reconfigurable man-machine cooperation mechanical arm system based on WIFI

InactiveCN106625683AFunction increaseRich layout and routingProgramme-controlled manipulatorReconfigurable antennaMotor drive

The invention discloses a reconfigurable man-machine cooperation mechanical arm system based on WIFI. The system comprises joints, a reconfigurable interface and an arm lever, wherein the joint is cooperated with the reconfigurable interface through the rabbet at a drive end of the reconfigurable interface; and the arm lever is cooperated with the reconfigurable interface; the system further comprises a smart terminal, a WIFI communication module, a joint servo controller, a sensor signal acquisition module, a motor driving module and a joint motor; the smart terminal is connected with the joint servo controller through the WIFI communication module; the output end of the joint servo controller is connected with the motor driving module; the output end of the motor driving module is connected with the joint motor; and the output end of the sensor signal acquisition module is connected with the input end of the joint servo controller. By use of the wireless communication, the fast reconstruction of the control system is facilitated; the stable data sending can be realized by taking the WIFI as the wireless communication way in the mechanical arm. The system can be extensively applied to the robot field.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

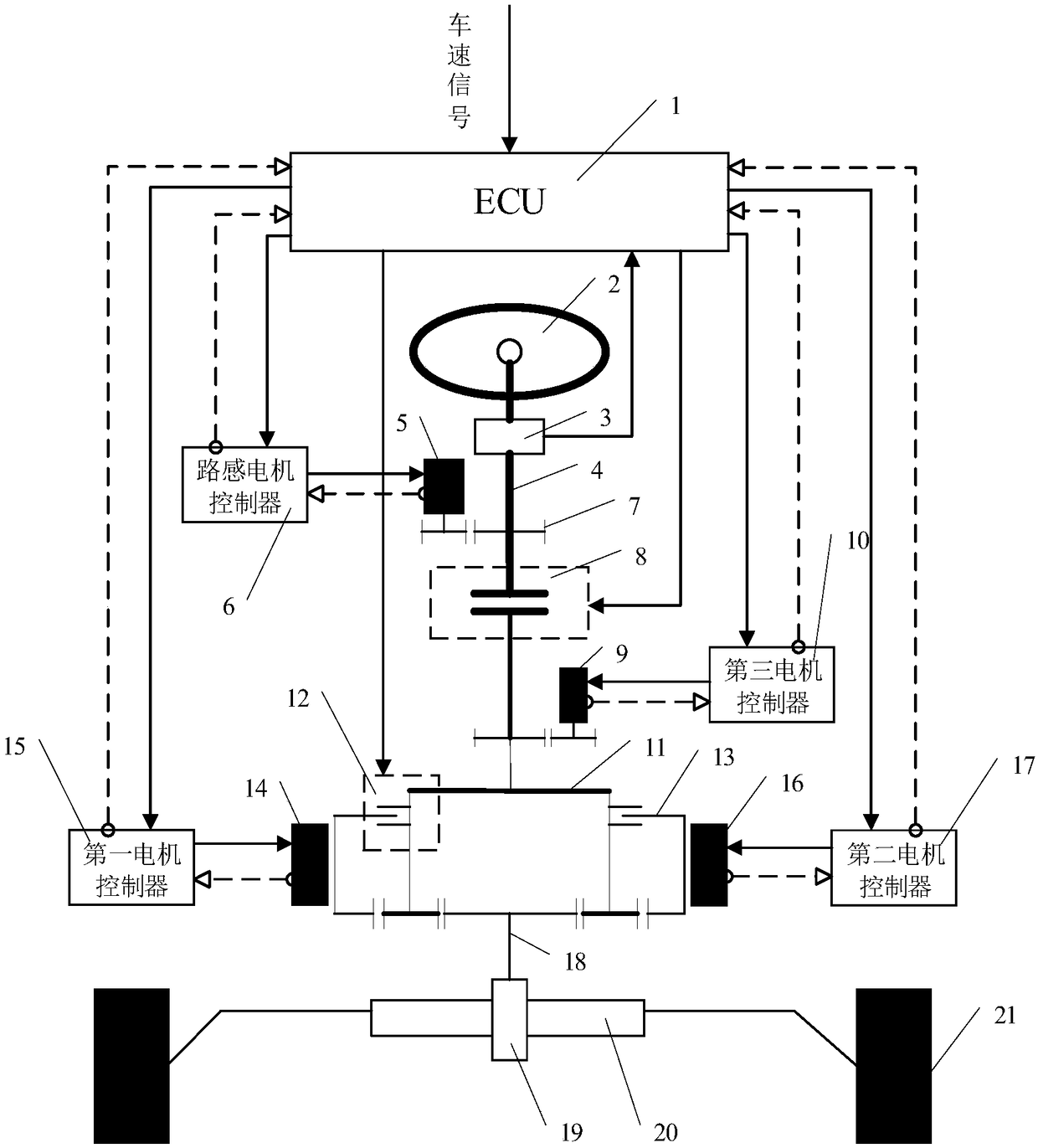

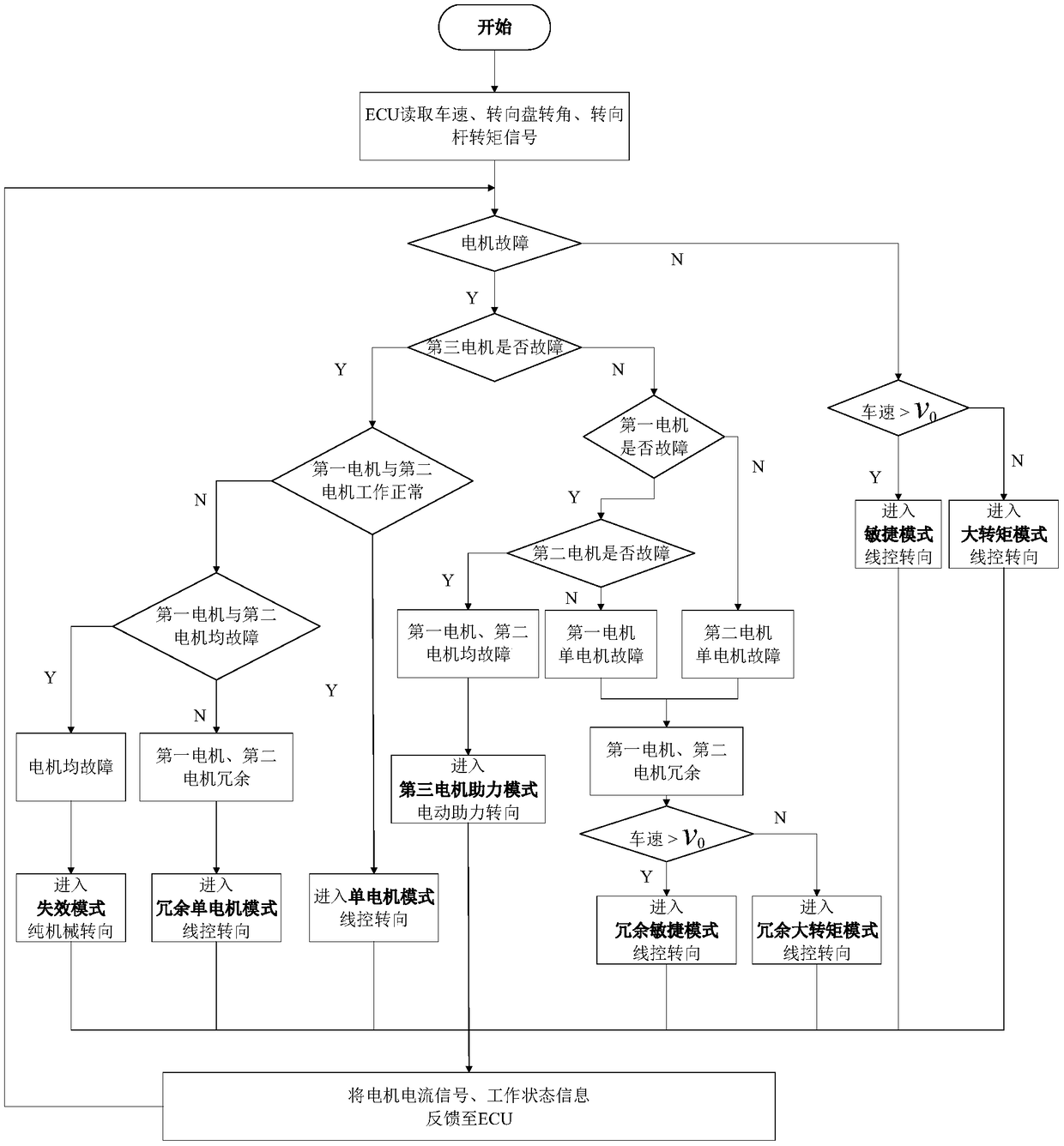

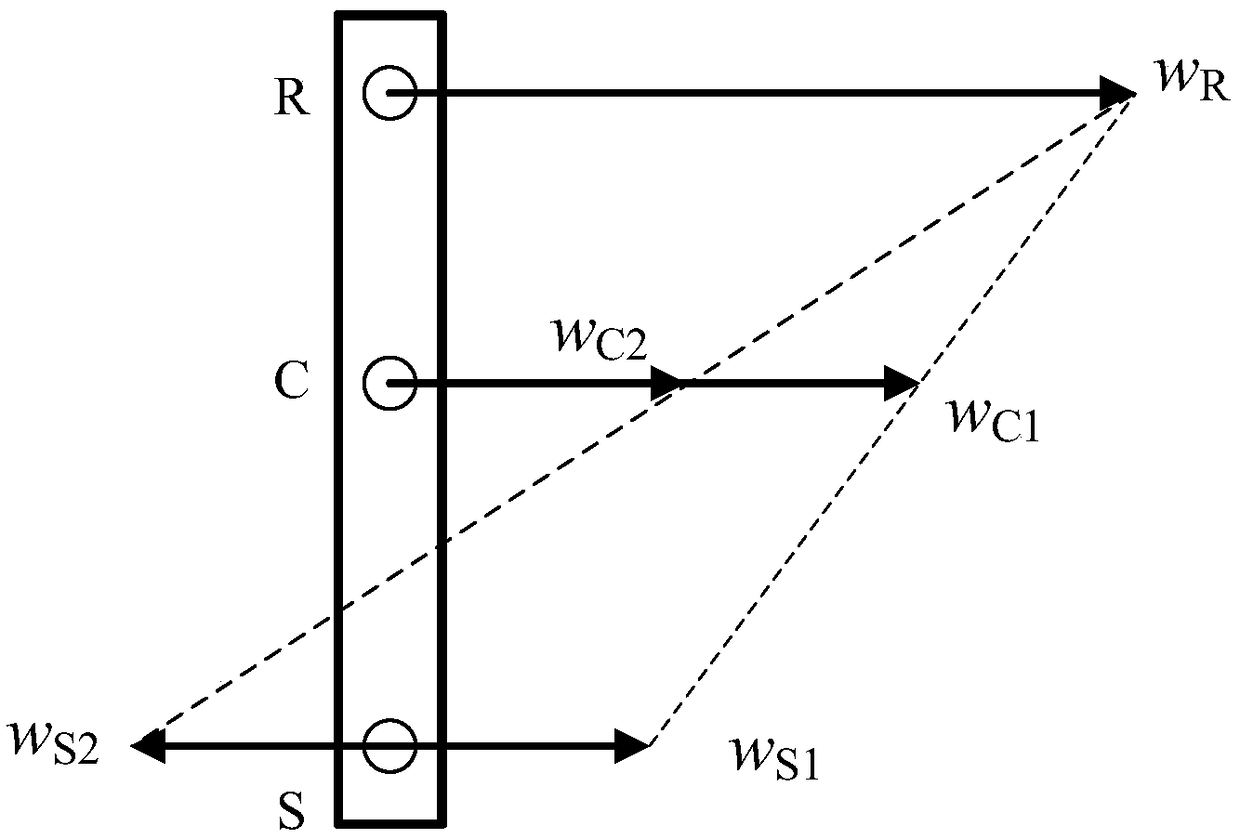

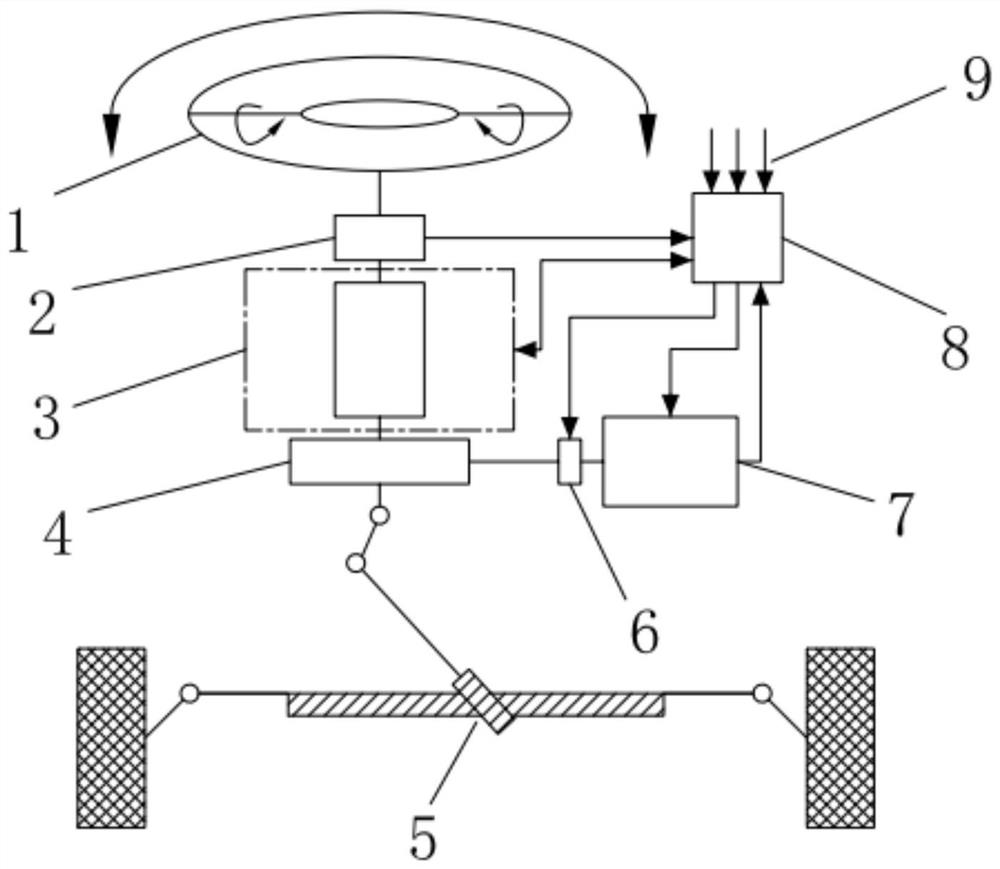

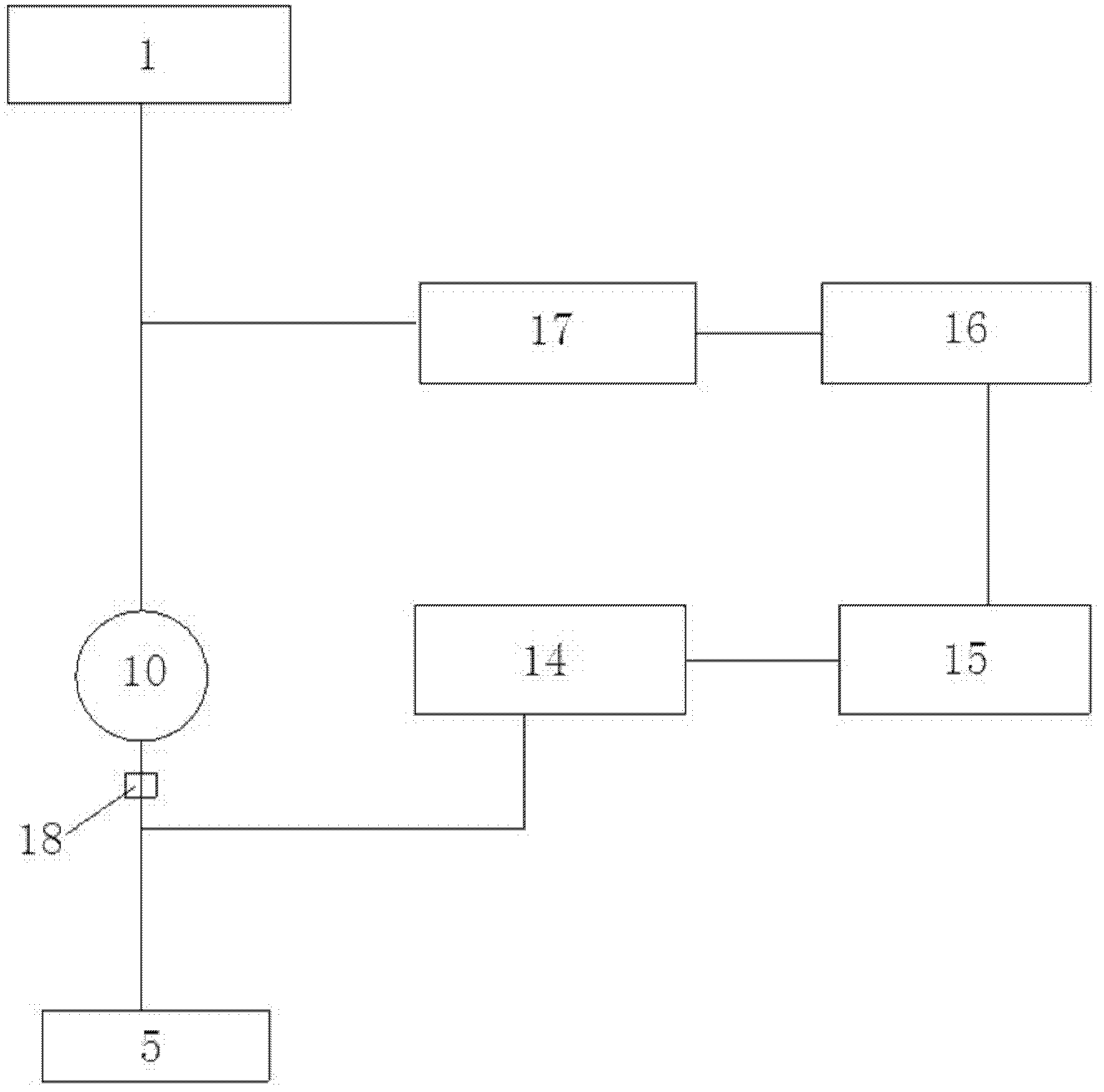

Three-motor steering-by-wire system and control method thereof

ActiveCN109466621AAvoid frequent forward and reverseExtended service lifeElectrical steeringCouplingTorque steering

The invention discloses a three-motor steering-by-wire system and a control method thereof. The system comprises a steering wheel module, a steering module and an ECU control module. The steering wheel module is used for a driver to operate and control a vehicle to turn, the steering module comprises a first clutch, a third motor, a planet gear mechanism, a second clutch, a first motor, a second motor, a steering gear and a steering rack, ECU in the ECU control module reads the vehicle running speed, a corner signal of a steering wheel, a torque signal of a rotating rod, current fed back by all motor controllers and other signals, the vehicle steering working conditions are analyzed and judged, and then running of all motors and on and off of the clutches are controlled; motor power is subjected to coupling and distribution through the planet gear mechanism and then cooperates with on and off of the clutches, switching of different steering modes of the steering system is achieved, andthen the requirements of the different steering working conditions and the safety of the system are met.

