Energy dissipation joint for connecting prefabricated shear wall and coupling beam and assembly method of energy dissipation joint

A prefabricated shear force and node technology, applied in the direction of walls, joists, girders, etc., can solve the problems of insufficient energy dissipation capacity, poor coupling beam ductility, poor seismic effect, etc. The effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

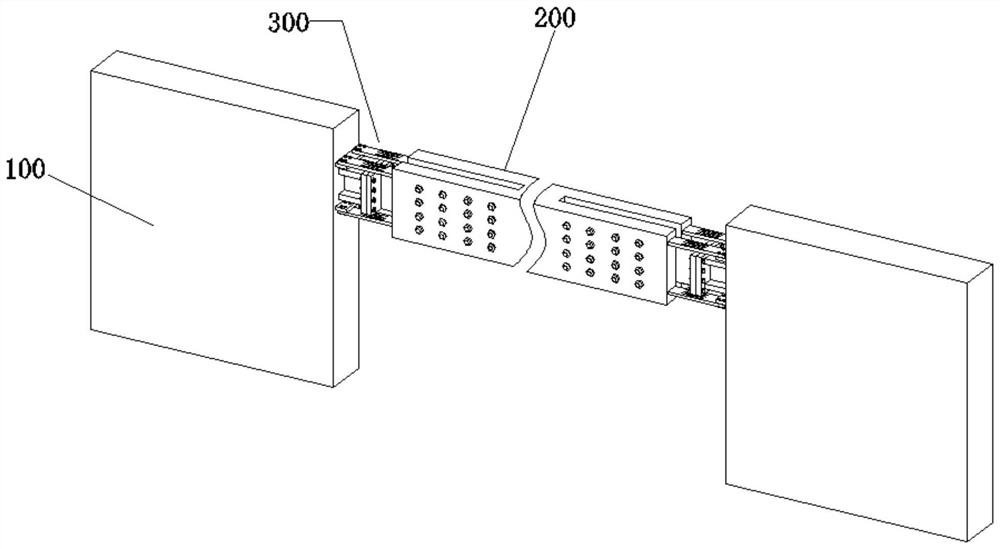

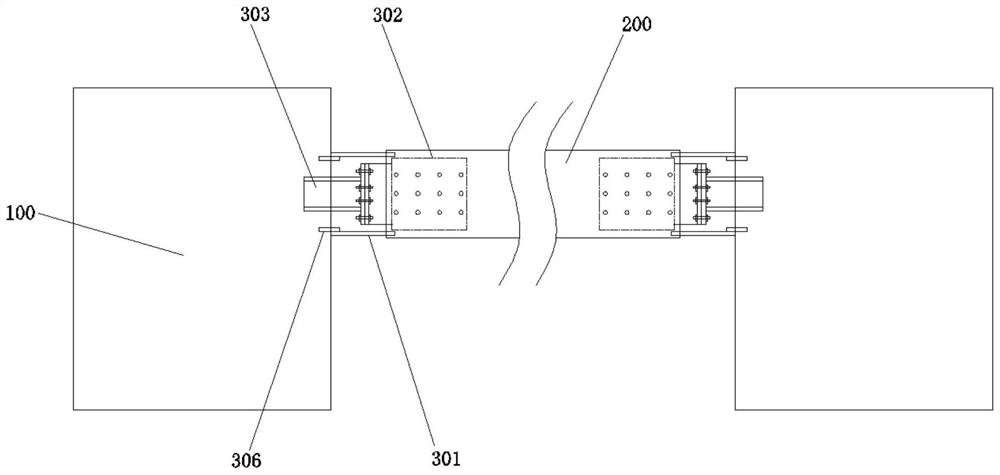

[0049] Embodiment 1 discloses an energy-dissipating node for connecting prefabricated shear walls and coupling beams, refer to the attached figure 1 , Attached Figure 2 and Attached image 3 , its main structure includes a prefabricated shear wall 100, a prefabricated connecting beam 200, and an energy-dissipating node assembly 300 arranged at the connection between the two ends of the prefabricated connecting beam 200 and the prefabricated shear wall 100. The main design points in this embodiment are The structural design of the energy consumption node assembly 300.

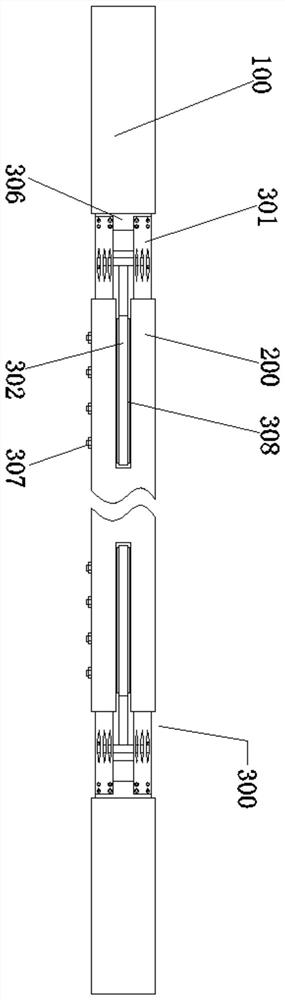

[0050] The energy dissipation node assembly 300 in this embodiment 1 includes a slotted steel plate 301, a damping steel plate 302, an I-beam 303, a first end plate 304, a second end plate 305, a backing plate 306 and a large number of high-strength friction bolts 307.

[0051] Reference attached figure 1 And attached Figure 10 When designing, four slotted steel plates 301 are arranged in a rectangular array...

Embodiment 2

[0059] The present embodiment 2 discloses a kind of assembling method of prefabricated shear wall and connecting beam connection energy-dissipating node, and this assembling method comprises the following steps:

[0060] Step 1: First, position and set out the wires, and install the prefabricated shear wall 100 on the floor.

[0061] Step 2: Place the brass friction plate 308 in the gap between the prefabricated connecting beam 200 and the steel damping plate 302, and connect through the high-strength friction bolt 307 to complete the splicing of the prefabricated connecting beam. It should be noted that in step 2, the bolt holes 3081 on the brass friction plate 308 are first aligned with the grooved holes 3021 on the damping steel plate 302, and then the high-strength friction bolts 307 are used to penetrate and connect to complete the splicing of the prefabricated connecting beams.

[0062] Step 3: pass the backing plate 306 in the prefabricated shear wall 100, the slotted s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com