Patents

Literature

111results about How to "Do not change frequently" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorescence intensity ratio temperature measurement method based on fluorescence spectral line broadening mechanism

InactiveCN105300555AShort wavelengthImprove anti-interference abilityThermometers using physical/chemical changesPhysicsTemperature measurement

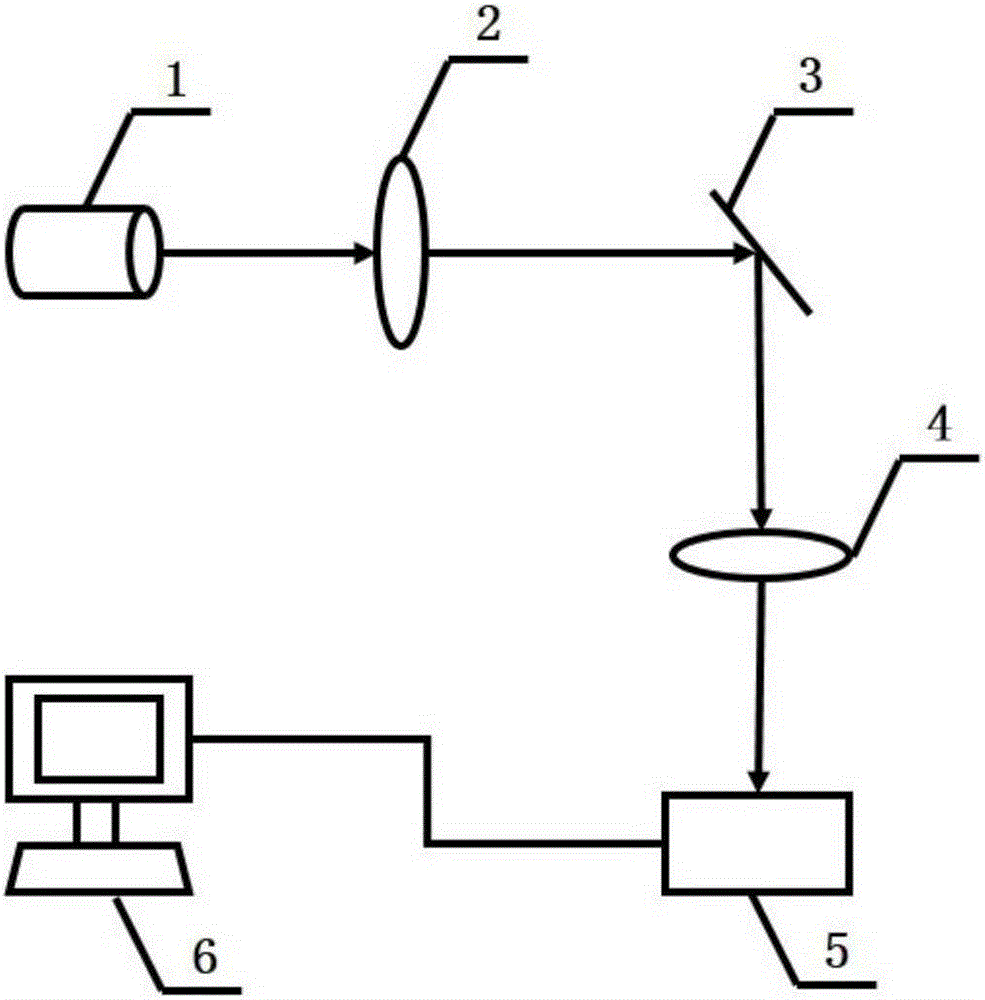

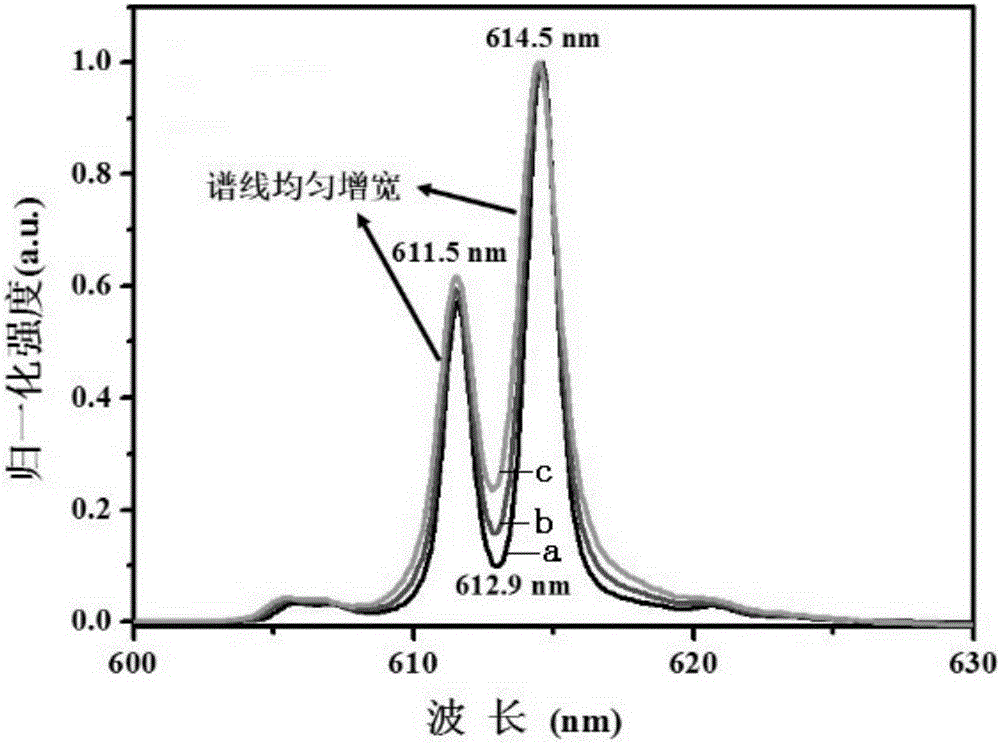

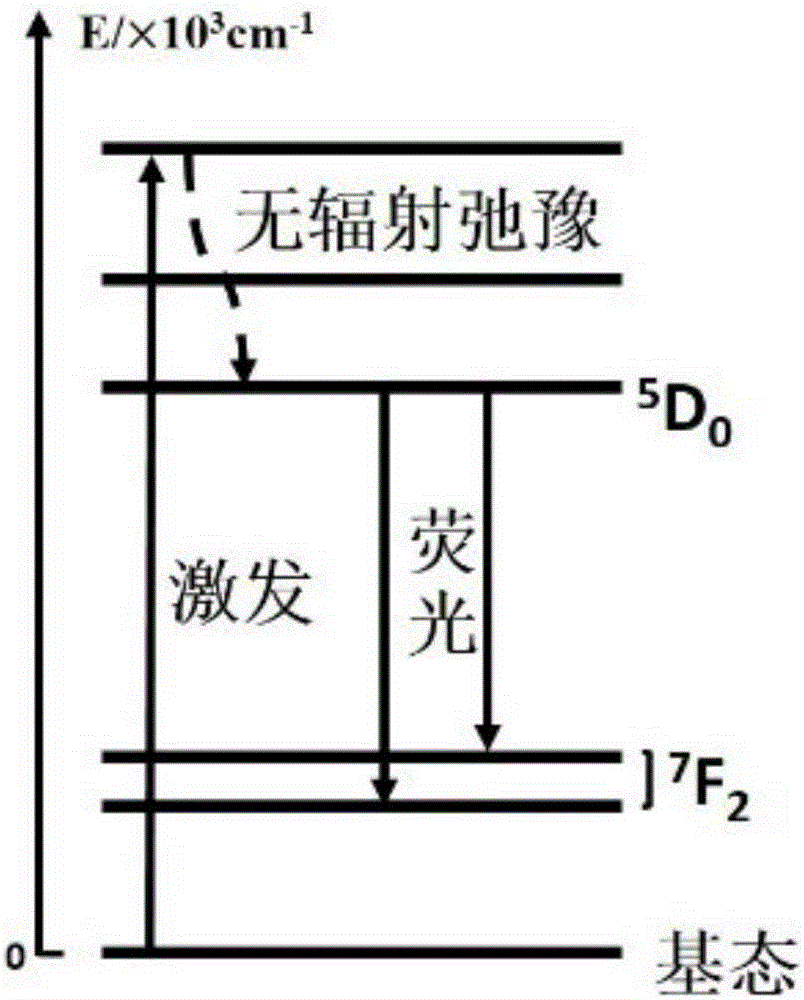

The invention discloses a fluorescence intensity ratio temperature measurement method based on fluorescence spectral line broadening mechanism. The invention solves the problems of low temperature measurement sensitivity and low temperature measurement accuracy in existing intensity ratio temperature measurement technology, and the method comprises the following steps: the near ultraviolet emitted by a 405nm LED passes through a convex lens and is gathered and irradiated on an Eu3+ doped temperature-sensitive material; the fluorescence emitted by the Eu3+ doped temperature-sensitive material is gathered through a convex lens and is incidented into an imaging spectrometer; the spectrometer is connected to a computer for data processing; a valley peak value fluorescence intensity ratio temperature curve is established; calibration is conducted; then the Eu3+ doped temperature-sensitive material is put in a temperature field to be measured; and the fluorescence emitted by the temperature-sensitive material is monitored and is compared with the valley peak value fluorescence intensity ratio temperature curve. Within a wide temperature scope, the sensitivity is appropriate; the temperature measurement scope is wide; and the temperature-sensitive material won't be replaced frequently. The method can be applied in rare earth fluorescence temperature measurement field.

