Electric machine with a brush carrier

A brush holder and brush technology, applied in the field of electric motors, can solve the problems of poor motor heat dissipation, motor power loss, imprecise positioning, etc., and achieve the effects of reducing tolerance accumulation, improving vibration performance, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

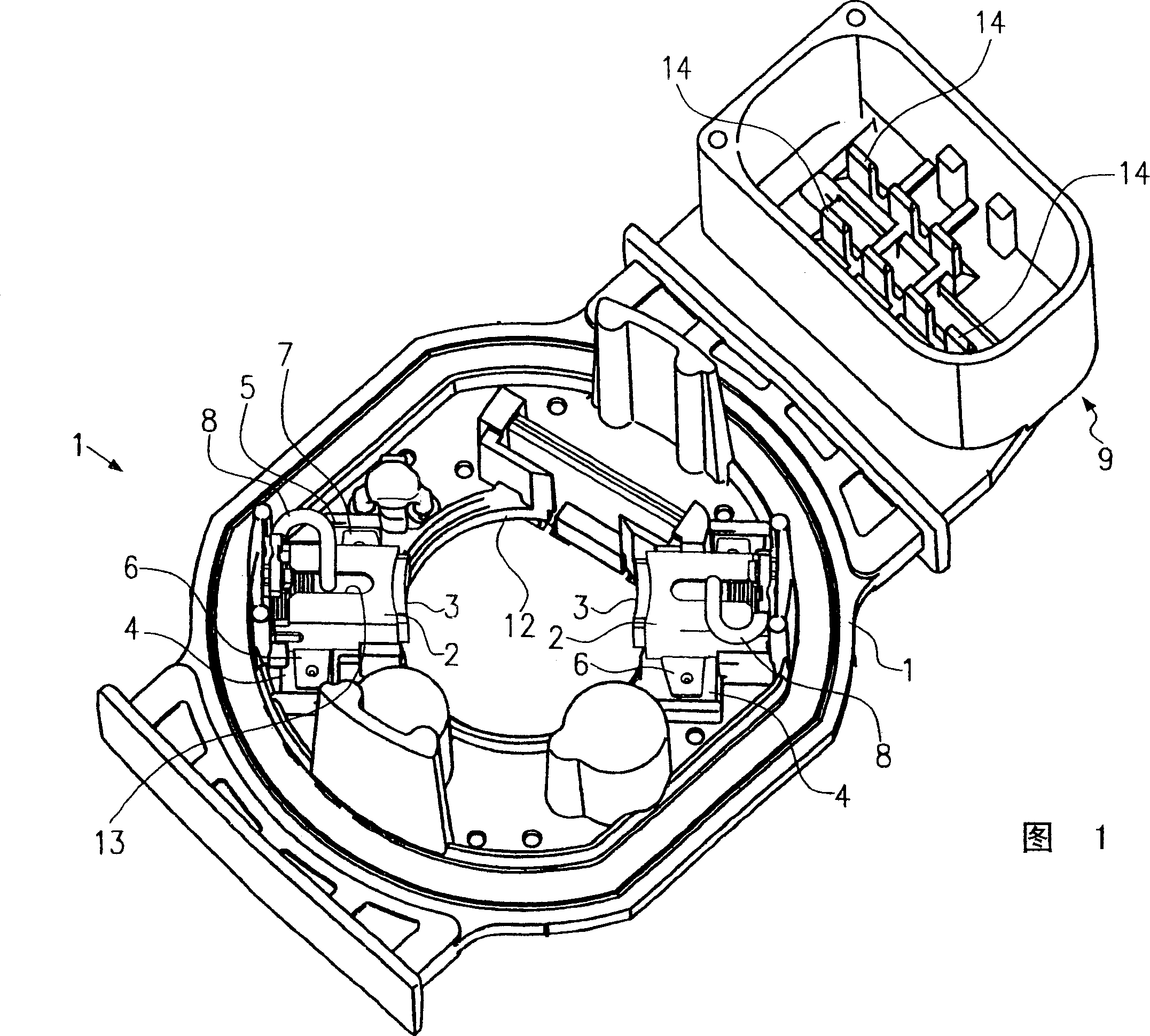

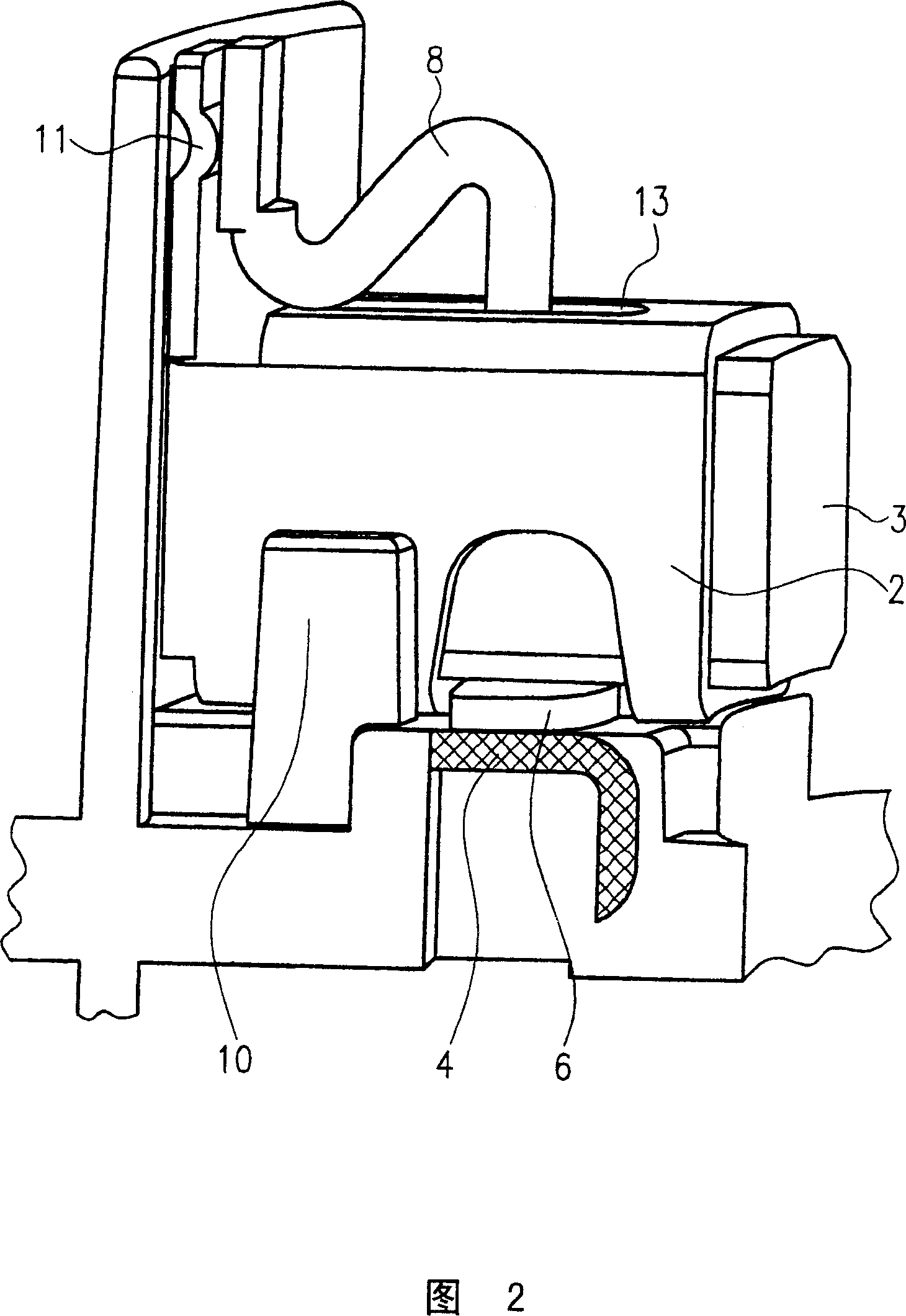

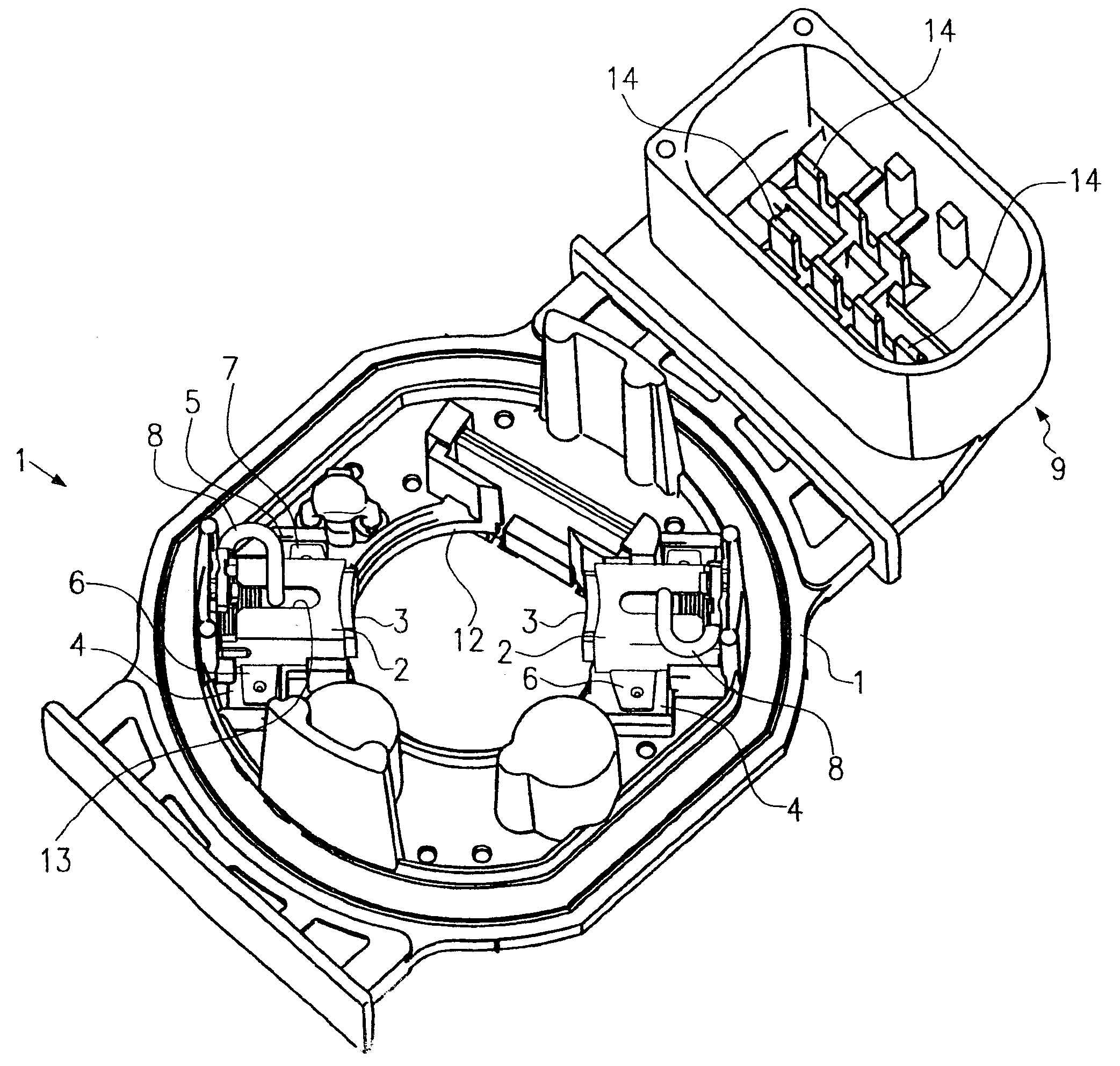

[0015] Hereinafter, an embodiment of the present invention will be described with reference to FIGS. 1 and 2. FIG.

[0016] Figure 1 shows a brush holder 1 of a motor, especially a commutator motor. The brush holder 1 is made of an electrically insulating material, such as plastic, by means of injection molding. The electrical connector 9 with the contact 14 is integrally formed on one side of the brush holder 1.

[0017] It can be seen from FIG. 1 that two brush containers 2 are arranged on the brush holder 1. Two brush containers 2 are arranged next to the center hole 12 of the brush holder 1 at 180° correspondingly. The central hole 12 is used in particular to pass the rotor shaft. The conductive material for the two brush containers 2 is preferably made of steel plate into a rectangular shape. Inside the brush container 2 is a bag-shaped cavity to accommodate the brush 3. The container 2 can be stamped and formed from a steel plate, for example.

[0018] As shown in FIG. 1, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com