Semi-hollow self-punching riveting screw with fastening thread and self-punching riveting equipment and method

A self-piercing riveting and thread tightening technology, applied in the directions of screws, rivets, mechanical equipment, etc., can solve the problems of rivet fracture failure, high cost, inapplicability, etc., to improve the material forming performance, simple structure, easy to process and manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

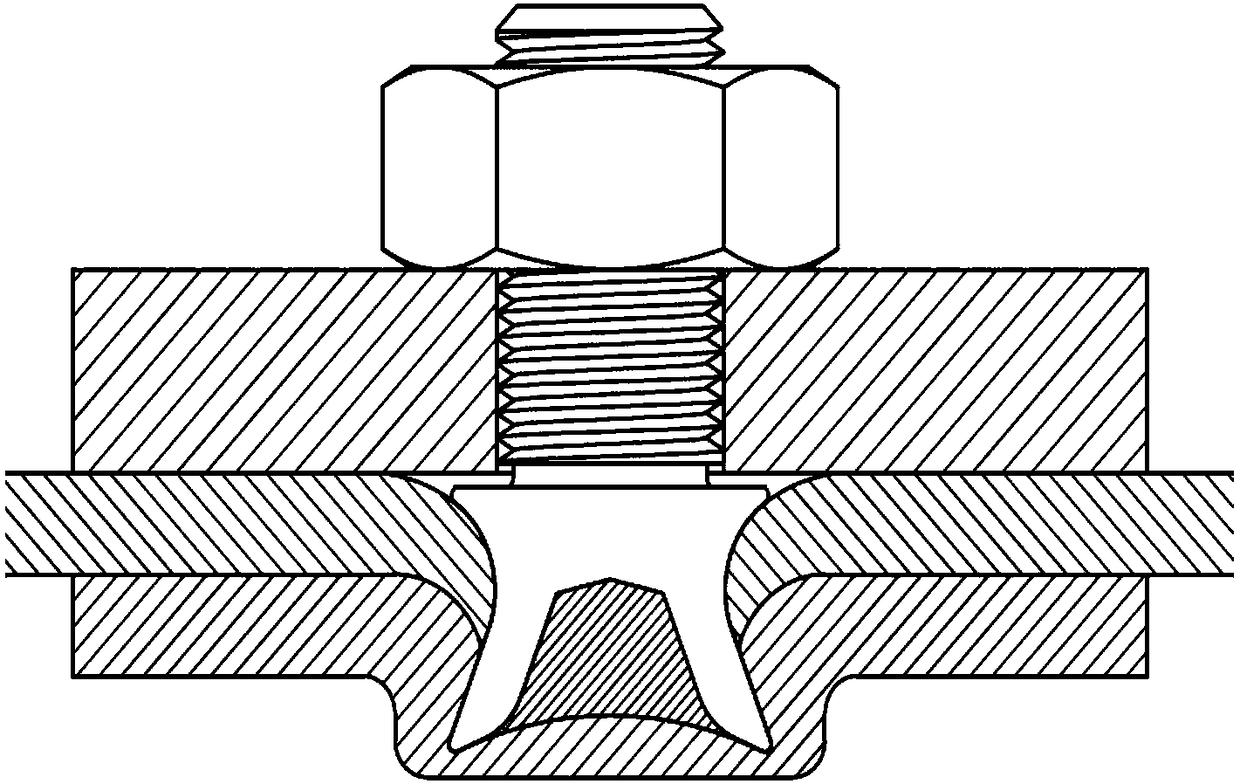