Owner:HARBIN INST OF TECH

Process method for producing zirconium tetrachloride through fluidizing chlorination method

ActiveCN104058454AReduce manufacturing costDo not change frequentlyChemical industryZirconium halidesTetrachlorideSilicon tetrachloride

The invention relates to a process method for producing zirconium tetrachloride through a fluidizing chlorination method. The process method comprises the following steps: smashing zircon sand to 300-325 meshes, smashing petroleum coke to 100-200 meshes, smashing chemical heat supplementing agent to 200-400 meshes, firstly fully mixing the zircon sand and the petroleum coke powder, simultaneously adding the mixture and the heat supplementing agent into a fluidizing chlorination furnace, introducing chlorine to carry out chlorination reaction and keeping the temperature of the fluidizing chlorination furnace at 1100 DEG C, wherein the chemical heat supplementing agent is silica powder or silicon carbide or a mixture of the silica powder and the silicon carbide; the reaction formula of the chemical heat supplementing agent is SiC+2Cl2=SiCl4+C or Si+2Cl2=SiCl4; the main reaction formula of producing the zirconium tetrachloride through zircon sand chlorination is ZrSiO4+4C+4Cl2=ZrCl4+SiCl4+4CO. According to the method disclosed by the invention, the heating problem of a zircon sand fluidizing chlorination furnace can be solved, the production cost of the zirconium tetrachloride is reduced and a byproduct: an important chemical raw material silicon tetrachloride can be produced, so that the process method has the advantages of increasing the working efficiency, saving the energy and reducing the production cost.

Owner:内蒙古自治区浩森新材料开发有限公司

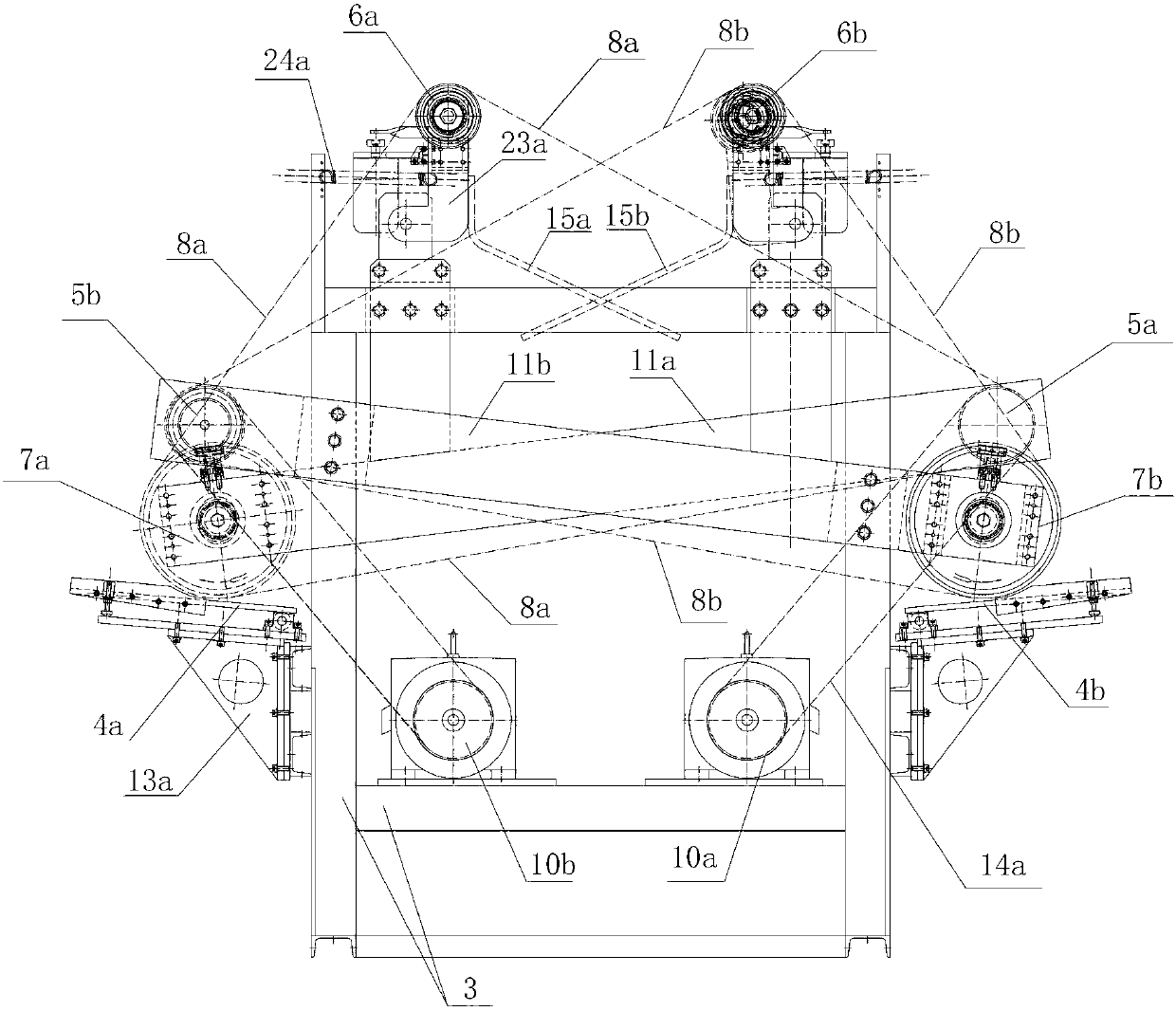

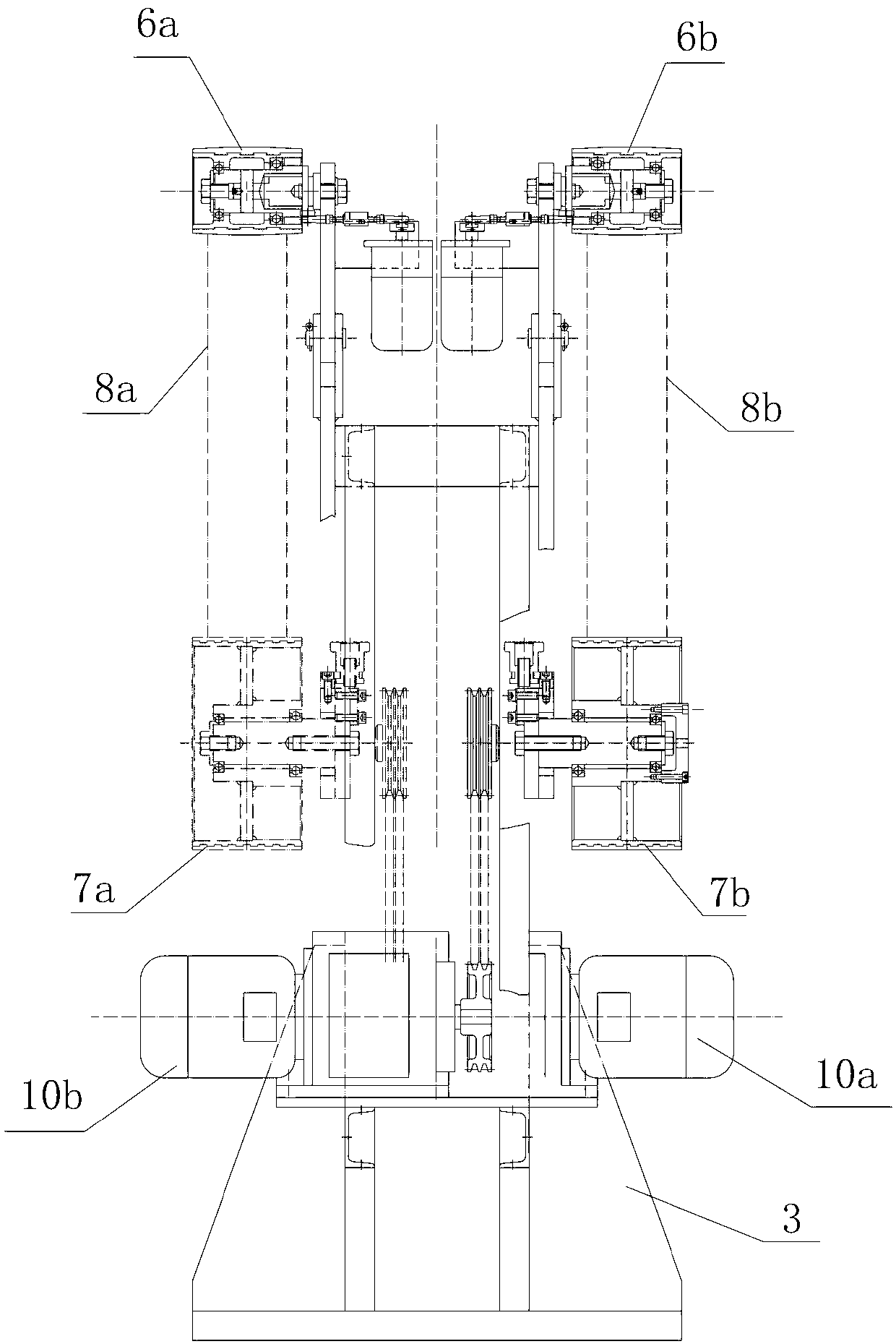

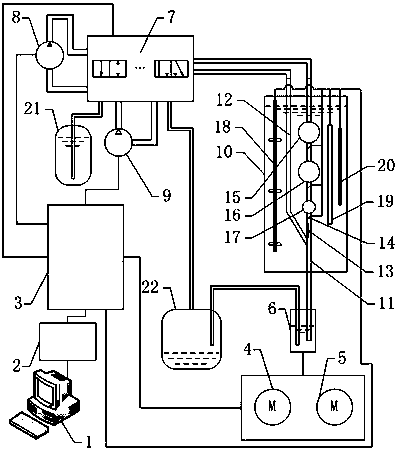

System and method for detecting cracks of fasteners of high-speed rails and subways

InactiveCN103010258AGuaranteed continuityGet clear images fastRailway auxillary equipmentRailway profile gaugesEngineeringRail infrastructure

The invention relates to equipment in the field of detection for railway foundation facilities, in particular to a system and a method for detecting cracks of fasteners of high-speed rails and subways. The system and the method for detecting the cracks of the fasteners of the high-speed rails and the subways aim to overcome the shortcoming that an existing fastener technology only can be used for detecting absence and looseness of fasteners but cannot be used for detecting whether the fasteners have cracks or not. The system and the method can be used for quickly detecting absence, partial damage and absence and the cracks of the fasteners of the high-speed rails and the subways in an online manner, and have the advantages of high identification speed, high detailed information embodiment effect, capability of precisely shooting the cracks, and the like. Images are respectively triggered and acquired bilaterally by utilizing the characteristic that the existing fasteners of the high-speed rails and the subways are bilaterally symmetrically mounted along the rails, and in other words, a right image acquisition system can acquire an image of a right fastener while a left photoelectric trigger is triggered by a left fastener of a rail.