Owner:JIANGSU UNIV

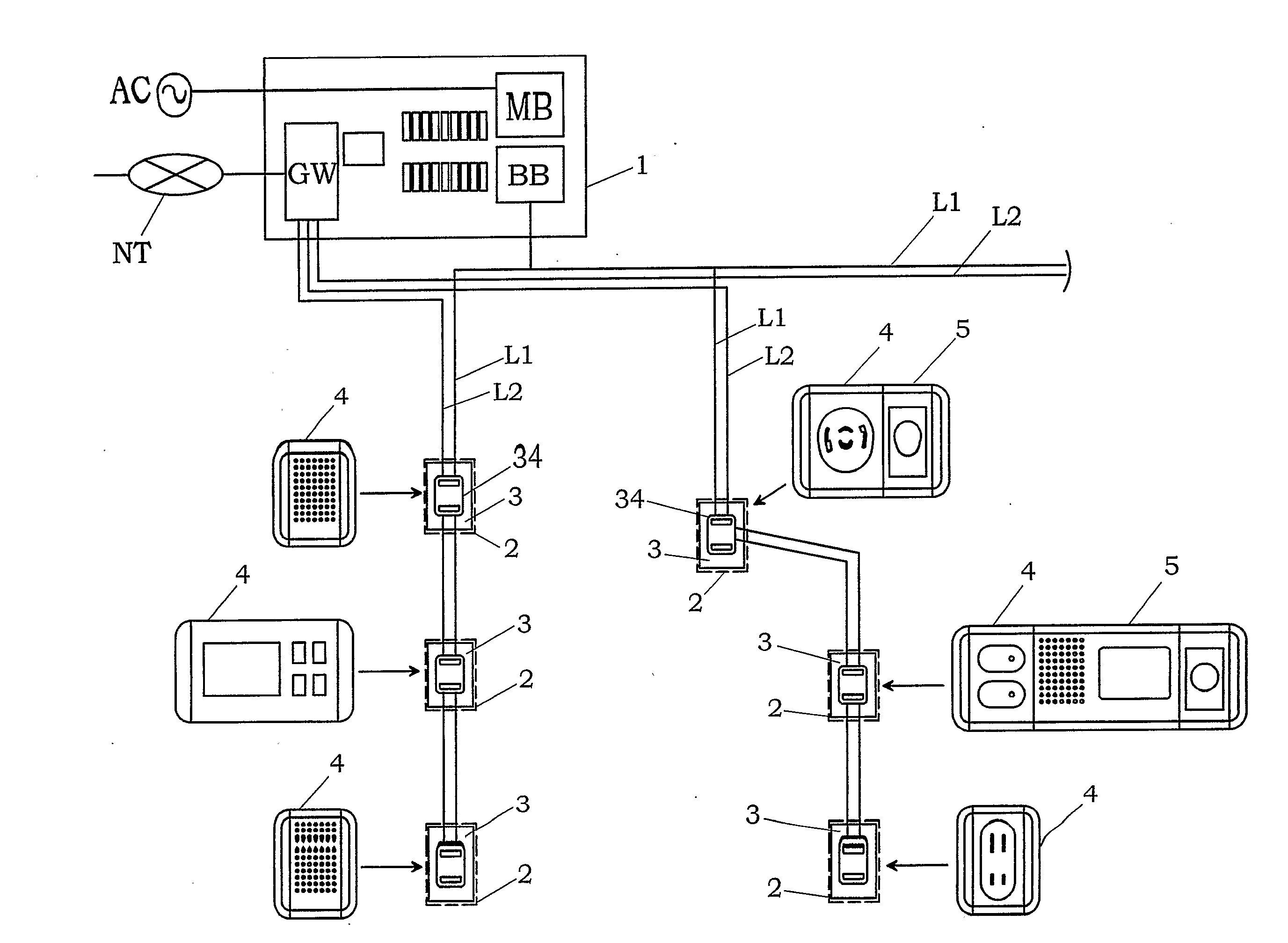

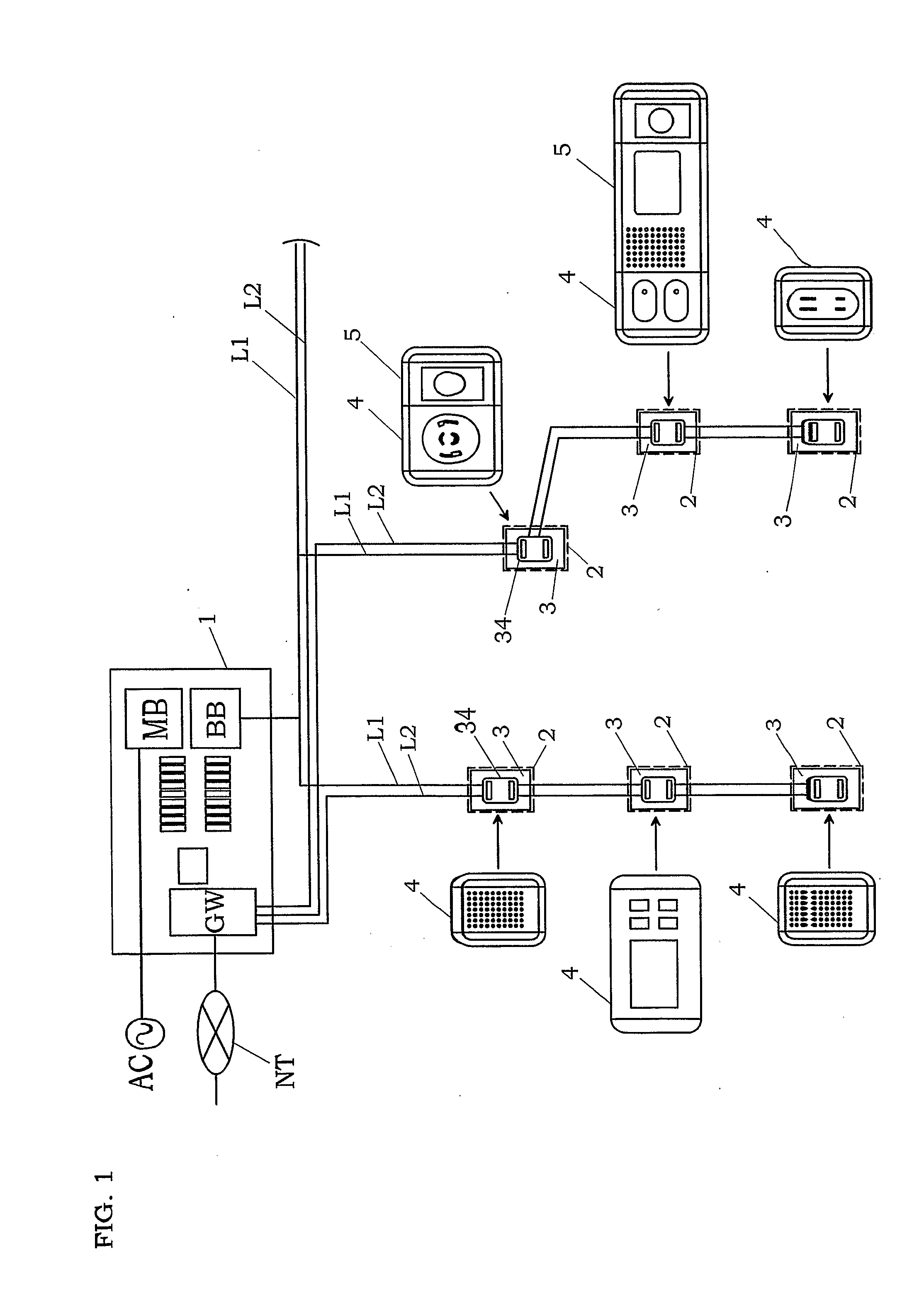

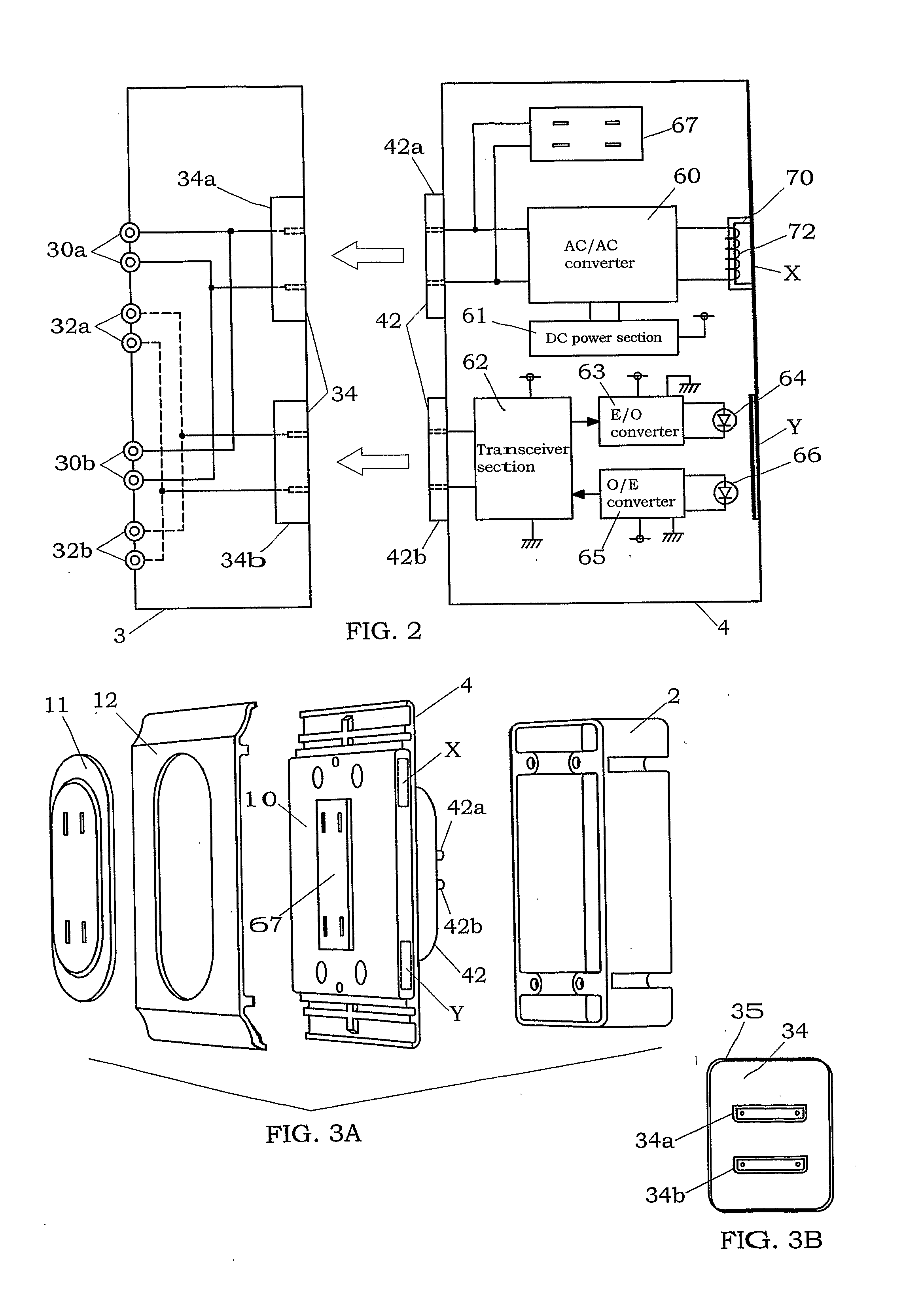

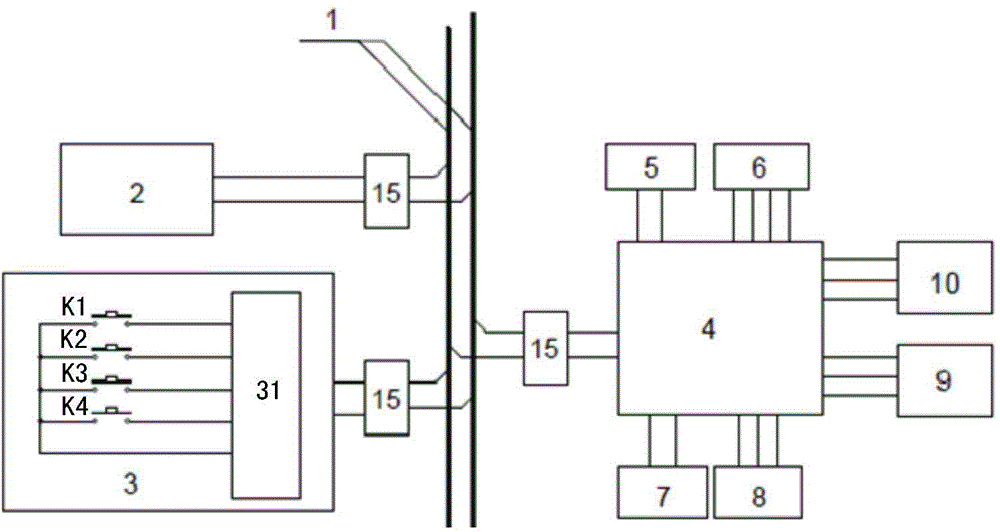

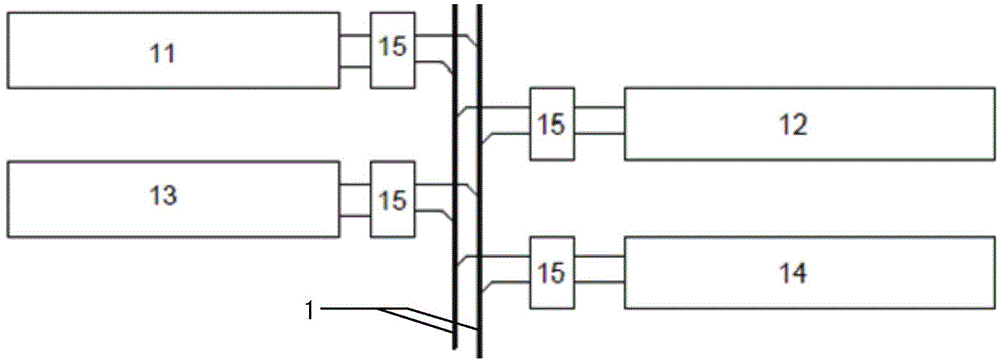

Function Unit for Dual Wiring System

InactiveUS20090051505A1Improve function scalabilityEasy exchangeabilityCoupling device connectionsElectric signal transmission systemsElectric power systemComputer module

A function unit having easy exchangeability in a dual wiring system is provided. The function unit is detachably connected to a gate device mounted in a wall surface of a structure, and connected to both of an electric power line and an information line previously installed in the structure. The function unit has at least one of functions for supplying electric power from the electric power line, outputting information from the information line and inputting information into the information line when connected with the gate device. The function unit has a module connector, which is configured to simultaneously establish both of supplying the electric power from the gate device to the function unit, and making a signal transmission between the gate device unit and the function unit when connected to a module port formed at the gate device. To improve function expandability, an additional function unit may be detachably connected to the function unit.

Owner:PANASONIC CORP

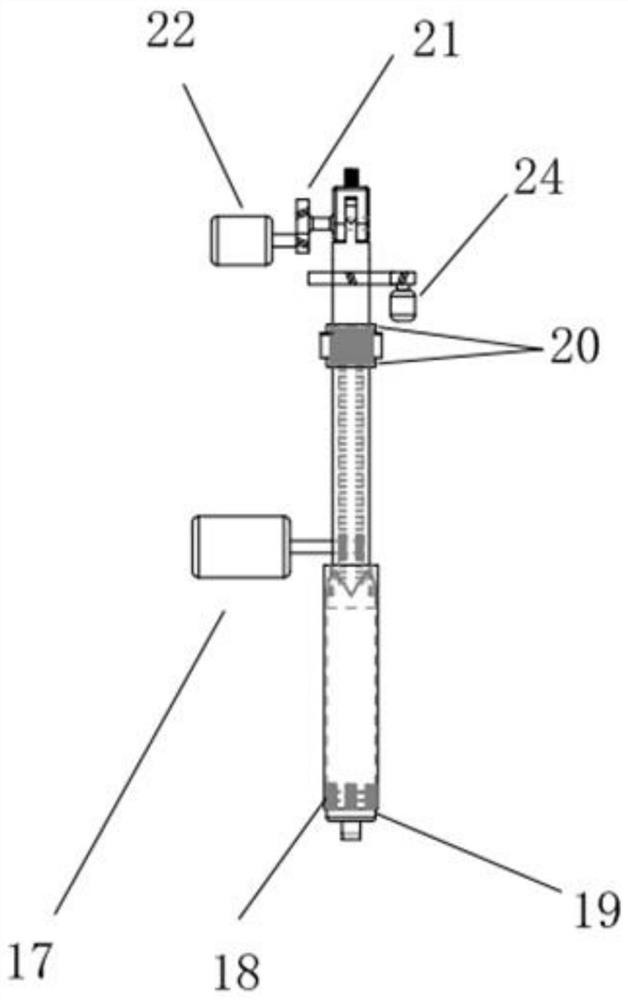

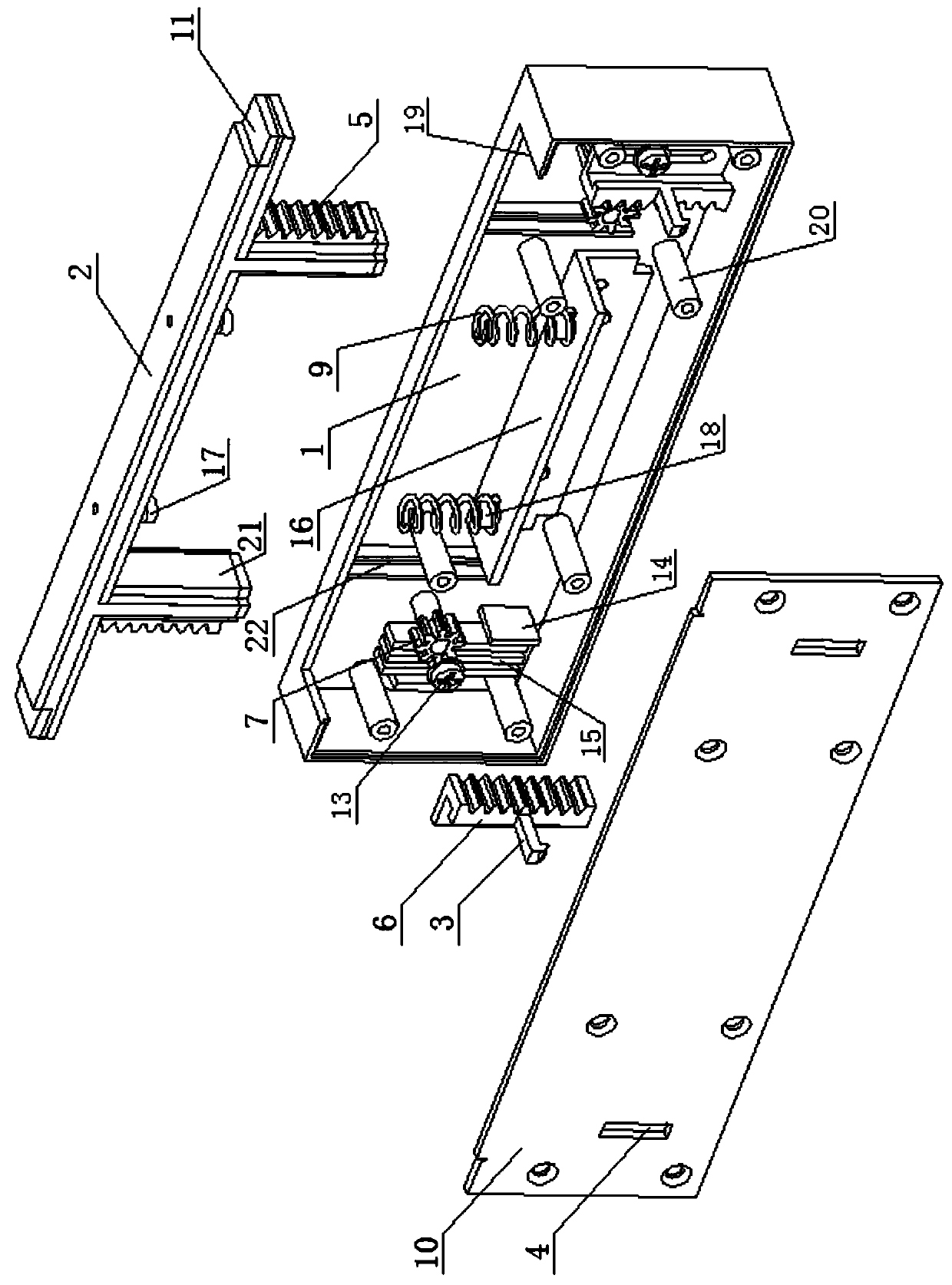

Detector and detection method for electromagnetic valve of automobile automatic transmission

InactiveCN102539137AEasy to achieve adjustabilityEasy to achieve constant pressure controlMachine part testingElectrical testingFrequency changerFuel tank

The invention relates to the technical field of automobile maintenance and detection equipment, in particular to a detector and a detection method for an electromagnetic valve of an automobile automatic transmission. The detector is characterized in that: an oil tank is fixed at the bottom of a chassis; the lower part of the right side of the oil tank is provided with an oil temperature heater; a pipeline connecting oil return chamber is formed at the center position of the upper part of the oil tank; the upper part of the oil return chamber is provided with an oil path transition plate; the upper part of the oil path transition plate is provided with an electromagnetic valve adapting base; the upper part of the electromagnetic valve adapting base is provided with an electromagnetic valve to be detected; the bottom of the electromagnetic valve to be detected is provided with a pipeline which is connected with a pressure sensor by passing through the oil path transition plate; one end of a pipeline tap at the bottom of the electromagnetic valve to be detected is connected with an oil pressure regulating valve; the lower part of the oil pressure regulating valve is connected with the output end of an oil pump; the input end of the oil pump is connected with the input end of a safety valve on the oil tank; the electromagnetic valve to be detected is provided with a PWM (Pulse-Width Modulation) power amplifying circuit B; the oil pressure regulating valve is provided with a PWM power amplifying circuit A; the heater is provided with a relay; and the oil pump is provided with a frequency converter. A power chip has the functions of short circuiting, overcurrent thermal protection and the like.

