Electric shaver

A technology of electric razors and knives, applied in clothing, metal processing, hairdressing equipment, etc., can solve the problem that beard residue cannot be cleaned, and achieve the effect of avoiding backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

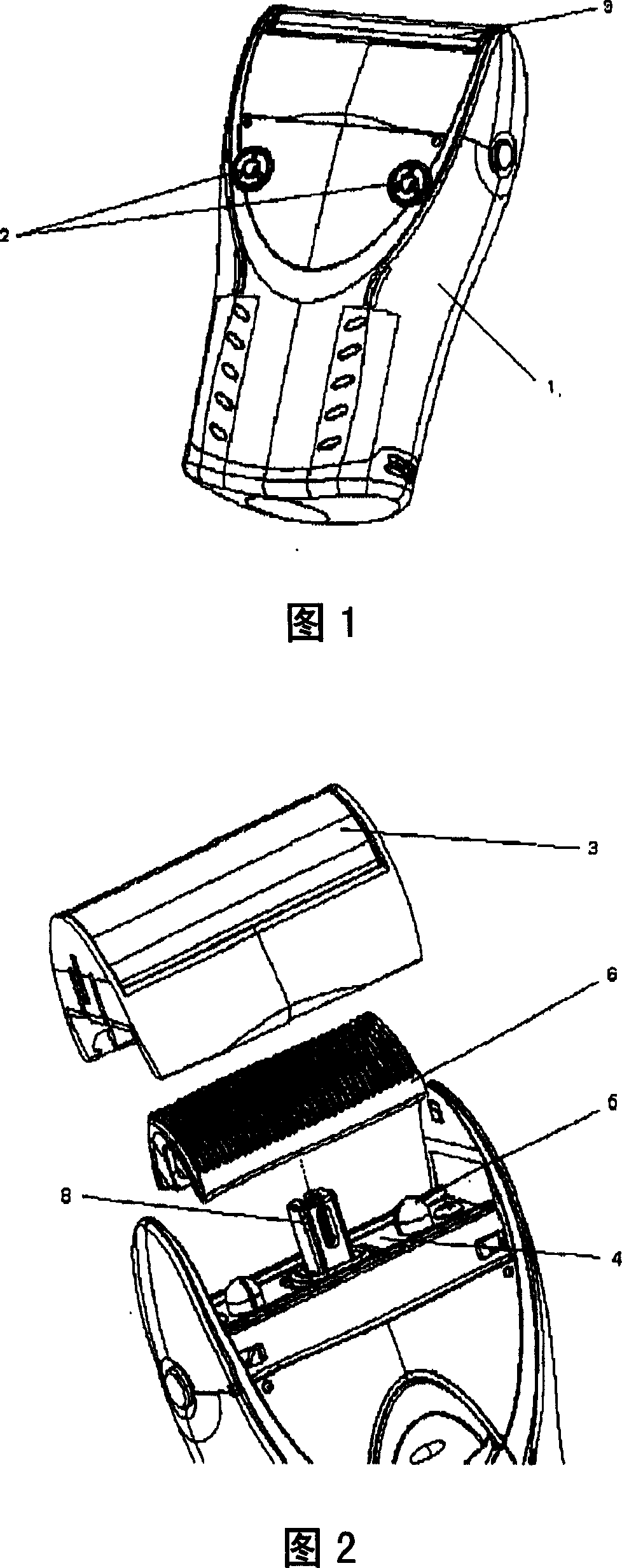