Owner:KUNMING JULIN TECH

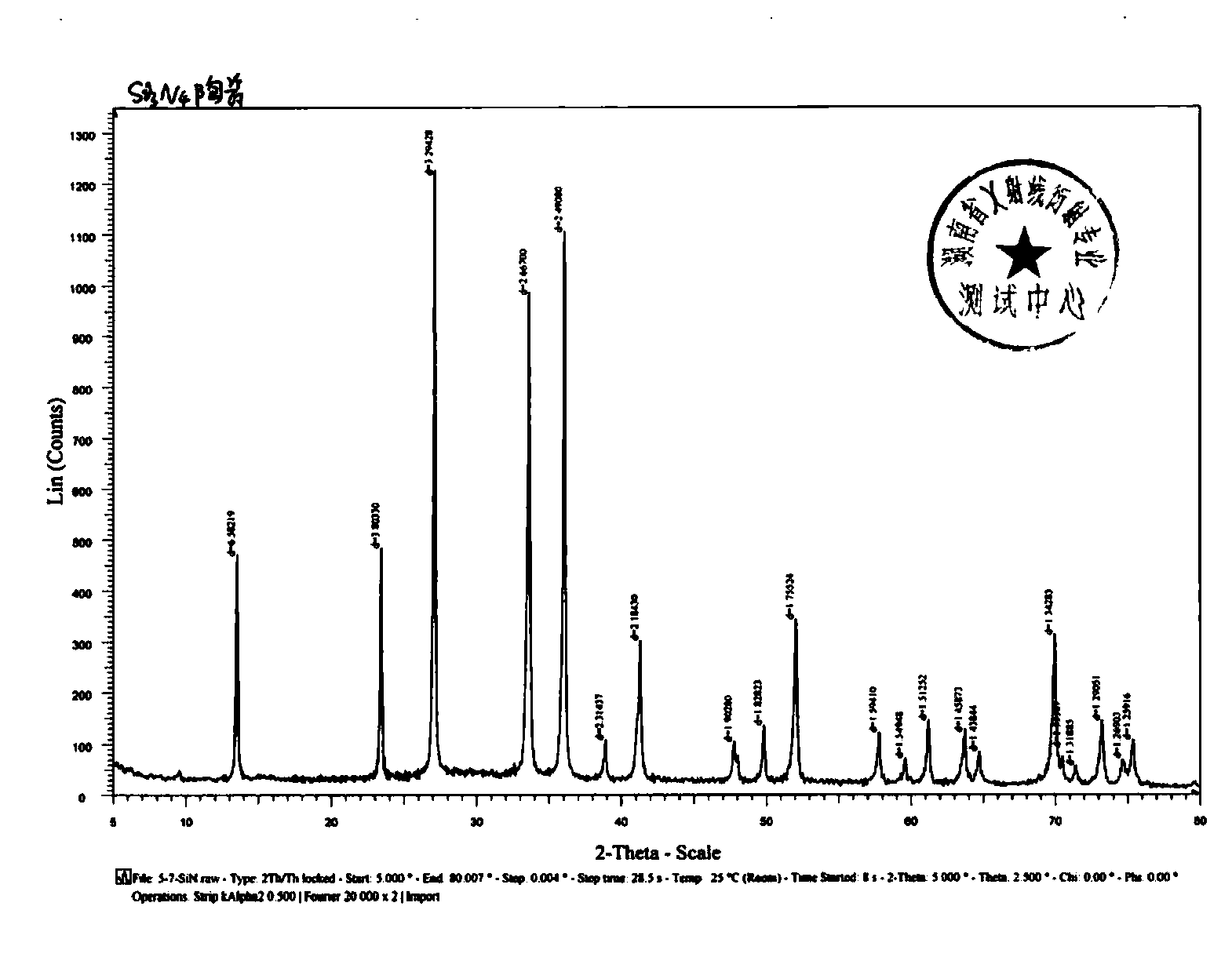

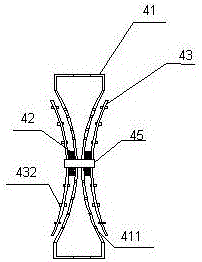

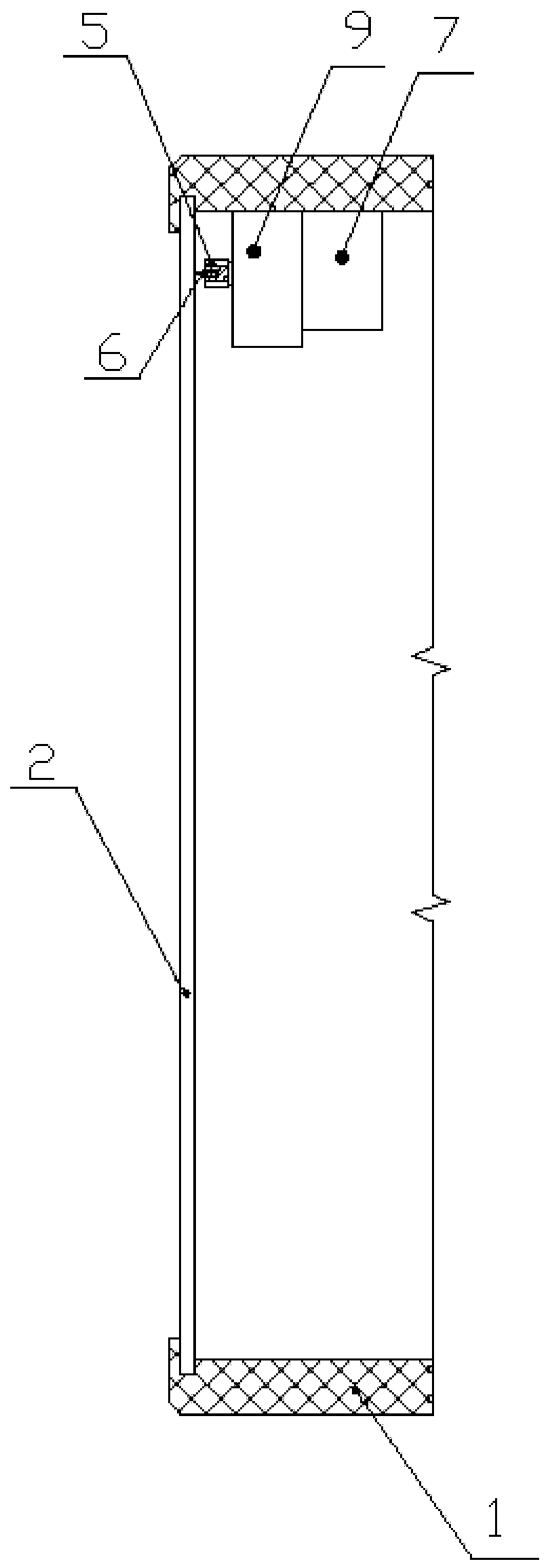

Microwave sintering preparation method of high purity silicon nitride ceramic lift tube for low-pressure casting

The invention discloses a microwave sintering preparation method of a high purity silicon nitride ceramic lift tube for low-pressure casting. The preparation method comprises the following steps: placing silicon nitride powder and an additive in a ball milling machine, carrying out wet method ball milling to obtain material slurry, drying and granulating the slurry, placing the granules into a mould, pressing, and forming so as to obtain a lift tube blank; and placing the blank into a sintering cavity to carry out microwave sintering so as to obtain the high purity silicon nitride ceramic lift tube; wherein the sintering cavity is prepared by overlapping corundum and mullite round tubes and graphite round tubes, and the upper opening and the lower opening of the sintering cavity are both provided with a graphite round plate. The preparation method utilizes the special wave bands of microwaves to couple the silicon nitride composite material to generate heats, the material is consumed to heat the composite material as a whole, the optimized microwave sintered structure is matched with the structural characteristics of high purity silicon nitride ceramic lift tube, and thus the utilization rate and efficiency of microwaves is maximized. The preparation method has the advantages of good sintering quality, high yield rate, low sintering temperature, short sintering time, and low sintering energy consumption.

