Double-ball-hinge steering connector of offset rod member

A technology for turning connectors and rods, which is applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of weakened component sections, large space occupied by connection boxes, and no reliable and convenient connection methods, etc., to achieve rapid construction and promote The effect of overall improvement and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

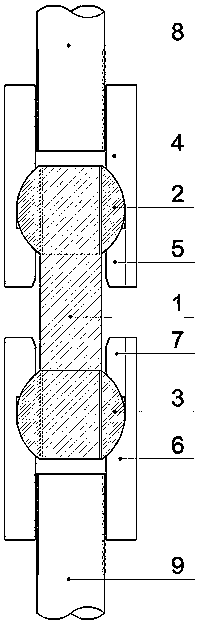

[0028] Such as figure 1 As shown, an embodiment of the present invention includes a dumbbell link , the first anchor sleeve , the second anchor sleeve .

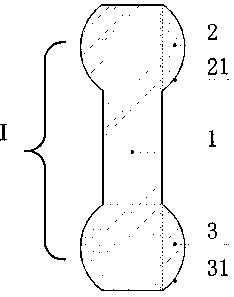

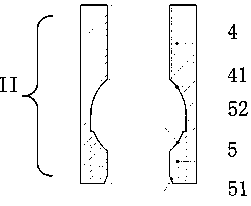

[0029] Wherein, the dumbbell link ( ) contains the middle connecting rod (1), the first spherical nut (2) and the second spherical nut (3); the first anchor sleeve ( ) contains the first sleeve anchor cup (4), the first sleeve end anchor plate (5); the second anchor sleeve ( ) contains the second sleeve anchor cup (6) and the second sleeve end anchor plate (7).

[0030] The first sleeve anchor cup (4) and the second sleeve anchor cup (6) are cup-shaped cylinders with an open end and a closed end.

[0031] The dumbbell linkage ( ) placed on the first anchor sleeve ( ) and the second anchor sleeve ( ), the first anchoring sleeve ( ) is directly or indirectly connected to the rod one (8), the first anchoring sleeve ( ) and the other end anchors the dumbbell link ( ) of the first spherical nut (2).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com