Elastic combination ring type anchoring offset rod piece connector

A technology of combining rings and connectors, which is applied to building components, building reinforcements, structural elements, etc., can solve the problems of difficult to break through the prefabrication assembly rate, extremely strict requirements on the positioning and production accuracy of connecting rods, and no reliable and convenient connection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

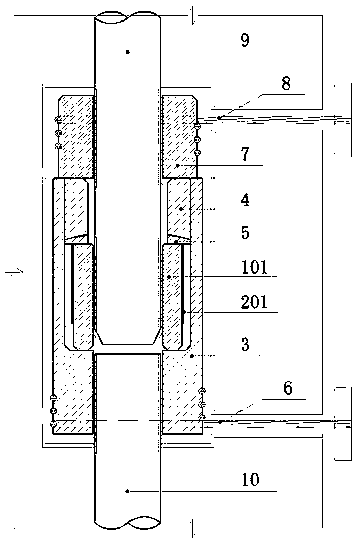

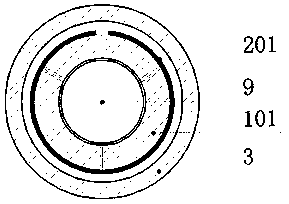

[0081] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention comprises an elastic combined anchor ring , anchor sleeve and pressure nut assembly , where the elastic combined anchor ring Contains a plurality of sawtooth thread clips 101 and an elastic constraint restoration part 2, an anchoring sleeve Contains anchor cup 3, open-end anchor plate 4, spherical washer 5, first lead-out tightening part 6, and bearing nut assembly It includes a pressure nut 7 and a second lead-out tightening screw 8 to form a fully serrated thread clip combined anchor ring offset rod connector to connect the rod 9 and the rod 10 .

[0082] The sawtooth thread clip 101 is in the shape of a fan-shaped ring cylinder, and the inner side of the sawtooth thread clip 101 is provided with a sawtooth thread, and the elastic constraint reset part 2 is a C-shaped open spring ring 201, and the elastic combination anchor ring Anchoring sleeve on the outside , elasti...

Embodiment 2

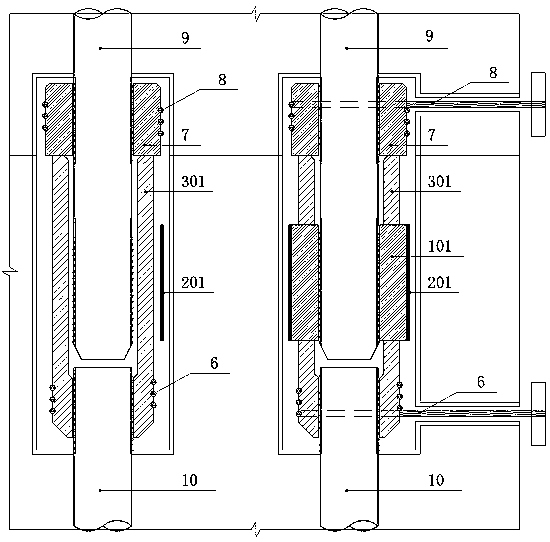

[0090] Such as image 3 , Figure 4 As shown, another embodiment of the present invention, comprising an elastic composite anchor ring , anchor sleeve and pressure nut assembly , where the elastic combined anchor ring It is composed of a plurality of sawtooth thread clips 101 arranged intermittently and an elastic restraint reset piece 201, and the anchoring sleeve Including the anchor cup 301 and the first lead-out tightening part 6, the bearing nut assembly It includes a pressure bearing nut 7 and a second lead-out tightening member 8 to form a semi-serrated thread clip combined anchor ring offset rod connector to connect the rod 9 and the rod 10 .

[0091] A plurality of square holes are provided in the middle area of the anchor cup 301, the number of the square holes is equal to the number of the serrated thread clips 101, and the serrated thread clips 101 pass through the square holes on the anchor cup 301 one by one, as Figure 4 As shown, the serrated thre...

Embodiment 3

[0096] Such as Figure 5 with Figure 6 As shown, yet another embodiment of the present invention, comprising an elastic composite anchor ring , anchor sleeve and pressure nut assembly , where the elastic combined anchor ring Contains a plurality of tapered thread clips 103, support springs 203, tapered thread clip constraints 204 and spring support plates 205, and the rest of the components are the same as in Embodiment 1, forming a tapered thread clip combined anchor ring offset rod The connector connects the rod 9 and the rod 10.

[0097] The tapered thread clip 103 includes a threaded inner wall, a tapered outer wall, a wider plane end and a narrower plane end, and the tapered thread clip 103 outside is provided with a tapered thread clip constraint 204, and the tapered thread clip constraint 204 It includes a cylindrical outer wall, a tapered inner wall matched with the tapered thread clip 103 , a wider annular plane end and a support column or support ring suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com