Rock mechanic testing machine capable of realizing continuous change of shear direction

A technology of rock mechanics and shear direction, applied in the field of geotechnical engineering, can solve the problems such as the failure to realize the experimental research of rock mass fracture surface, and achieve the effect of simple structure, convenient processing process and reducing error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

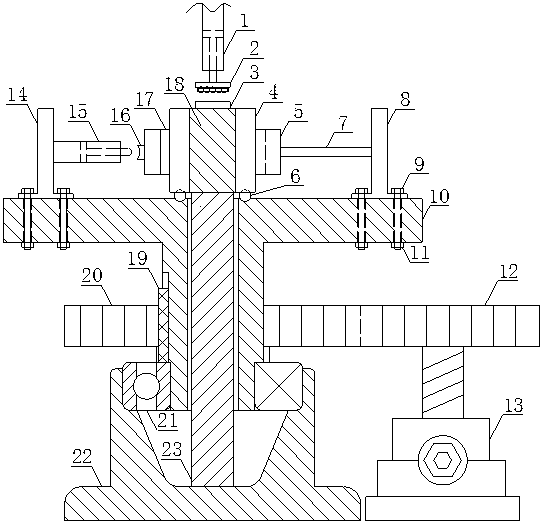

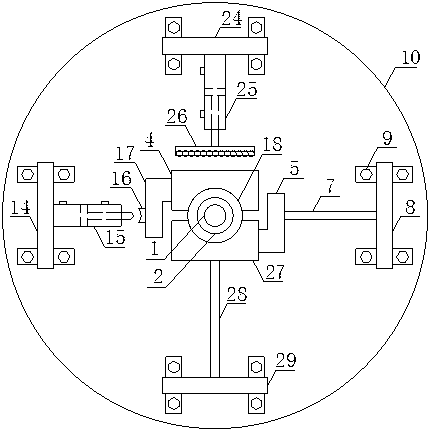

[0021] Below in conjunction with accompanying drawing, the present invention is further described, see accompanying drawing.

[0022] A rock mechanics testing machine that continuously changes the shear direction, the testing machine is composed of a platform 10, a first gear 12, a motor 13, a second gear 20, a bearing 21, a bearing end cover 22, a pillar 23, a shear box, a Force device composition.

[0023] The bearing platform 10 is in the shape of a three-stage hollow cylindrical boss with varying outer diameters. The upper boss of the bearing platform 10 is symmetrically provided with threaded holes along the orthogonal direction, and the middle boss of the bearing platform 10 is provided with a keyway. The gear pin 19 is placed on the bearing platform. In the keyway of the middle boss of the platform 10, the second gear 20 is mounted on the outside of the middle boss of the platform 10 through the gear pin 19, and the bearing 21 is installed on the outside of the lower bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com