Pneumatic helical tooth surface rotating table

A technology of helical tooth surface and rotary table, which is applied in the direction of transmission device, fluid transmission device, belt/chain/gear, etc., can solve the problems of high working environment requirements, large error, and inability to realize multi-angle control, etc., and achieve compact structure and installation , the effect of strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

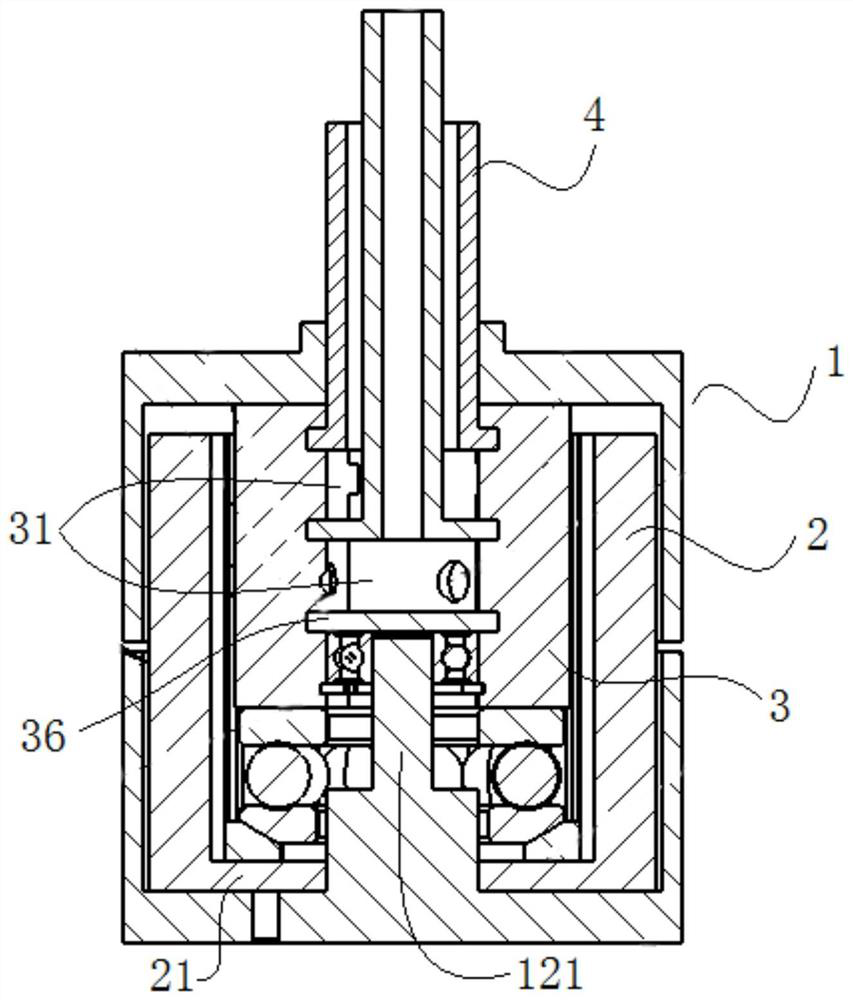

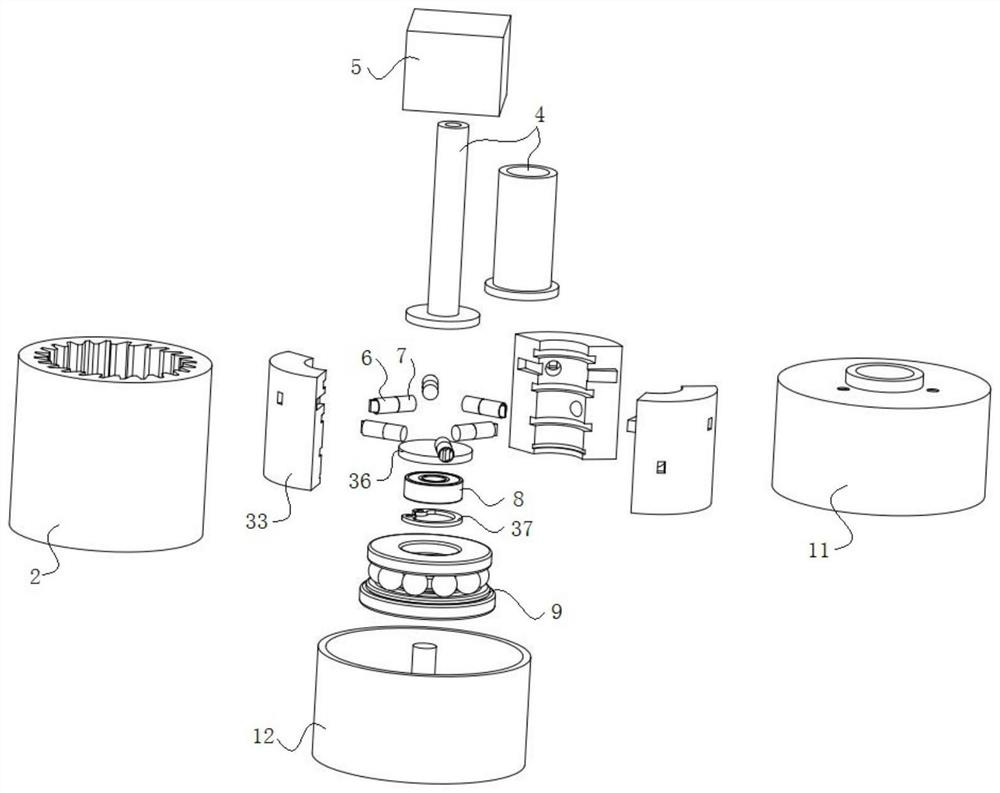

[0027] like Figure 1-2 As shown, this embodiment provides a pneumatic helical tooth surface rotary table, including a shell 1, an internal gear 2 and a cylinder block 3 arranged in sequence from outside to inside, the center of the shell 1, the internal gear 2, and the cylinder block 3 on the same axis.

