Optical fiber connector assembly

An optical fiber connector and connector technology, which is applied in optical components, light guides, optics, etc., can solve the problems of not easy bending of optical cables, inconvenient laying of optical cables, twisting and knotting of optical cables, etc., and achieve the effect of improving connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

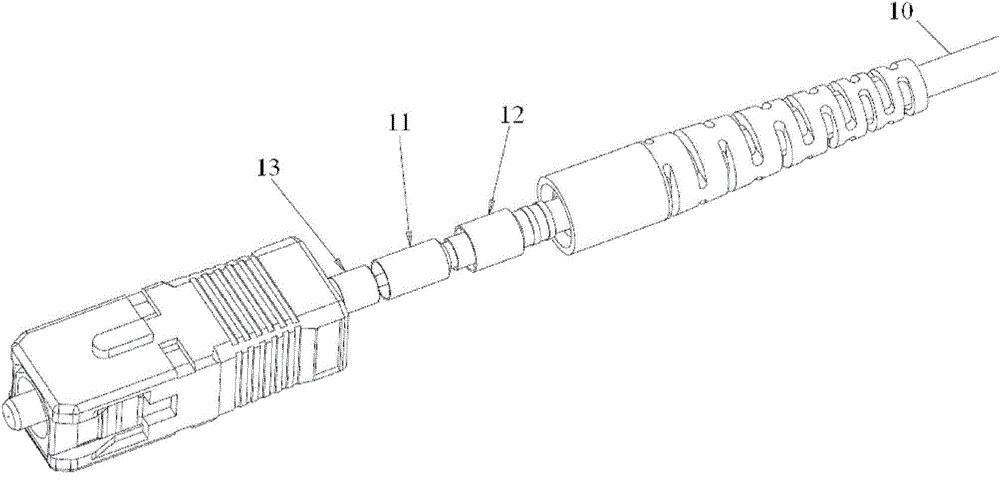

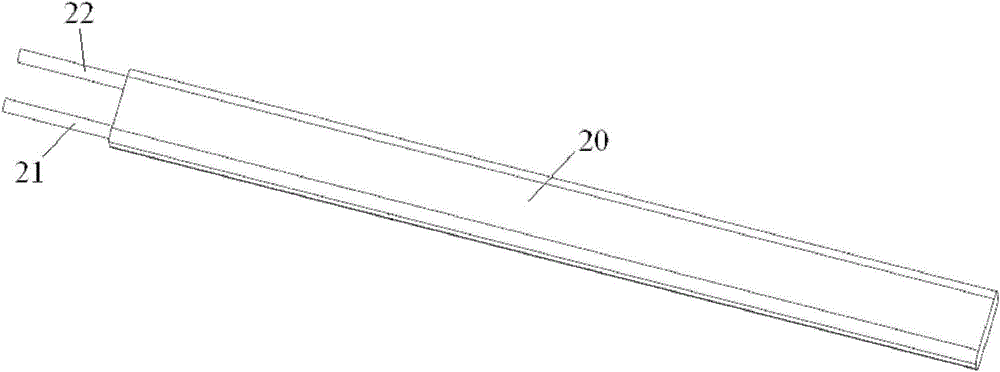

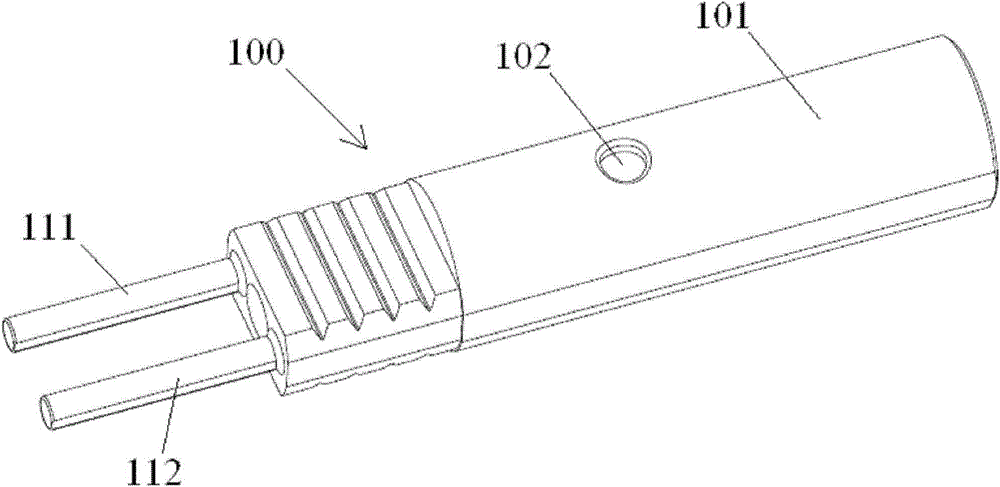

[0038] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0039] According to the concept of the present invention, an optical fiber connector assembly is provided, including: a connector; an optical cable 200, a reinforcing element layer 202 is arranged between the protective sleeve 203 of the optical fiber 204 of the optical cable 200 and the outer sheath layer 201; The transition piece 100 and the intermediate transition piece 100 are respectively glued to the reinforcing element layer 202 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com