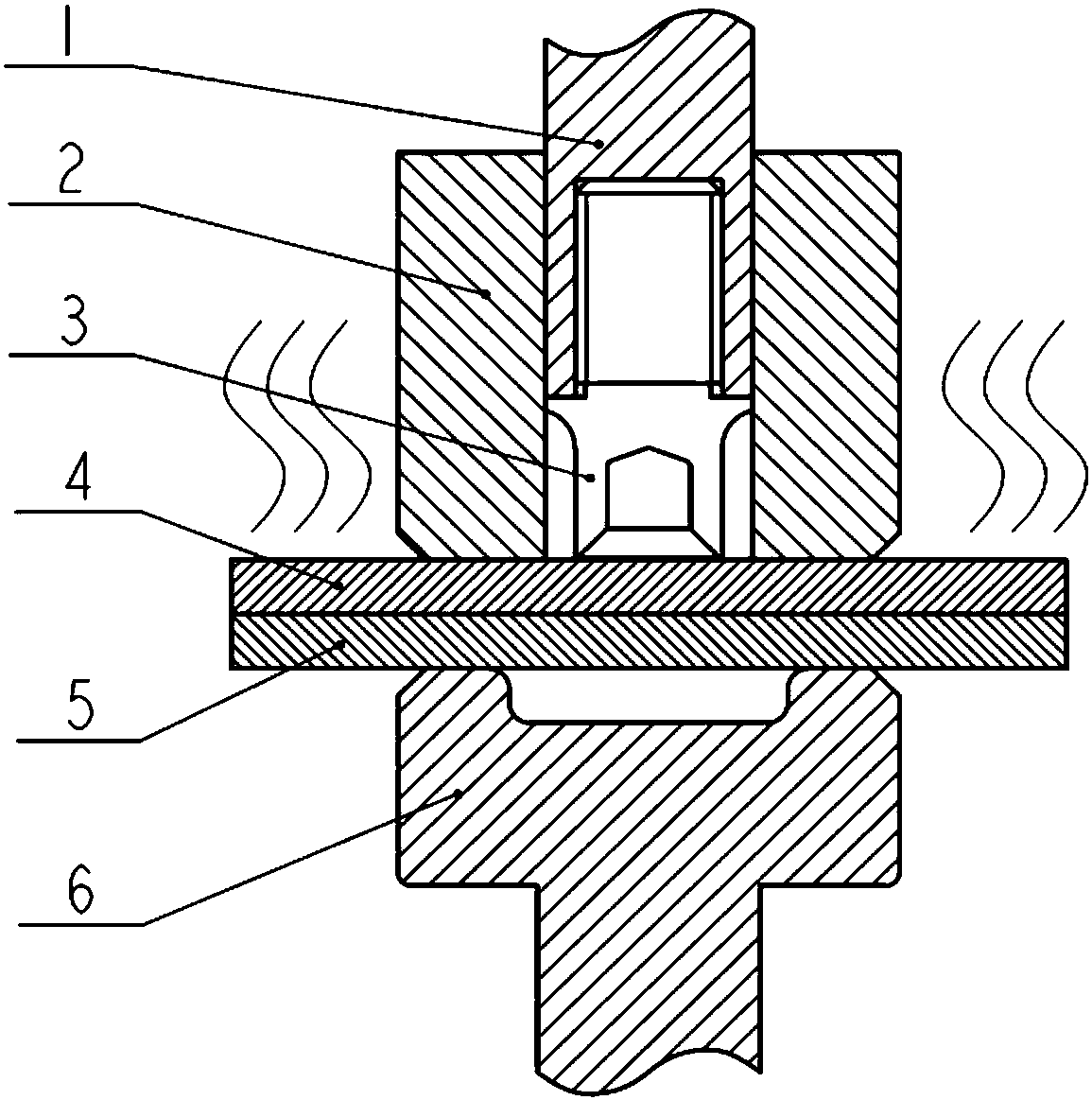

[0040] Such as image 3 As shown, the upper plate 4 used in this embodiment is a 2mm thick 6061-T6 aluminum alloy, the lower plate 5 is a 3mm thick Q235 low carbon steel and a 4mm thick carbon fiber plate, the total thickness of the plate is 9mm, wherein The yield strength of 6061-T6 aluminum alloy is 200-230Mpa, the tensile strength is 340-380Mpa, the yield strength of Q235 steel is 230-240Mpa, and the tensile strength is 370-500Mpa.

