Bidirectional deviation rod piece connector of elastic combined nut

A combination nut and connector technology, which is applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of insufficient direct force, complicated installation and tightening, and large space occupied by angle steel, so as to reduce the amount of materials used and meet the needs of applicable occasions. Broad, small overall length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

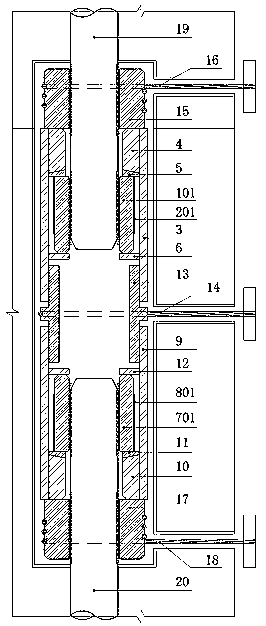

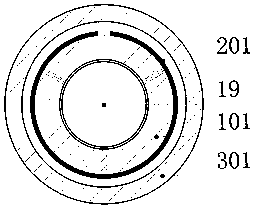

[0049] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention connects the first rod member 19 and the second rod member 20 with offsets on two assembly members, and is characterized in that it includes at least a first elastic combination nut I, a first anchor sleeve II , intermediate connecting sleeve , the second elastic combination nut , the second anchor sleeve , the first bearing nut assembly and second bearing nut assembly .

[0050] The first elastic combination nut 1 and the second elastic combination nut Each includes at least a multi-lobed threaded clip and an elastic constraint reset member. The inner surface of the threaded clip is provided with internal threads, and the ends of rod one 19 and rod two 20 are provided with external threads that match the threaded clips.

[0051] The threaded clips are cylindrical threaded clips 101, 701, and the multi-lobed cylindrical threaded clips 101, 701 enclose respectively to form ...

Embodiment 2

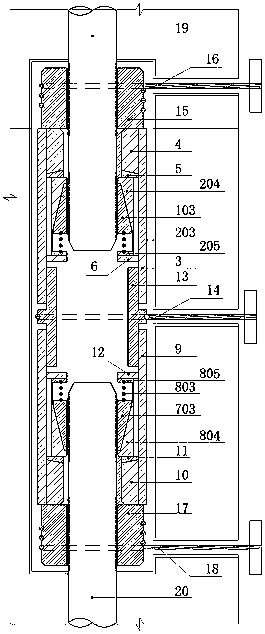

[0073] Such as image 3 and Figure 4 As shown, another embodiment of the present invention connects the biased rod one 19 and the second rod 20 on two assembly members, and is characterized in that it includes at least a first elastic combination nut I, a first anchor sleeve II , intermediate connecting sleeve , the second elastic combination nut , the second anchor sleeve , the first bearing nut assembly and second bearing nut assembly .

[0074] The first elastic combination nut 1 and the second elastic combination nut Each includes at least a multi-lobed threaded clip and an elastic constraint reset member. The inner surface of the threaded clip is provided with internal threads, and the ends of rod one 19 and rod two 20 are provided with external threads that match the threaded clips.

[0075] The first elastic combination nut 1 and the second elastic combination nut It is a tapered thread clip elastic combination nut, the first elastic combination nut 1 in...

Embodiment 3

[0083] Such as Figure 5 As shown, another embodiment of the present invention connects the biased rod one 19 and the second rod 20 on two assembly members, and is characterized in that it includes at least a first elastic combination nut I, a first anchor sleeve II , intermediate connecting sleeve , the second elastic combination nut , the second anchor sleeve , the first bearing nut assembly and second bearing nut assembly .

[0084] The first elastic combination nut 1 and the second elastic combination nut Each includes at least a multi-lobed threaded clip and an elastic constraint reset member. The inner surface of the threaded clip is provided with internal threads, and the ends of rod one 19 and rod two 20 are provided with external threads that match the threaded clips.

[0085] The threaded clips are cylindrical threaded clips 101, 701, and the multi-lobed cylindrical threaded clips 101, 701 enclose respectively to form a ring.

[0086] The first elastic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com