Owner:上海新孚美变速箱技术服务有限公司

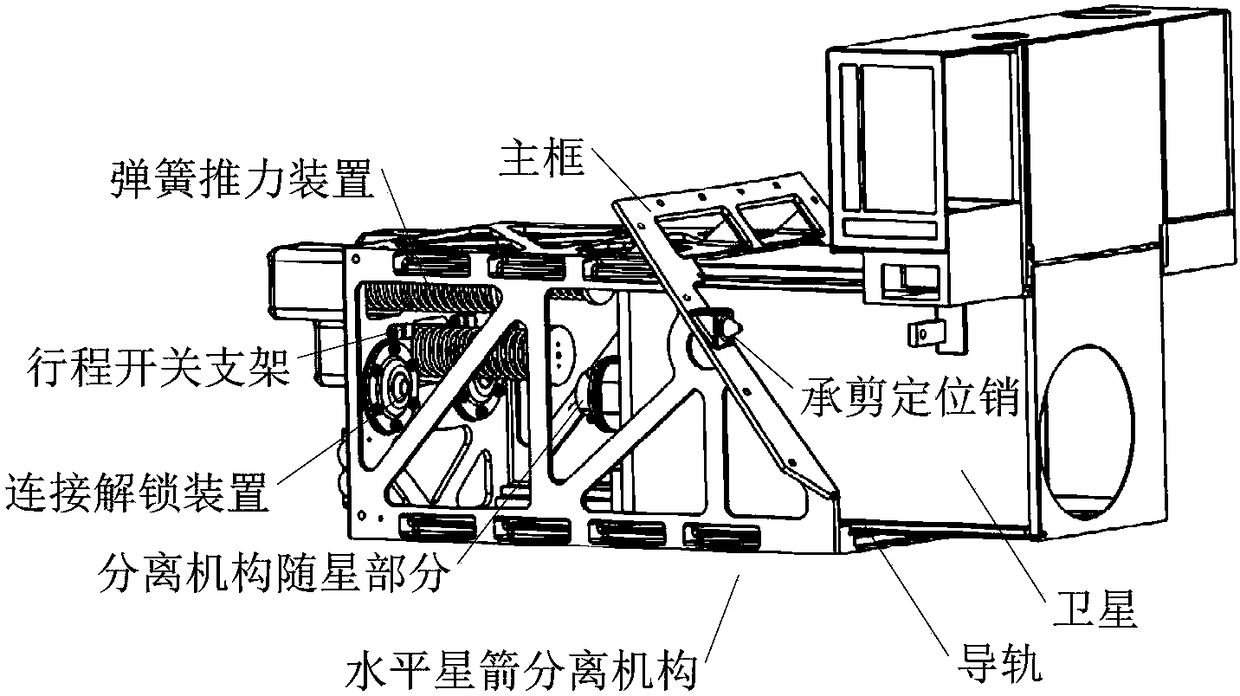

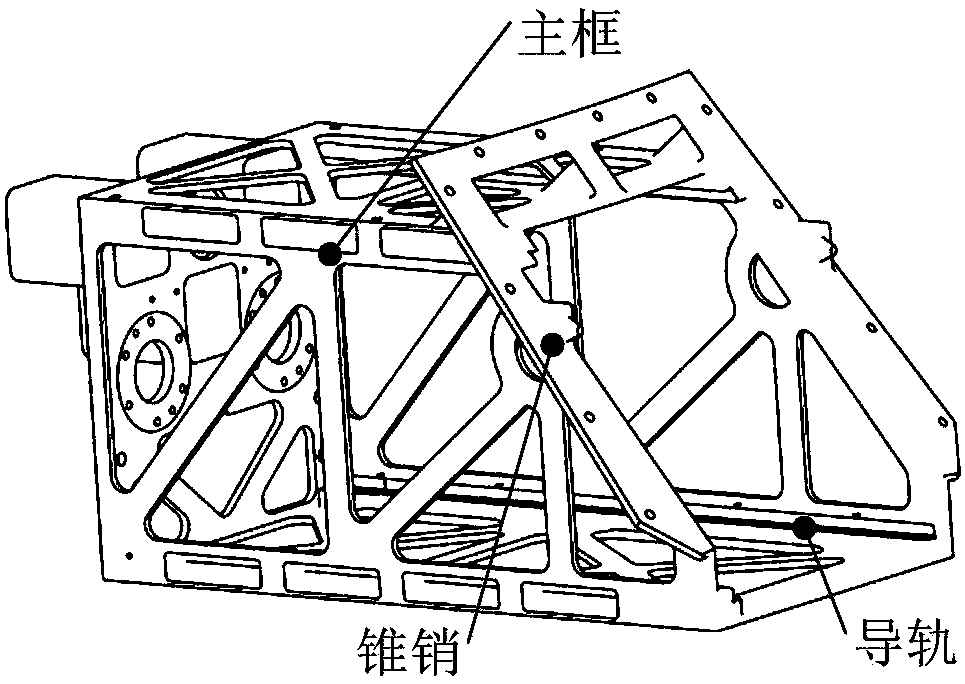

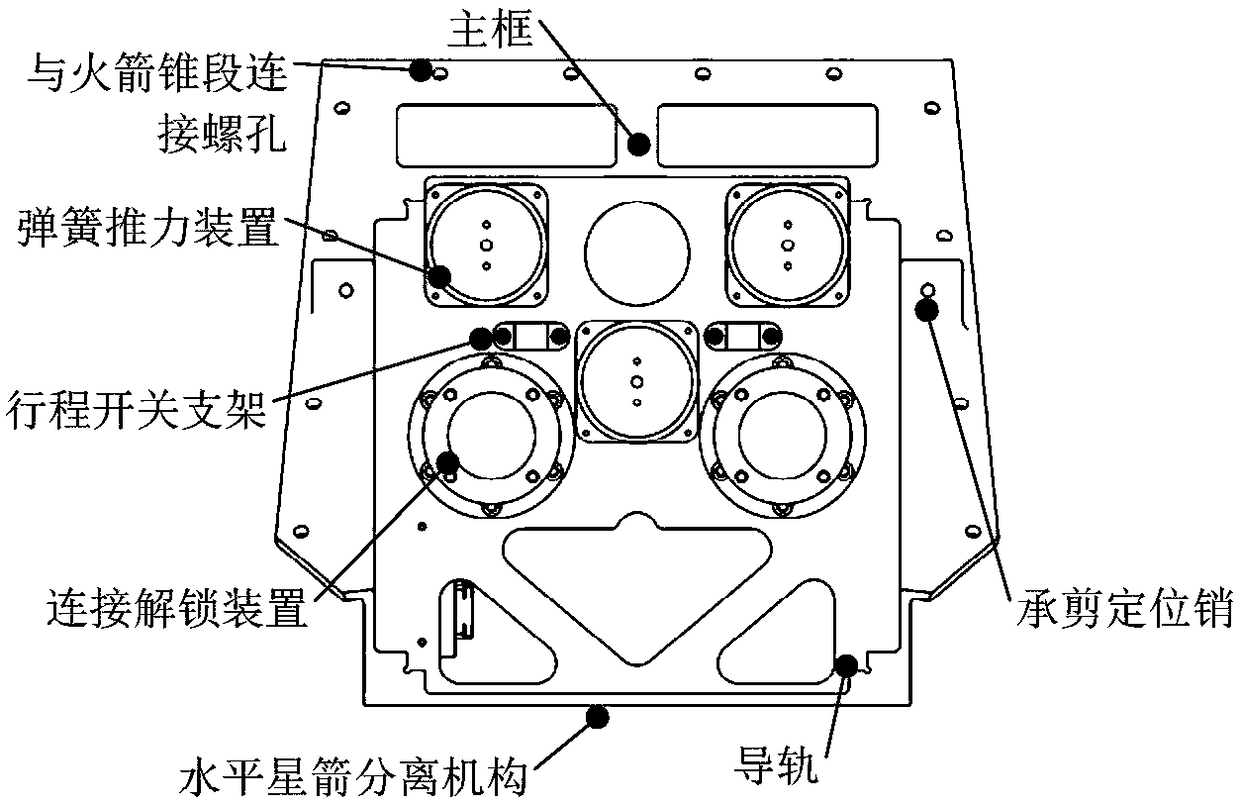

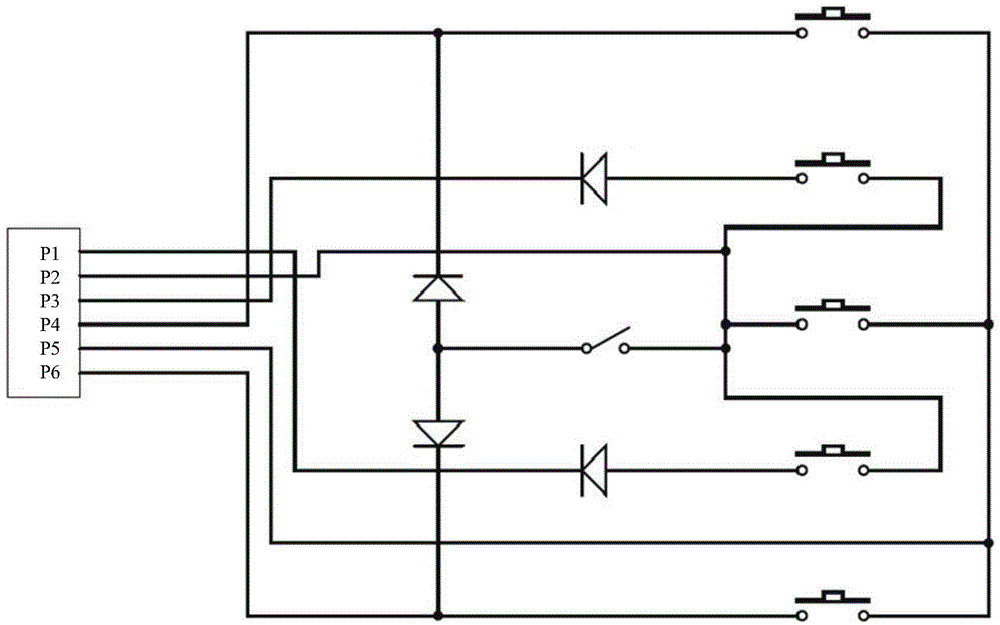

Horizontal satellite-rocket separation mechanism

ActiveCN108528766AAchieve mechanical connectionReliable unlockCosmonautic vehiclesCosmonautic component separationEngineeringRocket

Owner:上海中科辰新卫星技术有限公司

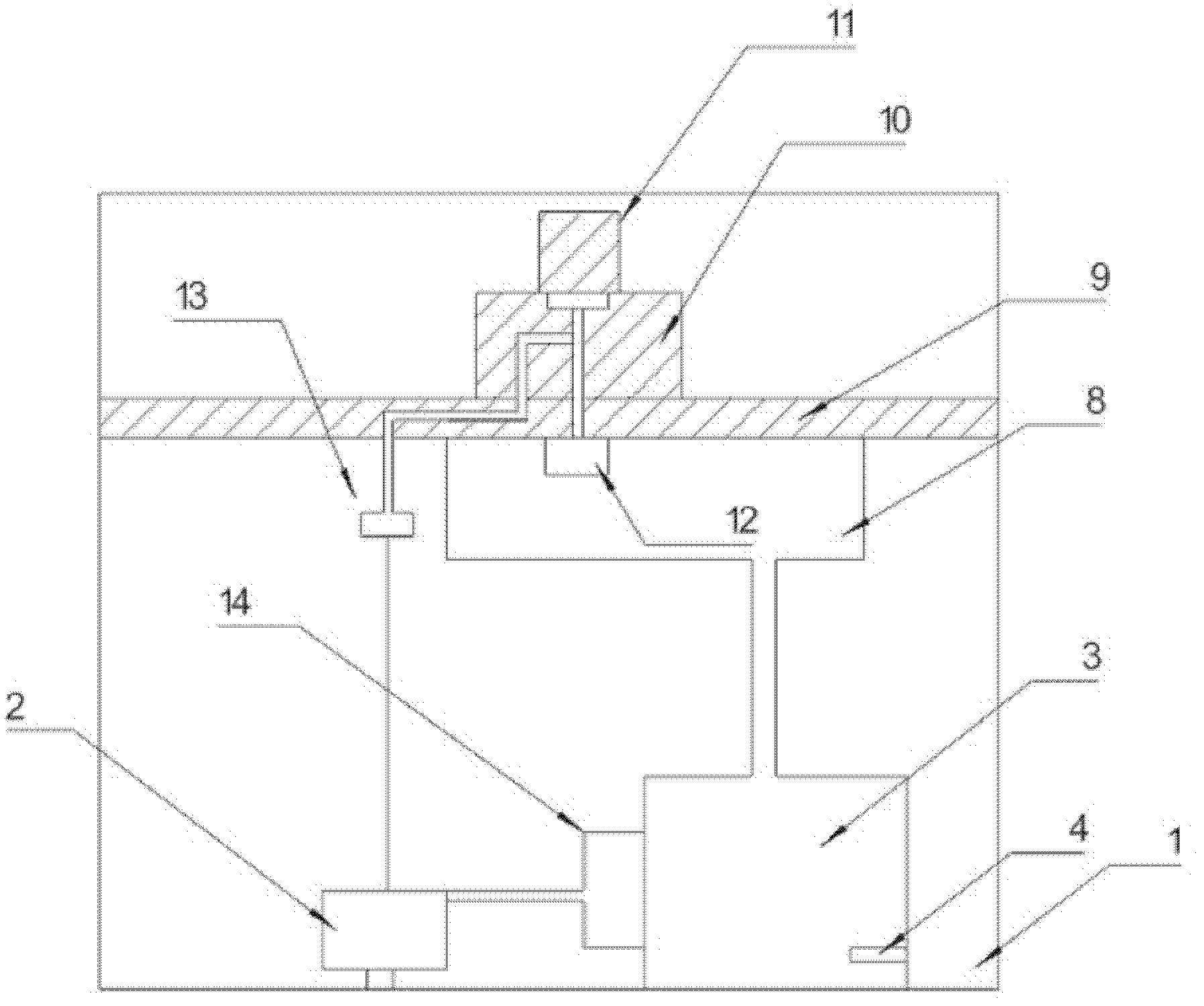

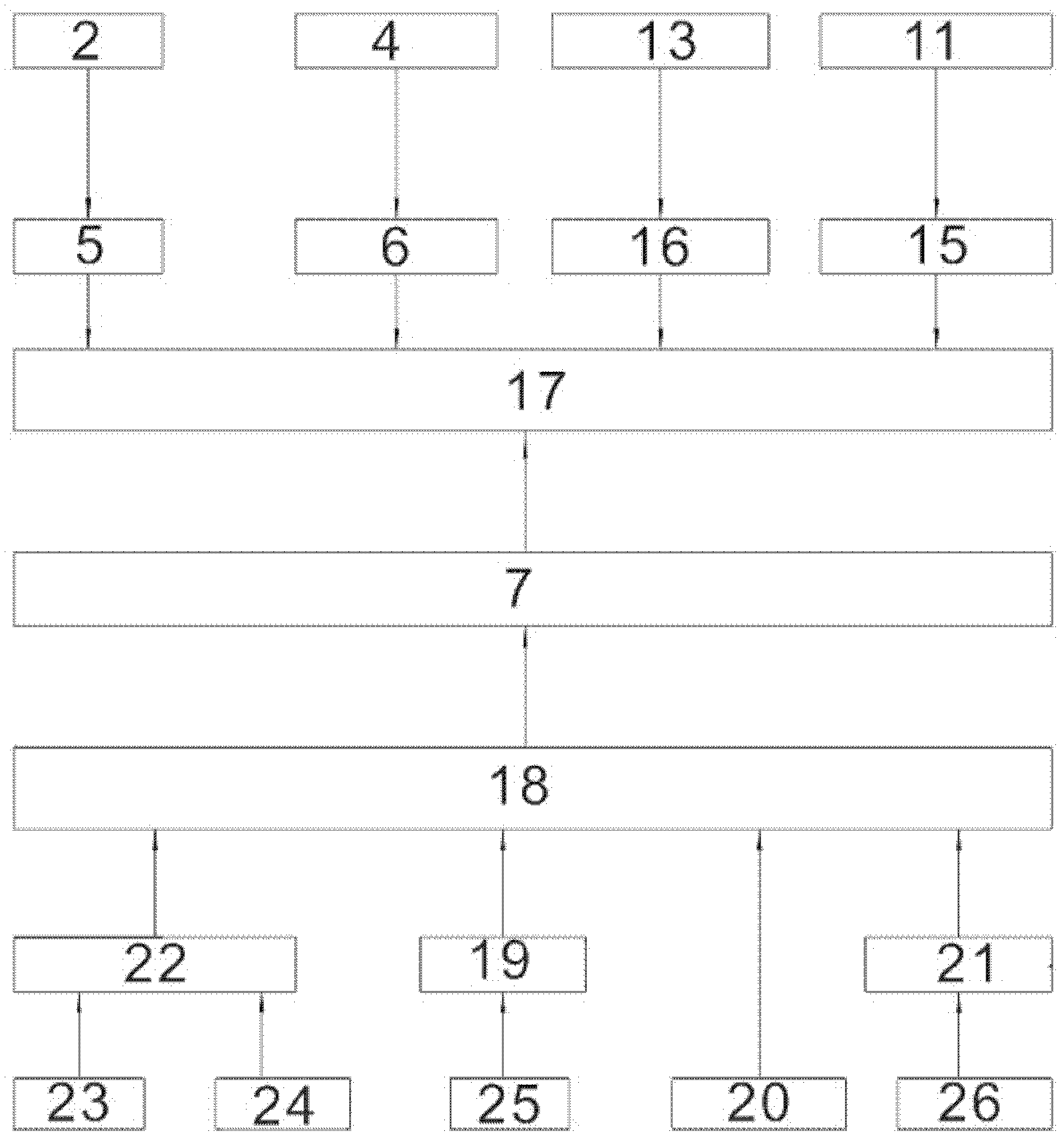

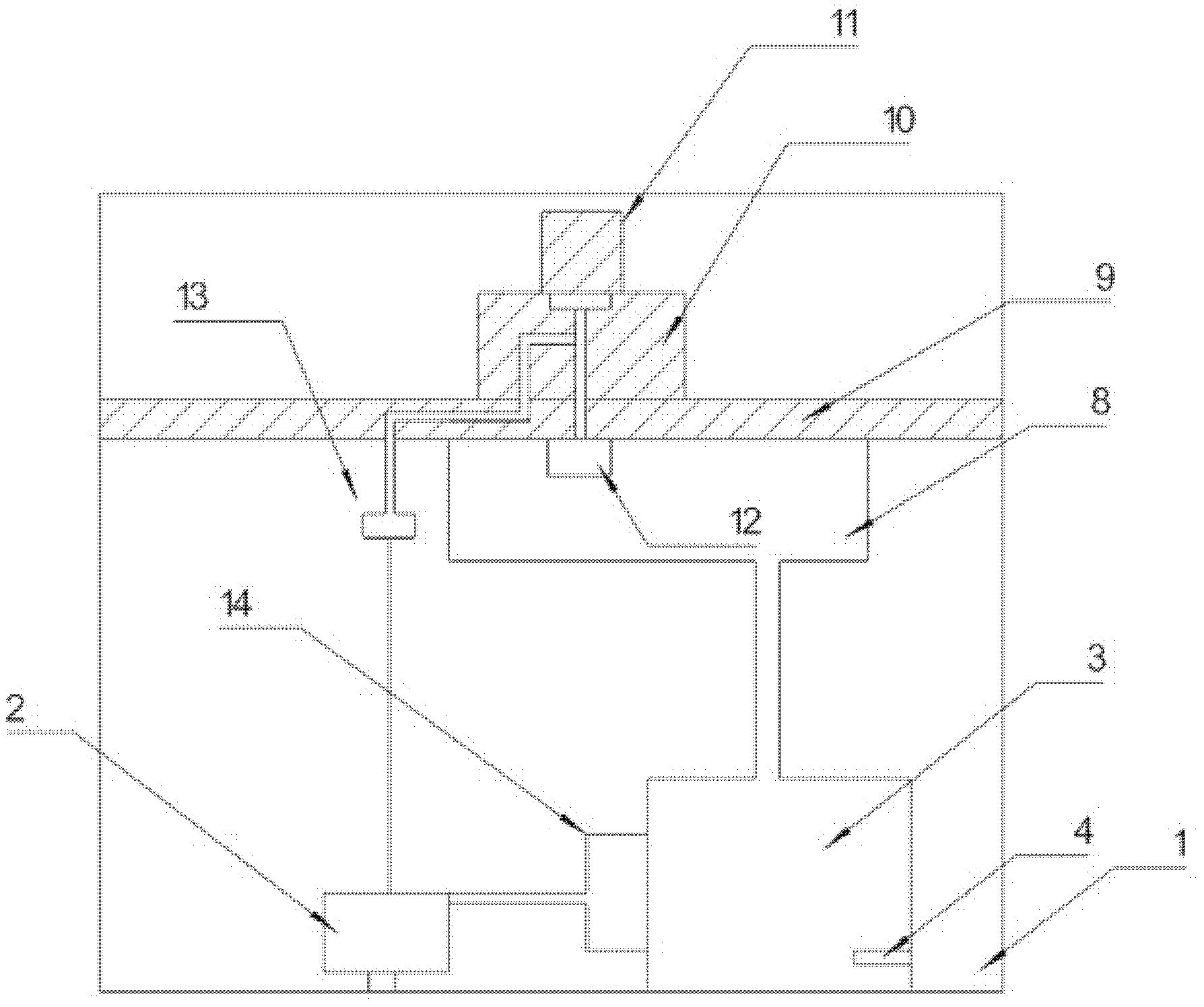

Medical crane tower system

ActiveCN104055576ANo need to change the lengthReduce the number of coresSurgeryDiagnostic recording/measuringTransmitted powerComputer module

The invention provides a medical crane tower system. The medical crane tower system comprises a movable component, an executive component and a bus, wherein the movable component comprises a keystroke control module; the keystroke control module comprises braking system control keys and crane tower lifting control keys; the executive component comprises an output control part; the output control part is connected with a concentration line power source, a crane tower motor and a braking system respectively; the movable component and the executive component are both connected to the bus; the bus is used for transmitting power source supply; the bus is further used for transmitting instructions from the movable component to the executive component. The medical crane tower system provided by the invention can achieve the following benefits: stepless regulation of the height direction can be realized; the lengths of cables are not required to be changed; core number of the cables is reduced; the circuit design is optimized; the installation is easy; the maintenance is easy; function integration and function extension are facilitated; the reliability is improved.

Owner:MAQUET SUZHOU

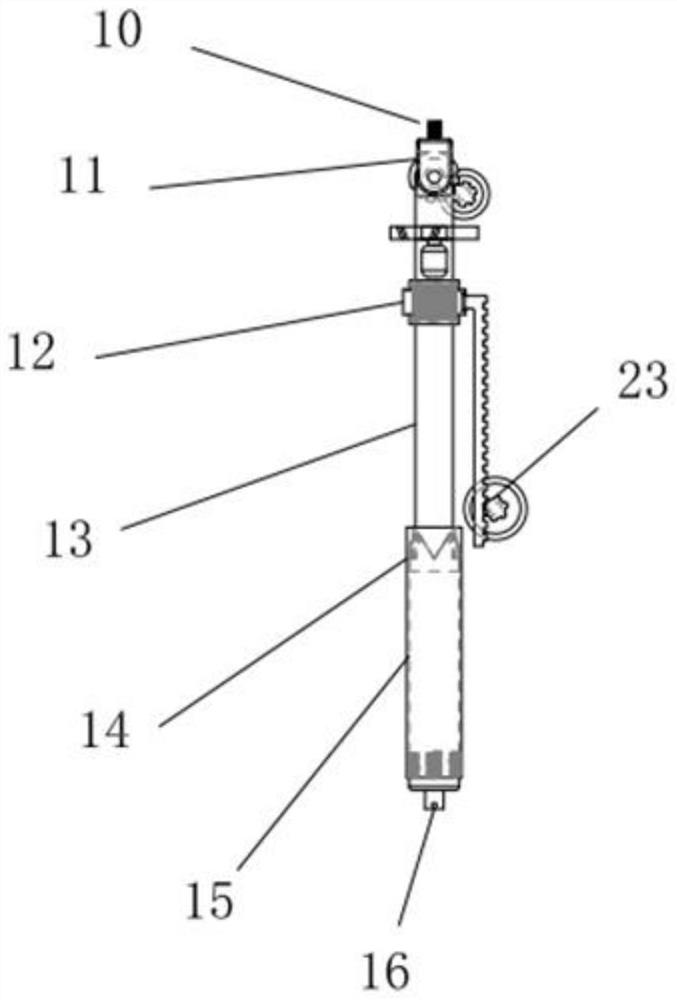

Automatic driving drive-by-wire telescopic mechanical redundancy type steering column

ActiveCN112061224AImprove convenienceMeet different requirementsHand wheelsElectrical steeringSteering wheelSteering column

The invention discloses an automatic driving drive-by-wire telescopic mechanical redundancy type steering column. The steering column comprises a steering wheel connecting thread, a steering wheel pitch angle adjusting mechanism, a bearing, a telescopic column, a clutch mechanism, a telescopic sleeve, a steering lower shaft, a steering lower shaft hinge joint hinged to the steering lower shaft, atelescopic thrust motor, a telescopic sleeve sealing thread, a telescopic sleeve lower connecting piece, a bearing fixing piece, a steering wheel pitch angle transmission gear, a steering wheel pitchangle adjusting motor, a telescopic column transmission gear and a steering wheel rotation angle adjusting motor. The automatic driving drive-by-wire telescopic mechanical redundancy type steering column is electrically telescopic, the getting-on and getting-off convenience can be improved for a safety officer or a driver, meanwhile, the flexibility of switching between the manned driving mode andthe unmanned driving mode is improved, meanwhile, different requirements of the manned driving and the unmanned driving for a steering system are met, and the requirement of automatic driving development is better met.

