Single-sleeve double-spherical nut offset rod piece connector

A technology of spherical nuts and double spherical surfaces, which is applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of complicated installation and tightening, large space required for connecting parts, and large space occupied by angle steel, so as to achieve rapid construction and promote The effect of overall improvement and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

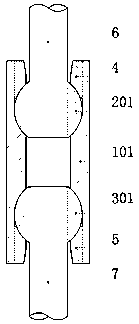

[0027] Such as figure 1 , figure 2 and image 3 As shown, an embodiment of the present invention includes an H-shaped sleeve 101 , a first ball joint nut 201 , a second ball joint nut 301 , a first end anchor plate 4 and a second end anchor plate 5 .

[0028] The first end anchor plate 4 and the second end anchor plate 5 are arranged at both ends of the H-shaped sleeve 101 , and the first end anchor plate 4 , the second end anchor plate 5 and the H-shaped sleeve 1 are connected by thread pairs.

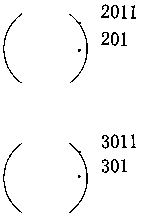

[0029] The wall thickness of the middle section of the H-shaped sleeve 101 is greater than that of both ends, and the transition area between the middle thick wall and the two ends of the H-shaped sleeve 101 is provided with a spherical surface. The end surfaces of the first ball hinge nut 201 and the second ball hinge nut 301 are spherical surfaces. The inner side of the end anchor plate 4 and the second end anchor plate 5 is a spherical surface, and the outer side of the first en...

Embodiment 2

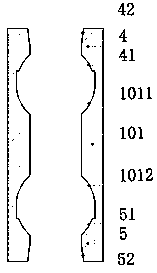

[0035] Such as Figure 4 , Figure 5 and Figure 6 As shown, another embodiment of the present invention includes an H-shaped sleeve 102 , a first compound spherical nut 202 , a second compound spherical nut 302 , a first end anchor plate 4 and a second end anchor plate 5 .

[0036] The first end anchor plate 4 and the second end anchor plate 5 are arranged at both ends of the H-shaped sleeve 102 , and the first end anchor plate 4 , the second end anchor plate 5 and the H-shaped sleeve 1 are connected by thread pairs.

[0037] The wall thickness of the middle section of the H-shaped sleeve 102 is greater than the wall thickness of both ends. The transition area between the middle thick wall and the two ends of the H-shaped sleeve 102 is provided with a spherical surface. The two end surfaces of the first composite spherical nut 202 and the second composite spherical nut 302 are spherical surfaces. The inner side of the first end anchor plate 4 and the second end anchor plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com