Built-in fuse connector

A fuse and connector technology, which is applied to the connection, the parts of the connection device, the coupling device, etc., can solve the problems of the installation line without overload protection, the installer missing the fuse box, and the large size of the fuse box, so as to save the installation. Space, increased convenience, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

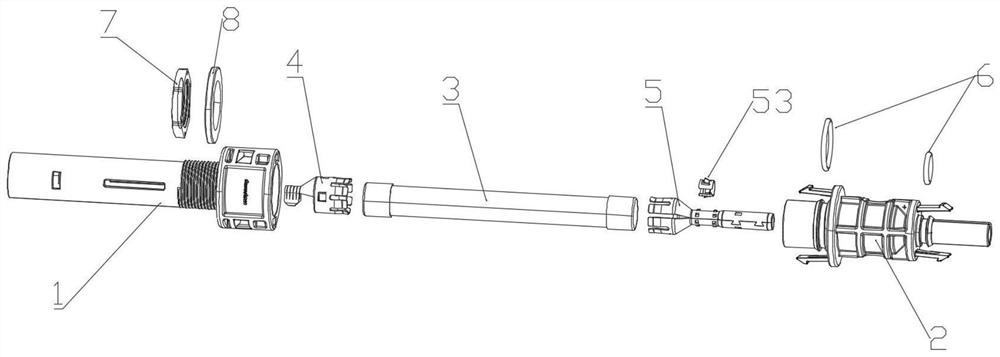

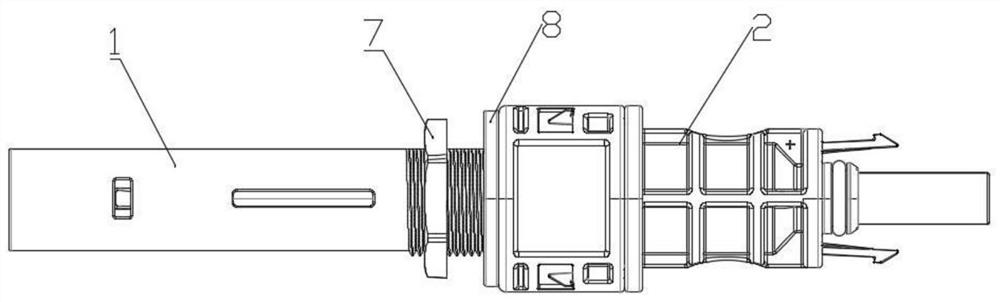

[0035] see Figure 1 to Figure 11 , figure 1 Schematic diagram of the exploded structure of the built-in fuse connector provided by the embodiment of the present application; figure 2 A schematic top view of the built-in fuse connector provided in the embodiment of the present application;

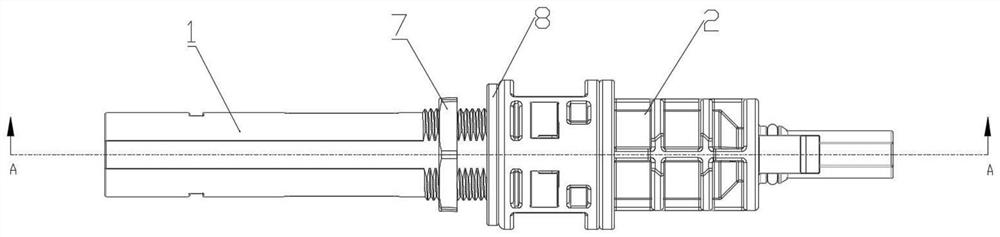

[0036] image 3 for figure 2 The schematic diagram of the front view structure of the built-in fuse connector shown; Figure 4 for image 3 Schematic diagram of the cross-sectional structure at position A in the center; Figure 5 and Figure 6 Schematic diagram of the structure of the fuse holder provided for the embodiment of the present application;

[0037] Figure 7 Schematic diagram of the structure of the connecting terminal provided in the embodiment of the present application; Figure 8 and Figure 9 Schematic diagram of the structure of the card socket provided in the embodiment of the present application; Figure 10 Schematic diagram of the structure of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com