Owner:开沃新能源汽车集团股份有限公司

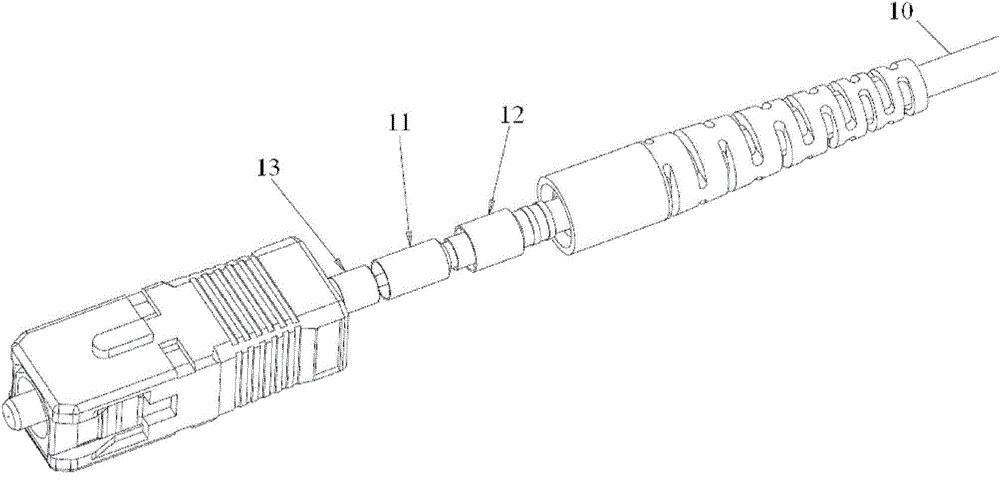

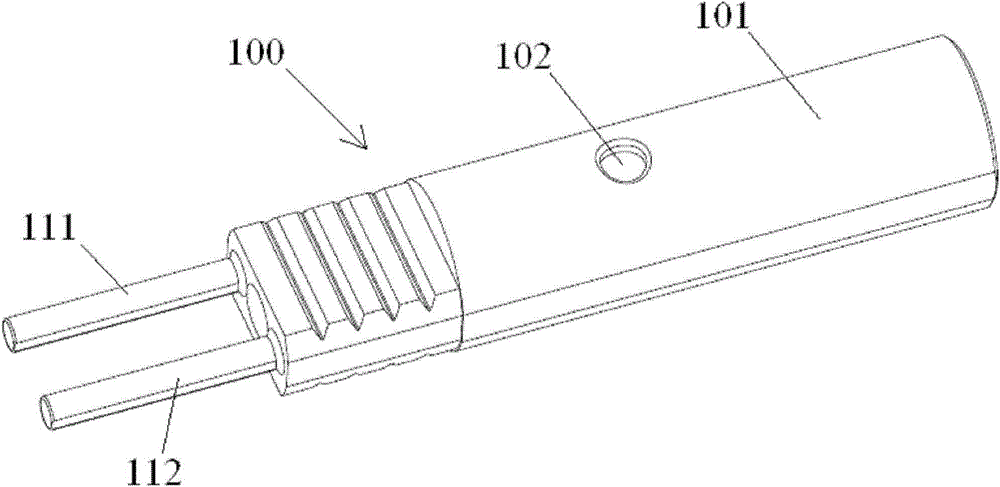

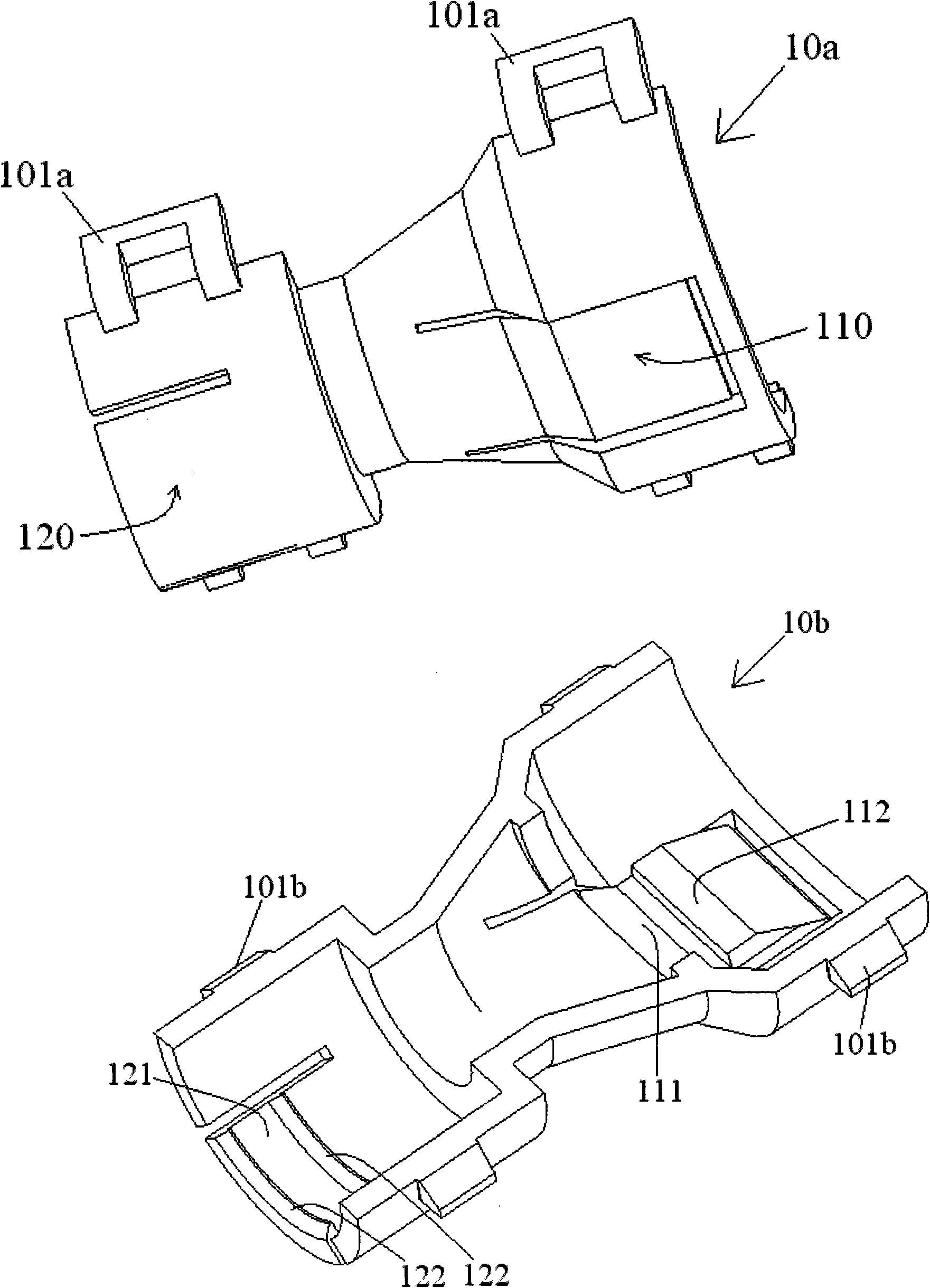

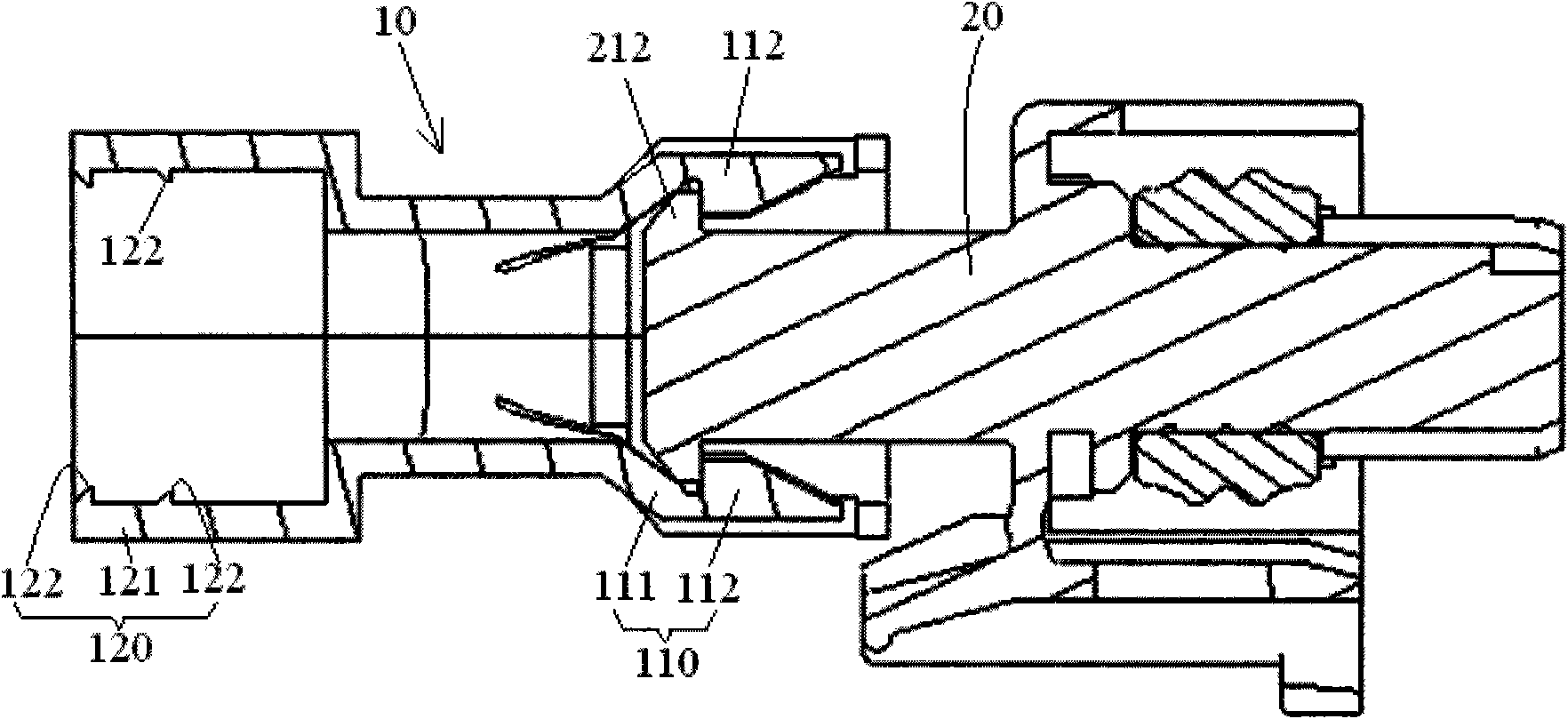

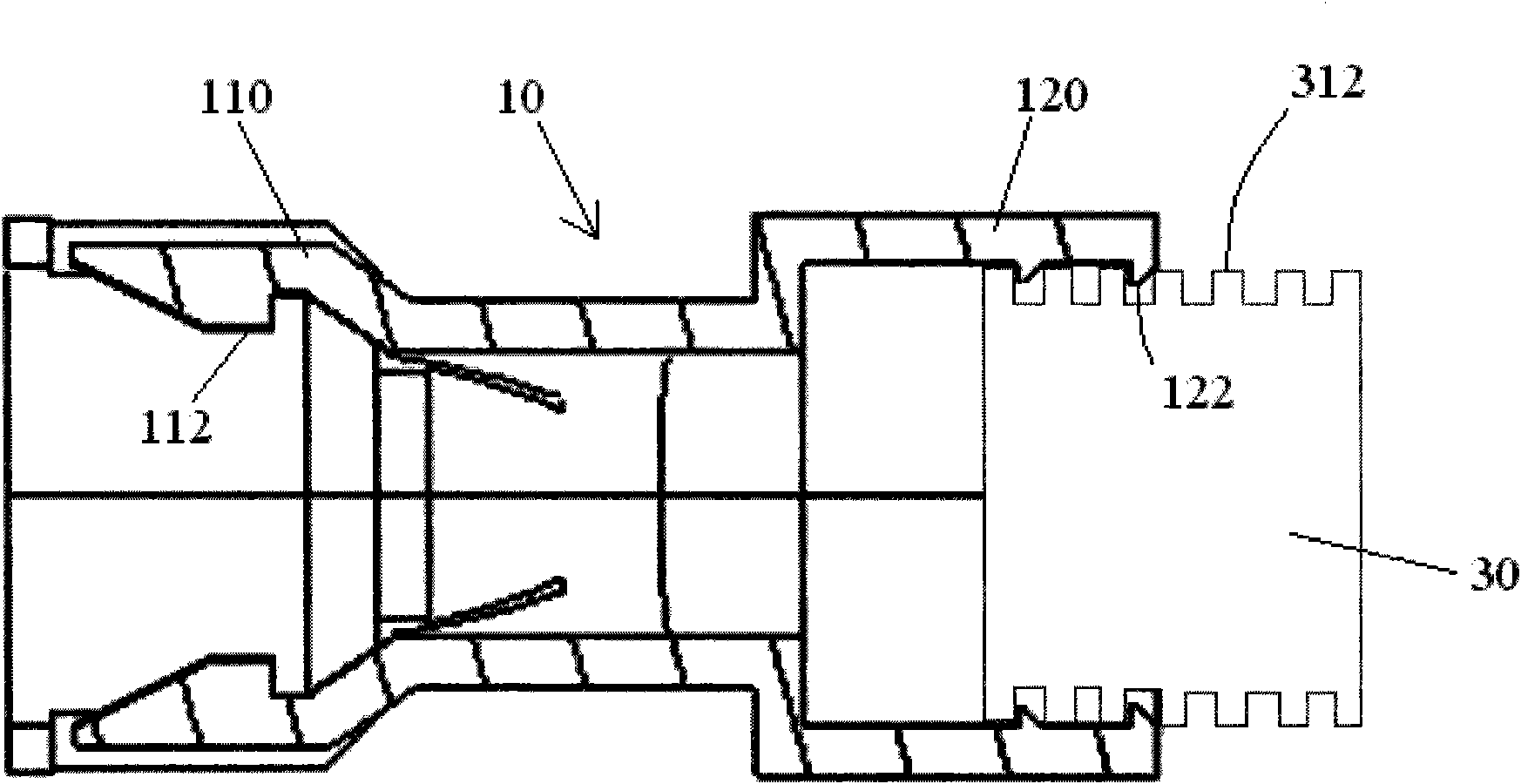

Optical fiber connector assembly

InactiveCN104977658ADoes not increase hardnessNot prone to twisting and knottingCoupling light guidesFibre mechanical structuresEngineeringUltimate tensile strength

The invention discloses an optical fiber connector assembly comprising a connector, a cable and an intermediate transfer member. A reinforced element layer is arranged between the protective sleeve pipe and outer sheath layer of the optical fiber of the cable. The intermediate transfer member is respectively adhered and connected with the reinforced element layer and the body of the connector, and thus the cable and the connector are connected together. Compared with the prior art, the connection strength between the cable and the connector is improved. In addition, since the reinforced element layer is a flexible thin layer which is uniformly distributed around the optical fiber protective sleeve pipe, the hardness of the cable is not increased, the cable can be bent, and the twisting and knotting phenomena of a cable in laying a long cable are prevented.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

Machine and method for detecting valve body of automobile automatic speed changer

InactiveCN102565615AGuaranteed accuracyConstant viscosityMachine part testingElectrical testingAutomatic transmissionFuel tank

The invention relates to the field of machines for detecting valve bodies during automobile maintenance, in particular to a machine for detecting the valve body of the automobile automatic speed changer. The machine comprises a case, a motor, an oil pump, an oil tank, a heater, a pressure regulation system, a valve body adaptation board, the valve body and a servo motor, and is characterized in that: the motor is arranged at the bottom of the case and connected with the oil pump; the oil tank is arranged in the middle of the case; the heater is arranged in the oil tank; an oil return disk is arranged at the bottom of the oil tank and connected with the inlet end of the oil pump through a pipeline; the outlet end of the oil pump is connected with the pressure regulation system through a pipeline; the top of the oil tank is connected with the valve body through the valve body adaptation board; the valve body is connected with the servo motor through a line; and the pressure regulation system is connected with the valve body through a pipeline. The machine can be used for comprehensively, effectively and accurately detecting electrical performance and mechanical performance of the valve bodies of various types of automatic speed changers.

