Horizontal satellite-rocket separation mechanism

A technology of star-arrow separation and separation mechanism, applied in the field of star-arrow separation system, can solve the problems of inability to meet the requirements of 50kg-class satellites, low utilization rate, large space occupation, etc., and achieves reliable unlocking, small separation angular velocity, and reduced impact effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present application will be clearly and completely described below in conjunction with the accompanying drawings and the embodiments of the present application.

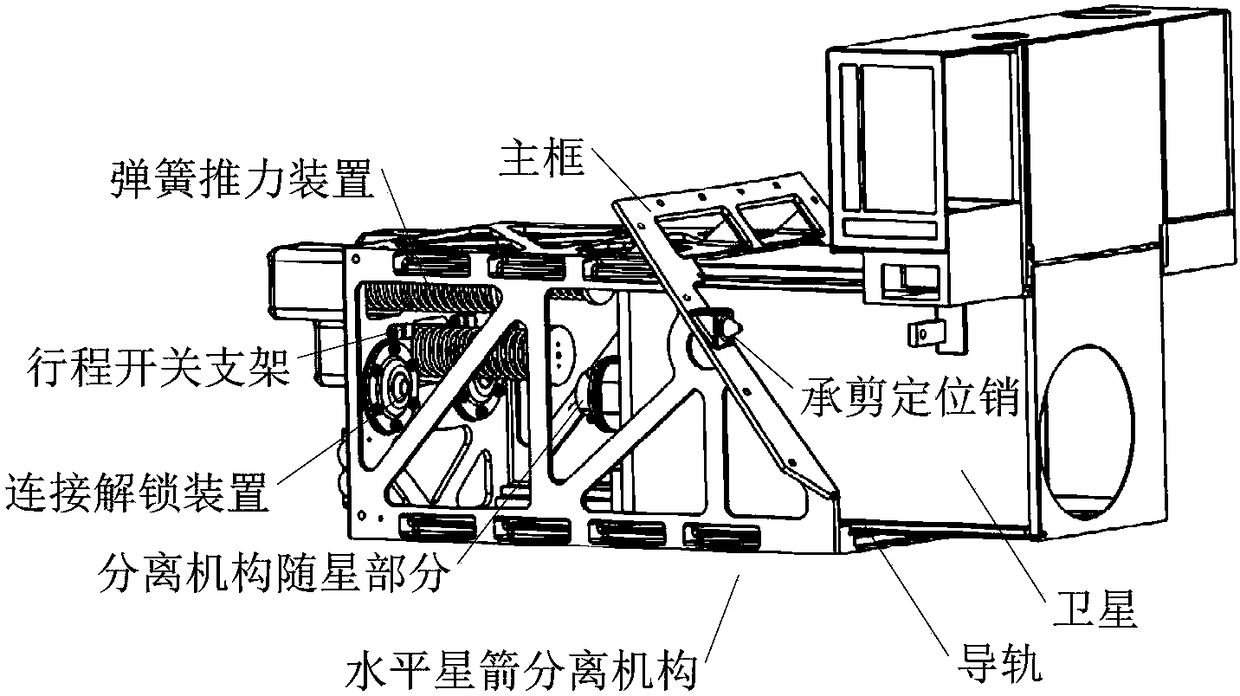

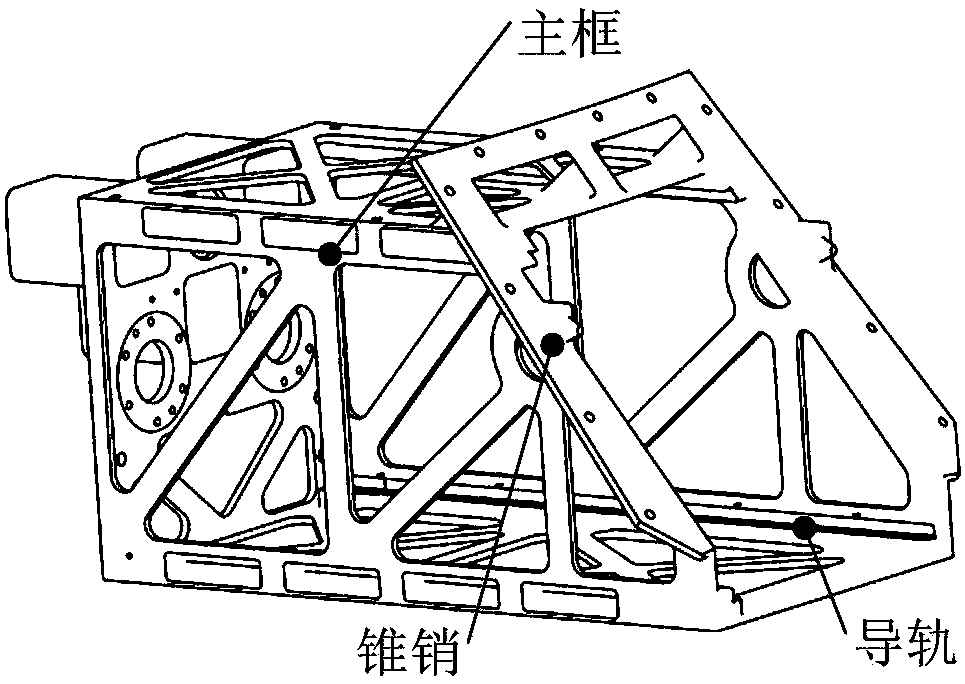

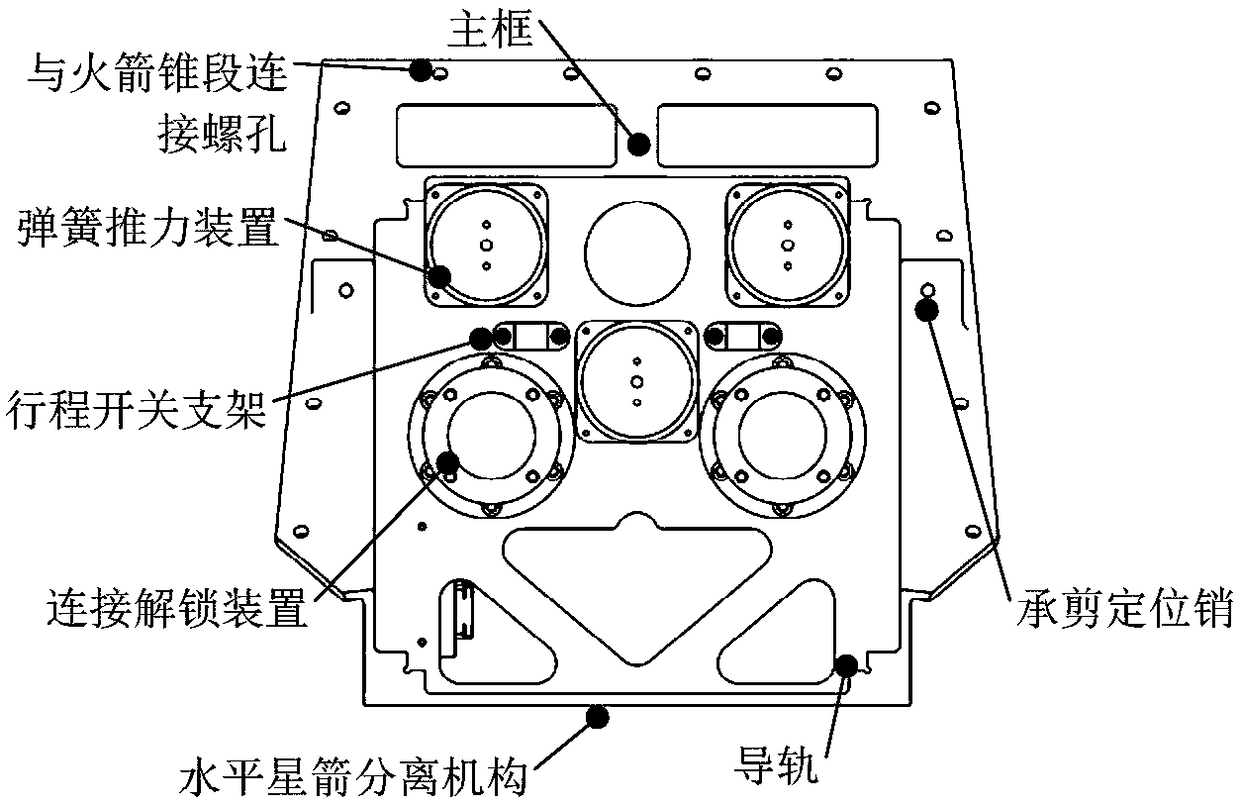

[0028] figure 1 It is a schematic diagram of the horizontal star-arrow separation mechanism of this application. Such as figure 1 As shown, the horizontal star-arrow separation mechanism of the present application mainly includes the following components: main frame, 2 sets of connection unlocking devices, 2 shear positioning pins (or taper pins), 3 sets of spring thrust devices, and travel switch brackets.

[0029] Due to the complex shape of the main frame, it can be formed by 3D printing as a whole. After forming, it will be machined to meet the precision requirements. Two taper pins cooperate with the taper holes of the satellite to bear the longitudinal load. The inner rail cooperates with the satellite outer rail. Considering the influence of manufacturing tolerance and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com