Adjustable steel bar thread connection device

A threaded connection and adjustable technology, applied to structural elements, building components, building reinforcements, etc., to achieve the effects of reducing construction difficulty, strong replacement, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

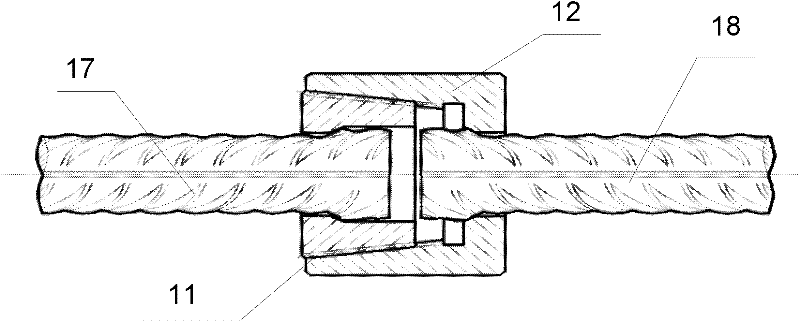

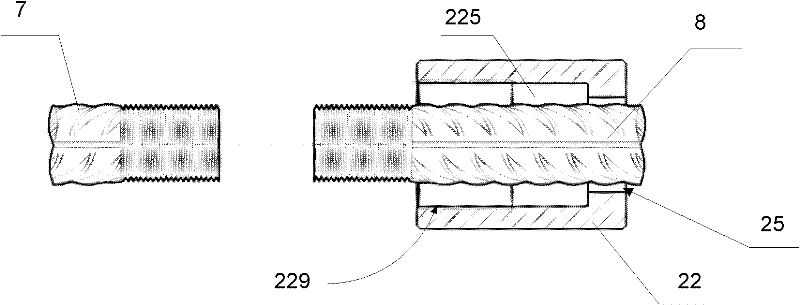

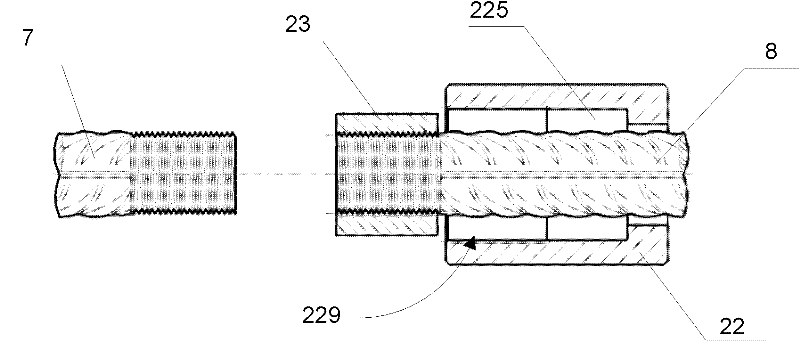

[0020] The structural composition of the adjustable steel bar threaded connection device according to the embodiment of the present invention and its implementation when used for connecting two steel bars will be described in detail below with reference to the accompanying drawings.

[0021] Such as Figure 2-Figure 5 As shown, the adjustable steel bar threaded connection device of the embodiment of the present invention includes a joint 22, a second threaded sleeve 21 and a first threaded sleeve 23 with an outer diameter D0. The outer wall of the second threaded sleeve 21 is provided with a straight thread 211 , and the inner wall is provided with a straight thread 212 . The joint 22 is a cavity with a cylindrical cavity 225, and one end of the joint 22 is provided with a hole 25 for being sleeved on the first steel bar 8, and the diameter of the hole 25 is D1; the first threaded sleeve 23 is located on the joint 22 In the cavity 225, the inner wall of the first threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com