Connecter of flexible inhaul cable offset rod part

A technology of flexible cables and connectors, which is applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of large space required for connectors, undetectable, and unclear acceptance standards, so as to promote overall improvement and development, Inspection and acceptance clear and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

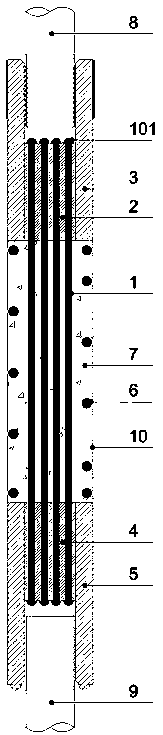

[0024] Such as figure 1 As shown, an embodiment of the present invention comprises a flexible stay cable 1, a first anchor head 2 of a stay cable, a first threaded sleeve 3, a second anchor head 4 of a stay cable, a second threaded sleeve 5, a spiral steel bar 6 and High-strength cement-based grouting material 7.

[0025] The first cable anchor head 2 and the cable second anchor head 4 respectively anchor the two ends of the flexible cable 1, and the flexible cable 1 is a plurality of separated high-strength tension filaments.

[0026] The first threaded sleeve 3 anchors the first anchor head 2 of the first anchor head 2 of the rod member 8 and the dragline respectively with a threaded pair.

[0027] The second threaded sleeve 5 anchors the rod part two 9 and the second anchor head 4 of the dragline respectively with a threaded pair.

[0028] The spiral steel bar 6 is arranged around the flexible cable 1; a cavity 10 is set in the area where the spiral steel bar 6 is located...

Embodiment 2

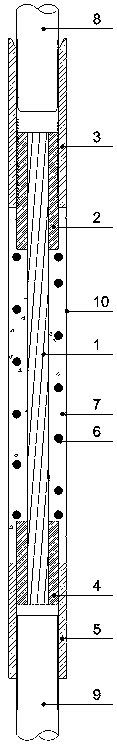

[0030] Such as figure 2 As shown, another embodiment of the present invention includes a flexible cable 1, a first anchor head 2 of the cable, a first threaded sleeve 3, a second anchor head 4 of the cable, a second threaded sleeve 5, and a spiral steel bar 6 And high-strength cement-based grouting material7.

[0031] The first anchor head 2 of the cable and the second anchor head 4 of the cable anchor the two ends of the flexible cable 1 respectively;

[0032] The first threaded sleeve 3 anchors the first anchor head 2 of the first anchor head 2 of the rod member 8 and the dragline respectively with a threaded pair.

[0033] The second threaded sleeve 5 anchors the rod part two 9 and the second anchor head 4 of the dragline respectively with a threaded pair.

[0034] The spiral steel bar 6 is arranged around the flexible cable 1; a cavity 10 is set in the area where the spiral steel bar 6 is located inside the prefabricated component, and the high-strength cement-based gro...

Embodiment 3

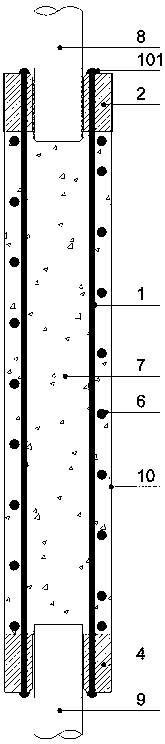

[0036] Such as image 3 As shown, another embodiment of the present invention includes a flexible cable 1 , a first anchor head 2 of the cable, a second anchor head 4 of the cable, a spiral steel bar 6 and a high-strength cement-based grouting material 7 .

[0037] The first anchor head 2 of the cable and the second anchor head 4 of the cable respectively anchor the two ends of the flexible cable 1; 8 and the periphery of rod part 2 9; the first anchor head 2 of the stay cable is a radial elastic nut with serrated threads.

[0038] The spiral steel bar 6 is arranged around the flexible cable 1; a cavity 10 is set in the area where the spiral steel bar 6 is located inside the prefabricated component, and the high-strength cement-based grouting material 7 is poured into the cavity 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com