Owner:HENGYANG KAIXIN SPECIAL MATERIAL TECH CO LTD

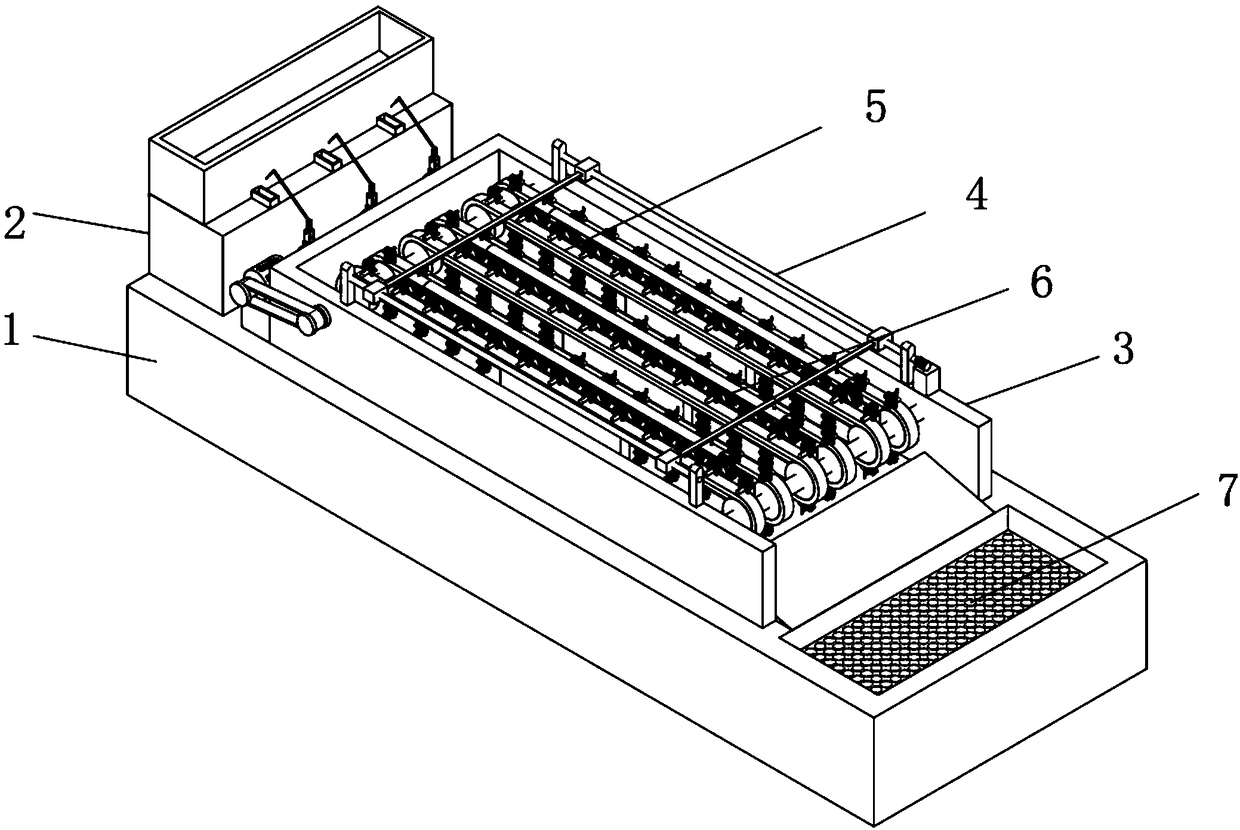

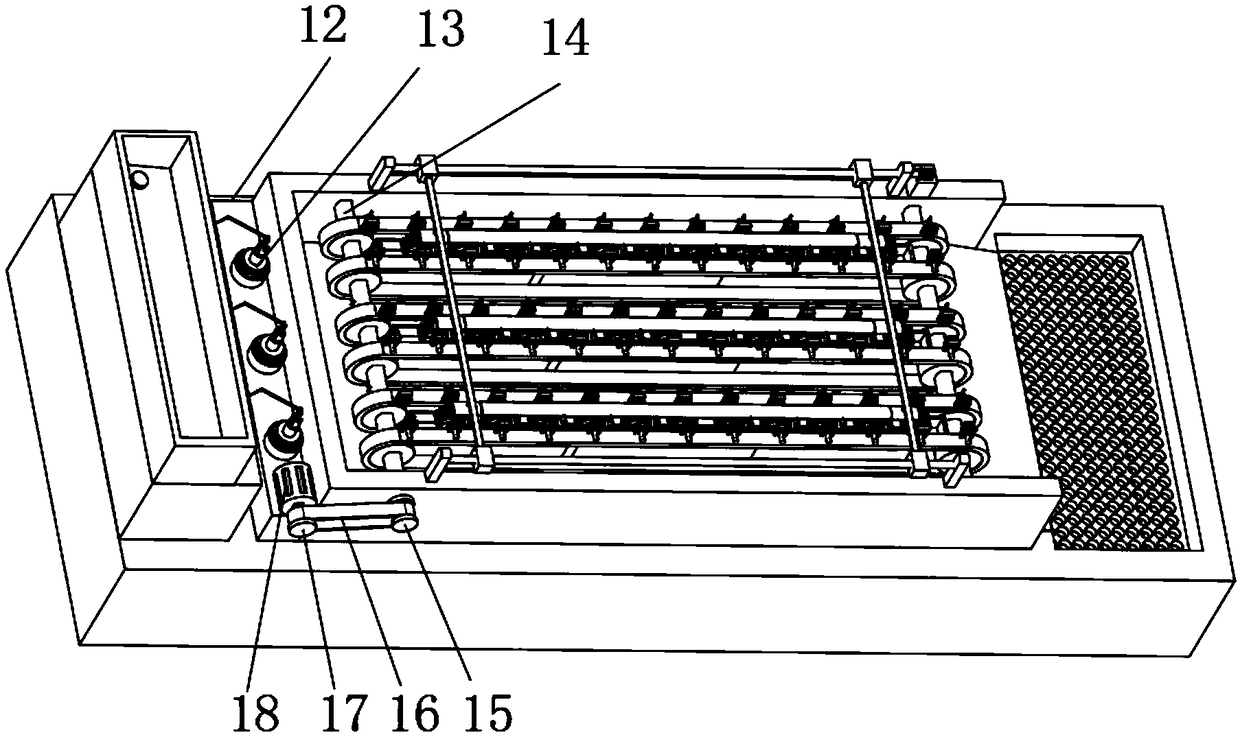

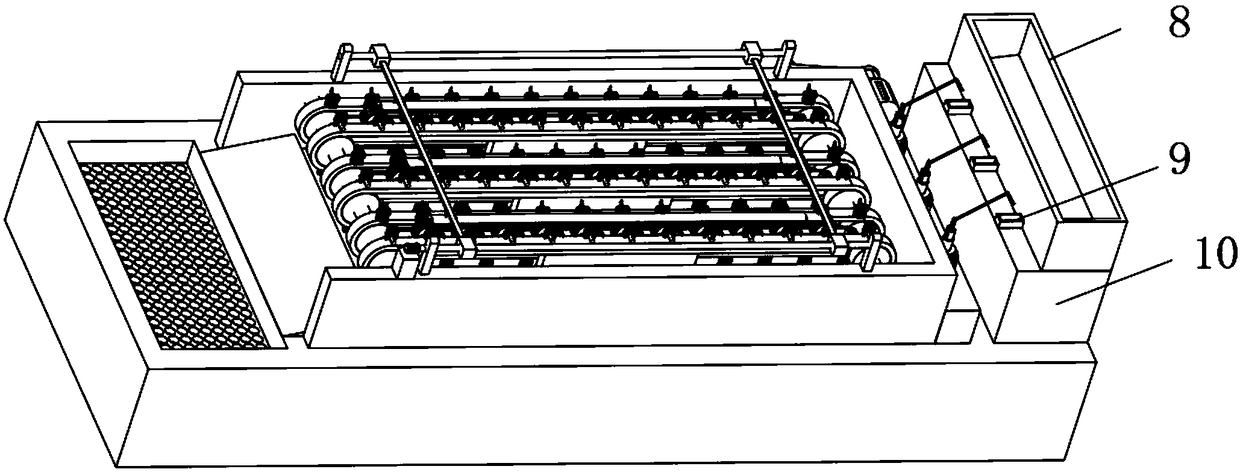

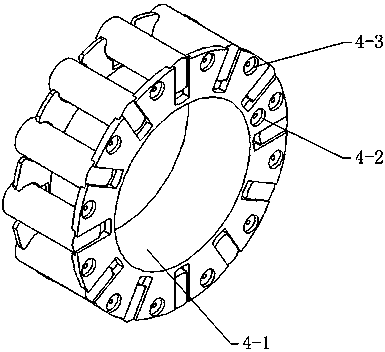

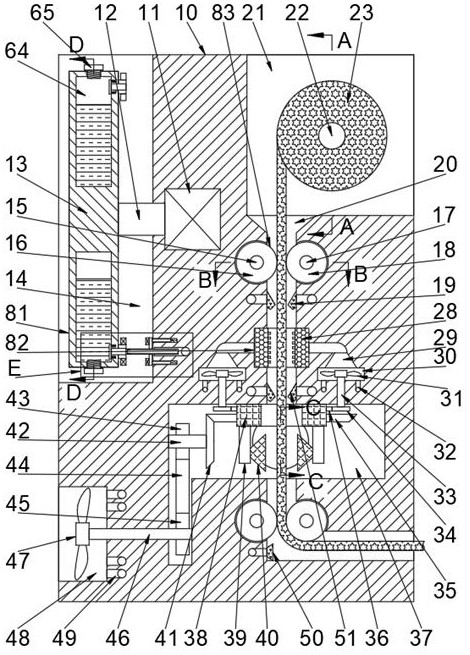

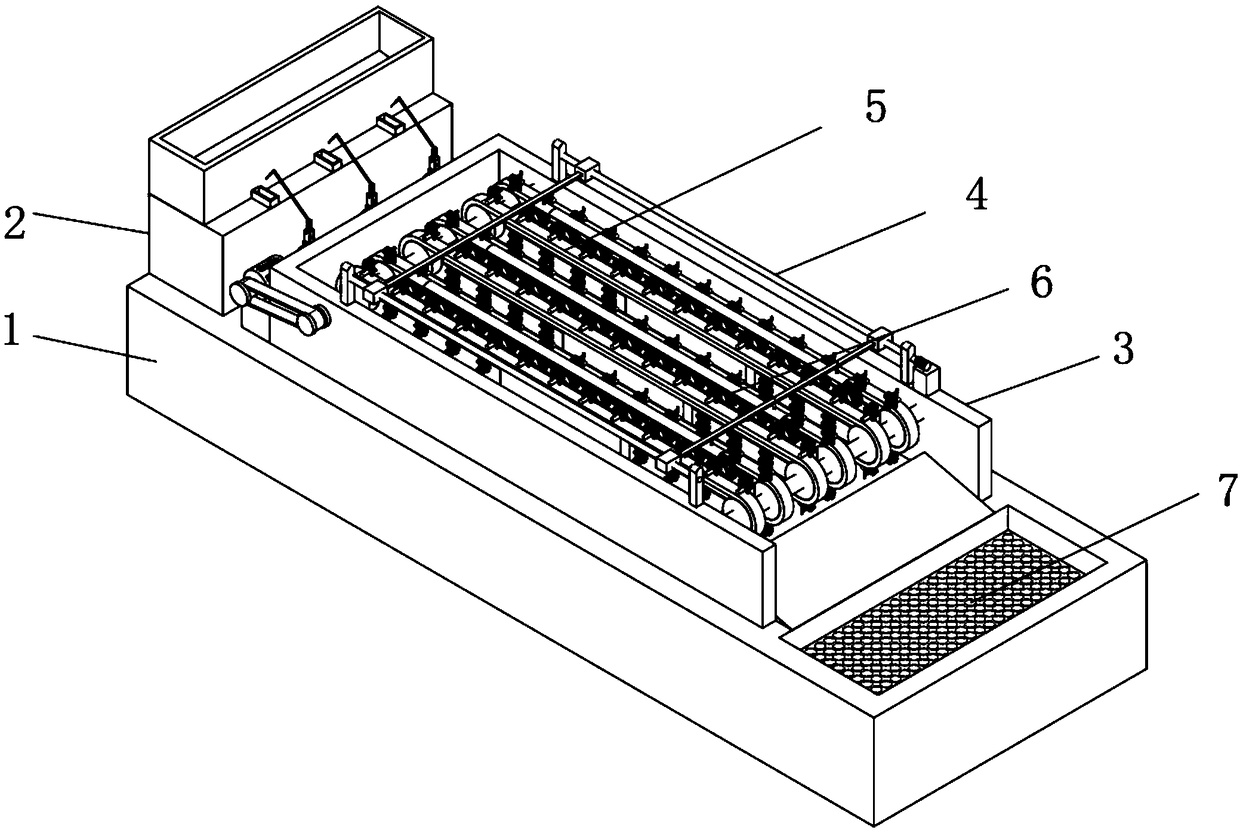

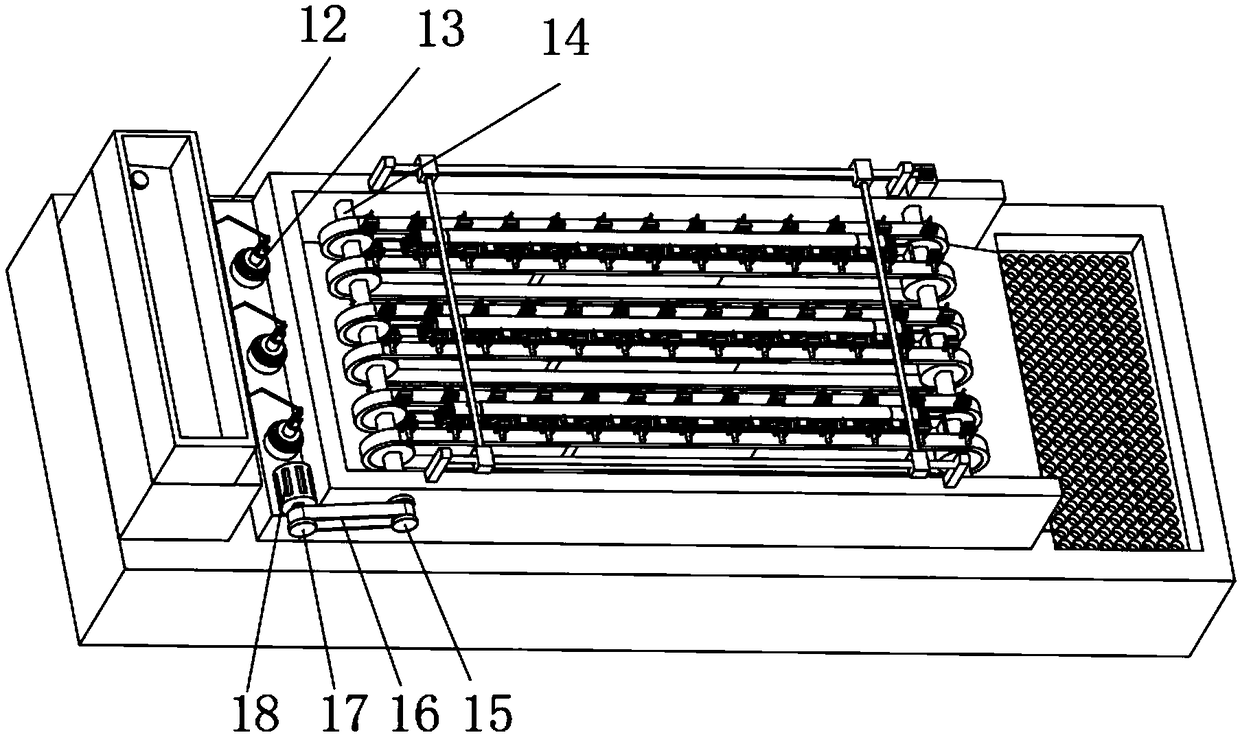

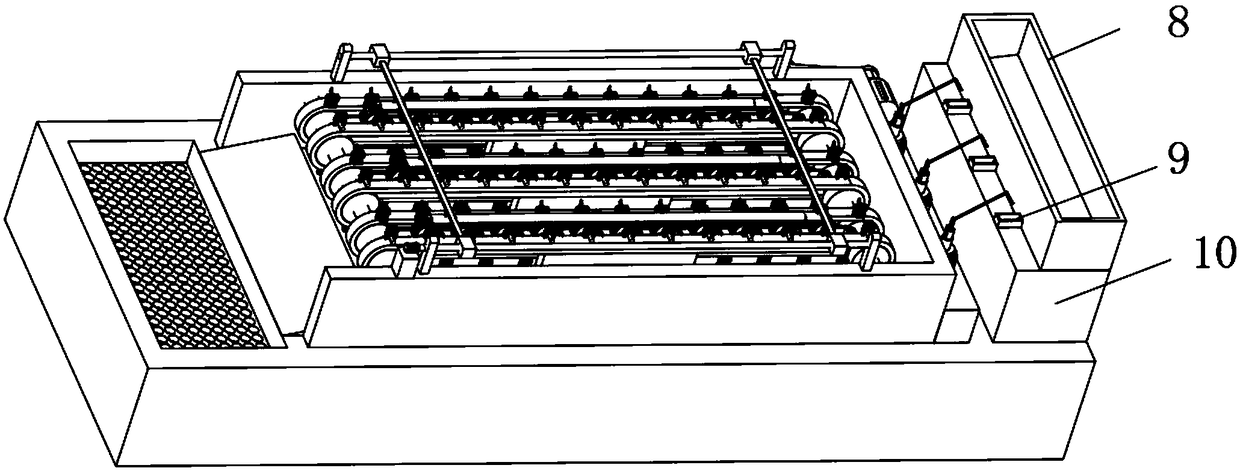

High-efficiency lobster washing device for food processing

ActiveCN109169817AIncrease productivityAccurate grippingShrimp/lobster processingEngineeringMechanical engineering

The present invention discloses a high-efficiency lobster washing device for food processing. The high-efficiency lobster washing device for food processing comprises a base, a rinsing device, a box body, a back rubbing device, conveying and clamping devices, abdomen washing devices and a draining device. One side of the top part of the base is fixedly provided with the rinsing device; one side ofthe rinsing device is provided with the box body; the box body is fixedly connected with the base; besides, the box body is equidistantly provided with the three conveying and clamping devices; besides, the lower part of each conveying and clamping device is correspondingly provided with the corresponding abdomen washing device; the upper sides of the conveying and clamping devices are provided with the back rubbing device; and besides, the back rubbing device is fixed on the top part of the box body. The high-efficiency lobster washing device for food processing solves problems that traditional manual brushing efficiency is low and the existing machine washing is not clean, and is high in washing efficiency, good in washing effects and also environmentally friendly and hygienic.

