Wear-resistant thin-wall polyvinyl chloride insulation automobile wire

A technology of polyvinyl chloride and electric wires, which is applied in the field of electric wires, can solve problems such as endangering the safety of automobiles, and achieve the effects of improving service life, avoiding assembly and disassembly operations, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

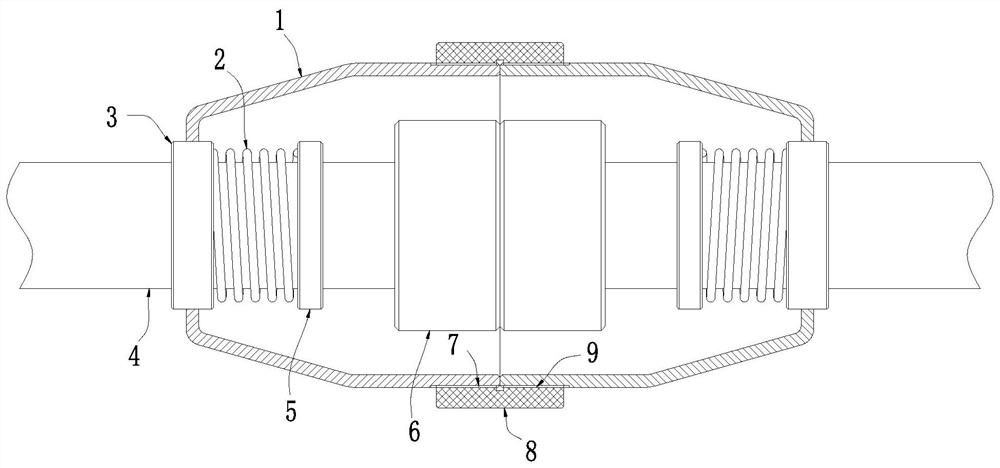

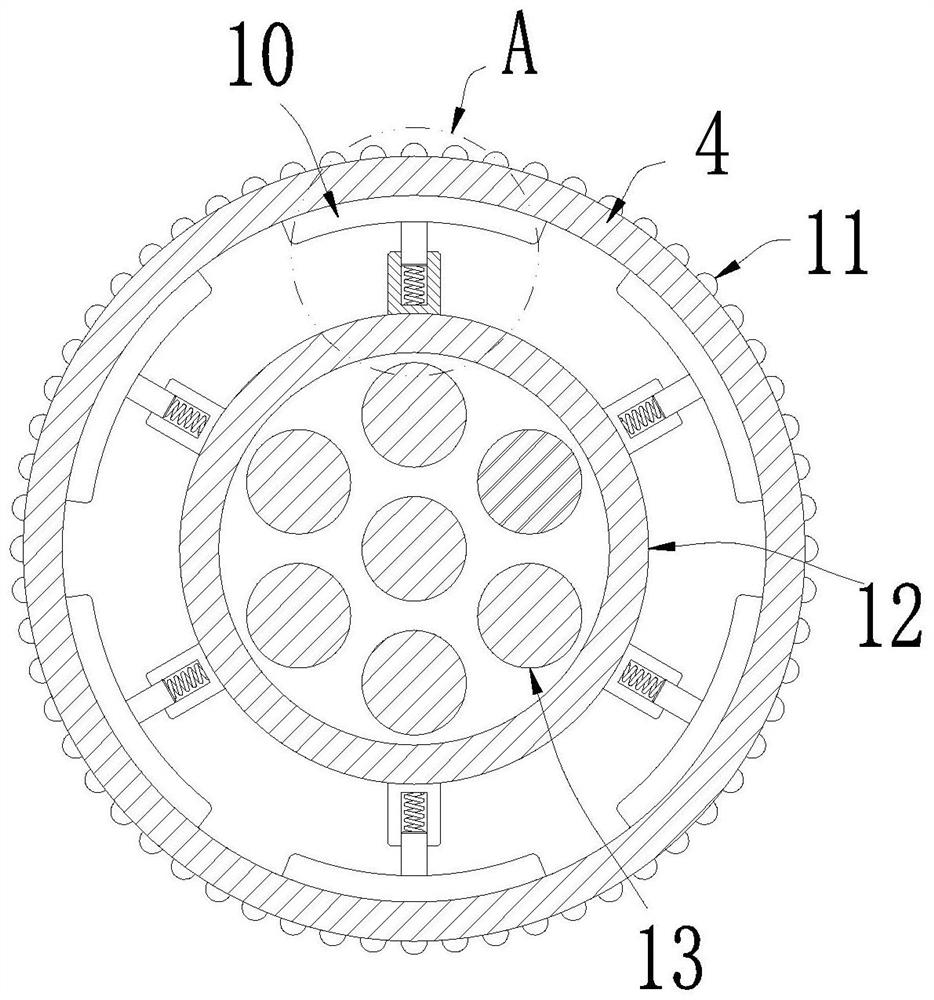

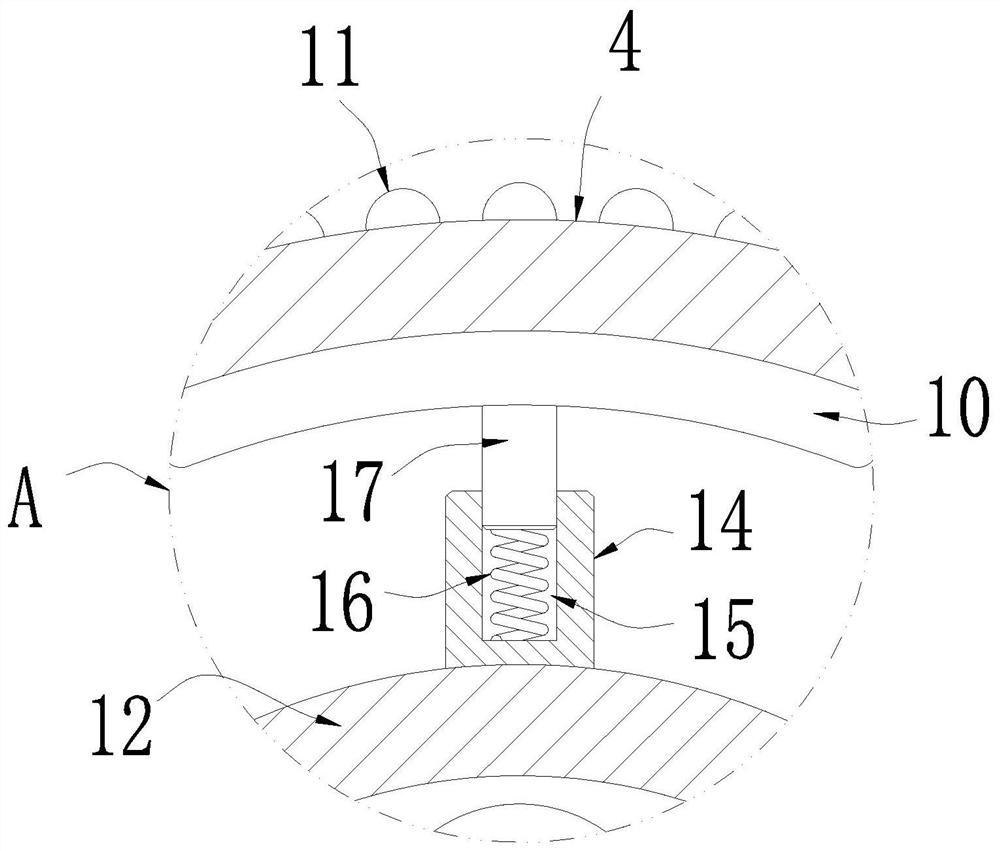

[0022] Such as Figure 1-3 As shown, a wear-resistant thin-walled polyvinyl chloride insulated automobile wire includes a joint 6 installed at the end of the wire, and two adjacent wires are electrically connected through the insertion of the two joints 6. As for the protection structure for protecting the joint 6, the protection structure includes two sliding rings 3 which are respectively fitted on two adjacent electric wires and can slide freely, and the protection cover 1 is set on the sliding ring 3, The opposite ends of the two protective covers 1 are jointly fitted with a rotating ring 8, and the axial ends of the rotating ring 8 are respectively provided with a first threaded hole 7 and a second threaded hole 9 with opposite screw directions. The opposite ends of the cover 1 are threaded on the first threaded hole 7 and the second threaded hole 9 respectively, and when the rotating ring 8 rotates, the opposite ends of the two protective covers 1 are opposed to each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com