Owner:上海新孚美变速箱技术服务有限公司

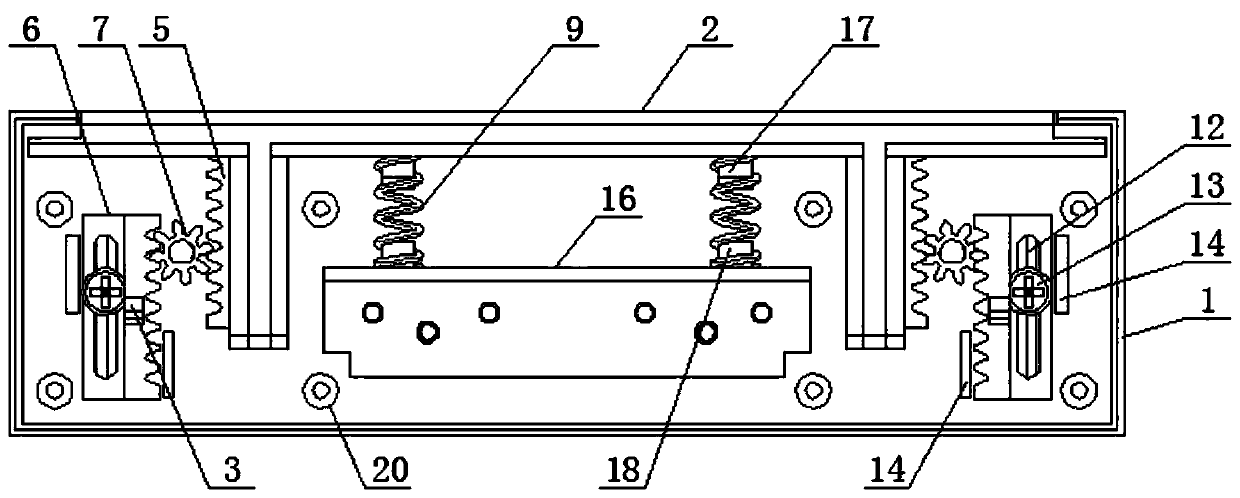

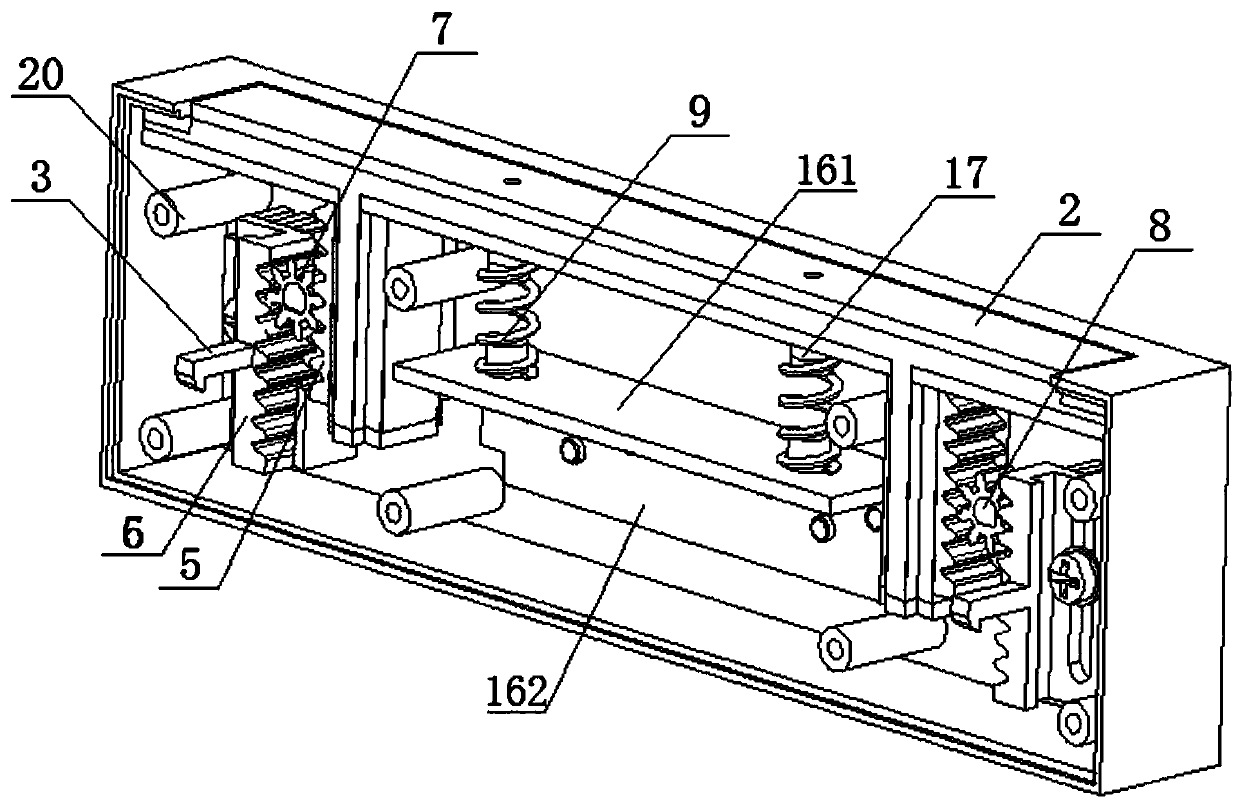

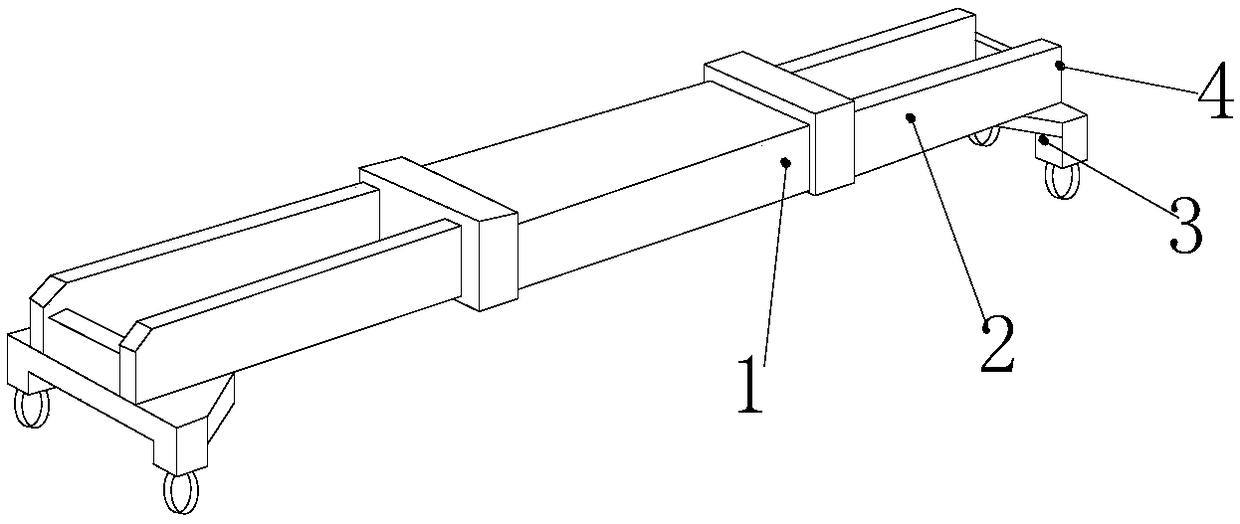

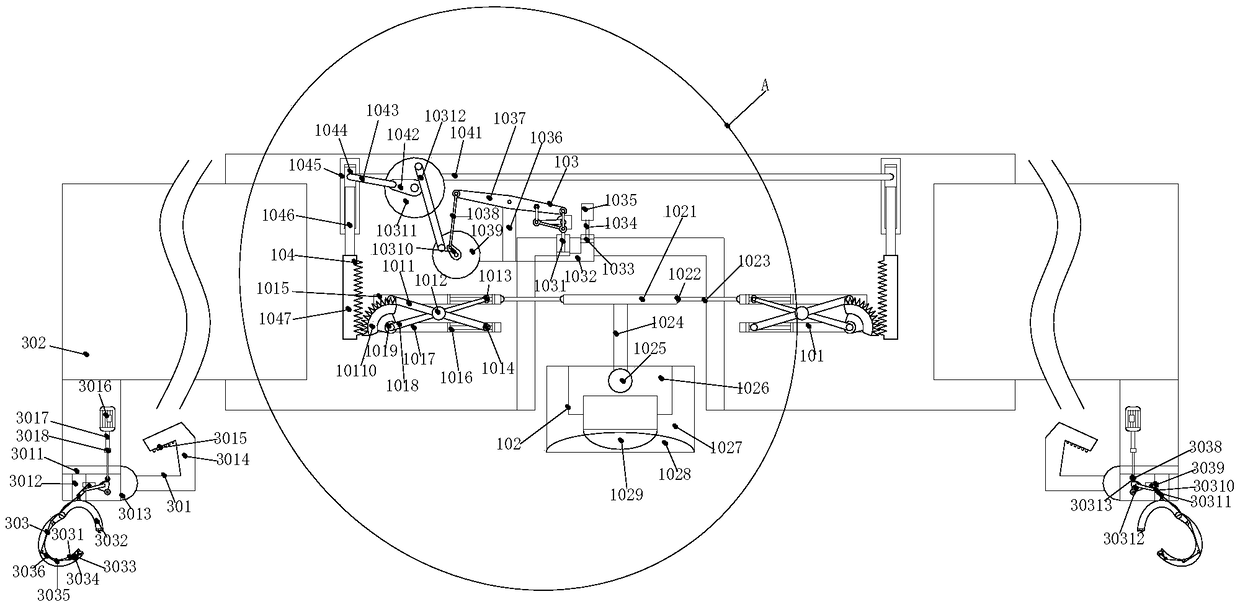

Reverse sliding pressing buckle mechanism, battery converter, battery and electric drive vehicle

ActiveCN110444708AEasy to operateEasy to install and connectCell component detailsGear wheelEngineering

The invention discloses a reverse sliding pressing buckle mechanism, a battery converter, a battery and an electric drive vehicle, and aims to enable a clamping hook to move upwards to be connected with a clamping groove in a battery shell. The buckle structure is characterized by comprising a shell, a pressing plate, a clamping hook and a lifting mechanism; the pressing plate is arranged on a topplate of the shell; the clamping hook and the lifting mechanism are arranged in the shell; the pressing plate drives the clamping hook to move up and down through the lifting mechanism; when the pressing plate is pressed down, the lifting mechanism drives the clamping hook to move upwards; and an avoiding groove allowing the clamping hook to extend out is vertically formed in the shell. The lifting mechanism comprises a driving rack, a driven rack and a reversing gear; the driving rack is arranged on the pressing plate; the driven rack is arranged on the shell in a sliding mode; the reversinggear is meshed with the driving rack and the driven rack; and the clamping hook is arranged on the driven rack. According to the invention, the lifting mechanism is driven by the pressing plate to drive the clamping hook to move upwards to be connected with the clamping groove, and the pressing plate is pressed again to enable the clamping hook to reset to be separated from a clamping opening, sothe battery converter can be plugged and unplugged conveniently.

Owner:SHANGHAI JUNZHENG NETWORK TECH CO LTD

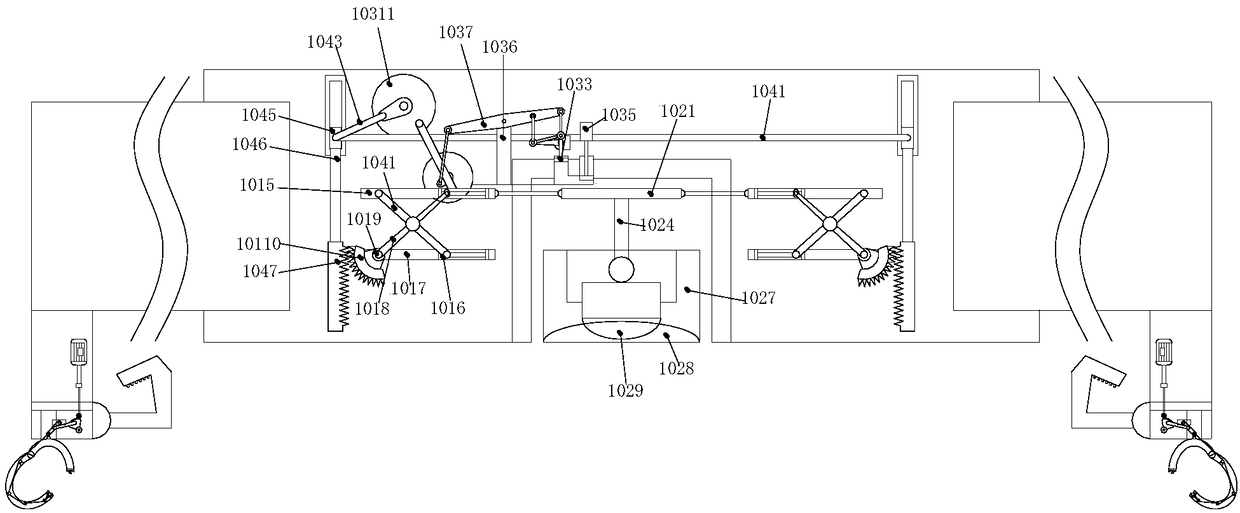

Device for automatically and optically determining target position of container spreader

InactiveCN109179215AAvoid misplacementVarious connection methodsLoad-engaging elementsEngineeringMechanical drive

The invention discloses a device for automatically and optically determining a target position of a container spreader. The device structurally comprises a container checking device, a connecting arm,a spreader mechanism and a shell, the container checking device is installed outside the shell, and the spreader mechanism is connected with the shell through the connecting arm. According to the device, through the combined action of a lifting mechanism, a detecting device, a mechanical driving device, a mechanical transmission mechanism, a first hanging mechanism and a second hanging mechanism,a container can be secondarily checked, and the condition that the container is moved wrongly by the spreader is avoided; and in addition, the connection modes between the spreader and the containerare diverse, and the actual using requirements are met.

Owner:南京溧水高新产业股权投资有限公司

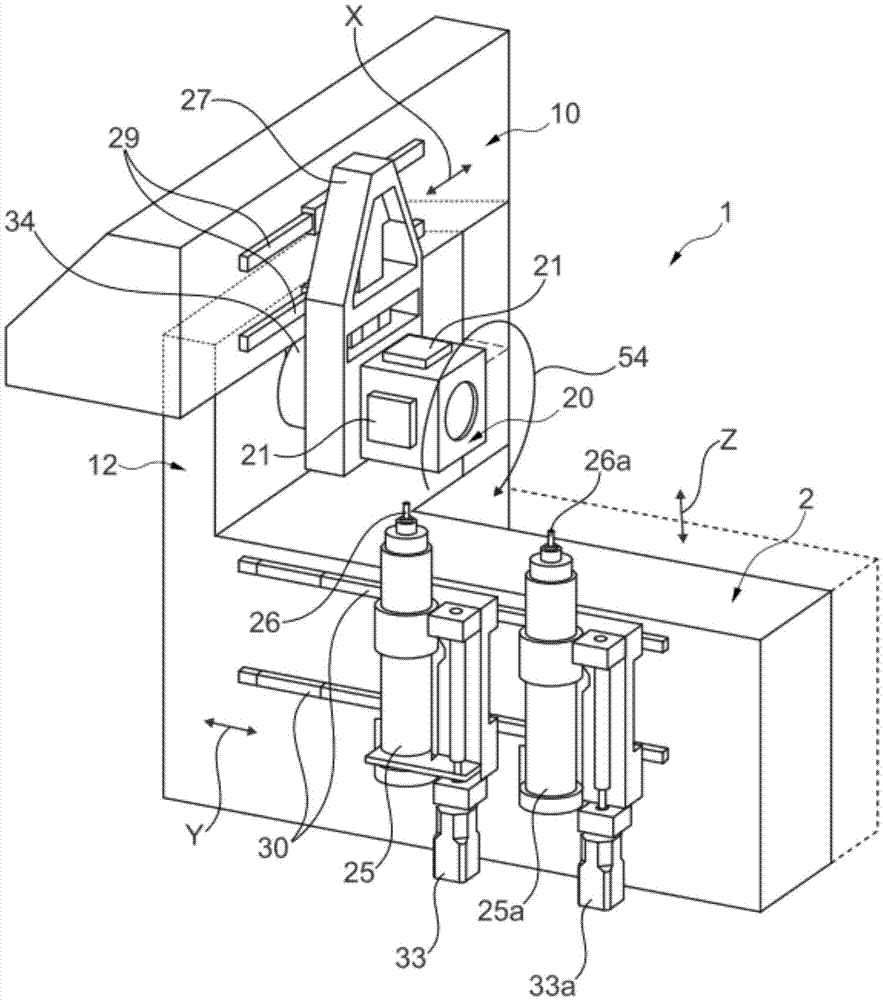

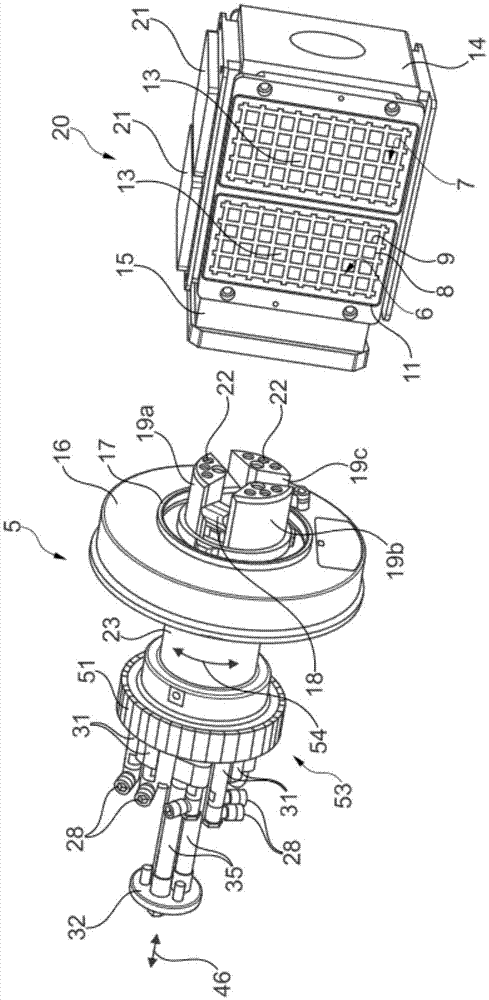

Workpiece clamping device with oscillating drive and vacuum supporting functions and relevant vacuum clamp

InactiveCN107081440AFast processingSimple and precise machiningChucksPositioning apparatusEngineeringMechanical engineering

The invention provides a workpiece clamping device (20) with an oscillating drive function, and the workpiece clamping device (20) is used for machining a workpiece (21) in a workpiece machining device (1). The workpiece clamping device (20) is provided with a plurality of vacuum clamping plates (6 and 7) distributed on different planes on the circumference, and the vacuum clamping plates (6 and 7) are connected with a vacuum clamp (5) in an airtight mode.

Owner:英格博格马夸特

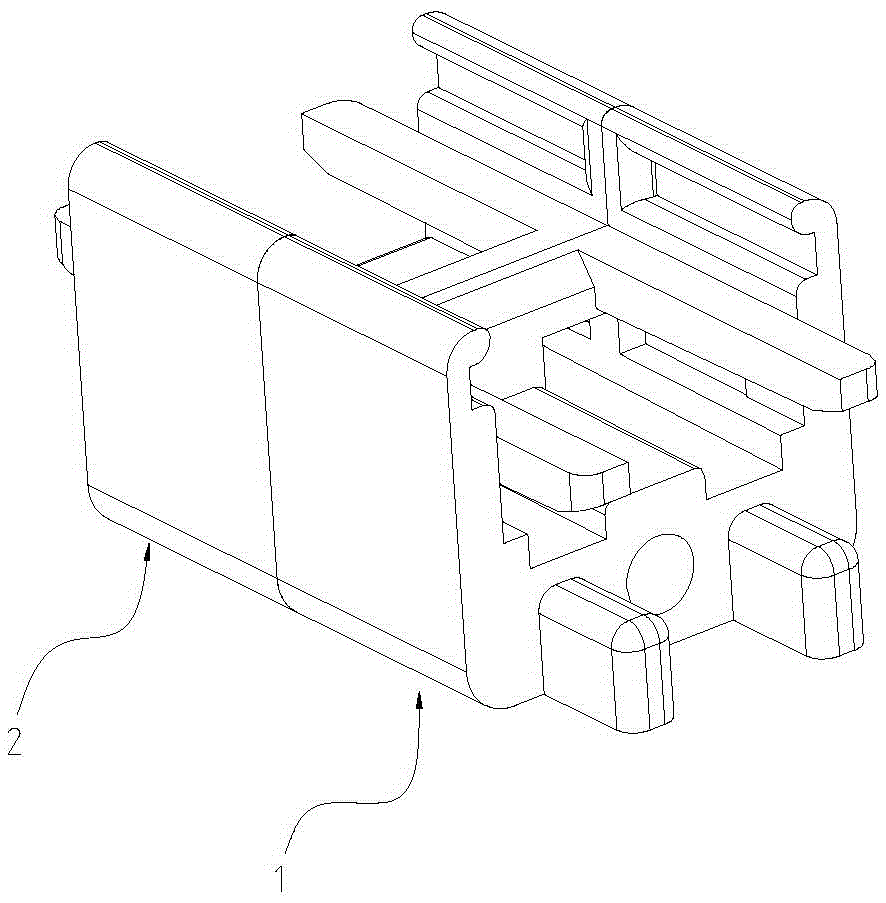

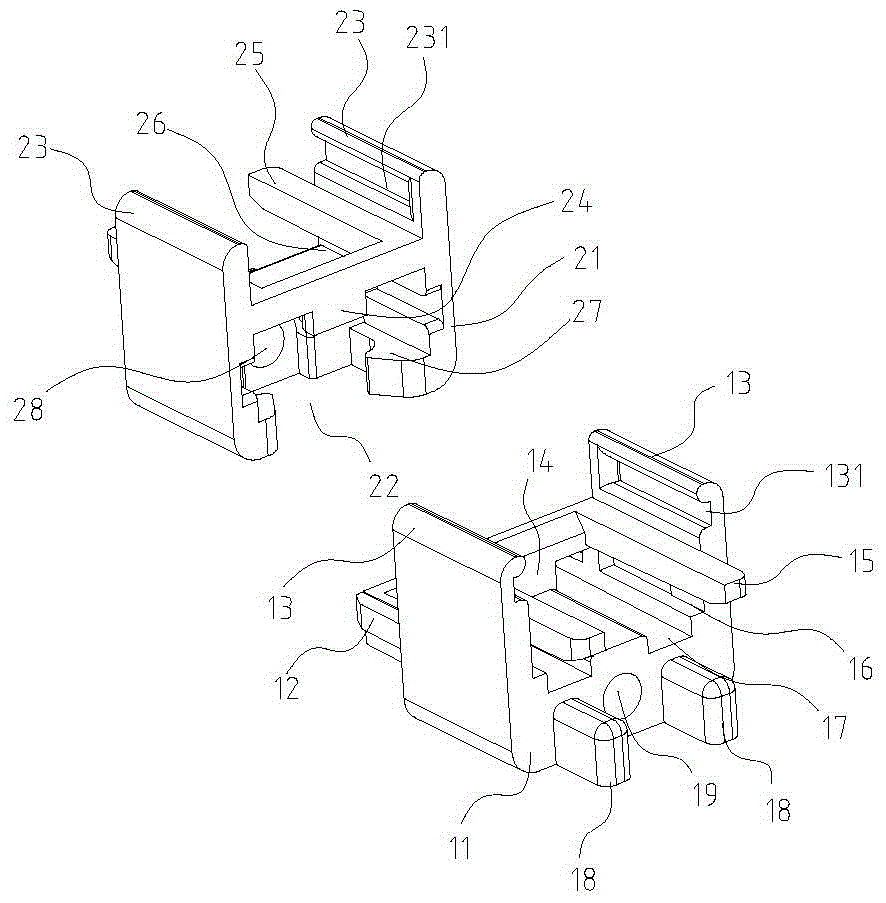

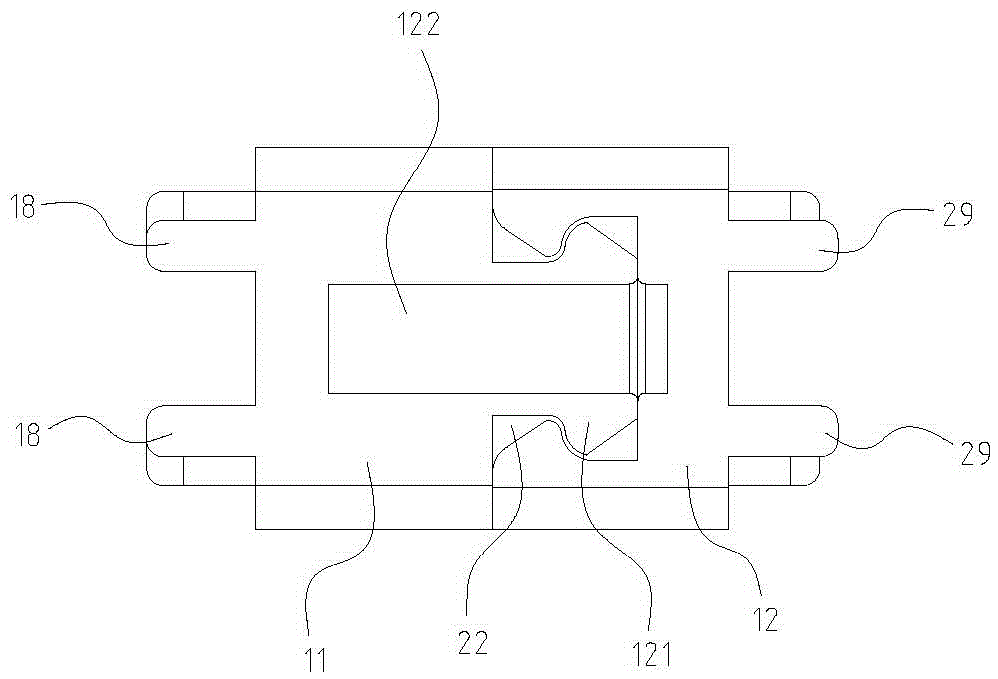

Connecting device

InactiveCN102758819AAchieve mutual separationAchieve mechanical connectionShrinkage connectionsMechanical engineeringEngineering