Owner:赵春华

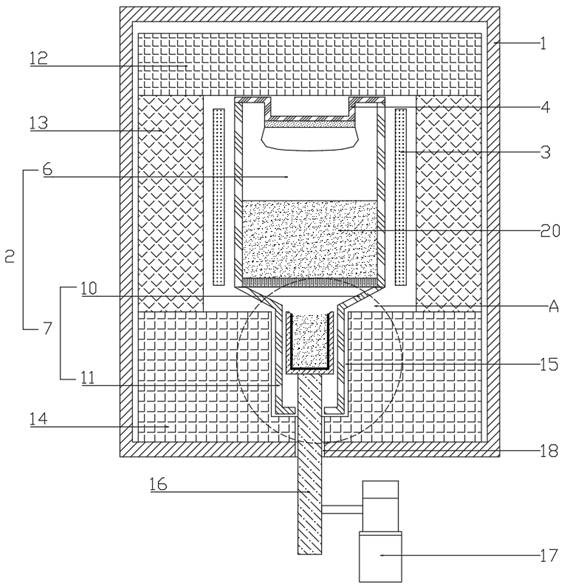

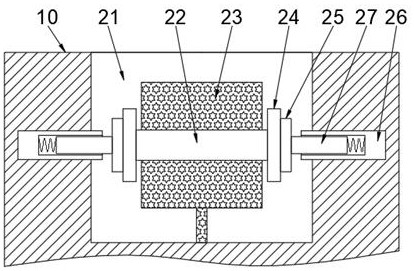

Silicon carbide crystal growth method and equipment capable of adjusting component balance

ActiveCN113249792AAvoid spiral misalignmentAvoid faultsPolycrystalline material growthFrom condensed vaporsCarbide siliconCrystal growth

The invention provides a silicon carbide crystal growth method and equipment capable of adjusting component balance, the equipment comprises a cavity, a graphite crucible, a heater and a growth tank, the graphite crucible and the heater are fixed in the cavity, a porous partition plate is horizontally arranged in the graphite crucible, the porous partition plate divides the graphite crucible into a crystal growth cavity and an auxiliary cavity, a silicon carbide raw material is contained in the crystal growth cavity, an auxiliary crucible is movably connected in the auxiliary cavity through a lifting assembly, and a silicon-rich raw material is contained in the auxiliary crucible; and the heater is used for uniformly heating the crystal growth cavity. The equipment comprises the graphite crucible and the auxiliary crucible adjusted by the lifting assembly, and along with continuous growth of crystals, the height of the auxiliary crucible is adjusted by the lifting assembly, so that silicon elements are supplemented into a silicon carbide raw material in the crystal growth process, and the balance of carbon components and silicon components in the silicon carbide raw material is adjusted; and the defects such as spiral dislocation, dislocation and microtubulation of silicon carbide crystals are avoided, and meanwhile the utilization rate of silicon carbide raw materials is increased.

Owner:SUZHOU UKING PHOTOELECTRIC TECH CO LTD

Novel chamber type pressure filter

InactiveCN105944418ADo not change frequentlyAvoid deformationFiltration separationFilter cakeAerospace engineering

The invention relates to a novel chamber type pressure filter. The novel chamber type pressure filter comprises a bracket, two cross beams, a thrust plate, a filtering unit, compressing devices and a feeding pump, wherein the two cross beams are arranged on the bracket and parallel to each other; the front end and the rear end of the thrust plate are fixedly arranged in the middle parts of the two cross beams; a feeding opening is formed in the bottom part of the thrust plate, and discharging openings are formed in the left sidewall and the right sidewall of the thrust plate; the feeding pump is connected with the feeding opening of the thrust plate; a plurality of filtering units are correspondingly arranged at the left side and the right side of the thrust plate, and the filtering units are parallel to the thrust plate and connected through pulling rod devices; the compressing devices, which can push the filtering unit to horizontally move on the cross beams, are arranged at the left end and the right end of the bracket. The novel chamber type pressure filter has the beneficial effects that the structure is simple, the extruding dewatering capacity is high, a filter cloth is prevented from being frequently replaced, a filtering plate is low in possibility of being deformed, and a filter cake can be conveniently discharged; the labor cost and the repair cost can be effectively decreased, and the working efficiency can be improved.

Owner:苏州志英明建信息科技有限公司

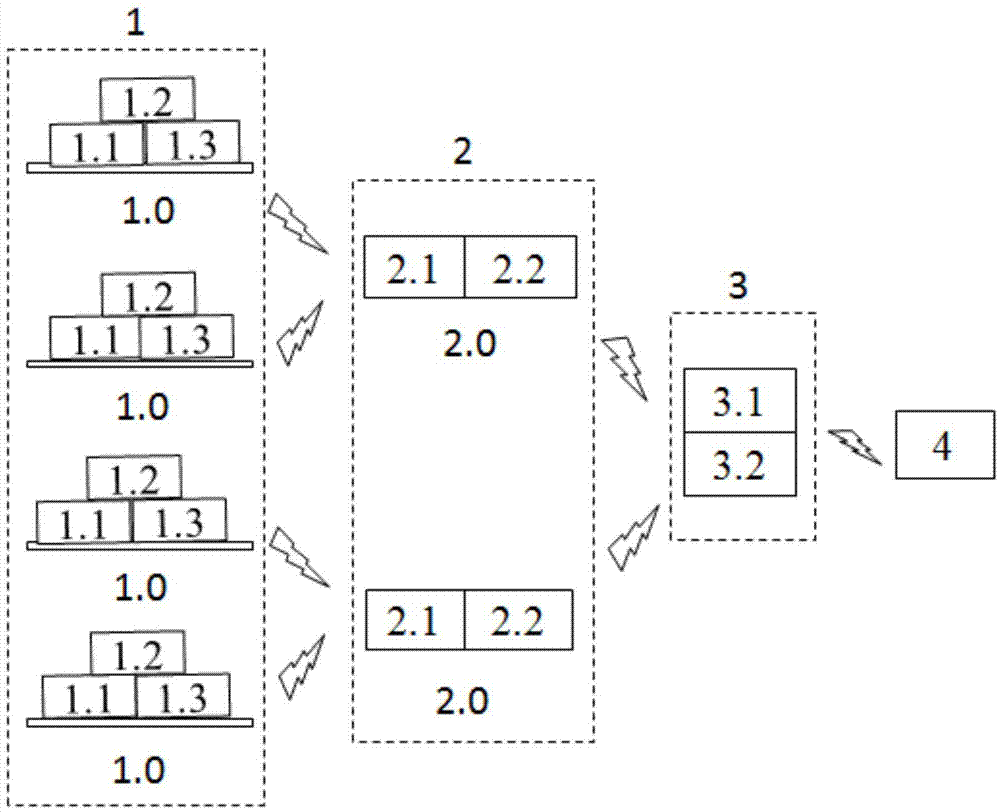

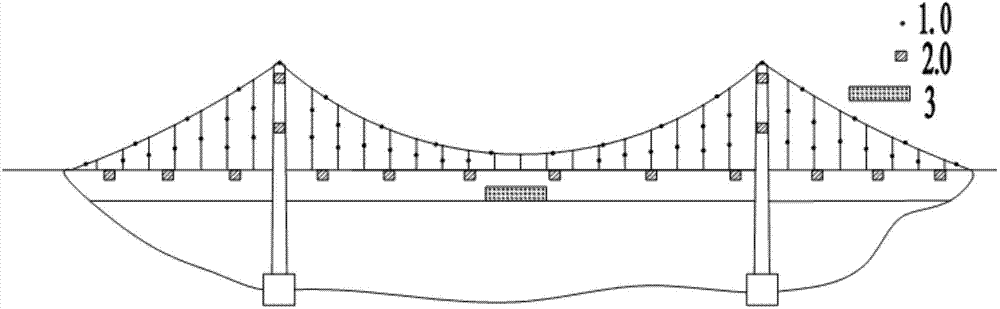

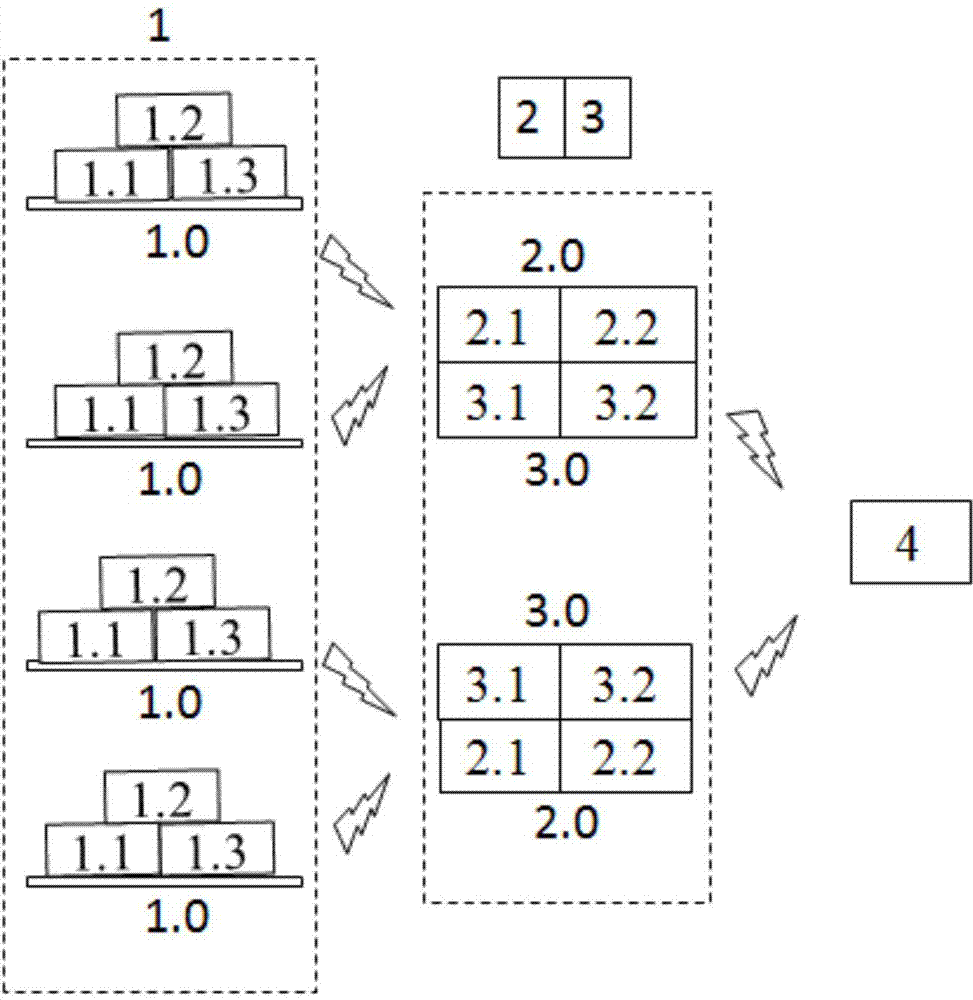

Comprehensive monitoring system and method of suspension bridge cable safety

ActiveCN104777815AImprove monitoring accuracyLow costTotal factory controlProgramme control in sequence/logic controllersMicrocontrollerData information

The invention discloses a remote monitoring system and method of suspension bridge cable state. The monitoring system comprises a sensor detection unit, wherein the sensor detection unit consists of a plurality of sensor detection subunits; each sensor detection subunit consists of a sensor, a microcontroller I and a radio frequency tag, detects a parameter of cable safety state, and transmits the parameter to a radio frequency read / write unit in a radio frequency manner; the radio frequency read / write unit consists of a plurality of radio frequency read / write subunits; each radio frequency read / write subunit consists of a radio frequency read / write device and a microcontroller II, reads data information of the radio frequency tag and transfers the data information to a wireless transmitting unit; the wireless transmitting unit comprises a wireless transmitter and a microcontroller III, receives the data information transferred by the radio frequency read / write device and transmits the data information to a remote control terminal; the remote control terminal receives and analyzes the data information transmitted by the wireless transmitter of the wireless transmitting unit and performs comprehensive assessment on the safety state of each position of the cable. According to the invention, the system can remotely monitor the safety state of the cable of a suspension bridge and is high in precision and low in cost.

