Connecting structure for vertical reinforcement bars of prefabricated wall parts

A technology for connecting structures and vertical steel bars, applied in structural elements, building components, building reinforcements, etc., can solve the problem of high cost, and achieve the effect of fast connection speed, convenient and fast alignment, and easy alignment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

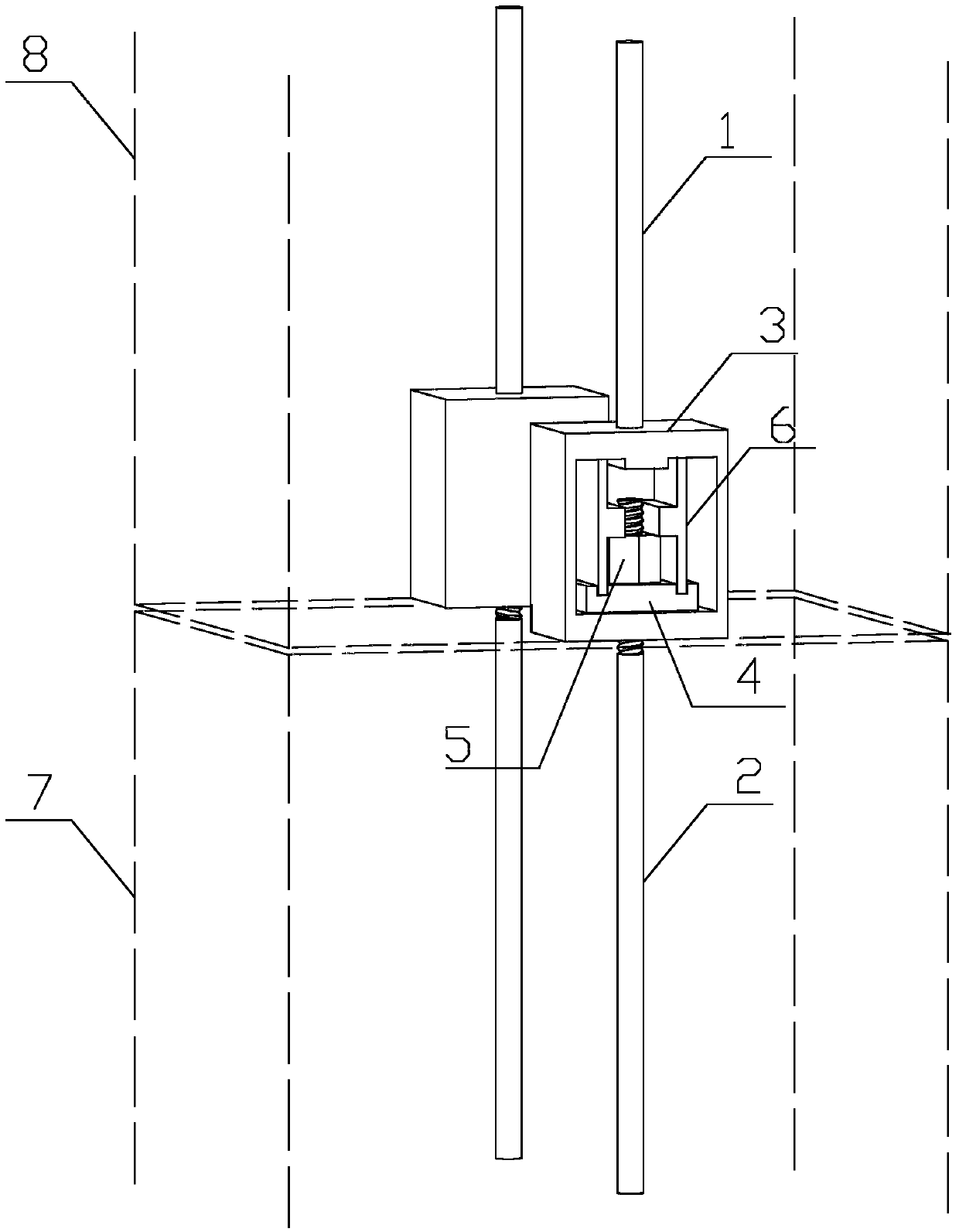

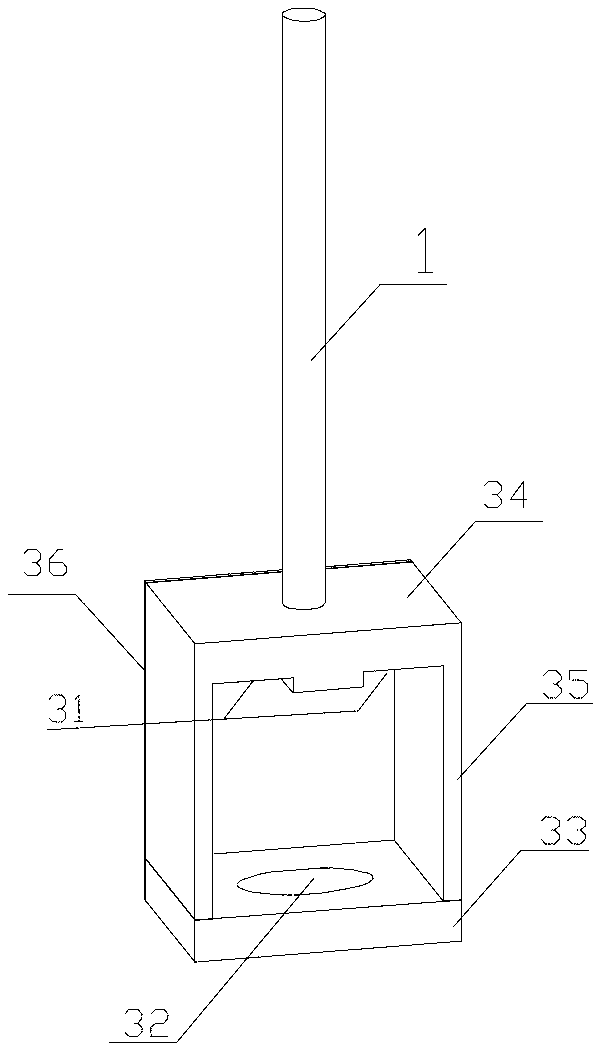

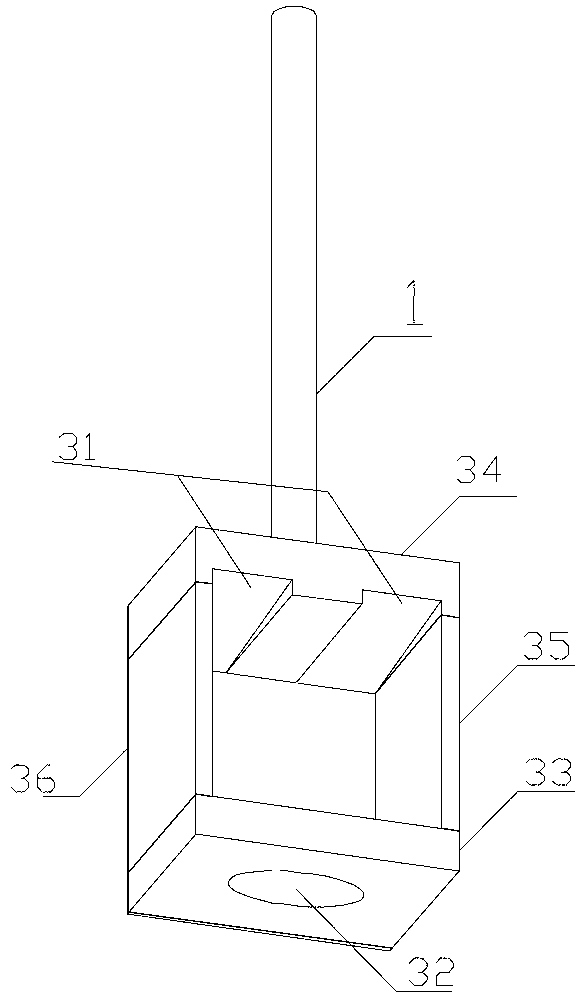

[0022] The vertical reinforcement connection structure of prefabricated wall components of the present invention comprises a steel box box 3 with an opening on one side, an upper side prefabricated member steel bar 1 fixedly connected to the top plate of the steel box box body 3, and a steel box box The opening 32 of the bottom plate of the body 3 penetrates the lower prefabricated component steel bar 2 inside the box body, the backing plate 4 and the nut 5 that are arranged inside the steel box box body 3 and cover the lower side prefabricated component steel bar 2 sequentially from bottom to top, and Two wedge plates 6 are arranged symmetrically on both sides of the lower prefabricated component steel bar 2 .

[0023] The backing plate 4 is provided with a steel bar installation hole 41 and two backing plate guide grooves 42 arranged in parallel on both sides of the steel bar installation hole 41. A section of lower prefabricated component steel bar 2 is placed on it. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com