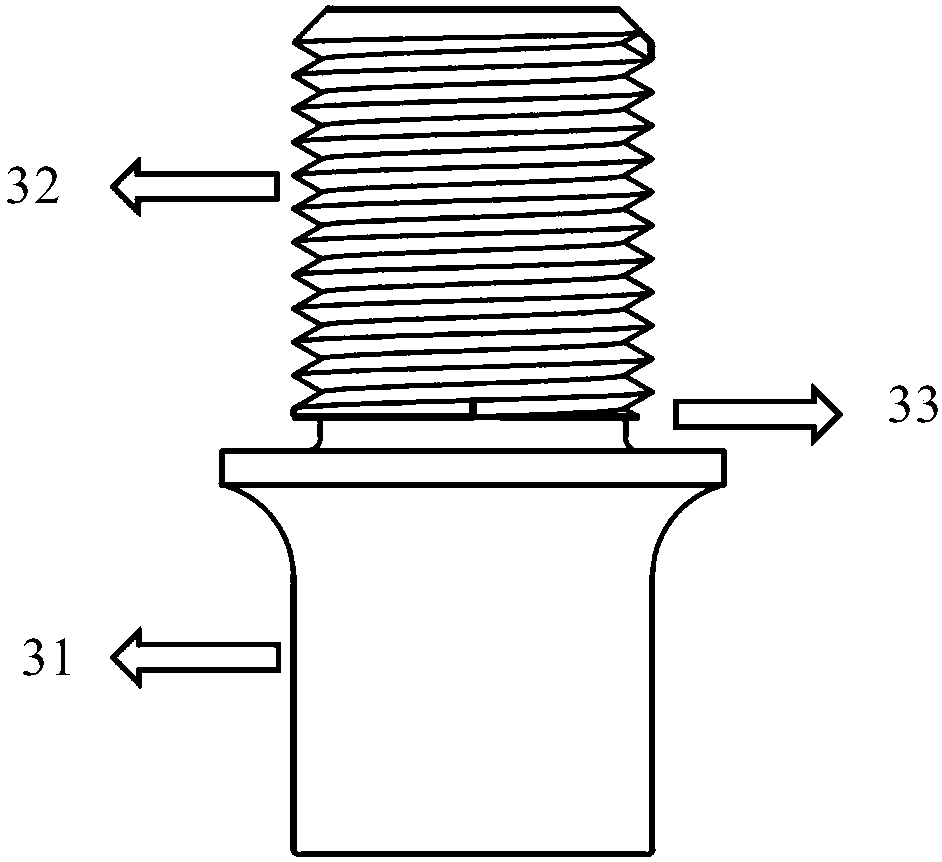

[0041] 6061-T6 aluminum alloy and Q235 low-carbon steel can achieve good self-piercing riveting at room temperature, among which Q235 with better plasticity is placed in the middle as the lower plate 5, and 6061-T6 aluminum alloy is placed on the upper layer, which can be realized after positioning and clamping Riveting molding, carbon fiber sheet is not suitable for riveting due to its poor plasticity, so it is used as the uppermost sheet after pre-punching. After riveting, the threaded head 32 passes through the through hole of carbon fiber a...

Embodiment 2

[0043] Such as image 3 As shown, the upper plate 4 and the lower plate 5 used in this embodiment are both 2 mm thick 7075-T6 high-strength aluminum alloys, and one layer of 6 mm thick high-strength steel plates. The total thickness of the plates is 10 mm, of which 7075-T6 aluminum alloy The yield strength is 480-520Mpa, and the tensile strength is 630-670Mpa; the yield strength of high-strength steel plate is 800-900Mpa, and the tensile strength is 1200-1300Mpa.

[0044] 7075-T6 aluminum alloy cannot be riveted and formed at room temperature, so heat treatment is performed first to improve the formability of the material.

[0045] Firstly, the double-layer 7075-T6 aluminum alloy sheet to be riveted is heated and solution treated, wherein the solution temperature is 470-480°C, and the holding time is 25-35min. The formability of 7075 aluminum alloy is better at about 400°C, so the solution After completion, when the 7075 aluminum alloy cools down to 380-410°C, the self-pierci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com