Remote-control unit assembling equipment

A technology for assembling equipment and remote control, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, and achieve the effect of improving efficiency, improving yield, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] specific implementation

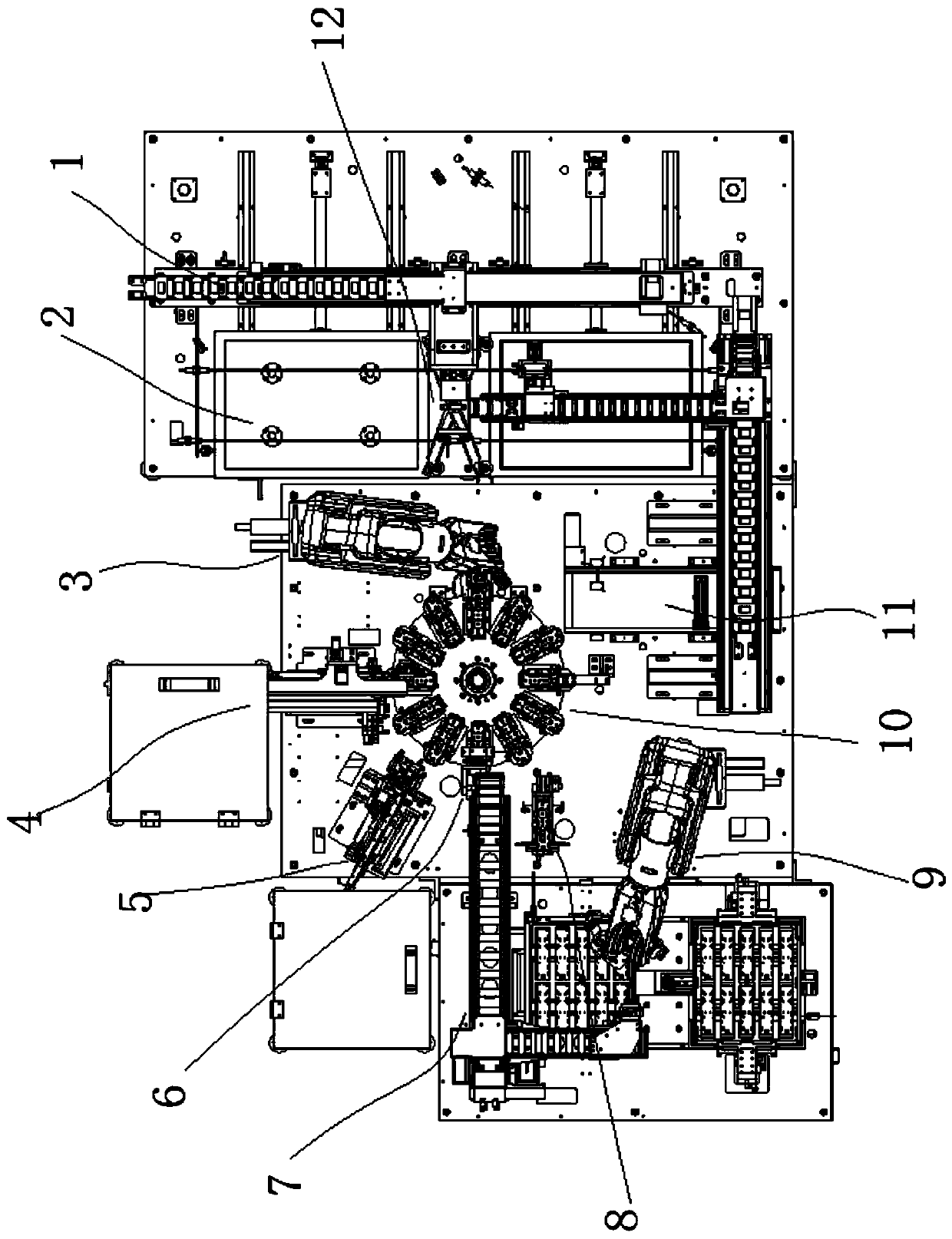

[0061] Such as figure 1 As shown, the present invention includes a rotating disk assembly 10, a first manipulator assembly 3 and a second manipulator assembly 9 for operating materials, and the first manipulator assembly 3 and the second manipulator assembly 9 are arranged on a rotating On both sides of the disk assembly 10, on the four sides of the rotating disk assembly 10, there are also shell sub-packaging assemblies 2, rubber block feeding assemblies 4, circuit board feeding assemblies 7, recovery assemblies 11 and The discharge assembly 12, wherein the shell subassembly assembly 2 and the discharge assembly 12 are arranged on the same side of the rotating disk assembly 10, and the rubber block feeding assembly 4 and the circuit board feeding assembly outside the rotating disk assembly 10 An iron cap feeding assembly 5 is also arranged between the assemblies 7, a pre-positioning assembly 8 is also arranged between the rotary disk assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com