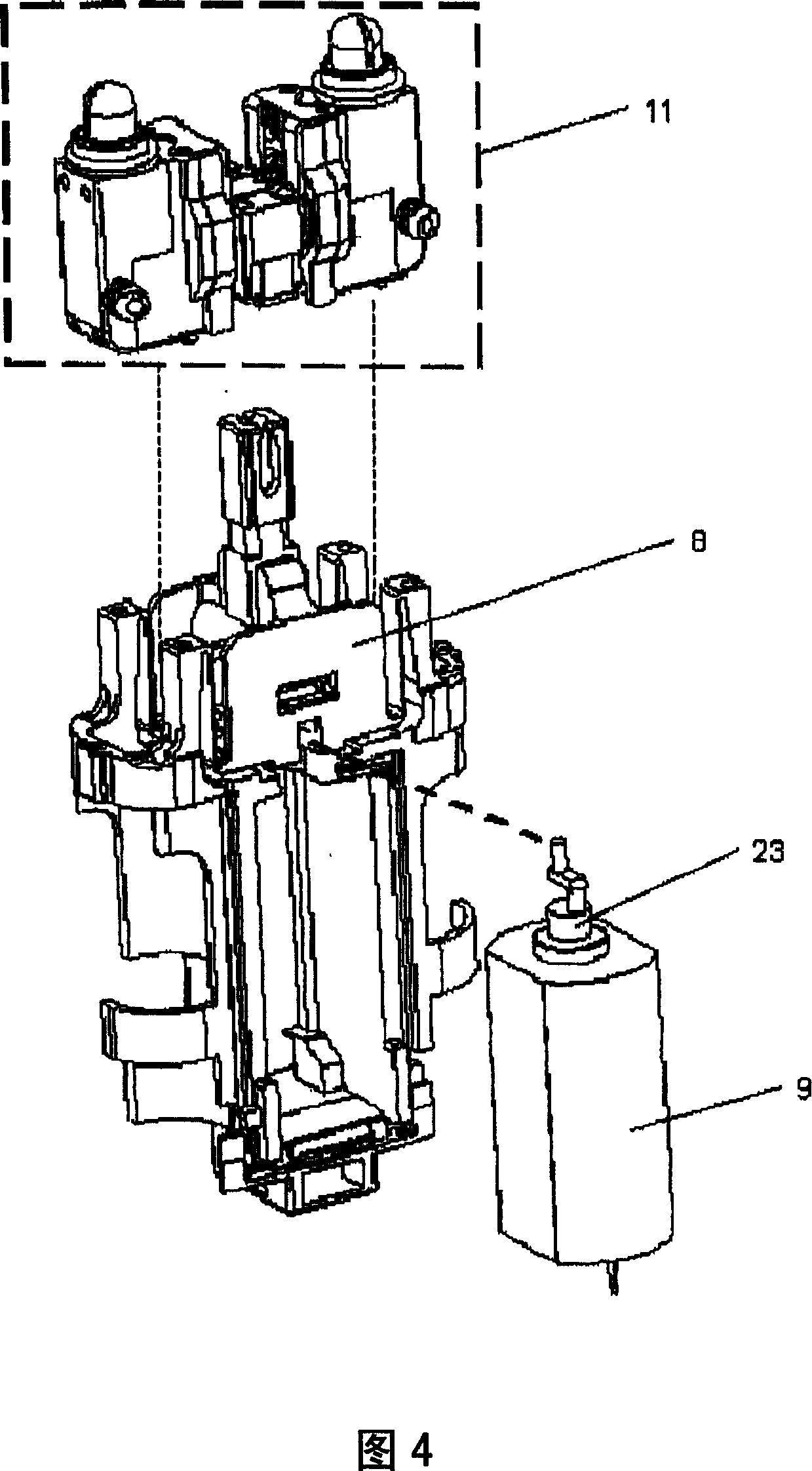

[0039] As shown in FIG. 1 , the cleaning liquid inlet 2 is arranged on the back side of the electric shaver 1 . Once the cleaning process is started, cleaning fluid is pumped into the cleaning pump 7 through the cleaning fluid inlet 2 (see FIG. 3 ).

