Packaging film texture collection method

A collection method and packaging film technology, applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of poor practicability, complicated operation, high manufacturing cost, etc., to improve the level of counterfeiting and anti-counterfeiting, and to identify accurately , the effect of flexible replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

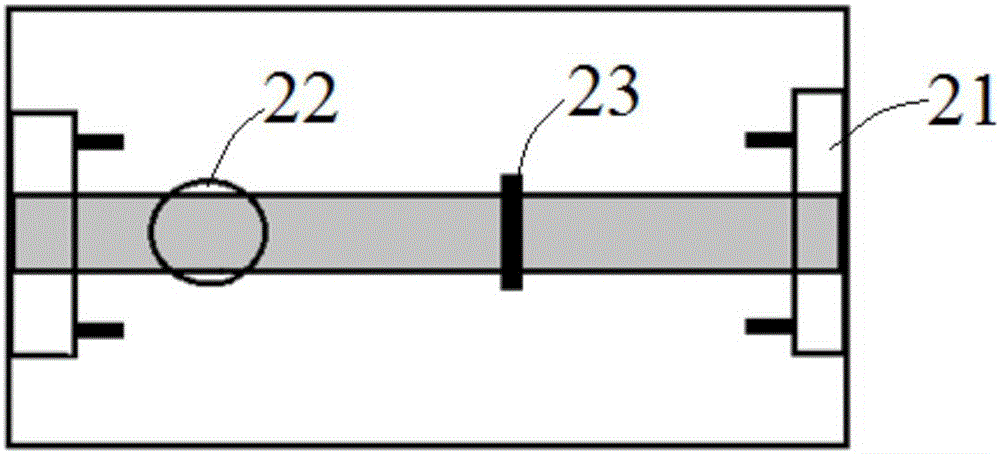

[0047] combine figure 2 , a packaging film texture acquisition device in this embodiment mainly includes a control mechanism 21 for the object to be measured, a camera 22 and a lighting mechanism 23, and the camera 22 and the lighting mechanism 23 are arranged on the upper part of the control mechanism 21 for the object to be measured . in:

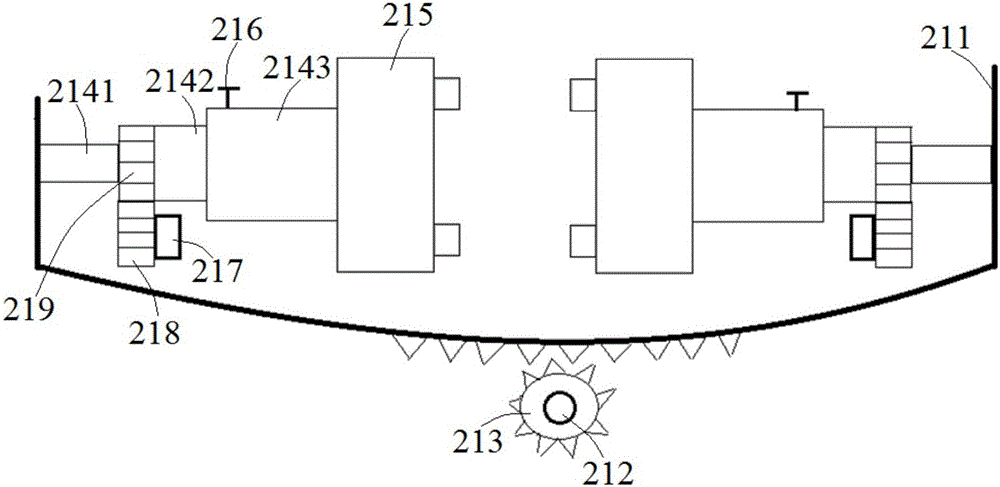

[0048] combine image 3 , the object to be measured control mechanism 21 is used to fix the object to be measured, and realize the translation and multi-angle rotation of the object to be measured, which includes a tray 211, the bottom of the tray 211 is provided with meshing teeth, the meshing teeth and the first driving shaft 213 Matched, the first driving shaft 213 is controlled by the first stepping motor 212; the two sides of the tray 211 are symmetrically provided with fixed components, and the fixed components include a primary connecting rod 2141, a secondary connecting rod 2142, a tertiary connecting rod 2143, fixed part 215,...