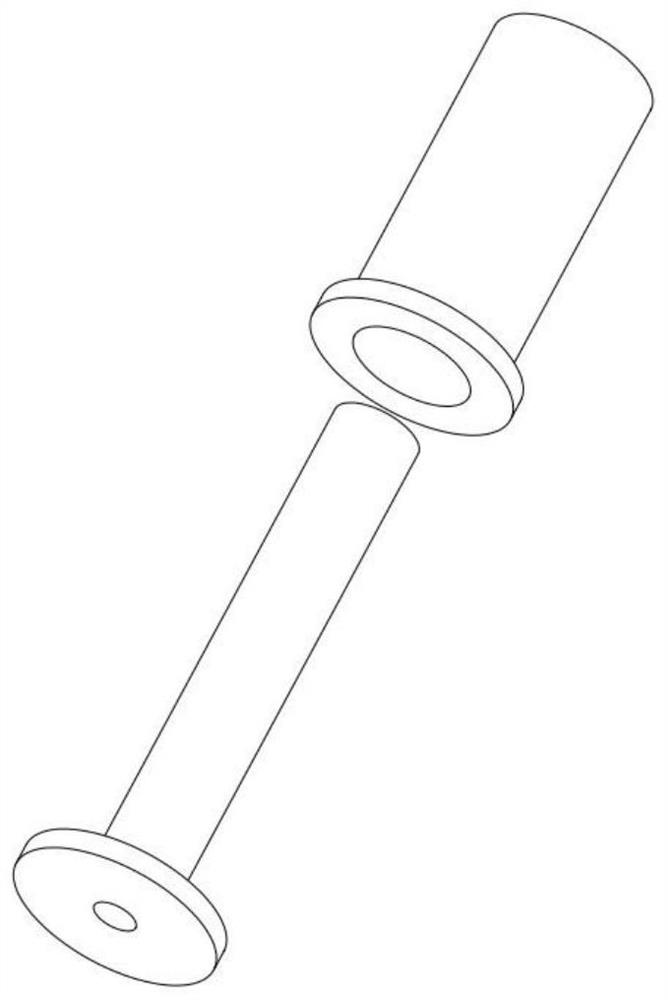

[0028] In this embodiment, the cylinder block 3 is a hollow cylinder with two air chambers 31 in the center. The two air chambers 31 are arranged in layers and are independent of each other. Each air chamber 31 extends outward with a separate air chamber channel 4, such as image 3 The coarse and fine air chamber channels 4 are shown, and the fine air chamber channels run through the coarse air chamber channels, so as to realize the same-direction airflow input. The air cavity channel 4 has a T-shaped structure, and the center of the cylinder block 3 is provided with a slot 35 for clamping the T-shaped structure of the air cavity channel 4, and at the same time, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com