Ribbon electron beam traveling wave tube output structure

An output structure, electron beam technology, applied in the direction of the coupling device of the transit time type electron tube, etc., can solve the problems of device performance stability, affecting tube performance and life, limited working bandwidth, etc., to achieve expanded bandwidth and good transmission performance. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

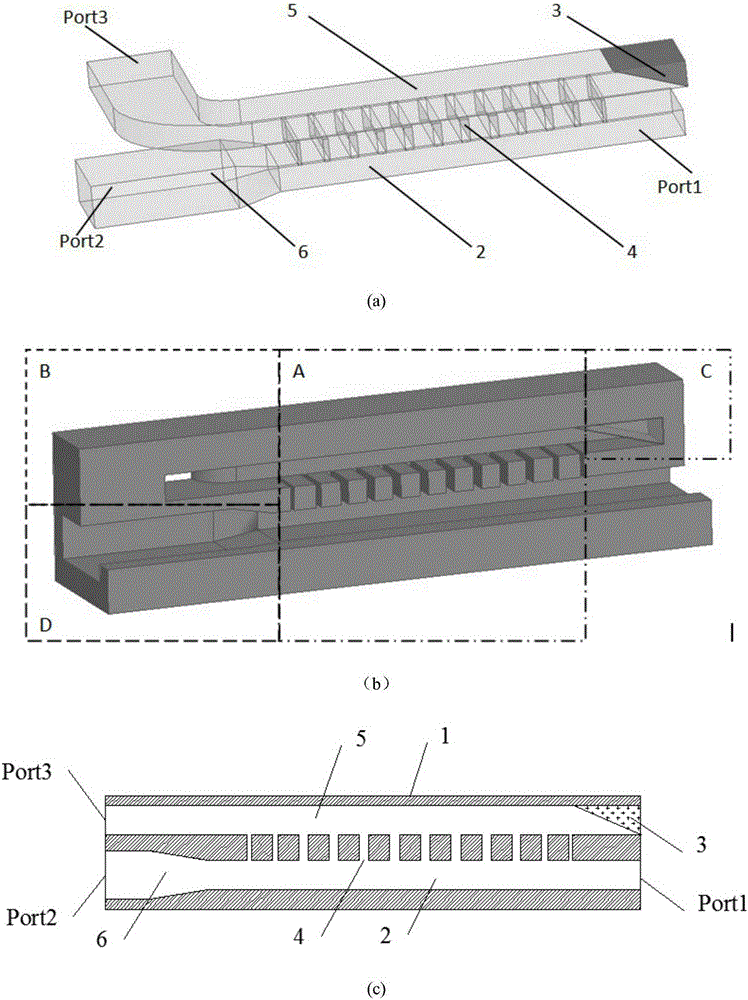

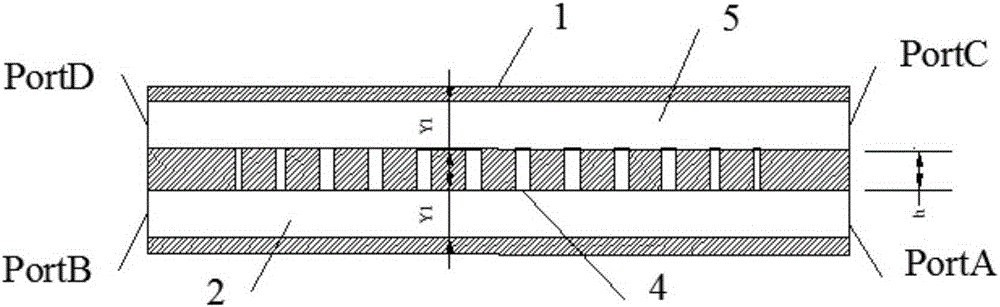

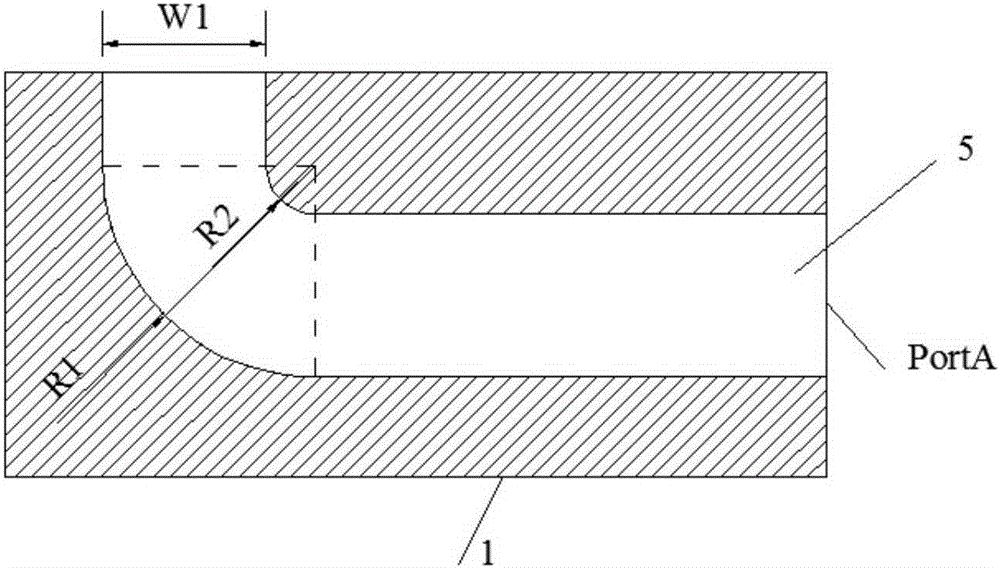

[0028] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings. For the convenience of description, only the output structure of the strip beam traveling wave tube of 36GHz-52GHz is used for detailed description, but the protection scope of the present invention is not limited thereto. Based on other frequency bands of the present invention, other strip beam traveling wave The tube output structure and any changes or replacements conceivable by anyone familiar with the technology within the technical scope disclosed in the present invention should be covered within the scope of the present invention. Therefore, the protection scope of the present invention should be determined by the protection scope of the claims.

[0029] Such as Figure 1-5 Shown is the output structure of the strip electron beam traveling wave tube in this embodiment, including a double rectangular waveguide coupling structure A, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com