Owner:成都申开科技有限公司

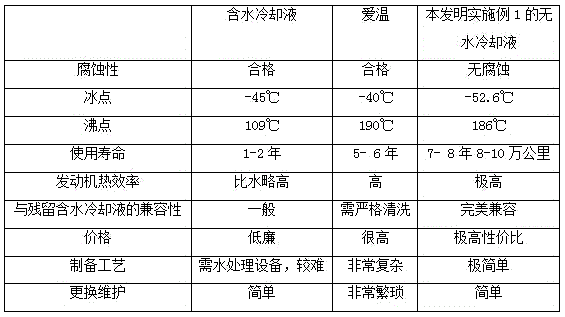

Anhydrous coolant and preparation method thereof

InactiveCN105524598AImprove anti-corrosion performancePrevent accidental ingestionHeat-exchange elementsBittering AgentsNoise reduction

The invention discloses an anhydrous coolant and a preparation method thereof. The anhydrous coolant comprises raw materials in parts by weight as follows: 1,000 parts of propylene glycol, 2.4-2.6 parts of an acidic preservative, 1.5-1.7 parts of borax, 1.4-1.6 parts of sodium nitrite, 1.4-1.6 parts of triethanolamine, 0.2-0.4 parts of benzotriazole, 0.05-0.15 parts of a defoaming agent, 5-7 parts of a bittering agent and 0.009-0.011 parts of a pigment. All components of the anhydrous coolant supplement one another and cooperate with one another to have the synergistic effect, the anhydrous coolant has the excellent performance and the wide adaptability, can be perfectly compatible with a hydrous coolant left during replacement of the coolant, enables an engine cooling system to work in a non-pressure or micro-pressure environment, can play a noise reduction role in an engine and cannot age and damage rubber pipelines in advance, so that usage and maintenance costs are reduced, and the service life of the engine is greatly prolonged. Besides, no water exists, so that propylene glycol cannot be acidic at the high temperature, the service life can be prolonged, frequent replacement is not required, the more environment-friendly effect is realized, and the long-term comprehensive cost performance is particularly high.

Owner:WUWEI LONGHUAWEI IND & TRADE CO LTD

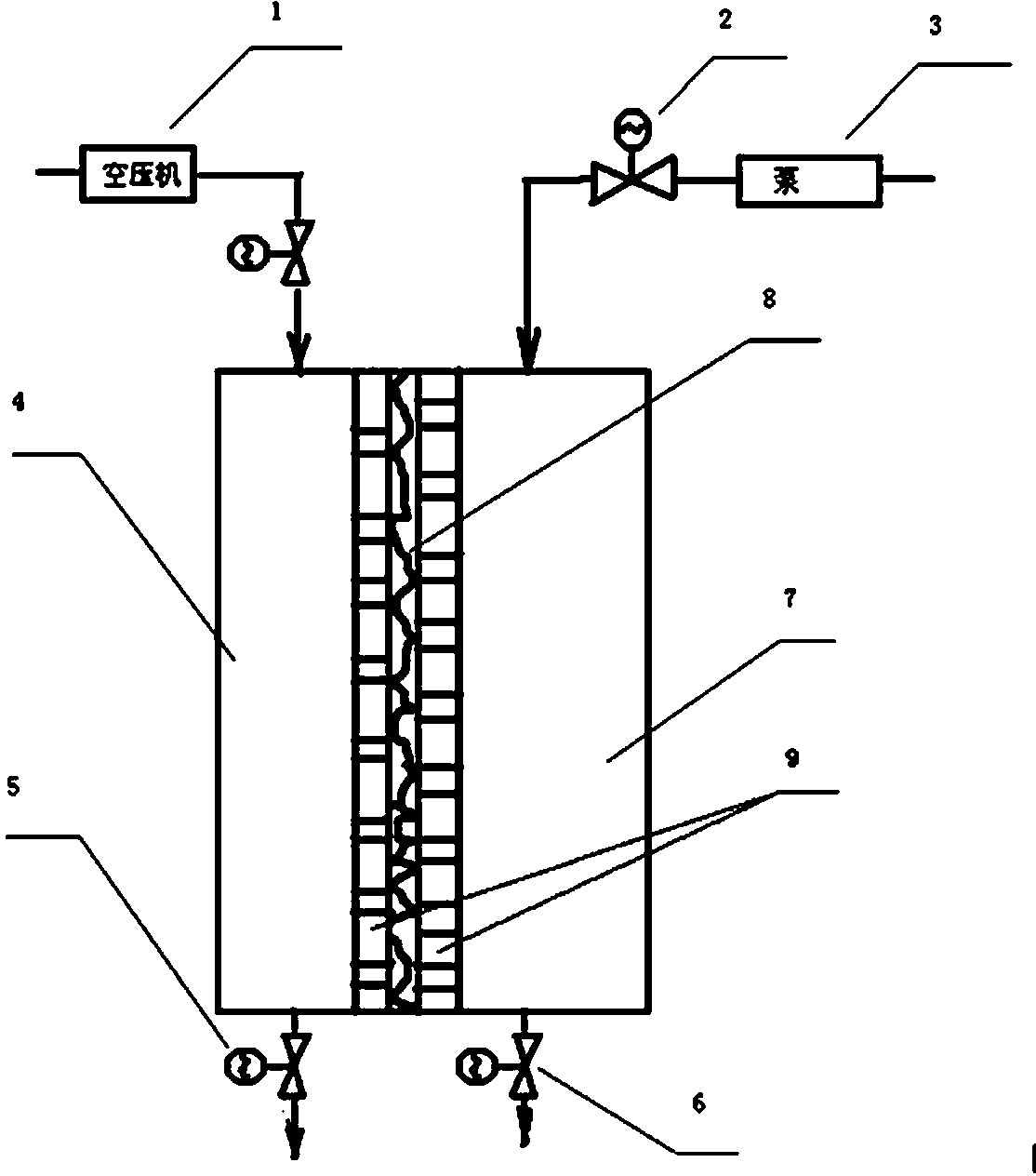

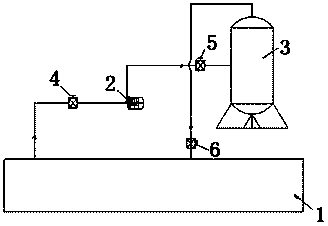

Drilling fluid filtrate separator

InactiveCN105498327AContinuous productionDo not change frequentlyStationary filtering element filtersBiomedical engineeringDrilling fluid

The invention provides a drilling fluid filtrate separator capable of continuously producing drilling fluid filtrate. According to a technical scheme, the drilling fluid filtrate separator comprises a pump, a filtering container, a filter fabric or filter screen and a filter fabric or filter screen support and is characterized in that the filtering container is an enclosed container, the filter fabric or filter screen and the filter fabric or filter screen support are longitudinally arranged at a central position in the filtering container together, the top and bottom of the part, located at a same side as the filter fabric or filter screen support, of the filtering container are respectively provided with a drilling fluid inlet and a drilling fluid outlet, and the top and bottom of the part of the filtering container at the other side are respectively provided with a compressed air inlet and a filtrate outlet. The drilling fluid filtrate separator provided by the invention realizes continuous filtrate preparation from a drilling fluid, overcomes the problem of obstruction of the filter screen at the same time, does not need frequent replacing of the filter screen and is especially applicable to on-site continuous generation of drilling fluid filtrate for drilling engineering to facilitate on-line monitoring of the ion content of the drilling fluid filtrate.