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

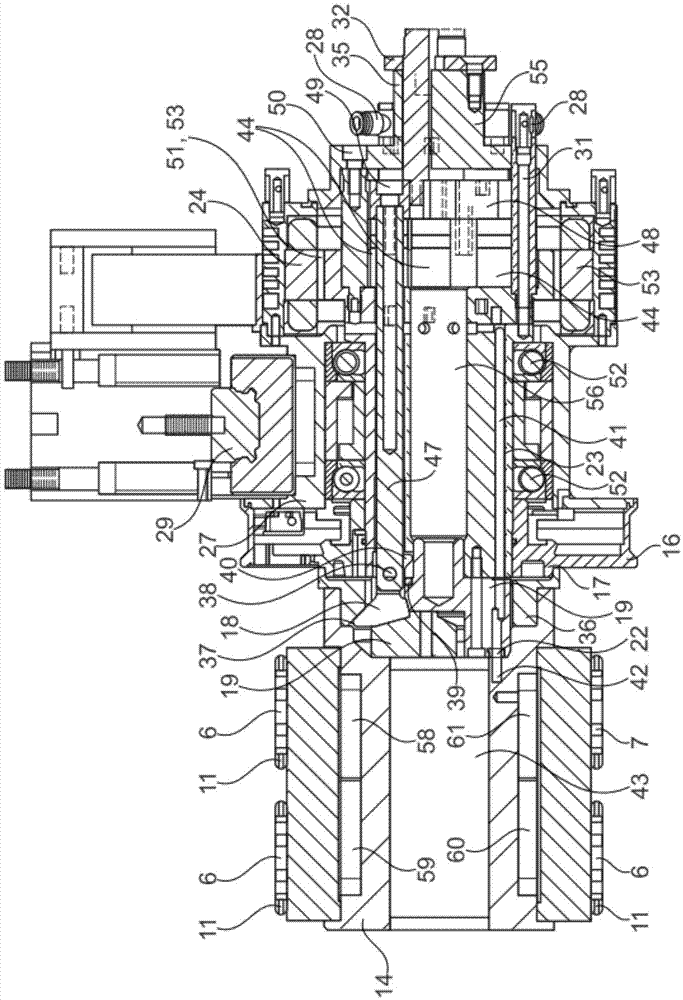

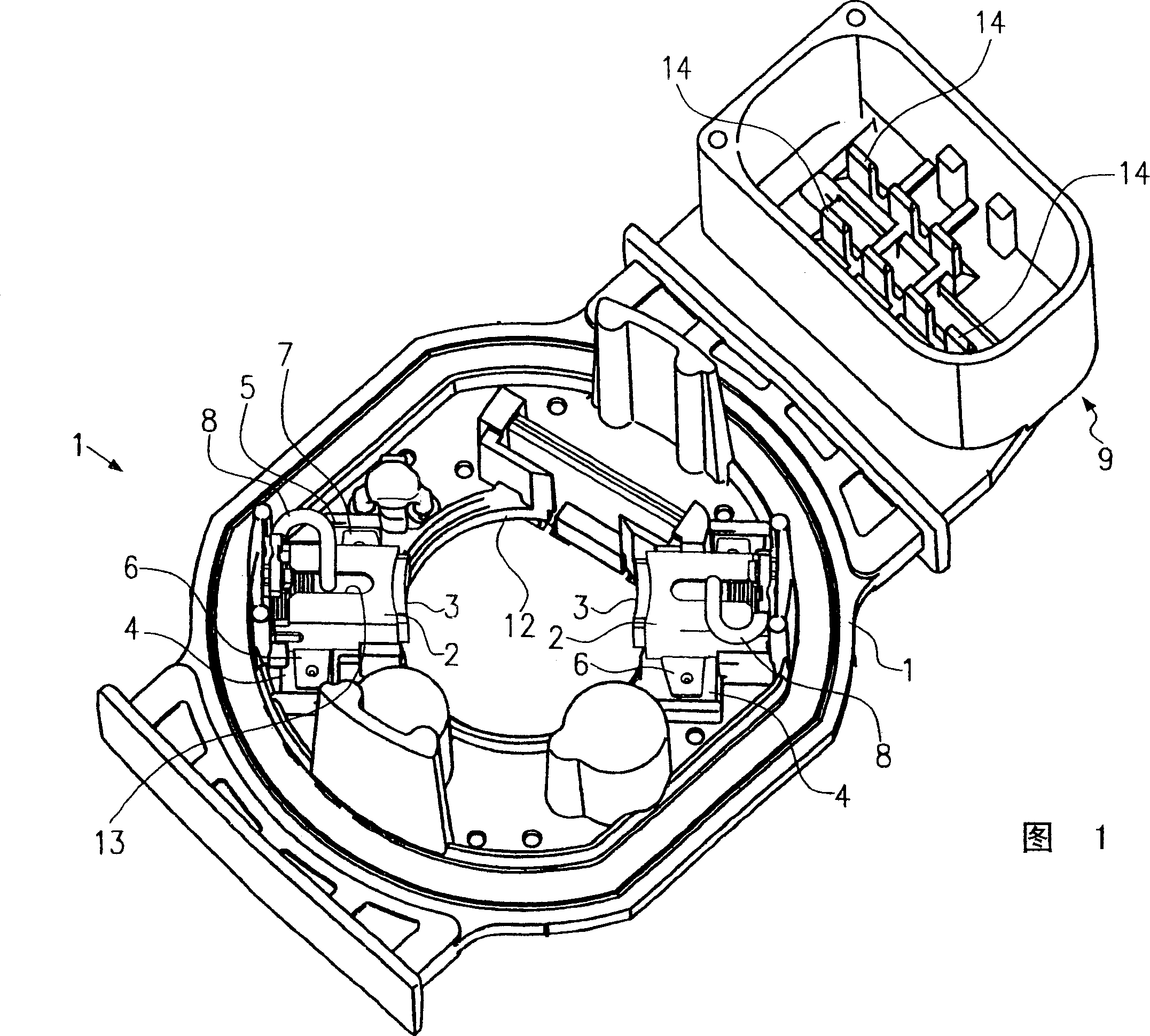

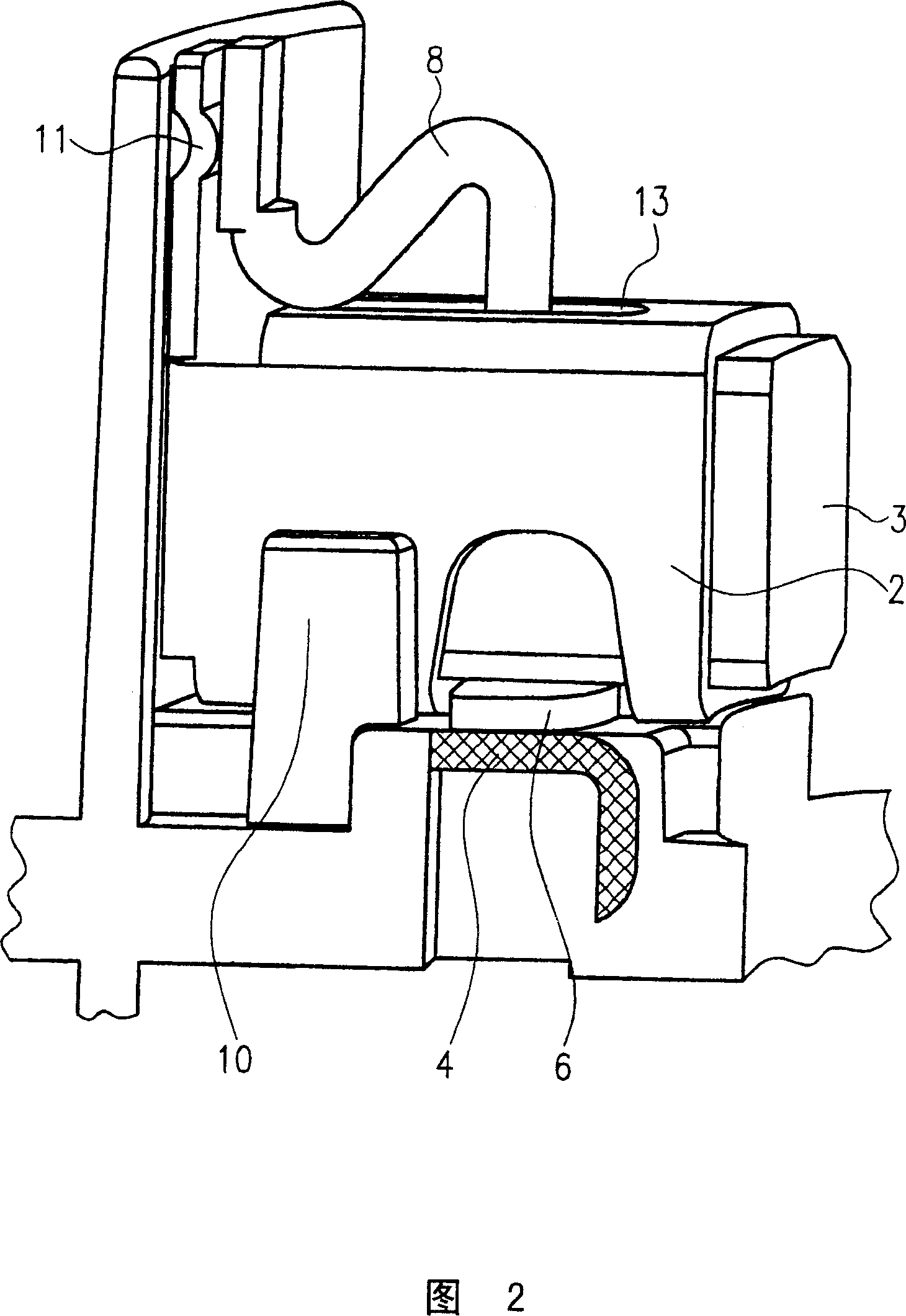

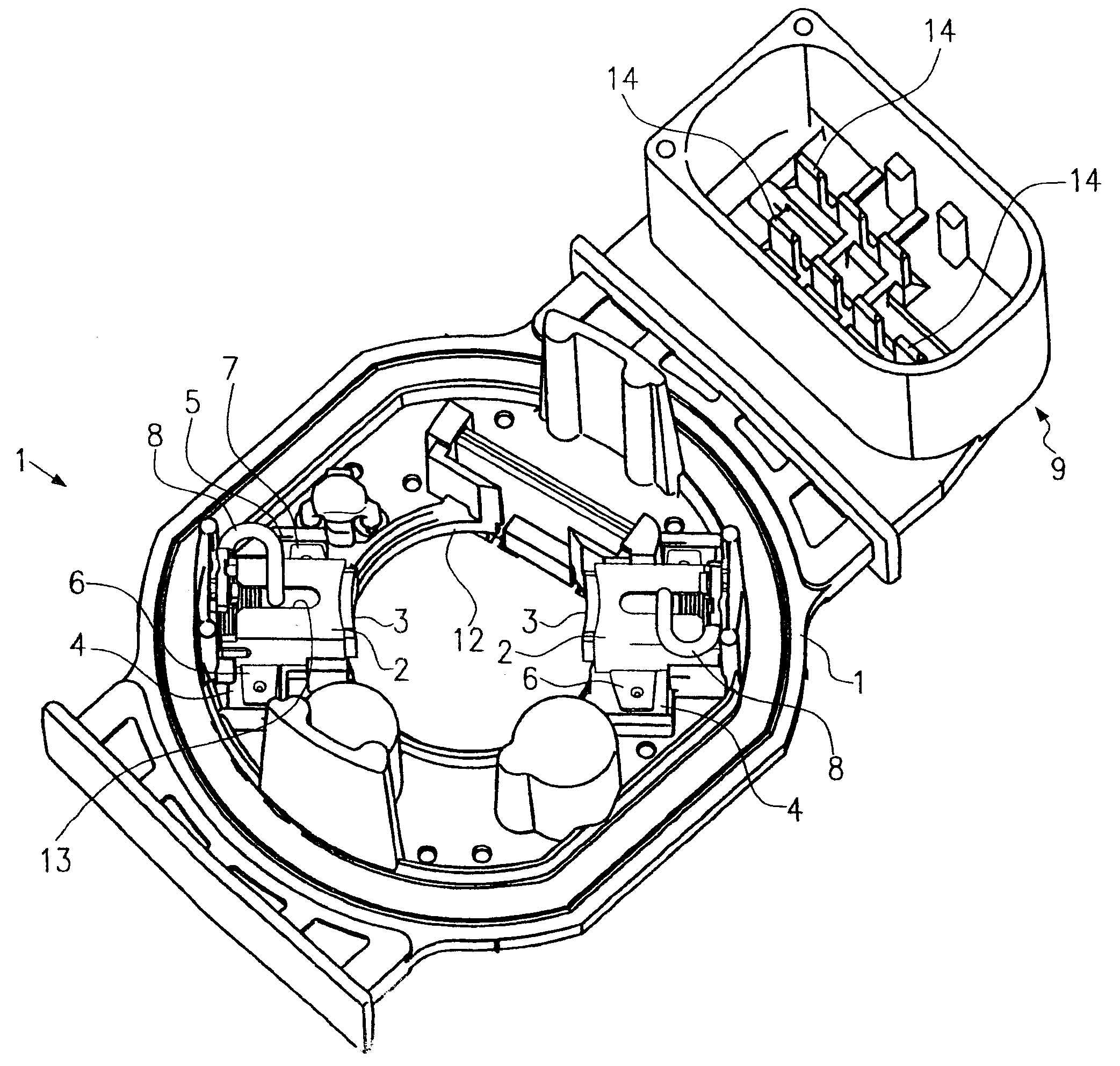

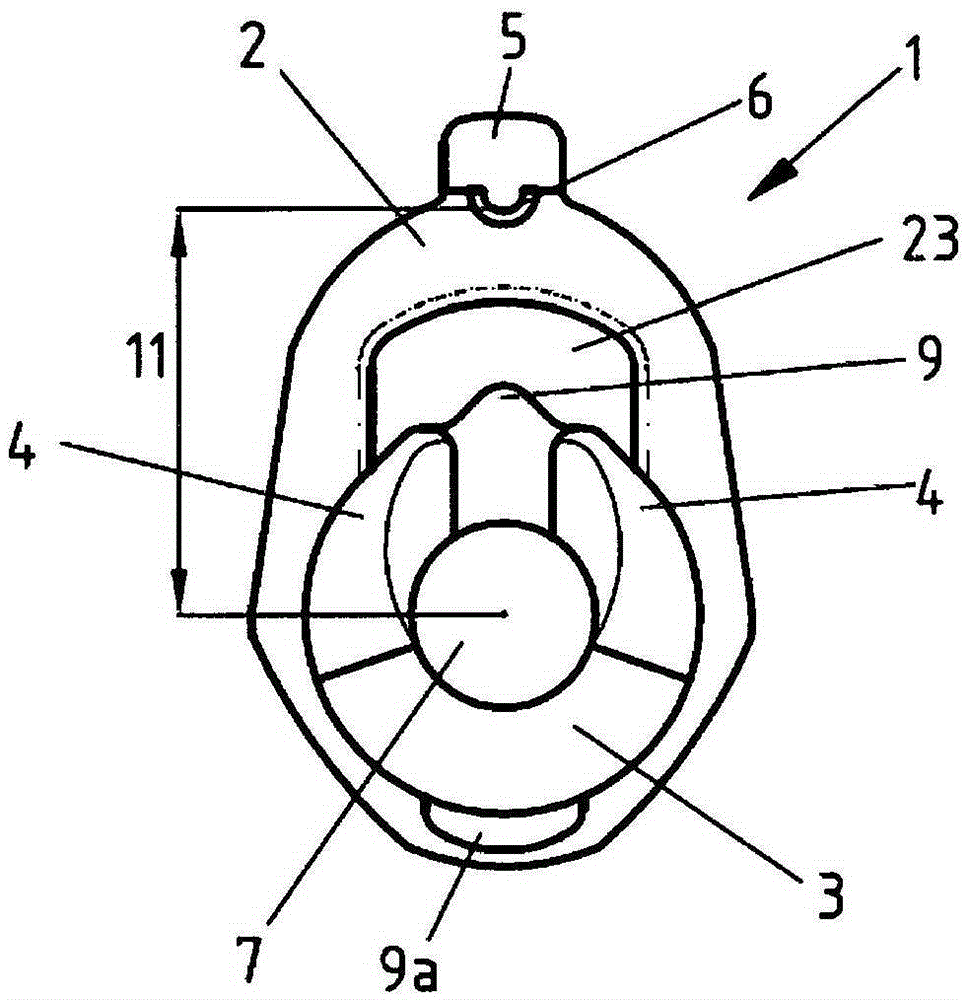

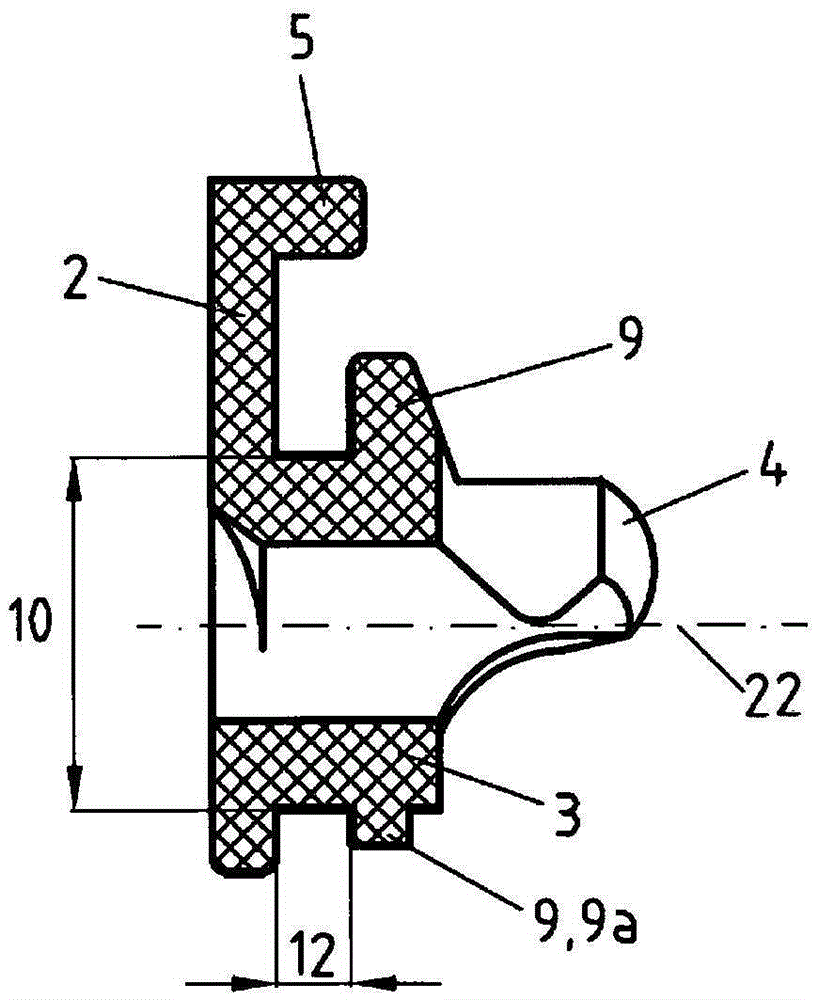

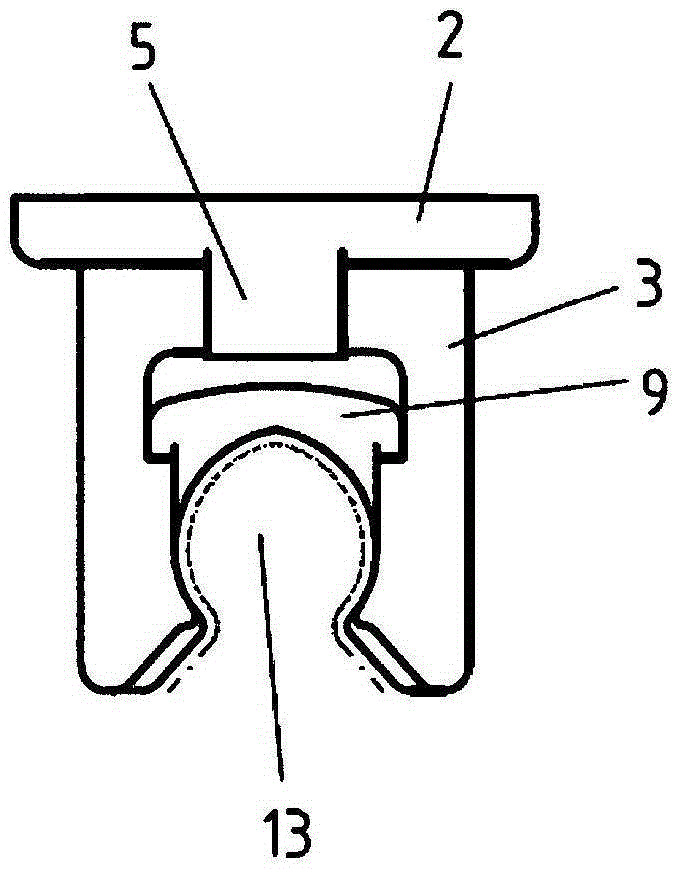

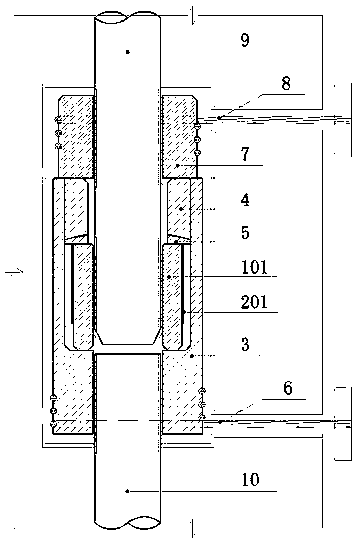

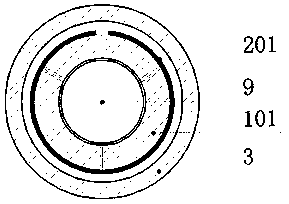

Electric machine with a brush carrier

InactiveCN100342599CImprove cooling effectEasy to installRotary current collectorSupports/enclosures/casingsElectric machineElectrical connection

The invention relates to an electric machine, especially an electric motor, comprising a brush carrier (1) made of an insulating material and at least one brush (3) arranged in a tubular brush holder (2). The tubular brush holder (2) is made of a conducting material and is disposed in such a way that it is exposed on the brush carrier (1). An integral electric connection element (4,5) is provided in the brush carrier (1) for electrical connection.

