Detector and detection method for electromagnetic valve of automobile automatic transmission

A technology of automatic transmission and solenoid valve, which is applied in the testing, instrumentation, measuring electricity of machines/structural components, etc., can solve the problems of slipping and burning of automatic transmission, complicated structure of solenoid valve, and impact of transmission shifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings, and this manufacturing technique is clear to those skilled in the art.

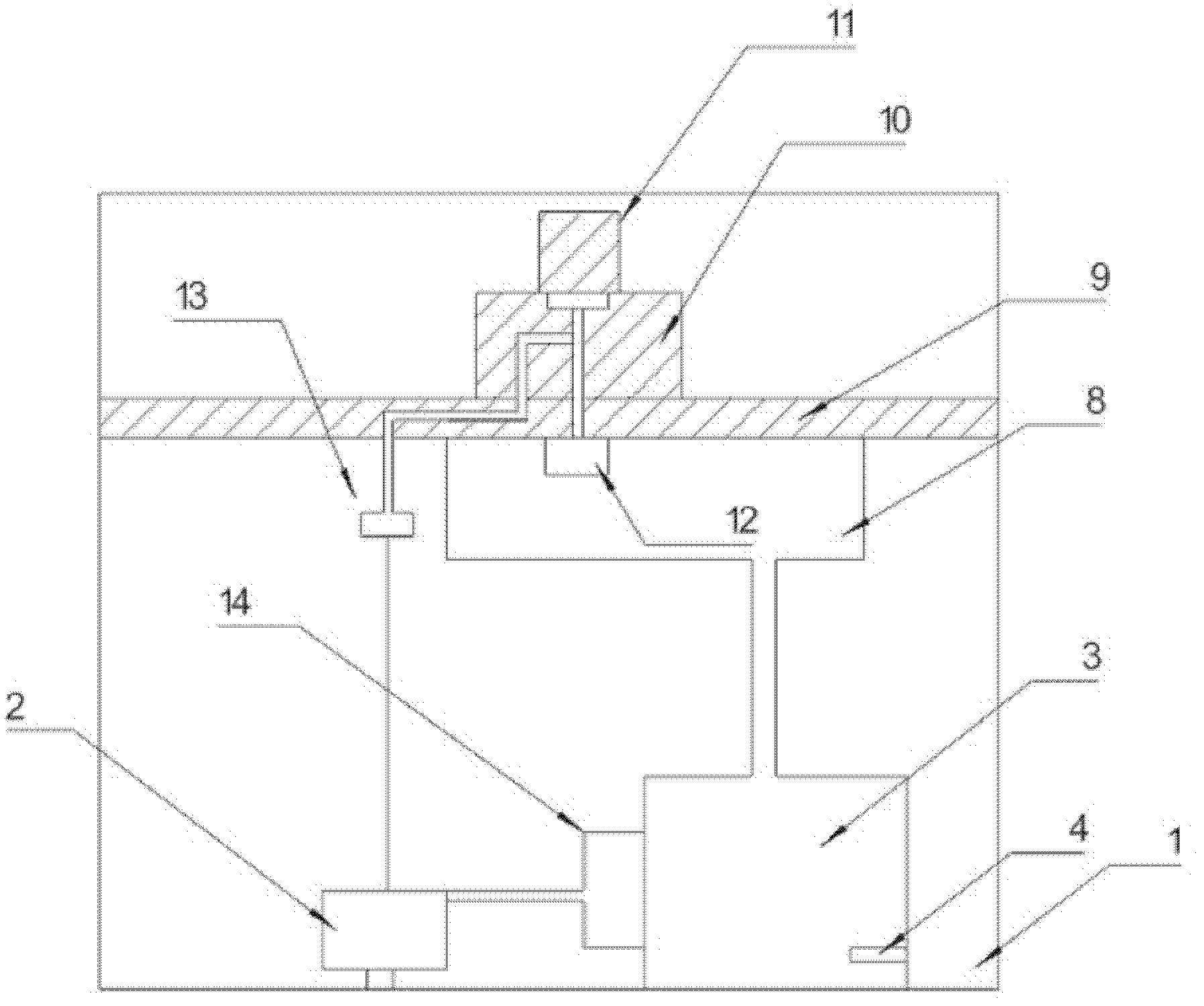

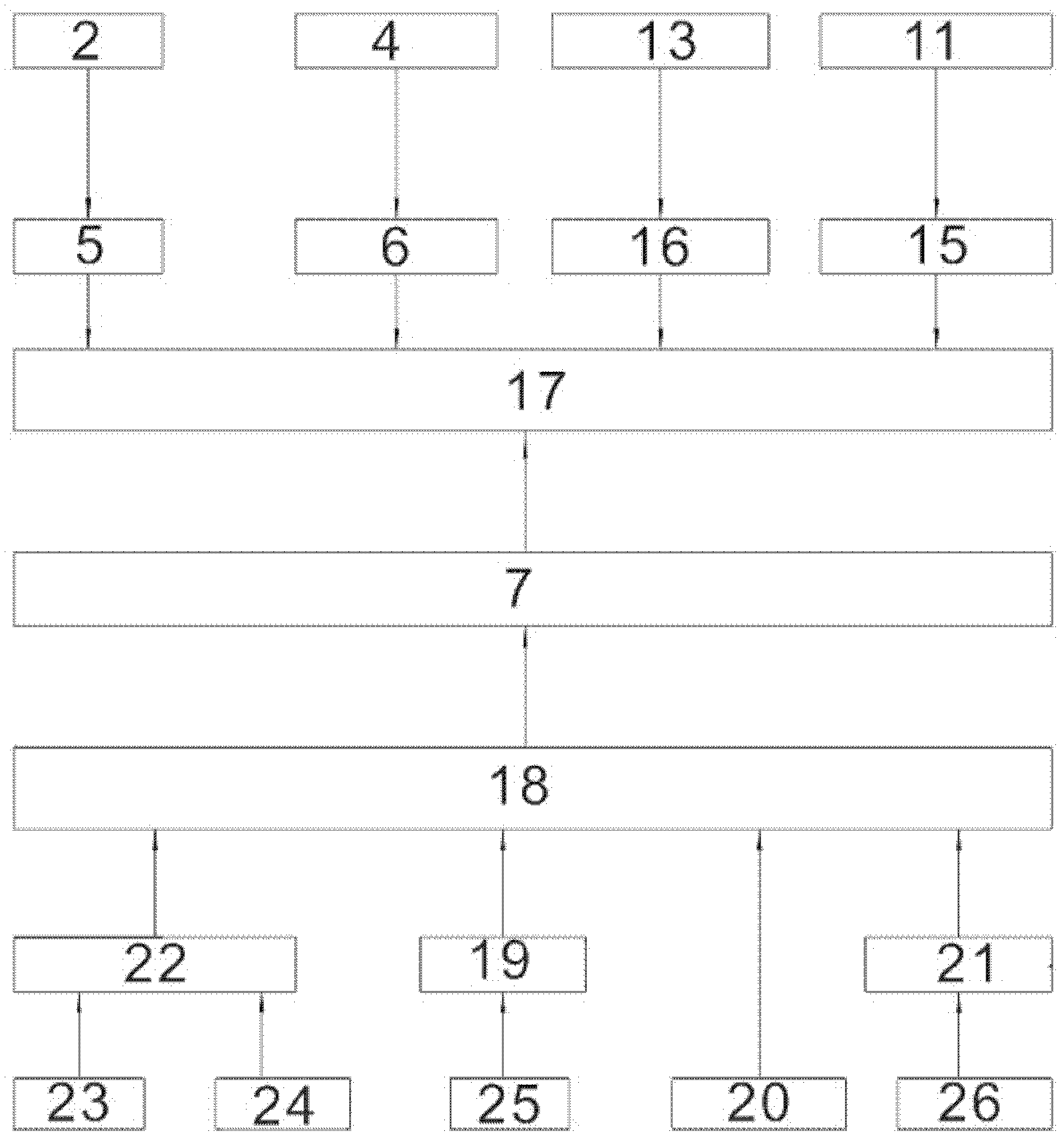

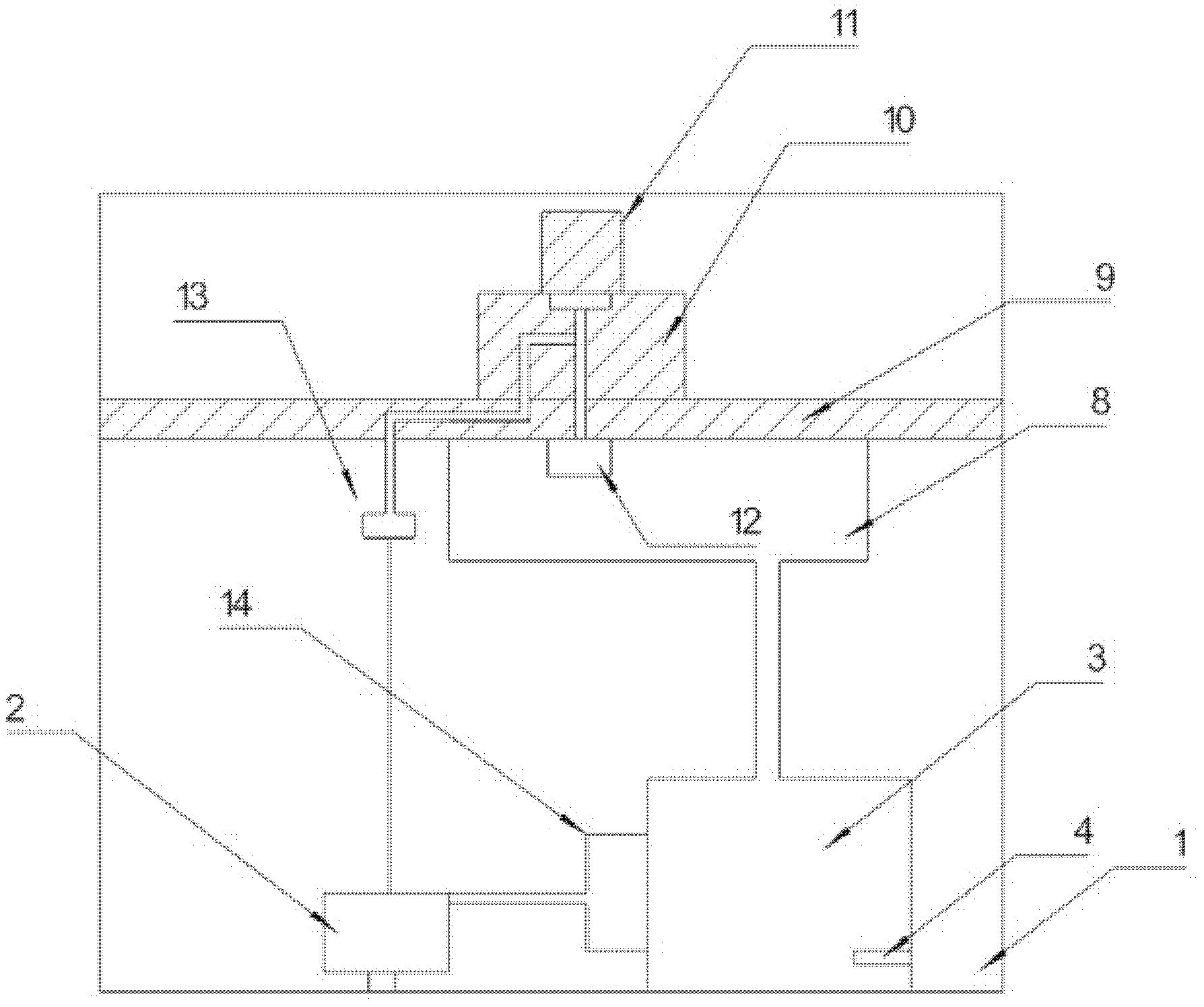

[0017] Such as figure 1 As shown, the solenoid valve detector for automatic transmission of automobiles is composed of chassis, motor, oil pump, fuel tank, oil temperature heater, oil return plate, pressure regulating solenoid valve, frequency converter, relay, PWM power amplifier circuit, and PC. The fuel tank is fixed on At the bottom of the case, an oil temperature heater is installed at the lower right side of the fuel tank, and a pipeline is installed at the center of the upper part of the fuel tank to connect the oil return chamber, and then an oil passage transition plate is installed on the upper part of the oil return chamber, and a solenoid valve adapter seat is installed on the upper part of the oil passage transition plate , the upper part of the solenoid valve adapter seat is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com