Elastic sleeve rod piece connector

An elastic sleeve and connector technology, which is applied to building components, building reinforcements, structural elements, etc., can solve the problems of insufficient direct force, complicated installation and tightening, and large space for angle steel. Wide range of occasions, small overall length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

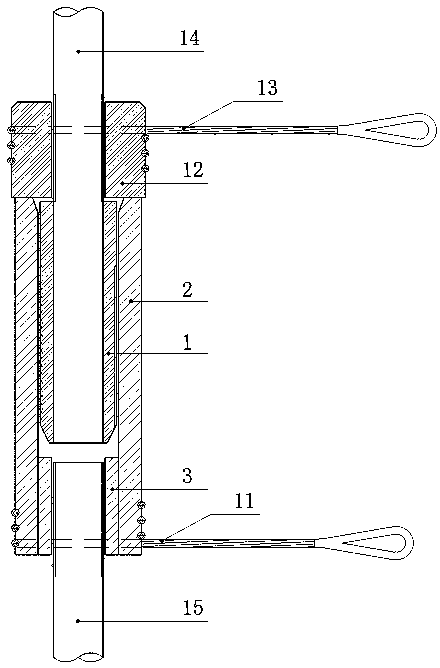

[0062] Such as Figure 1~Figure 4 As shown, a specific embodiment of the present invention includes a slit waist drum type threaded inner sleeve 1-1, a first outer sleeve 2, an anchor plate 3 at the end of the first outer sleeve, a first flexible tension member 11, and a pressure nut 12 And the second flexible tension member 13.

[0063] The first outer casing end anchor plate 3 is arranged on one end of the first outer casing 2 and is connected with a thread pair, and the inner side of the other end of the first outer casing 2 is provided with a flared tapered surface; the first outer casing end anchor plate 3 is connected to the second rod 15 . The elastic inner sleeve 1 is arranged at the end of the first rod 14 and connected with a threaded pair.

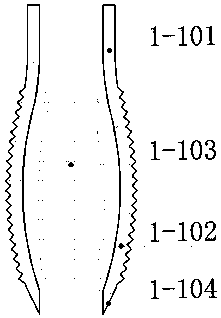

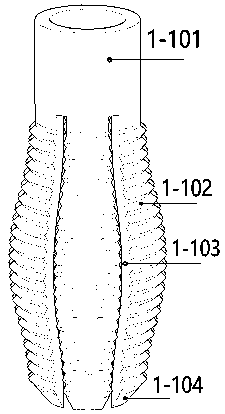

[0064] The elastic inner sleeve 1 is a slit waist drum type thread inner sleeve 1-1, and the slotted waist drum type thread inner sleeve 1-1 includes a straight thread sleeve 1-101 at the head of the inner sleeve, and a convex ...

Embodiment 2

[0069] Such as figure 1 , Figure 5~7 As shown, another specific embodiment of the present invention includes a slit umbrella threaded inner casing 1-2, a first outer casing 2, an anchor plate 3 at the end of the first outer casing, a first flexible tension member 11, and a pressure nut 12 and the second flexible tension member 13.

[0070] The first outer casing end anchor plate 3 is arranged on one end of the first outer casing 2 and is connected with a thread pair, and the inner side of the other end of the first outer casing 2 is provided with a flared tapered surface; the first outer casing end anchor plate 3 is connected to the second rod 15 . The elastic inner sleeve 1 is arranged at the end of the first rod 14 and connected with a threaded pair.

[0071] The slotted umbrella-shaped threaded inner casing 1-2 includes the straight threaded casing 1-201 at the head of the inner casing, the umbrella-shaped threaded casing 1-202 at the tail of the inner casing and multipl...

Embodiment 3

[0077] Such as figure 1 , Figure 8~11 As shown, another specific embodiment of the present invention comprises a serrated thread elastic composite sleeve 1-3, a first outer sleeve 2, an anchor plate 3 at the end of the first outer sleeve, a first flexible tension member 11, a pressure nut 12 and The second flexible tension member 13 .

[0078] The first outer casing end anchor plate 3 is arranged on one end of the first outer casing 2 and is connected with a thread pair, and the inner side of the other end of the first outer casing 2 is provided with a flared tapered surface; the first outer casing end anchor plate 3 is connected to the second rod 15 . The elastic inner sleeve 1 is arranged at the end of the first rod 14 and connected with a threaded pair.

[0079] The sawtooth thread elastic combination sleeve 1-3 includes a slotted inner sleeve 1-301 and an elastic sawtooth thread ring 1-302.

[0080] A plurality of circumferential grooves 1-303 are arranged on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com