Owner:ROBERT BOSCH GMBH

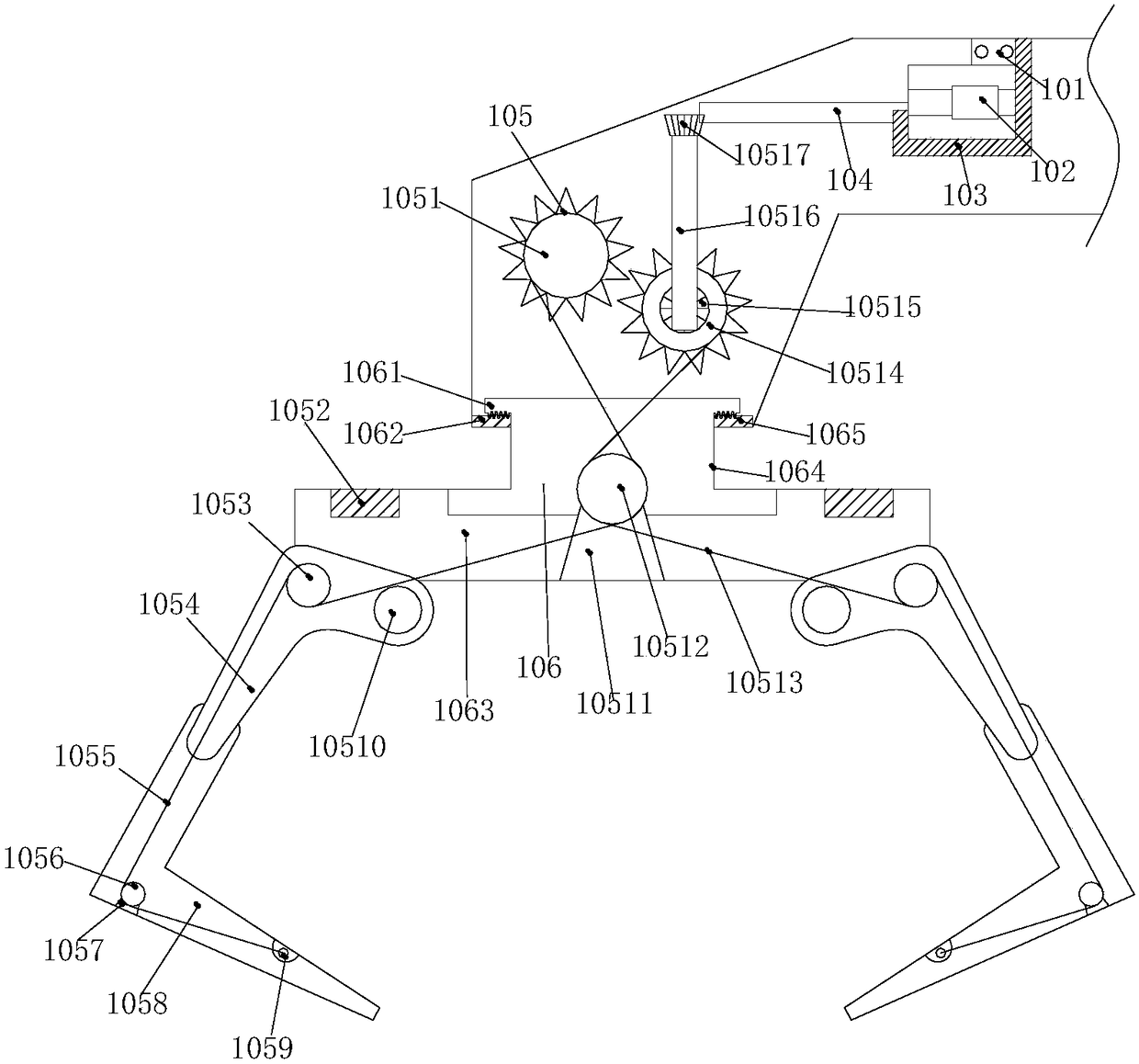

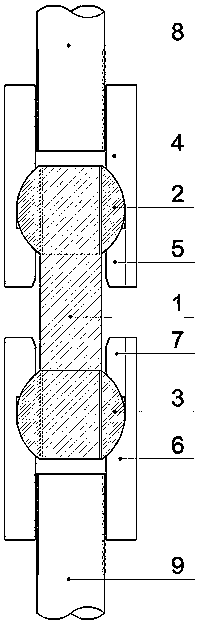

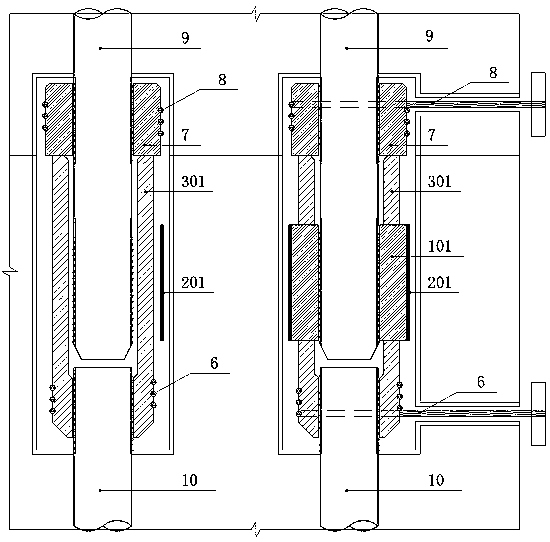

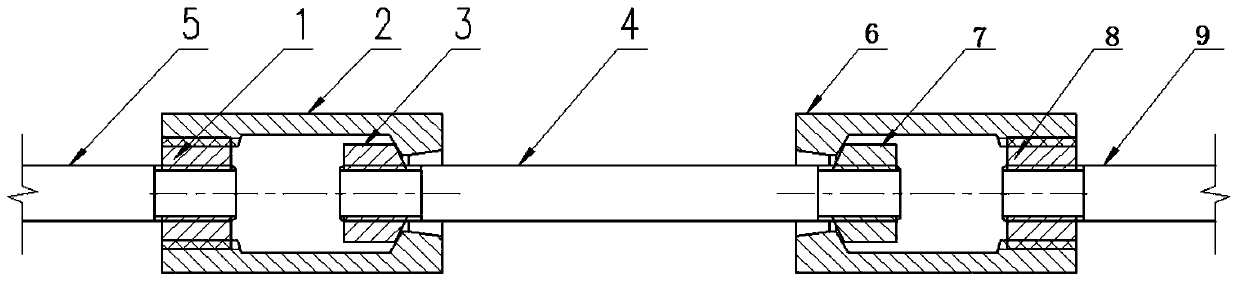

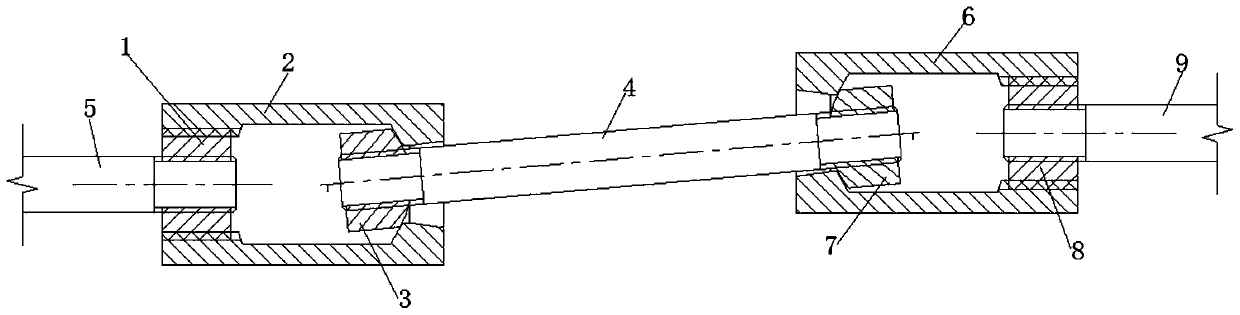

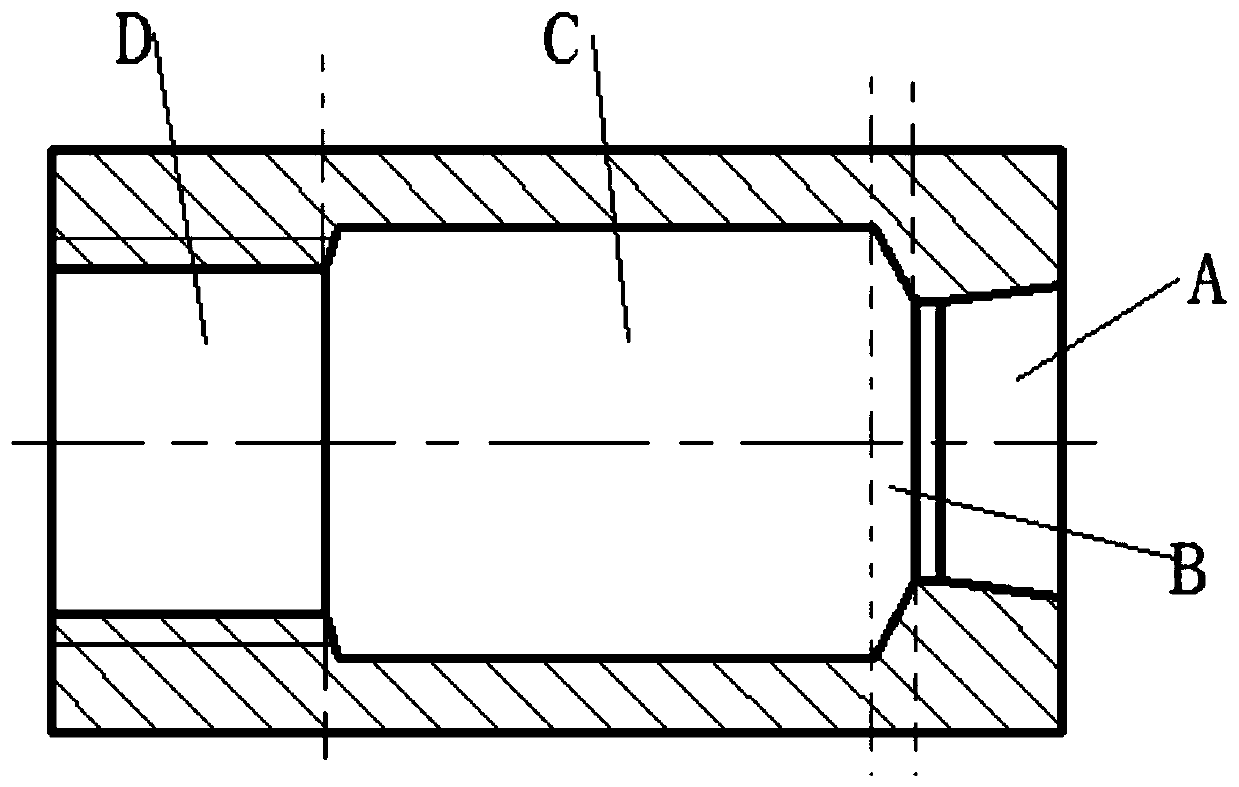

Sawtooth clutch lead screw anchoring spherical nut offset rod part connector

InactiveCN109853867ASolve mechanical docking problemsAchieve mechanical connectionBuilding reinforcementsDumbbellMaterial consumption

The invention relates to an overrunning clutch lead screw anchoring spherical nut offset rod part connector, and offset rod parts connected to two embedded assemblies. The connector comprises an overrunning clutch lead screw anchoring sleeve, a second anchoring sleeve, a dumbbell connecting rod and a pressure-bearing nut assembly, wherein the dumbbell connecting rod is placed between the overrunning clutch lead screw anchoring sleeve and the second anchoring sleeve to adapt to multi-directional deviations between the two rod parts; the first rod part is anchored to one end of the overrunning clutch screw anchoring sleeve, a first spherical nut of the dumbbell connecting rod is anchored to the other end of the overrunning clutch screw anchoring sleeve; a second spherical nut of the dumbbellconnecting rod is anchored to one end of the anchoring sleeve, and the second rod part is anchored to the other end of the second anchoring sleeve, and the tensile function of the connector is realized; and the overrunning clutch lead screw anchoring sleeve is compressed tightly by the pressure-bearing nut, and the compression resistance of the connector is realized. According to the overrunningclutch lead screw anchoring spherical nut offset rod part connector, the size is small, the material consumption is reduced the construction speed is fast, the detection and inspection are convenient,the acceptance criteria is clear, and the requirements of existing mechanical connection specifications are met.

Owner:SHANGHAI YIPINLILIAN CONSTR TECH CO LTD

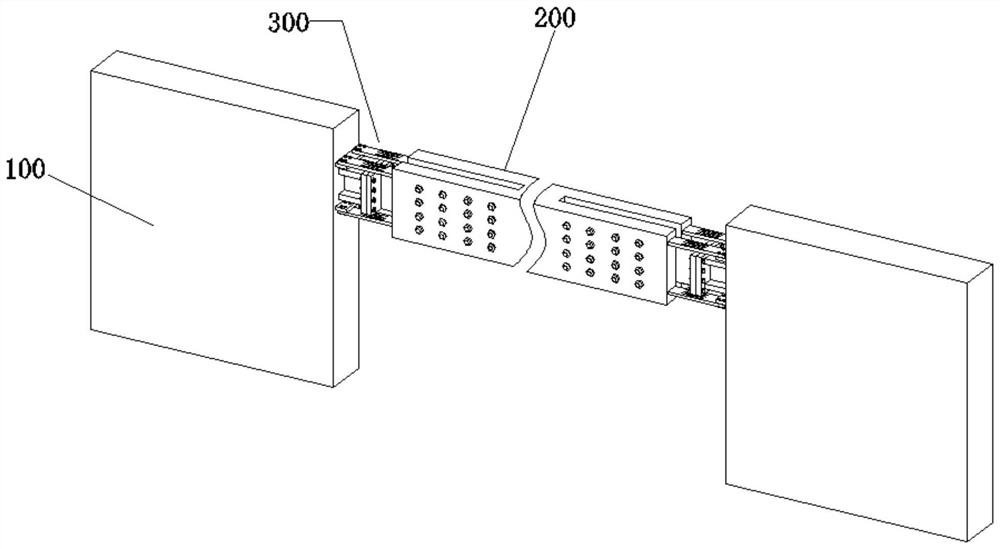

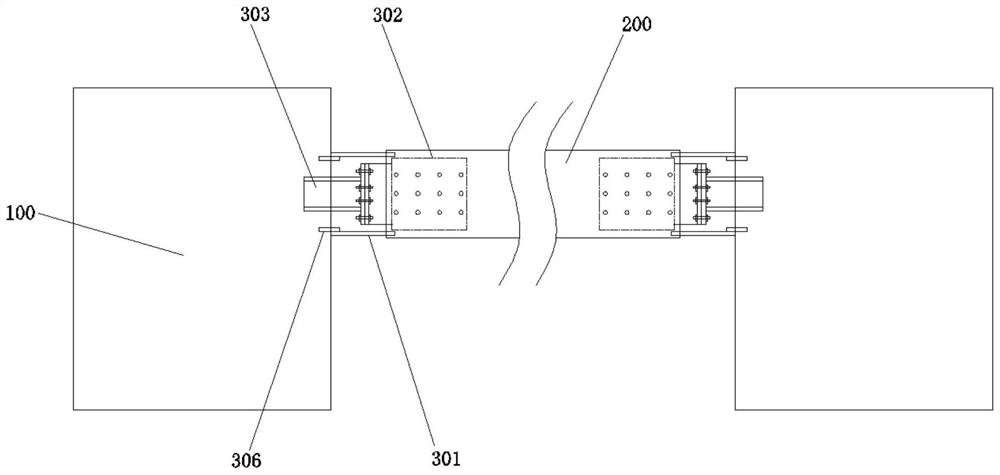

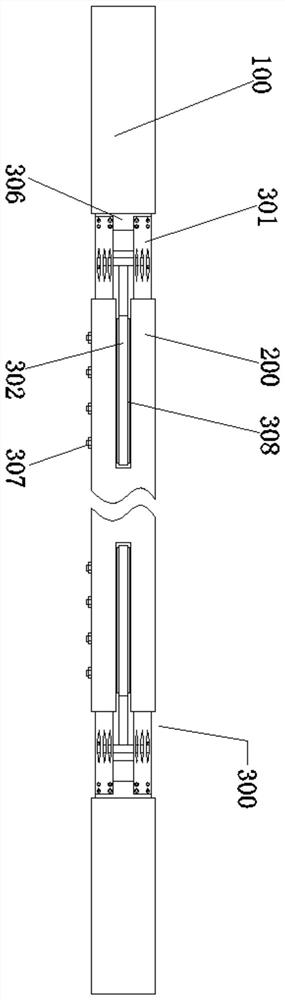

Energy dissipation joint for connecting prefabricated shear wall and coupling beam and assembly method of energy dissipation joint

ActiveCN113756447AConvenient detachable installationQuality assuranceWallsGirdersClassical mechanicsMechanical engineering

The invention relates to the technical field of buildings, and particularly discloses an energy consumption joint for connecting a prefabricated shear wall and a coupling beam and an assembly method of the energy consumption joint. The energy consumption joint comprises a slotted steel plate, a damping steel plate, I-shaped steel, a first end plate, a second end plate, a base plate and high-strength friction type bolts, the slotted steel plate is arranged on the end face of a prefabricated coupling beam, the slotted steel plate and the prefabricated coupling beam are integrally prefabricated and formed, and the damping steel plate is perpendicular and fixedly connected with the prefabricated coupling beam through the bolts; a brass friction plate is arranged between the contact surfaces of the steel damping plate and the prefabricated coupling beam, the end part of the steel damping plate is welded with the end plate, and the other end part of the I-shaped steel and the prefabricated shear wall are integrally prefabricated. A wall body and the connecting beam are prefabricated, mechanical connection of the wall body and the connecting beam is achieved through the slotted steel plate, the damping steel plate, the I-shaped steel, the base plate and the like, an energy dissipation joint assembly can deform towards the energy dissipation assembly during an earthquake, earthquake energy is dissipated, and therefore the excellent energy dissipation and shock absorption effects are achieved.

Owner:JIANGSU OCEAN UNIV +1

Intelligent ex-warehouse device used for plate production line

InactiveCN108453724AAchieve mechanical connectionAchieve separationProgramme-controlled manipulatorGripping headsProduction lineEngineering

The invention discloses an intelligent ex-warehouse device used for a plate production line. The intelligent ex-warehouse device structurally comprises a plate grabbing head, a connecting arm, a connecting head, a connecting column, a checking device, a shell and a base; the plate grabbing head is installed on the connecting arm and is mechanically matched with the connecting arm, the end, far away from the plate grabbing head, of the connecting arm is mechanically connected with the connecting column through the connecting head, the shell is installed on the base and is mechanically matched with the base, and the checking device is arranged in the shell and is mechanically connected with the connecting column. According to the intelligent ex-warehouse device, under joint effects of a grabbing device control mechanism, a connecting mechanism, a first rotating mechanism, a driving rotation mechanism, a second rotating mechanism, a driving device and a clamping rod mechanism, a plate canbe grabbed by the grabbing head to check whether the weight of the plate reaches the standard or not, and the product ex-warehouse yield is improved.

Owner:庄楠键

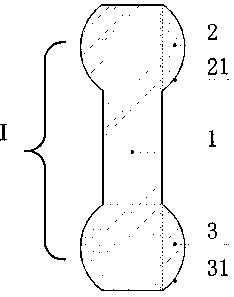

Double-ball-hinge steering connector of offset rod member

PendingCN109653444AAchieve mechanical connectionImprove scalabilityBuilding reinforcementsEngineeringMulti directional

The invention relates to a double-ball-hinge steering connector of an offset rod member. The double-ball-hinge steering connector is used for connecting offset rod members on two embedded components.The double-ball-hinge steering connector of the offset rod member comprises a dumbbell connecting rod, a first anchoring sleeve and a second anchoring sleeve; the dumbbell connecting rod is arranged between the first anchoring sleeve and the second anchoring sleeve and is suitable for multi-directional offset between two rod members; one end of the first anchoring sleeve is connected with a rod member I directly or indirectly, and the other end of the first anchoring sleeve anchors a first spherical nut of the dumbbell connecting rod; and one end of the second anchoring sleeve anchors a secondspherical nut of the dumbbell connecting rod, and the other end of the second anchoring sleeve is directly or indirectly connected with a rod member II. The double-ball-hinge steering connector of the offset rod member is small in size, material-saving, high in construction speed, convenient in detection and inspection, definite in verification standard and capable of meeting the existing mechanical connection standard requirements.

Owner:SHANGHAI YIPINLILIAN CONSTR TECH CO LTD

Fastening element for connecting transmission means to lever element

ActiveCN105378304AAchieve mechanical connectionAvoid lossBearing assemblyVehicle locksBowden cableMechanical engineering

Owner:KIEKERT AG

LED cabinet light

ActiveCN106594562AAchieve mechanical connectionQuick connectionMechanical apparatusDomestic lightingEngineeringLED lamp

A LED cabinet light comprises two or more LED light bars. The adjacent LED light bars are connected through a splicing device. The LED light bars are fixed to the wall through a fixing device. The splicing device comprises a male joint and a female joint. The first LED light bar is mechanically connected with the male joint through a first connecting mechanism. The second LED light bar is mechanically connected with the female joint through a second connecting mechanism. The male joint and the female joint are quickly connected through the cooperation of a buckle and a clamping groove, so that quick mechanical connection of the two adjacent LED light bars is achieved. A conductive slot is formed in a first seat body and extends to the male joint. After the two LED light bars are mechanically connected, electric contact chips of the two LED light bars form electric connection at the same time; and the fixing device comprises a magnet arranged at the bottom of a light body and one or more fixing clamps distributed in the length direction of the LED light bars. Due to the fact that a fixing clamp fixing manner and a magnet fixing manner are free of bolt connection, the LED light bars can be disassembled and assembled more conveniently and faster.

Owner:GUANGZHOU LEDIA LIGHTING CO LTD

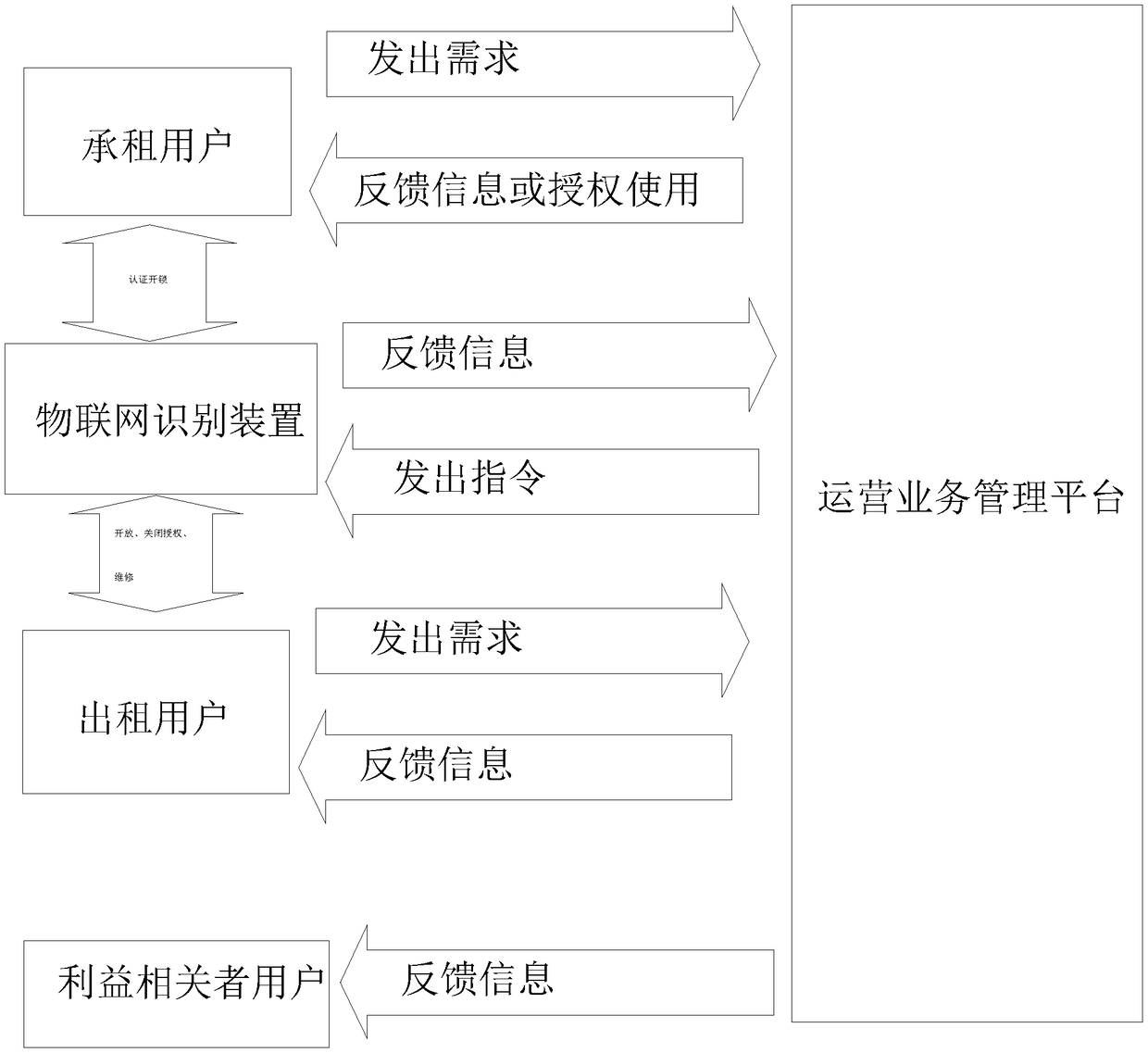

Intelligent system for unattended original-return sharing device and using method thereof

InactiveCN109118665AAchieve mechanical connectionIncrease usageApparatus for meter-controlled dispensingBuying/selling/leasing transactionsThe InternetREMS Stakeholder

The invention discloses an intelligent system for an unattended original-return sharing device and a using method thereof. The technical solution of the invention is that the system comprises: a tenant user terminal, an Internet of Things identification device terminal, a rental user terminal, an operation service management platform, and a stakeholder user terminal, wherein the Internet of Thingsidentification device terminal includes an Internet of Things identification device identification module, which is used for realizing the matching between an rental object and the terminal of the Internet of Things identification device. The one-to-one matching method can achieve the purpose of original return, and each terminal can realize intelligent operation through contact with the operation service management platform. Compared with the prior art the solution achieves unattended original-return goals, and increases the efficiency and reduces the costs.