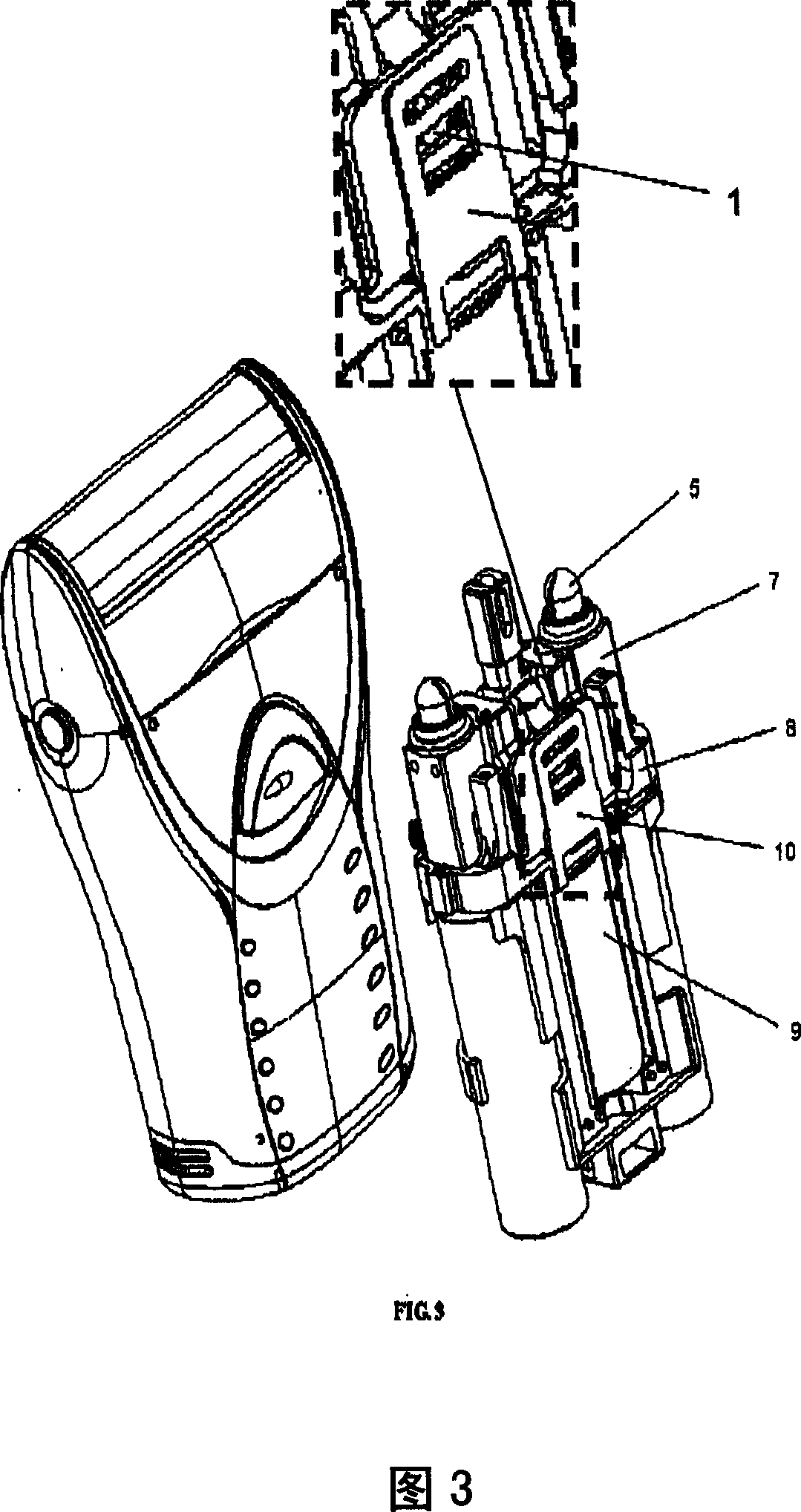

[0040] Figure 2 shows a shaving system. The shaving system includes a shaver 6 , a blade 3 and a shaving chamber 4 . Normally after shaving shaving residue is collected in the shaving system. The shaver 6 is mounted on a movement converter 8 so that vibration of the shaver 6 is achieved. In the present invention, two nozzles 5 are provided, and the nozzles 5 are connected to the outlet of the cleaning pump 7, and the cleaning liquid is directly introduced into the shaving system, so that the shaving system itself can be used for cleaning the shaver after shaving. s installation.

[0041] Fig. 3 is a perspective view of the internal structure of the electric shaver, in which the movement converter 8 constitutes a main part. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com