Hand-held self-rotated reinforcing steel bar hook

A self-rotating, hand-held technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of low work efficiency and difficult operation, and achieve the effect of high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

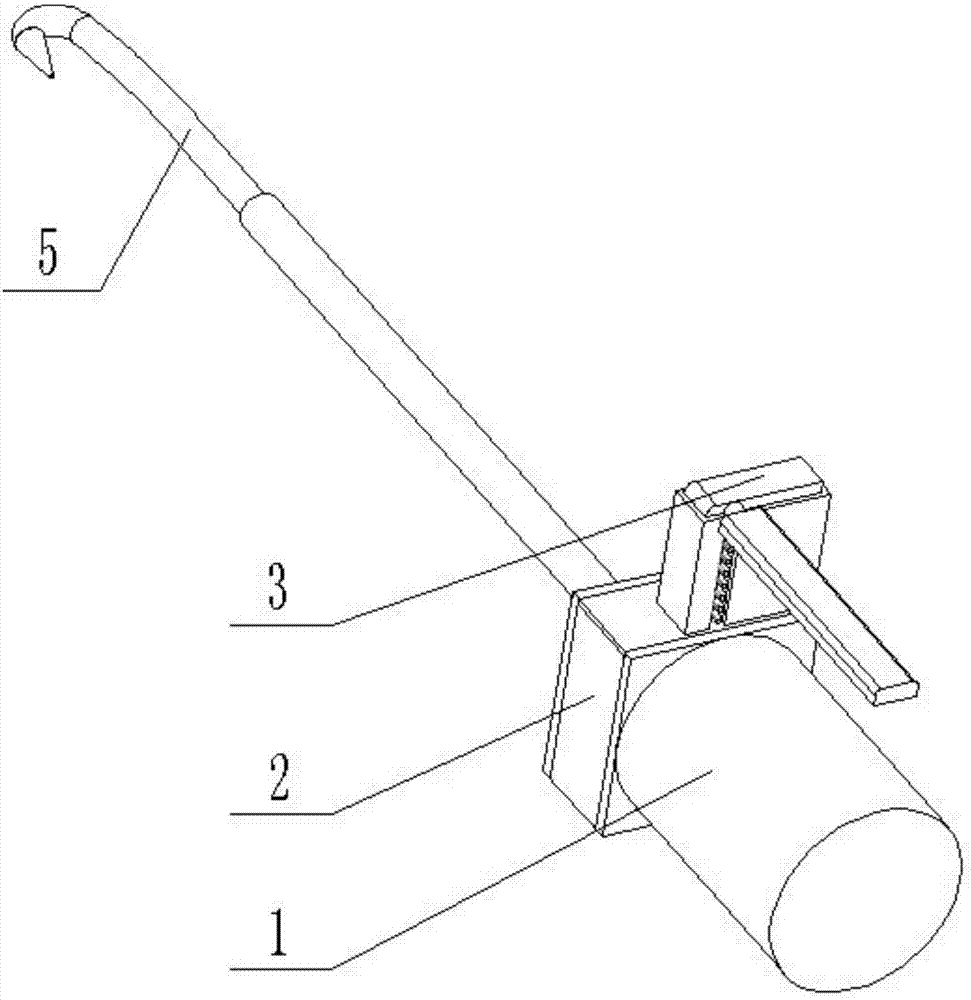

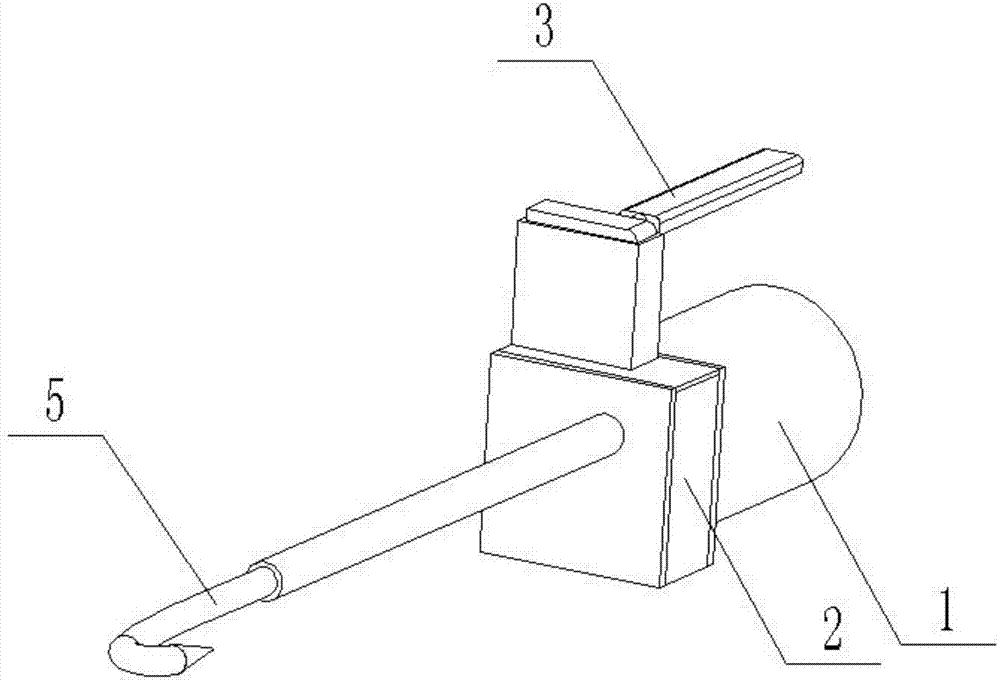

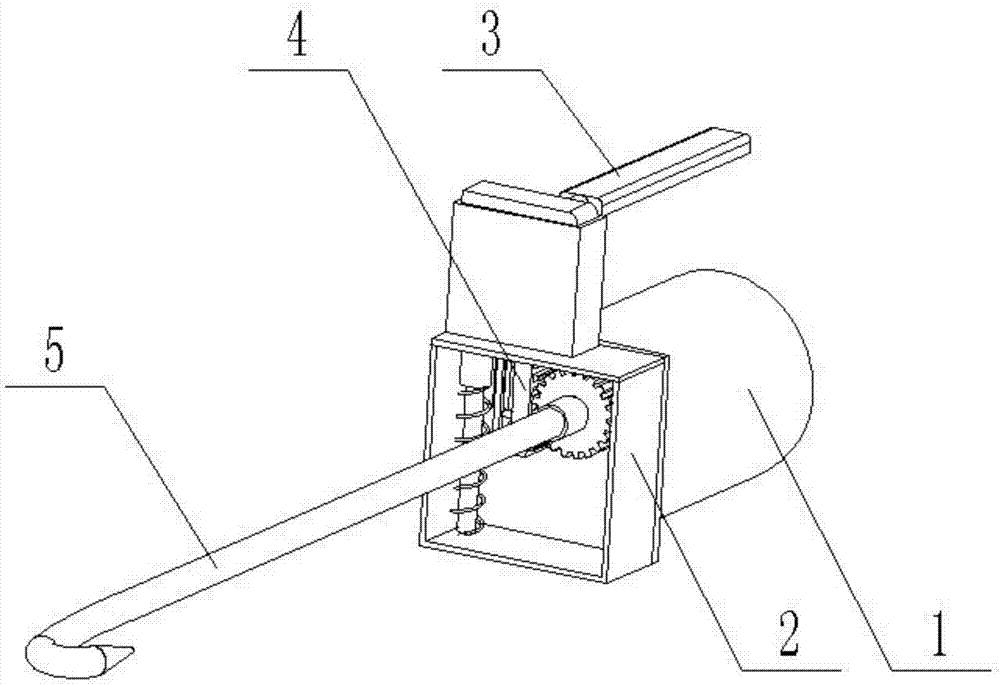

[0053] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 illustrate this embodiment, a hand-held self-rotating steel bar hook, including a handle 1, a device box 2, a push The pressing device 3, the rack device 4, and the rotating device 5 are characterized in that: the front end of the handle 1 is provided with a device box 2, the upper end of the device box 2 is provided with a pushing device 3, and the inside of the device box 2 is provided with a rack device 4 and a rotating device 5. The rotating device 5 is arranged at the left end of the rack device 4 .

specific Embodiment approach 2

[0055] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 illustrate this embodiment, the device box 2 includes a rear end cover 2-1, an upper end cover 2- 2. Plug box 2-3, inverted door-shaped frame 2-4, front cover 2-5, bushing Ⅰ 2-6, rear cover 2-1 front end welded and connected upper cover 2-2, The right end of the upper end cover plate 2-2 is welded and connected to the plug box 2-3, the front end of the rear end cover plate 2-1, the lower end of the upper end cover plate 2-2 is welded and connected