Moving drivepipe neat-joint assembling rod piece connecting device

A connector and rod technology, which is applied in the field of mobile sleeve jointed rod connectors, can solve the problems of insufficient direct force, inconvenient transportation and installation, large space occupied by angle steel, etc. Wide, small overall length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

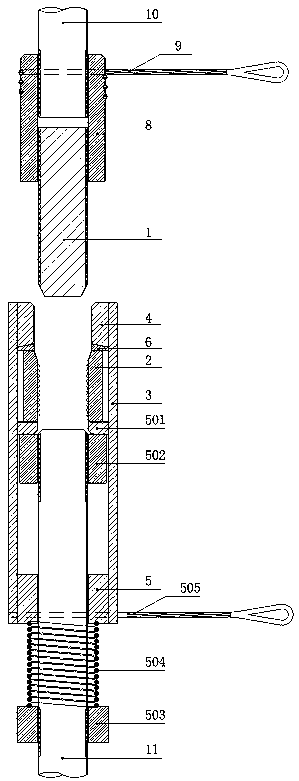

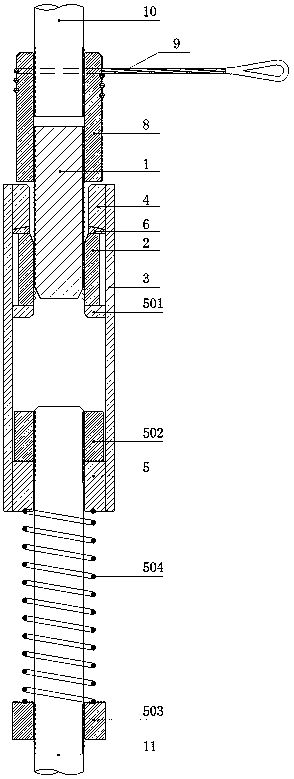

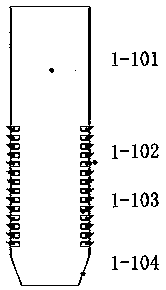

[0068] Such as Figure 1~Figure 4 As shown, a specific embodiment of the present invention includes a serrated thread elastic combined connecting shaft 1-1, an inner casing 2, an outer casing 3, a first end anchor plate 4, a second end anchor plate 5, a spherical gasket 6, The second connection sleeve 8 , the middle anchor plate 501 , the first nut 502 , the elastic body support 503 , the elastic body 504 , the fixing pin 505 and the first flexible tension member 9 .

[0069] The first end anchor plate 4 and the second end anchor plate 5 are respectively arranged at both ends of the outer casing 3 and connected by screw pairs, and the middle anchor plate 501 is arranged at the middle position of the outer casing 3 .

[0070] The inner casing 2 is arranged in the outer casing 3, the outer diameter of the inner casing 2 is smaller than the inner diameter of the outer casing 3, the first end anchor plate 4 and the middle anchor plate 501 are arranged at both ends of the inner cas...

Embodiment 2

[0079] Such as Figure 1~2 , Figure 5~6 As shown, another specific embodiment of the present invention includes a tapered thread elastic combined connecting shaft 1-2, an inner casing 2, an outer casing 3, a first end anchor plate 4, a second end anchor plate 5, and a spherical gasket 6. The second connection sleeve 8 , the middle anchor plate 501 , the first nut 502 , the elastic body support 503 , the elastic body 504 , the fixing pin 505 and the first flexible tension member 9 .

[0080] The first end anchor plate 4 and the second end anchor plate 5 are respectively arranged at both ends of the outer casing 3 and connected by screw pairs, and the middle anchor plate 501 is arranged at the middle position of the outer casing 3 .

[0081] The inner casing 2 is arranged in the outer casing 3, the outer diameter of the inner casing 2 is smaller than the inner diameter of the outer casing 3, the first end anchor plate 4 and the middle anchor plate 501 are arranged at both ends...

Embodiment 3

[0090] Such as Figure 1~2 , Figure 7~8 As shown, another specific embodiment of the present invention includes a wolf tooth connecting shaft 1-3, an inner casing 2, an outer casing 3, a first end anchor plate 4, a second end anchor plate 5, a spherical gasket 6, a first end anchor plate Two connection sleeves 8 , an intermediate anchor plate 501 , a first nut 502 , an elastic body support 503 , an elastic body 504 , a fixing pin 505 and a first flexible tension member 9 .

[0091] The first end anchor plate 4 and the second end anchor plate 5 are respectively arranged at both ends of the outer casing 3 and connected by screw pairs, and the middle anchor plate 501 is arranged at the middle position of the outer casing 3 .

[0092] The inner casing 2 is arranged in the outer casing 3, the outer diameter of the inner casing 2 is smaller than the inner diameter of the outer casing 3, the first end anchor plate 4 and the middle anchor plate 501 are arranged at both ends of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com