Sawtooth clutch lead screw anchoring spherical nut offset rod part connector

A spherical nut, lead screw nut technology, applied in building components, building reinforcements, structural elements, etc., can solve the problems of complicated installation and tightening, long waiting time, large space occupation, etc., to promote the overall improvement and development, material The effect of reduced dosage and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

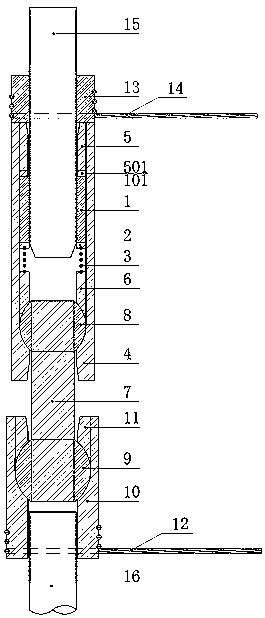

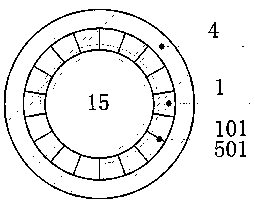

[0036] Such as figure 1 and figure 2 As shown, an embodiment of the present invention includes a roller-type serrated clutch lead screw anchor sleeve , dumbbell link and second anchor sleeve and pressure nut assembly .

[0037] Roller Serrated Clutch Lead Screw Anchor Sleeve Including lead screw nut 1, support plate 2, elastic member 3, first sleeve anchor cup 4, first end anchor plate 5 and first middle anchor plate 6; the dumbbell connecting rod Contains an intermediate connecting rod 7, a first spherical nut 8 and a second spherical nut 9; the second anchor sleeve It includes a second sleeve anchor cup 10 and a second sleeve end anchor plate 11 .

[0038] The first sleeve anchor cup 4 and the second sleeve anchor cup 10 are cup-shaped cylinders with an open end and a closed end.

[0039] The dumbbell link Place the anchor sleeve on the serrated clutch lead screw and the second anchor sleeve between; the serrated clutch lead screw anchor sleeve One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com