to the inverted door-shaped frame 2-4, and the upper end cover plate 2- 2. The front end, the inverted door-shaped frame 2-4 is welded to the front end cover plate 2-5, the rear end cover plate 2-1, the upper end cover plate 2-2, the inverted door-shaped frame 2-4 and the front end cover plate 2-5 constitutes an internal hollow cuboid structure, and the front end of the front cover plate 2-5 is welded to connect the casing I2-6;

[0056] The rear end c...

specific Embodiment approach 3

[0064] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 illustrate this embodiment, the pushing device 3 includes a pressing rod 3-1, a connecting shaft 3-2, Pressing plate 3-3, down-pressing connecting rod 3-4, positioning attachment plate 3-5, casing II 3-6, pressing rod 3-1 is welded and connected to connecting shaft 3-2 at the front end, connecting shaft 3-2 is welded and connected to pressing plate 3 at the front end -3, the right end of the lower end of the pressing plate 3-3 is welded and connected to the sleeve II 3-6, the left end of the lower end of the pressing plate 3-3 is welded and connected to the lower pressing connecting rod 3-4, the right end of the lower pressing connecting rod 3-4 is welded and connected to the positioning attachment plate 3- 5;

[0065] Described pressing down connecting rod 3-4 comprises first connecting rod 3-4-1, second connecting rod 3-4-2, upper positioning shaft 3-4-3, lower positioning shaft 3-4-4, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com