Wire and bar production line and high-precision product intelligent control system and control method suitable for wire and bar production line

A control system and production line technology, which is applied in the direction of overall factory control, rolling mill control device, rolling force/roll gap control, etc., can solve the problem of not being able to track the size data of the rolled piece of the unit in real time, so as to reduce labor intensity and workload, The effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

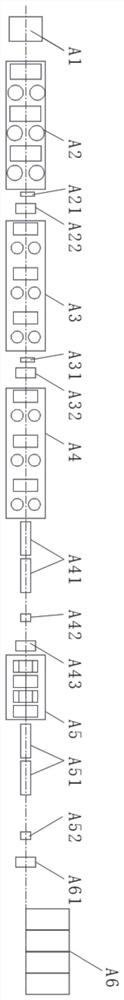

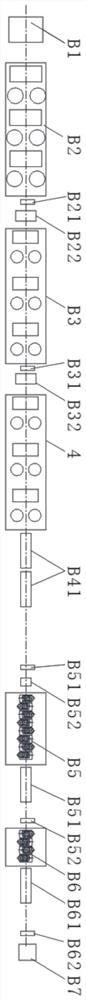

[0039] like figure 1 A bar production line shown in the figure includes a heating furnace I, a rough rolling production unit I, a medium rolling production unit I, a finishing rolling production unit I, a reducing and sizing production unit I, which are connected in sequence and are connected in sequence. A rolling stock size data detection unit I for rolling stock size data after being rolled by the rough rolling production unit I, the intermediate rolling production unit I, the finishing rolling production unit I and the reducing and sizing production unit I.

[0040] The rough rolling production unit I includes a rough rolling group I and a first flying shear IA22 arranged behind the rough rolling group IA2; the intermediate rolling production unit I includes an intermediate rolling group IA3 and a second rolling group arranged behind the intermediate rolling group IA3. Flying shear IA32; the finishing rolling production unit I includes a finishing rolling unit IA4, a first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com