Device for automatically and optically determining target position of container spreader

A container spreader and target position technology, applied in the field of optical determination of the target position, can solve the problems of changing the connection mode between the spreader and the container, the connection mode is single, and the container cannot be checked twice, so as to achieve the effect of diversification of the connection mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

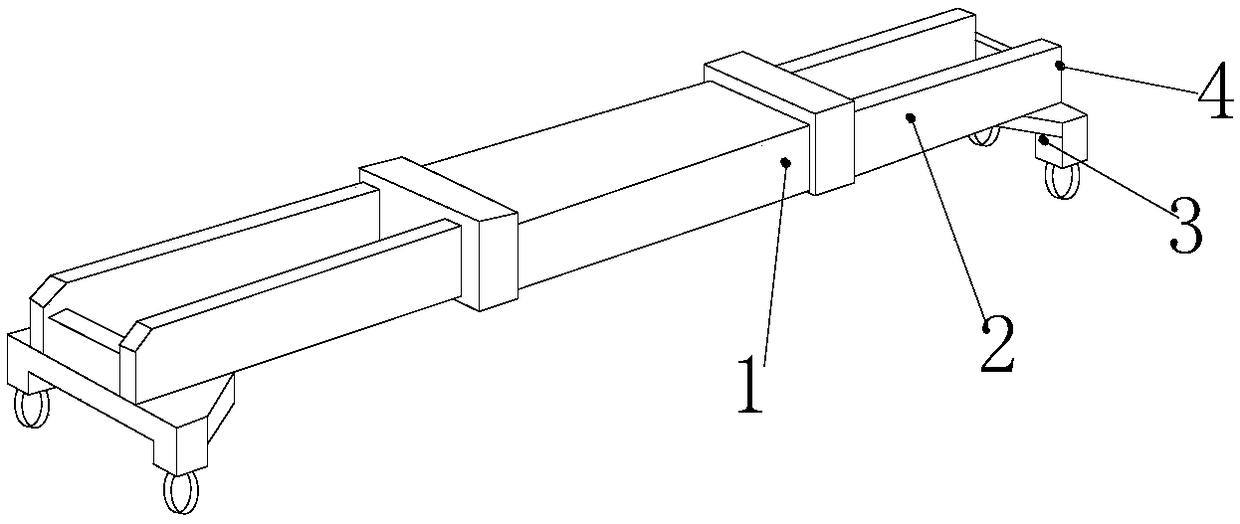

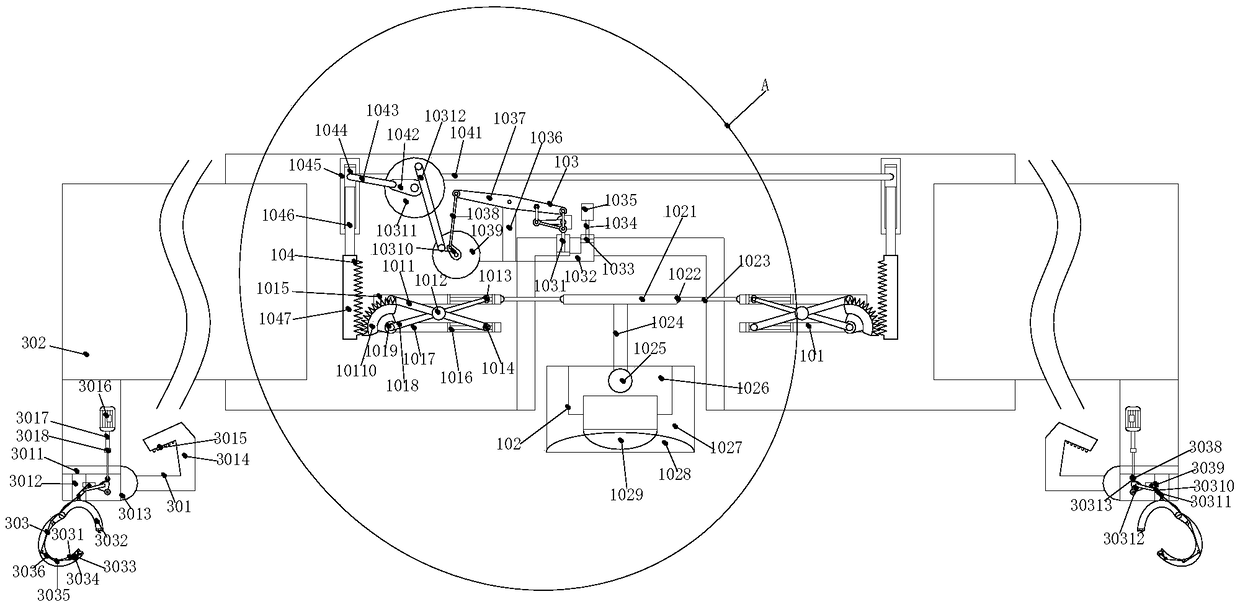

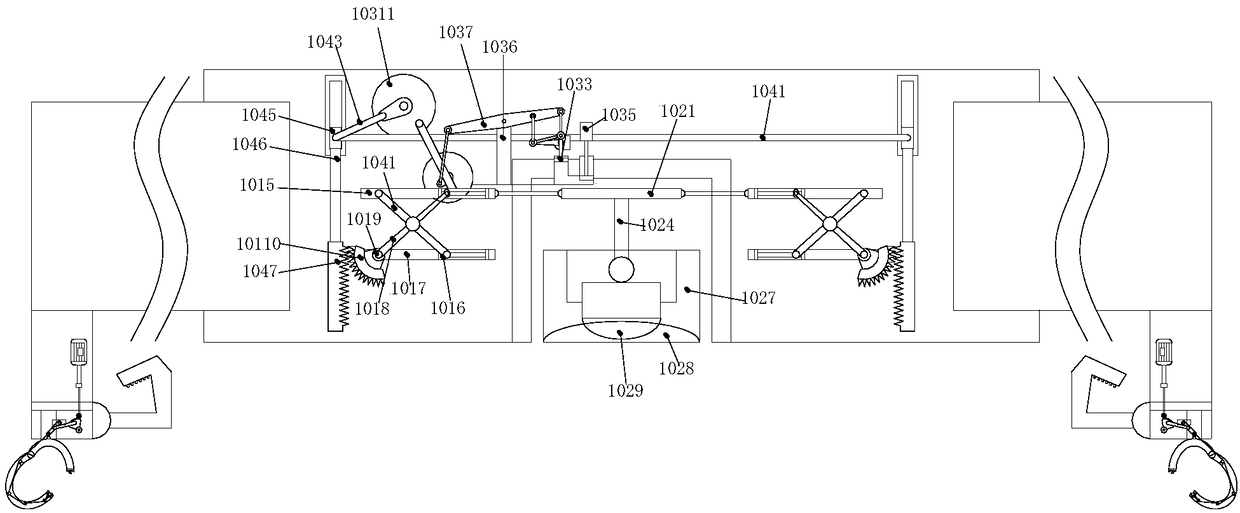

[0027] see Figure 1-Figure 6 The present invention provides a device for automatically optically determining the target position of a container spreader. Its structure includes a container calibration device 1, a connecting arm 2, a spreader mechanism 3, and a housing 4. The container calibration device 1 is installed in the housing 4, The spreader mechanism 3 is connected with the shell 4 through the connecting arm 2;

[0028] The container checking device 1 is composed of a lifting mechanism 101, a detection device 102, a mechanical driving device 103, and a mechanical transmission mechanism 104;

[0029] The lifting mechanism 101 is mechanically connected with the detection device 102, the detection device 102 is installed in the center of the bottom of the housing 4, the lifting mechanism 101 is mechanically matched with the mechanical transmission mechanism 104, and the mechanical transmission mechanism 104 is connected with the mechanical drive The device 103 is mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com