Embodiment 2

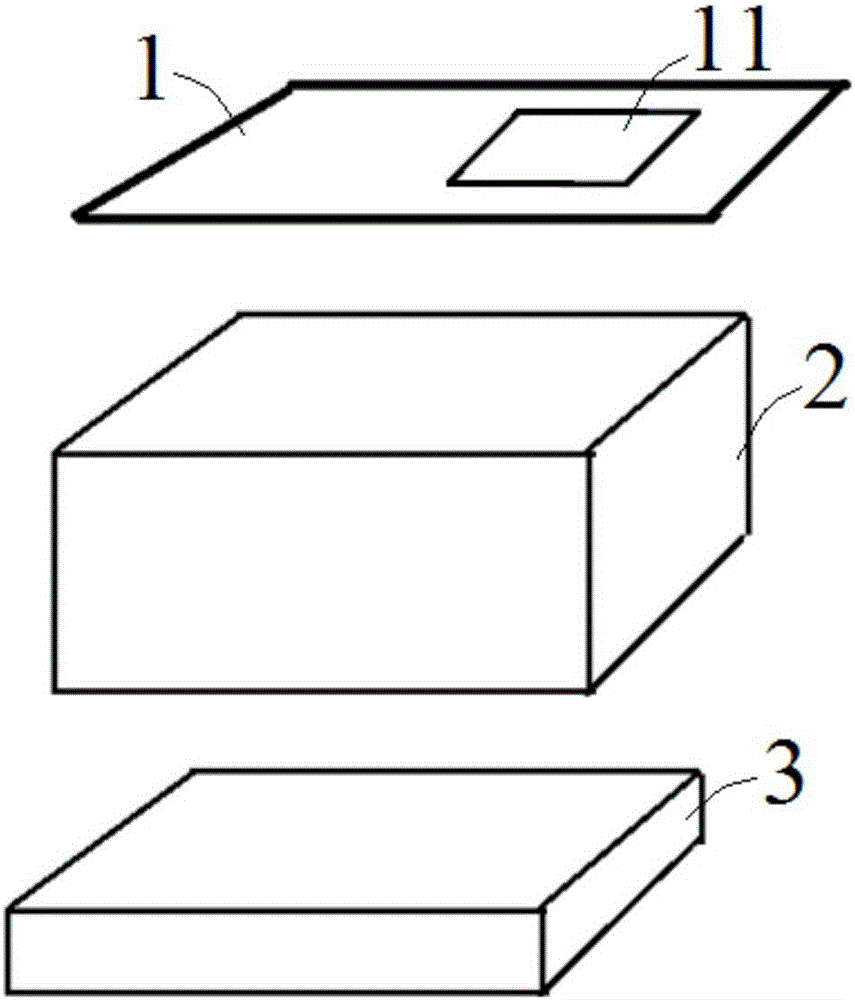

[0056] combine figure 1 , a packaging film texture acquisition device in this embodiment is basically the same as in Embodiment 1, except that the texture acquisition device in this embodiment adopts a box structure, and the box body adopts a multi-layer design, including an operation layer 1, The control layer 2 and the interface layer 3, the control mechanism 21 of the object to be measured, the camera mechanism 22 and the lighting mechanism 23 are all arranged in the control layer 2, the operation layer 1, the control layer 2 and the interface layer 3 are independent of each other, assembled into a box body. This embodiment adopts a multi-layer design, and each layer is independent of each other, mainly to facilitate the carrying and assembly of the collection device during actual use, and secondly, it is also convenient for flexible replacement when any layer is damaged or has special use requirements. Function can also be further expanded.

[0057] The upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com