Owner:太仓市小车东汽车服务有限公司

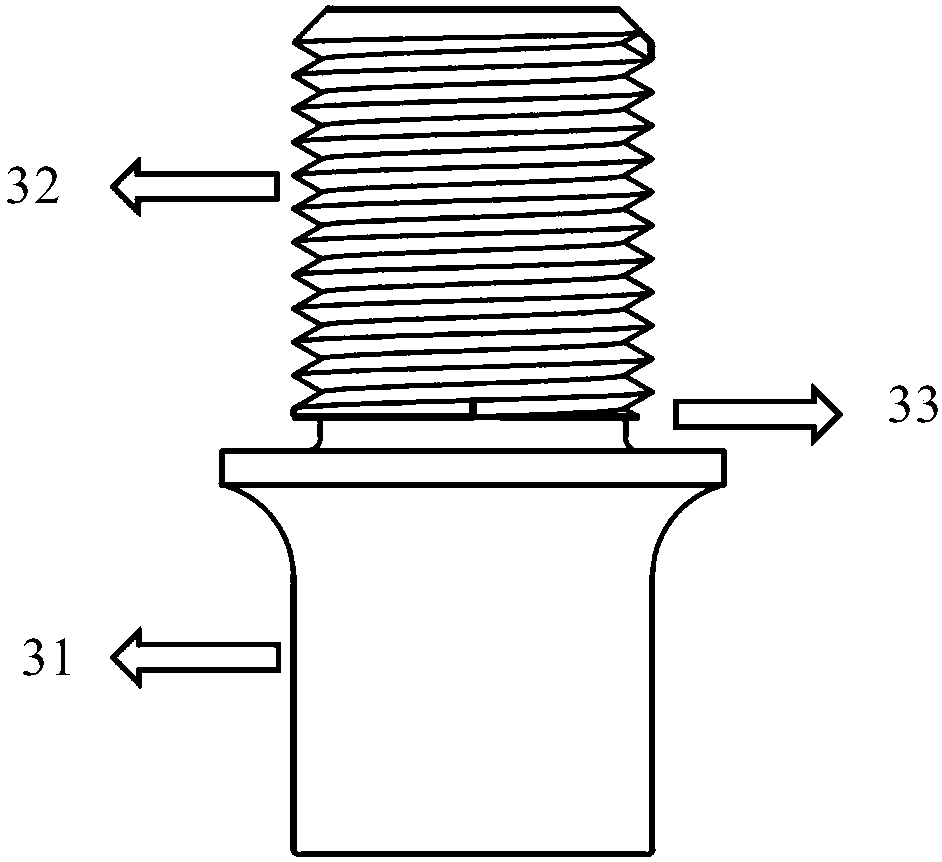

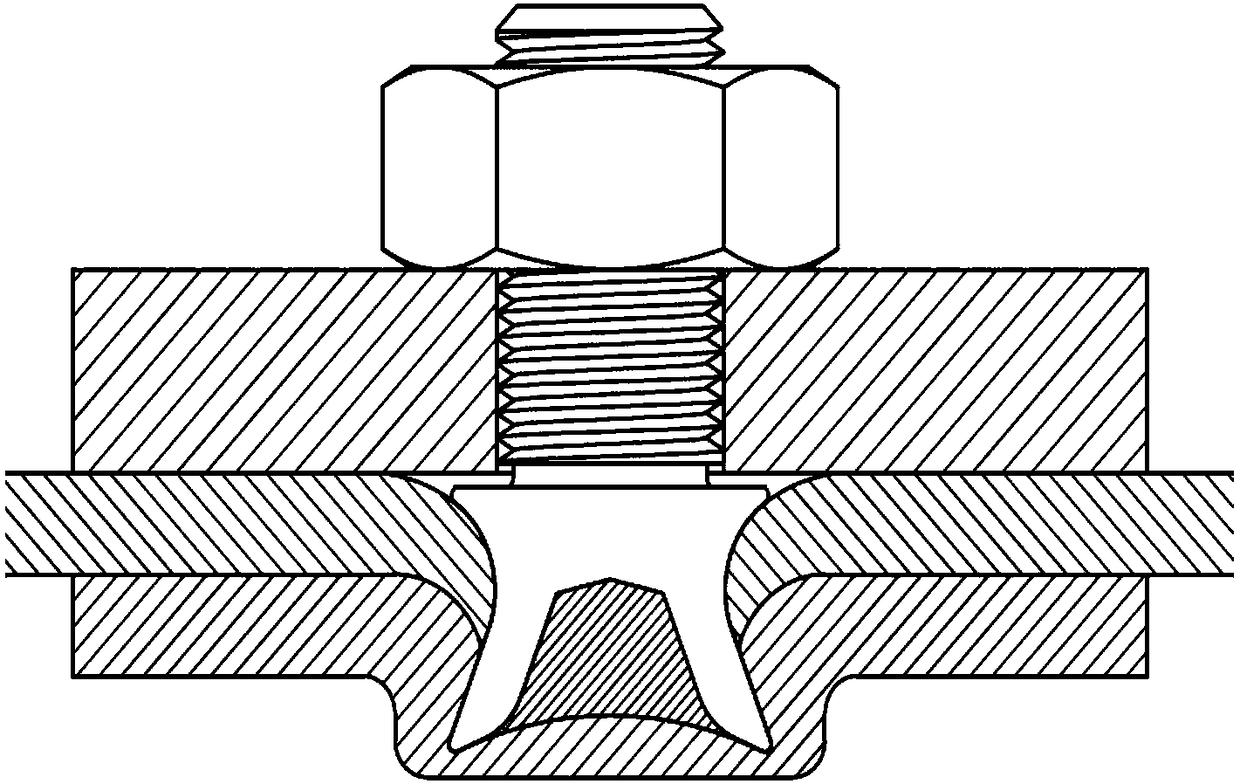

Semi-hollow self-punching riveting screw with fastening thread and self-punching riveting equipment and method

PendingCN108457954AImprove material formabilitySimple structureRivetsSheet joiningEngineeringThick plate

The invention provides a semi-hollow self-punching riveting screw with a fastening thread. The screw is characterized by comprising a rivet body with a semi-hollow structure, and a thread head which is arranged on the upper end face of the rivet body and provided with the fastening thread. The bottom of the thread head is provided with a cutter withdrawal groove facilitating cutter withdrawal after thread machining is finished. The outer diameter of the rivet body is the same as that of the thread head. The invention further discloses self-punching riveting equipment method adopting the riveting screw. An improved self-punching riveting rod pushes the semi-hollow self-punching riveting screw to achieve riveting and forming of thin plates, and then mechanical connection between thicker plates is achieved by means of a thread mechanism. The screw is simple in structure form, machining and manufacturing are facilitated, the cost is low, the limitation to a traditional semi-hollow self-punching riveting screw from the thickness of riveted plates is overcome, and mechanical connection between three-layer or multi-layer thicker plates can be achieved.

Owner:DALIAN UNIV OF TECH

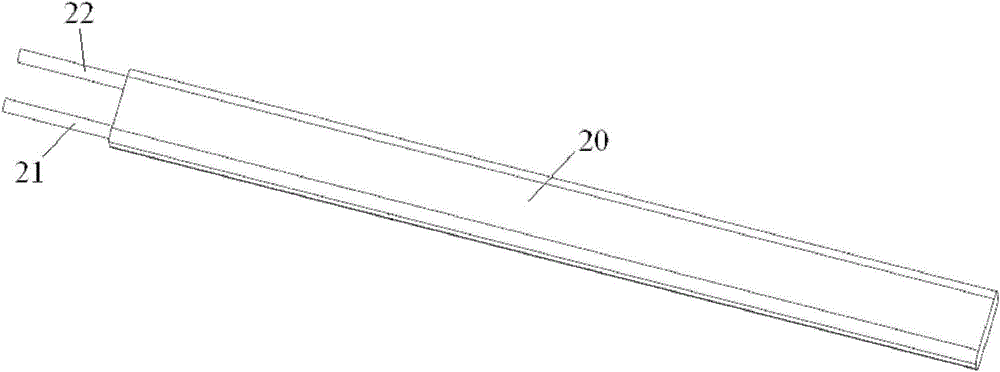

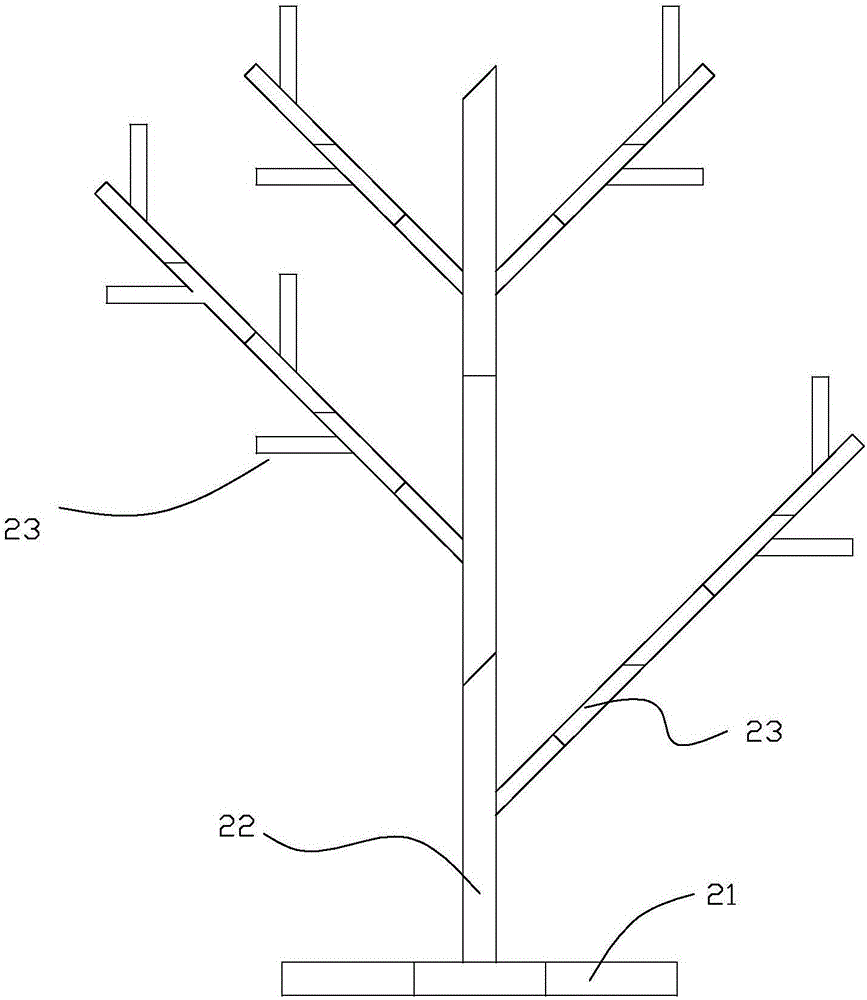

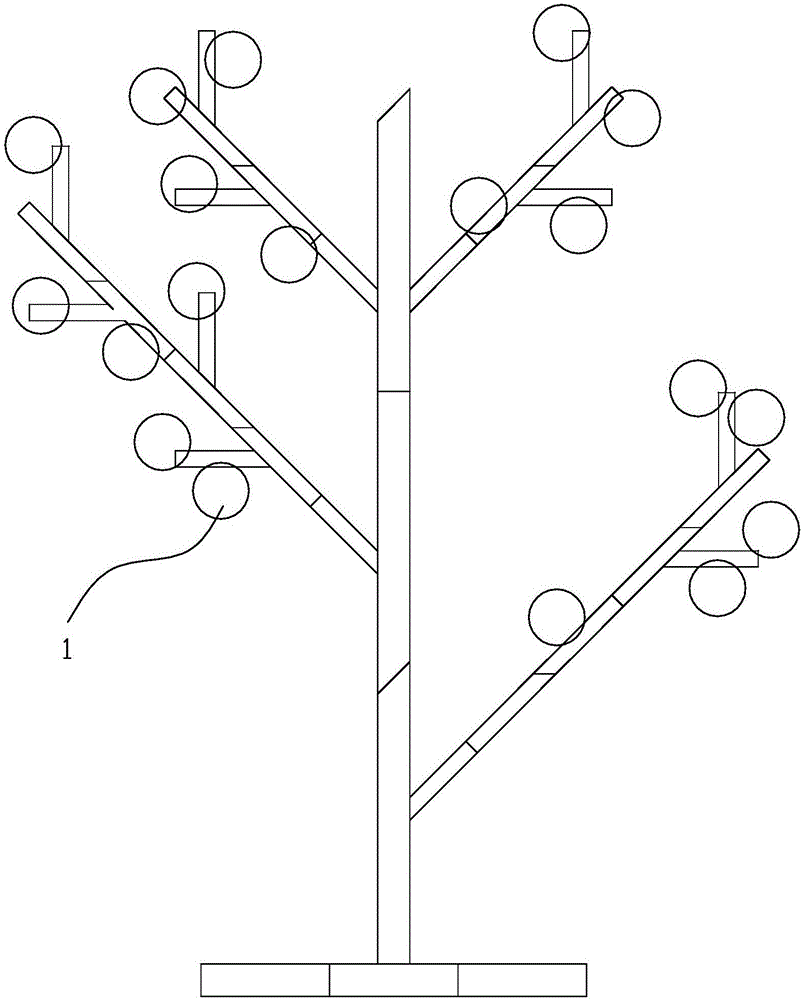

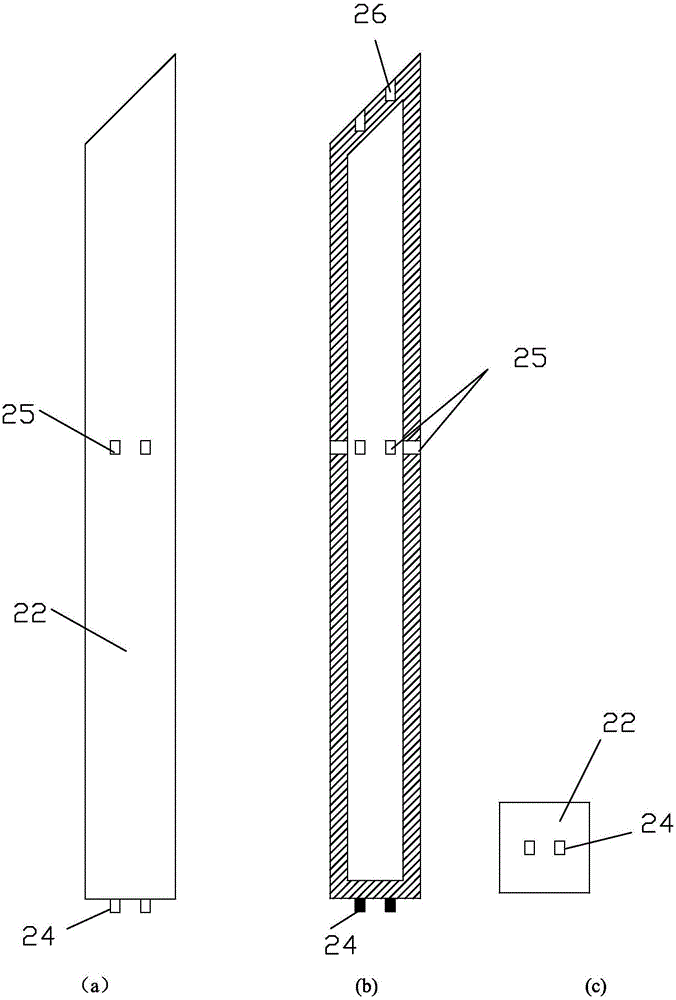

Decorative lamp tree trunk assembled based on plurality of branch segments

InactiveCN106402811AGood flexibilityReduce connection difficultyElectrical apparatusLighting support devicesStraight segmentEngineering

The invention discloses a decorative lamp tree trunk assembled based on a plurality of branch segments. The decorative lamp tree trunk comprises a main trunk (22) and branches (23), wherein the branches are connected with the main trunk; the main trunk is formed by a plurality of branch segments which are connected; the branches are formed by a plurality of branch segments which are connected; two end faces of a straight segment are each provided with a connecting terminal; the connecting terminals on the two end faces are connected by wires inside the branch segments; the connecting terminal on one end face is an end part connecting socket (26), and the connecting terminal on the other end face is an end part connecting plug (24); and the straight segment is of a square columnar structure. At least one side surface of the middle part of the straight segment is provided with a side part connecting socket (25), and the branches are connected with the main trunk through the side part connecting sockets. The decorative lamp tree trunk assembled based on the plurality of branch segments is simple in structure, easy to connect and assemble and good in flexibility.

Owner:长沙修恒信息科技有限公司

Elastic combination ring type anchoring offset rod piece connector

PendingCN109853859ASolve mechanical docking problemsAchieve mechanical connectionBuilding reinforcementsEngineeringMulti directional

The invention relates to an elastic combination ring type anchoring offset rod piece connector. The elastic combination ring type anchoring offset rod piece connector comprises elastic combination anchoring rings, an anchoring sleeve and a pressure bearing nut combination piece; the elastic combination anchoring rings comprise at least a plurality of curved clamping pieces and an elastic resettingpiece, the anchoring sleeve includes at least one anchoring cup and a first guiding-out tightening combination piece, and the pressure bearing nut combination piece includes a pressure bearing nut and a second guiding-out tightening combination piece; the anchoring sleeve forms a multi-directional constraint and anchoring effect on the elastic combination anchoring rings, the closing-up ends of the anchoring cups are connected with a rod piece on one side, and the elastic combination anchoring rings form a one-way anchoring structure with a rod piece on the other side; the first guiding-out tightening combination piece disposed on the outer side of the anchoring cups is externally pulled, and the anchoring cups are rotated to tighten the connector, and the tension connection of the rod pieces is realized; and by pulling the second guiding-out tightening combination piece, the pressure bearing nut presses the anchoring sleeve to provide the pressure resistance of the rod pieces. The elastic combination ring type anchoring offset rod piece connector is small in size, saves materials, and is high in construction speed, convenient in detection and inspection and clear in acceptance standard.

Owner:SHANGHAI YIPINLILIAN CONSTR TECH CO LTD

Universal reinforcing steel bar connecting assembly

PendingCN110388004AAchieve mechanical connectionReduce volumeBuilding reinforcementsFault toleranceRebar

The invention relates to a universal reinforcing steel bar connecting assembly for connecting a first target reinforcing steel bar and a second target reinforcing steel bar. The universal reinforcingsteel bar connecting assembly comprises a first barrel, a connecting rod and a second barrel. The universal reinforcing steel bar connecting assembly is characterized in that one end of the connectingrod is spherically hinged to the first target barrel while the other end of the connecting rod is spherically hinged to the second barrel; a first connecting part connected to the first target reinforcing steel bar is detachably mounted in the first barrel, and a second connecting part connected to a second target reinforcing steel bar is detachably mounted in the second barrel. The universal reinforcing steel bar connecting assembly can connect two target reinforcing steel bars mechanically. Compared with an existing grouting bushing, the universal reinforcing steel bar connecting assembly is small in size, great in fault tolerance, reliable in connection and low in cost after batch production, can be widely applied to prefabricated shear walls, prefabricated columns, prefabricated beams, prefabricated floorslabs and the like, and can promote assembled buildings to take a giant step forward.

Owner:HUNAN YUANDA ENG DESIGN CO LTD

Side wall open-hole anchoring bidirectional off-position rod piece connector

InactiveCN109853868AShorten the overall lengthReduce material usageBuilding reinforcementsMaterial consumptionBiomedical engineering

The invention relates to a side wall open-hole anchoring bidirectional off-position rod piece connector. The side wall open-hole anchoring bidirectional off-position rod piece connector comprises first elastic combination nuts, a first anchoring sleeve, a middle connecting sleeve, second elastic combination nuts, a second anchoring sleeve, a first pressure-bearing nut assembly and a second pressure-bearing nut assembly; the first elastic combination nuts and the second elastic combination nuts include a plurality of pieces of threaded clamping pieces in elastic reset parts, and the first anchoring sleeve and the second anchoring sleeve include open-hole anchor cups; the first pressure-bearing nut assembly and the second pressure-bearing nut assembly include pressure-bearing nuts and guide-out screwing combination pieces, and a plurality of window holes are formed in the side walls of first open-hole anchor cups and second open-hole anchor cups; the first elastic combination nuts and the second elastic combination nuts are oppositely arranged in the window holes of the side walls, and the first anchoring sleeve is connected with the second anchoring sleeve through the middle connecting sleeve, and the first anchoring sleeve and the second anchoring sleeve are anchored by the middle connecting sleeve; and the pressure-bearing nuts tightly press the anchoring sleeve to provide thecompressive capacity of rod pieces. According to the side wall open-hole anchoring bidirectional off-position rod piece connector, the size is small, the material consumption is less, the construction speed is fast, the detection and the inspection are convenient, and the acceptance criteria is clear.

Owner:SHANGHAI YIPINLILIAN CONSTR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com