Precisely imitated manually extruding type dough making device

An extruding and manual technology, which is applied in the direction of mixing/kneading with vertical installation tools, can solve the problems of high labor intensity, lack of competitiveness, and low efficiency of manual kneading, and achieve labor saving, good taste, and improved speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

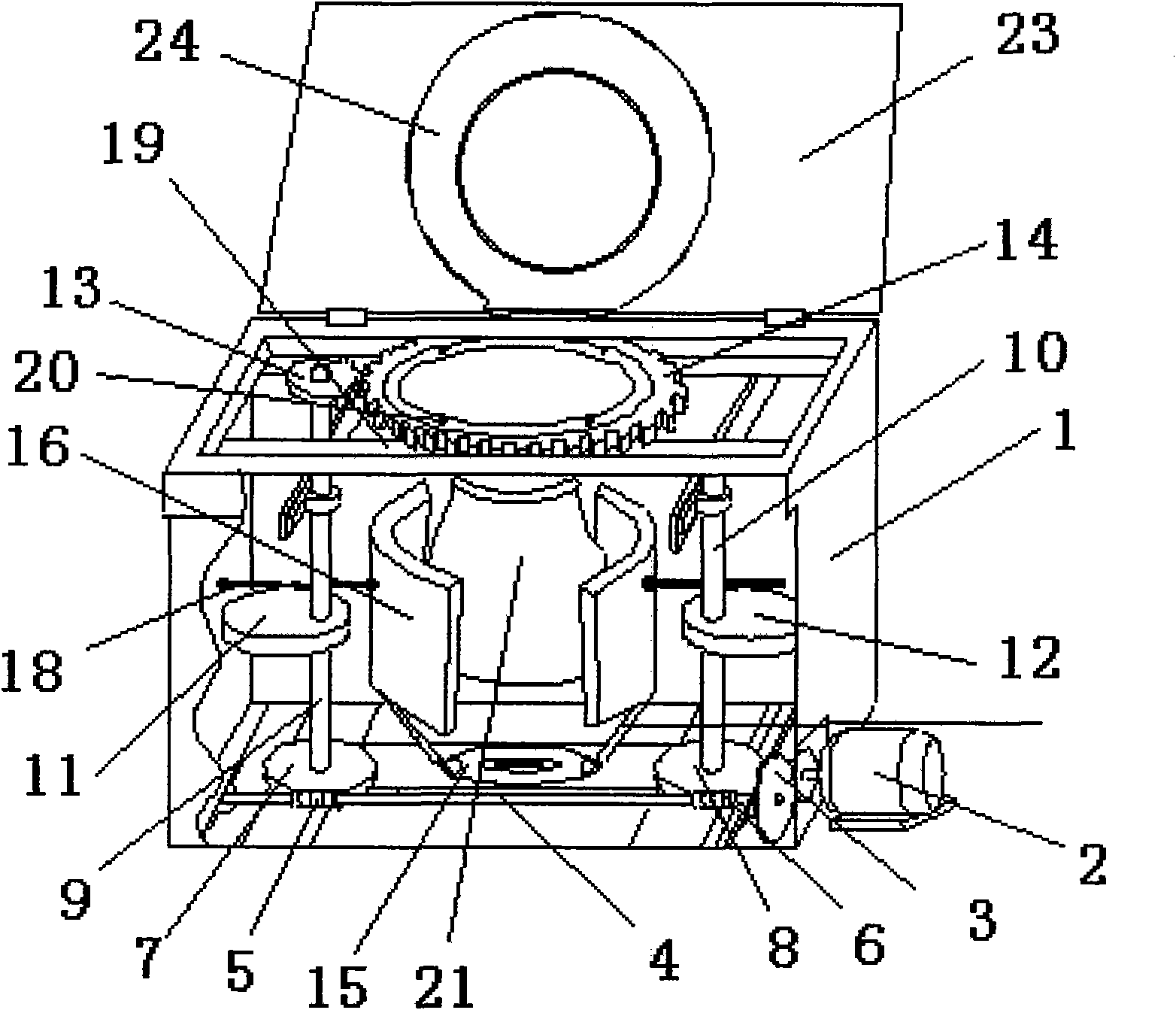

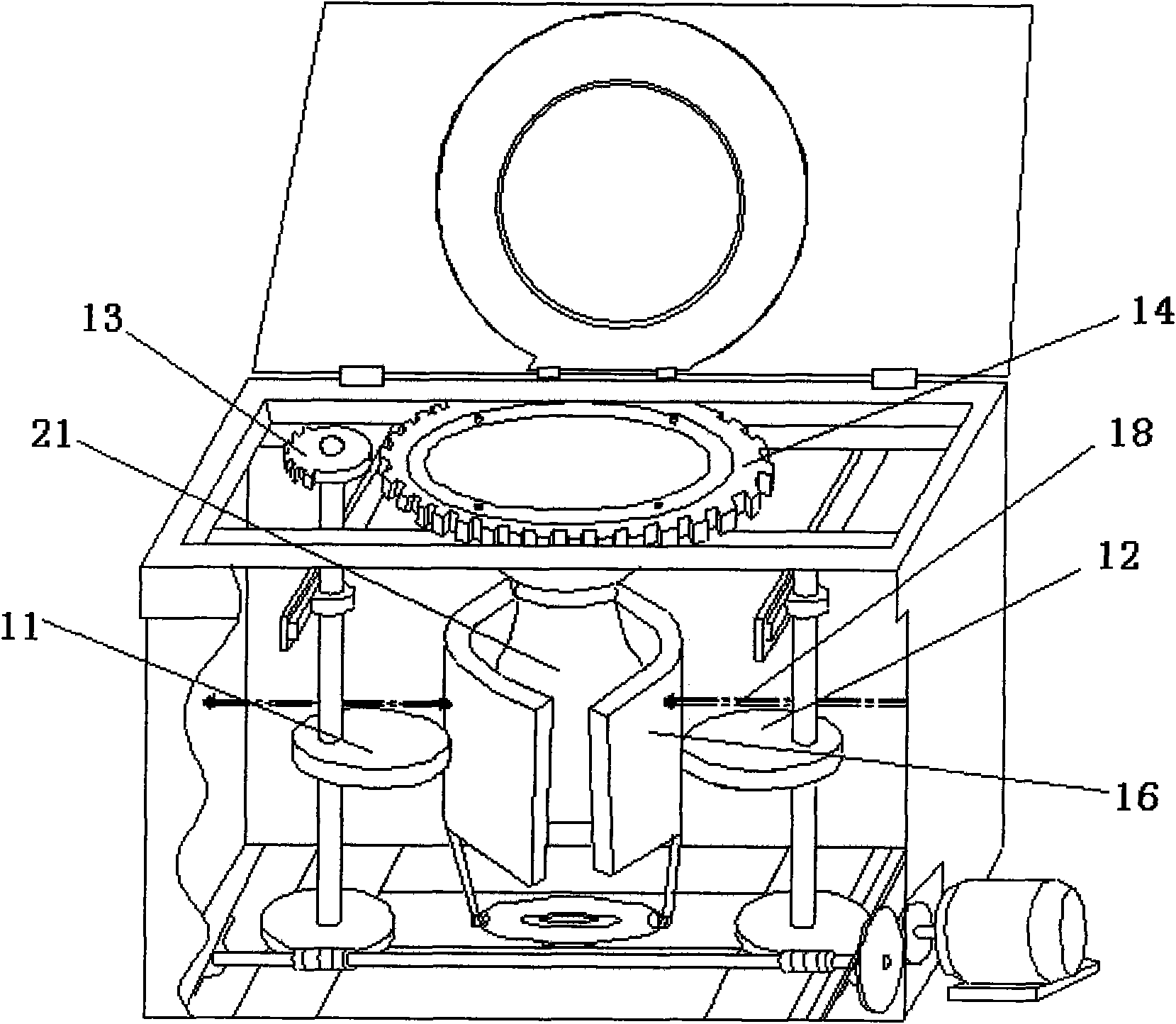

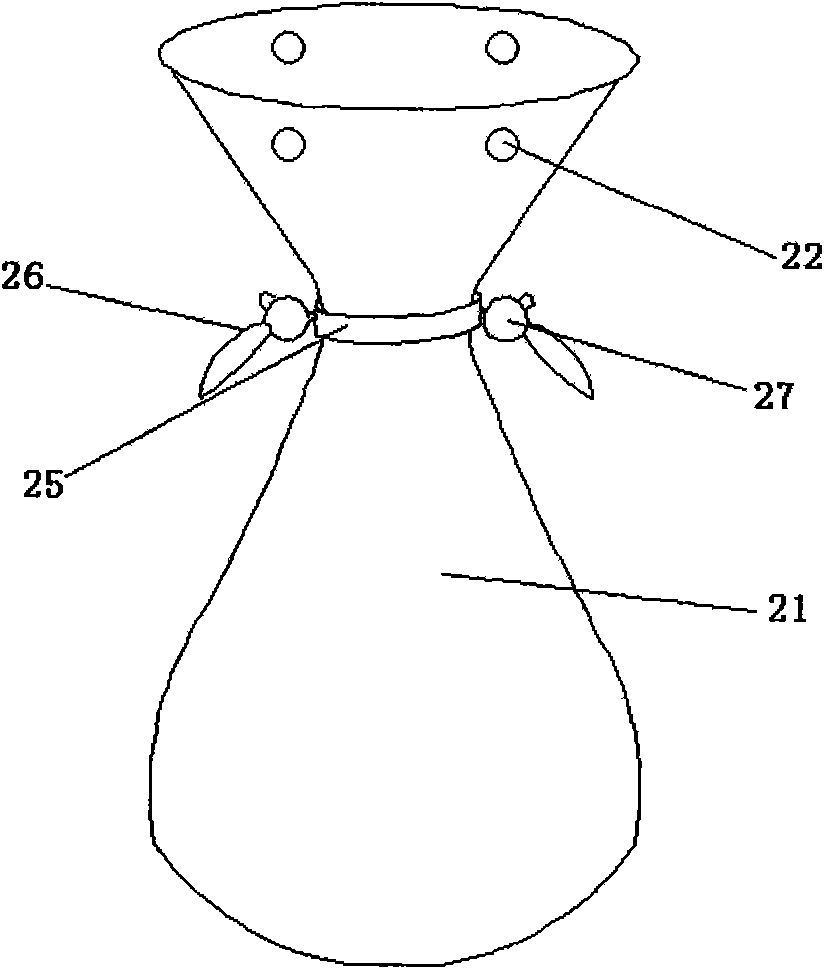

[0014] like figure 1 , figure 2 As shown, the present invention includes a housing 1, and a motor 2 is arranged outside the housing 1, the output end of the motor 2 is connected to a worm shaft 4 laterally supported in the housing 1 through a transmission device 3, and the worm shaft 4 is spaced Two worms 5, 6 are provided, and the two worms 5, 6 respectively drive a worm wheel 7, 8, and the two worm wheels 7, 8 are respectively supported in the casing by a vertical shaft 9, 10, and a pair of vertical shafts 9, 10 are arranged symmetrically in the middle Symmetrically shaped cams 11, 12, wherein a half gear 13 is arranged on the top of one vertical shaft 9, and an outer ring gear 14 meshes with the half gear 13. The long end of the centermost tooth and the cam 11 on the half gear 13 is set at 180°.

[0015] Two elastic brackets 15 (such as two compression springs) are arranged at the bottom center of the housing 1, and the tops of the two elastic brackets 15 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com