Right-angled piezoelectric cantilever beam vibration energy harvester

A technology of vibration energy collection and cantilever beam, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of single operating frequency, large randomness, and piezoelectric vibration Problems such as energy harvester collection and conversion efficiency reduction, to achieve the effect of small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

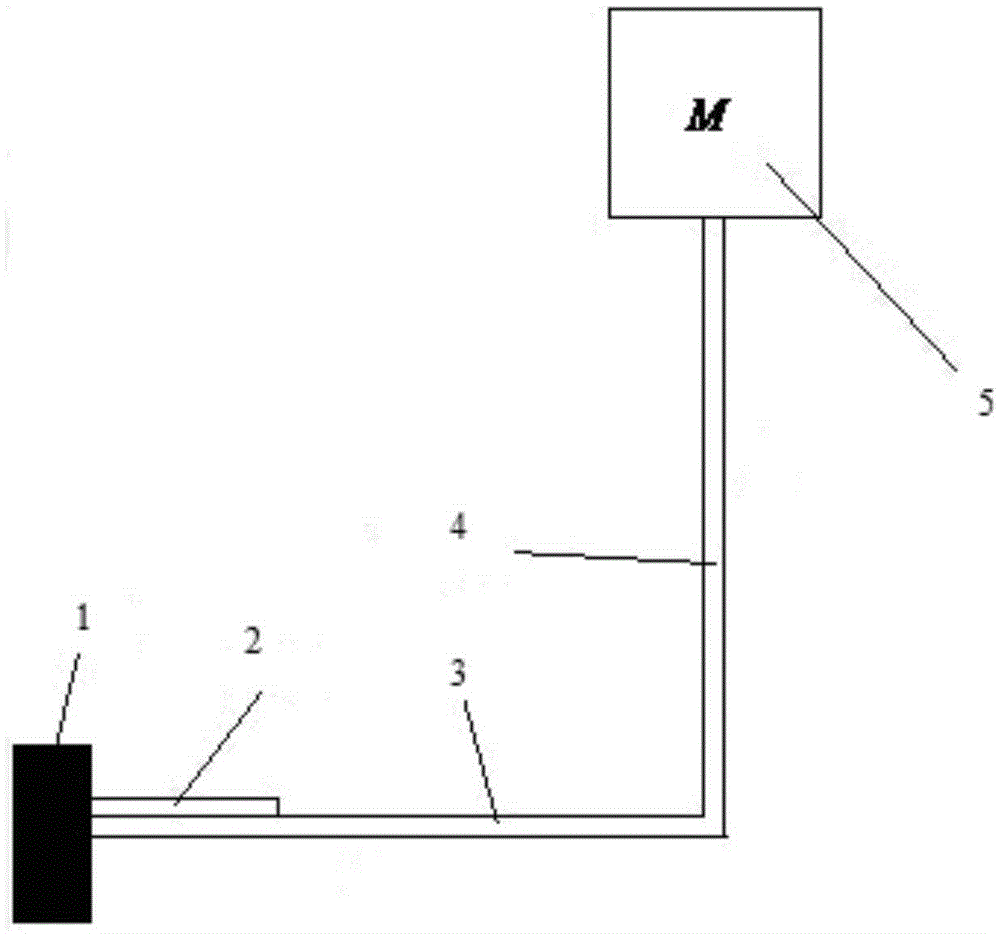

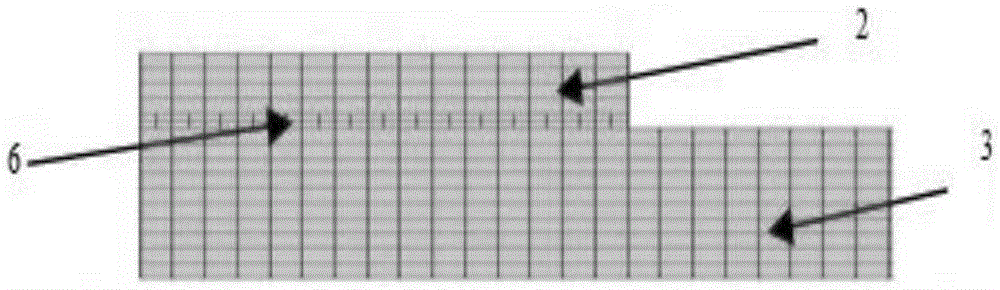

[0024] refer to figure 1 , The right-angle piezoelectric cantilever vibration energy harvester proposed by the present invention consists of a support 1, a piezoelectric ceramic wafer 2, a horizontal metal substrate 3, a vertical metal substrate 4, and a mass 5. The left end of the horizontal metal substrate 3 is fixed on the support 1; the piezoelectric ceramic chip 2 is bonded and fixed on the outer surface of the horizontal metal substrate 3 near the fixed end on the left side through the adhesive layer 6, and the two ends of the vertical metal substrate 4 are connected to the The mass block 5 is connected to the horizontal metal base plate 3; the mass block 5 is fixed at the upper end of the vertical metal base plate 4. The horizontal metal substrate 3 and the vertical metal substrate 4 are perpendicular to each other to form a right-angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com