Owner:CHINA PETROCHEMICAL CORP +1

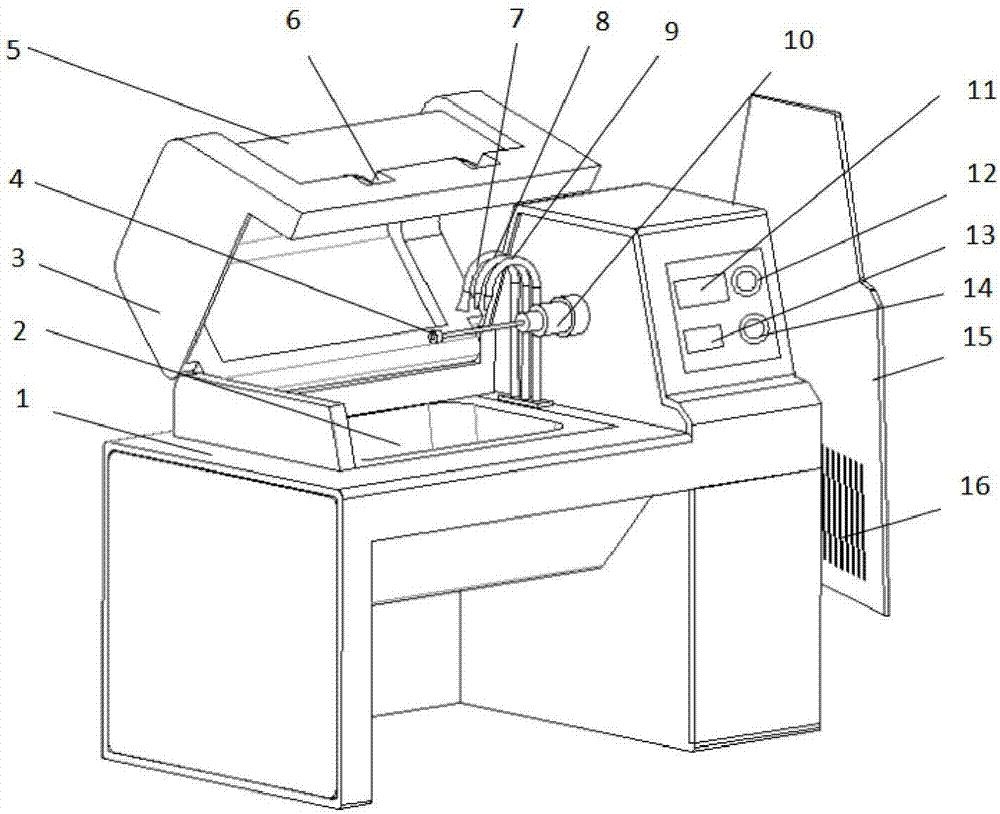

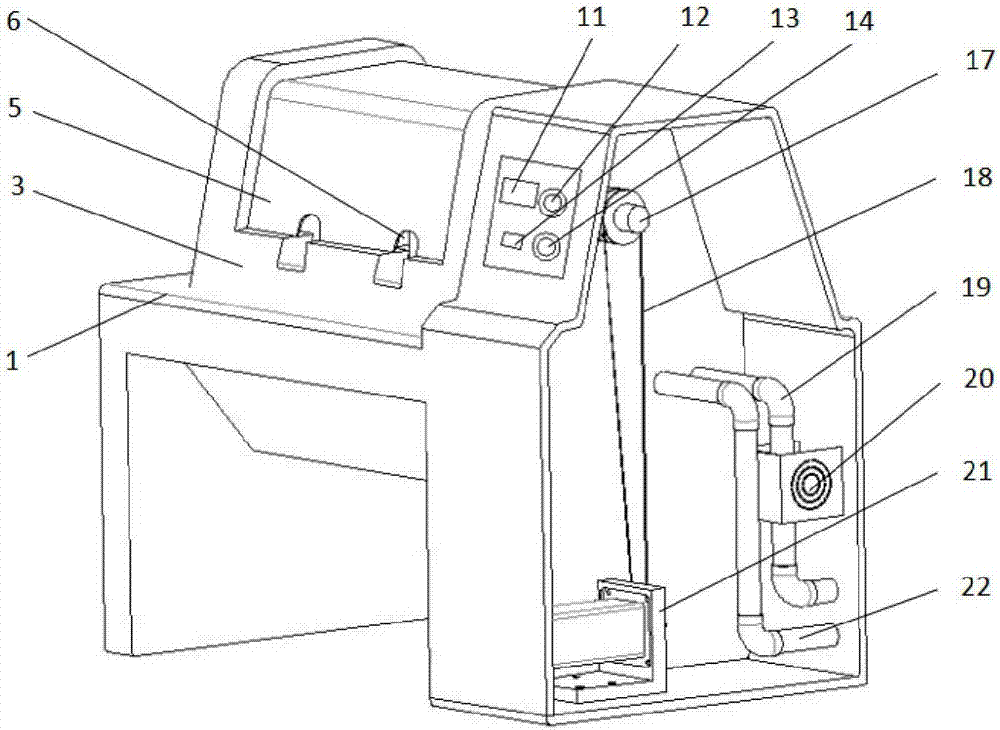

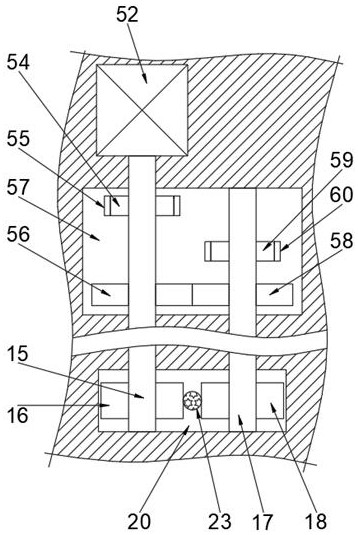

Integrated type one-operator jade machining device and method

InactiveCN106956169AHighly integratedCompact structureLapping machinesGrinding/polishing safety devicesSpray nozzleWorking environment

An integrated type one-operator jade machining device comprises a work tabletop, a protective cover, a grinding device, a power system, an operation lamp, a dust collecting device and a polishing solution spray nozzle. A water trough is formed in the middle of the work tabletop. The operation lamp, the dust collecting device and the polishing solution spray nozzle are arranged on the edge of the water trough. The grinding device is arranged over the water trough. The power system provides power for the grinding device. The protective cover is hinged to the work tabletop. When the integrated type one-operator jade machining device is in the work state, the protective cover covers the work tabletop, and the operation lamp, the dust collecting device, the polishing solution spray nozzle and the grinding device are covered with the protective cover. According to the integrated type one-operator jade machining device, the surface of jade is grinded through cerium oxide grinding particles, jade surface grinding and polishing are achieved, the machining efficiency is high, and the machining quality is good; and because the jade machining area is covered with the protective cover, and on the premise of guaranteeing higher machining efficiency and better machining quality, it is effectively avoided that jade powder and splashed cerium oxide solution pollute the work environment and do harm to workers.

Owner:UNIV OF SCI & TECH LIAONING

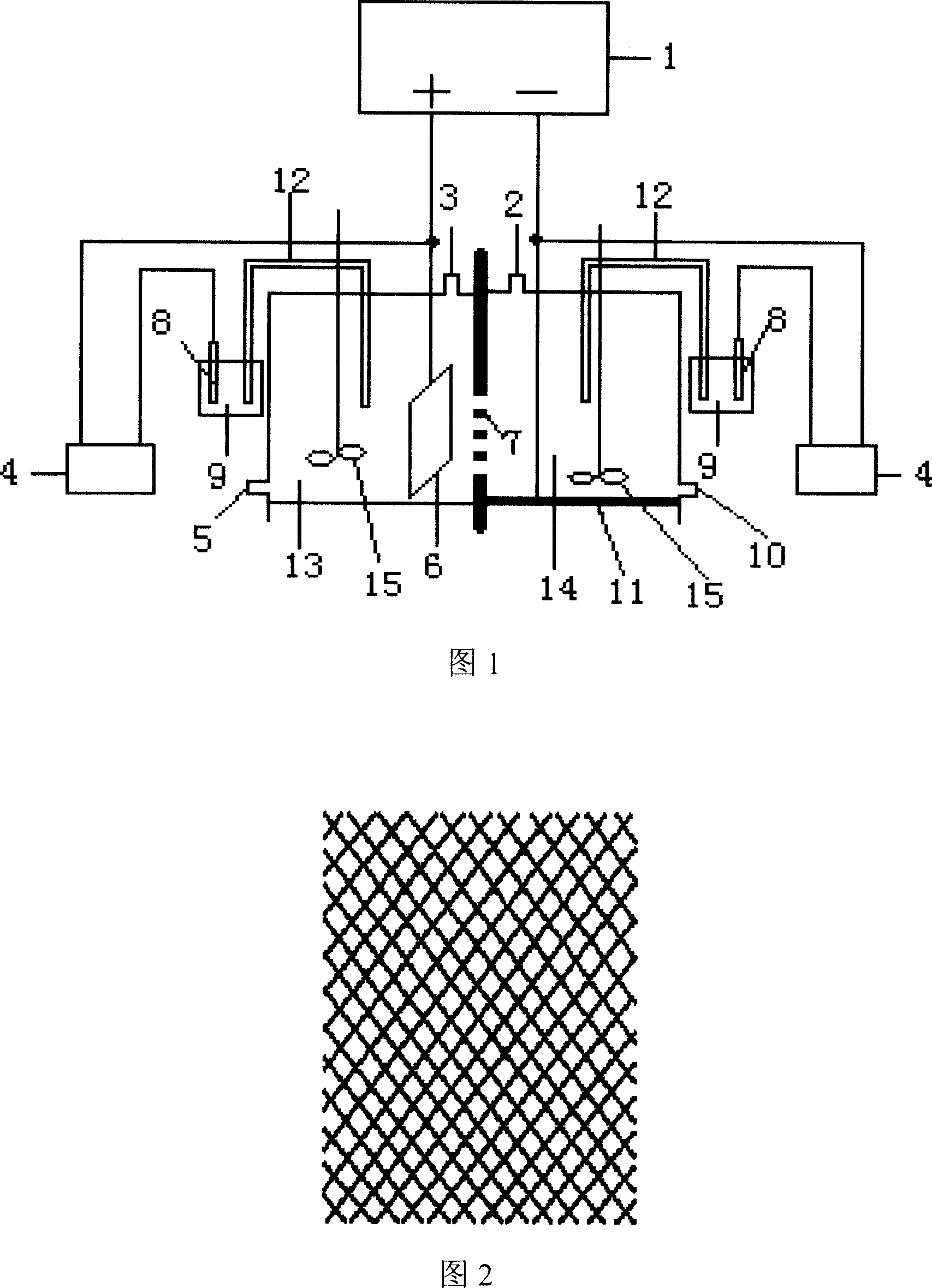

Simultaneous process of electroreducing ytterbium and oxidizing cerium

InactiveCN1986895APrevent volatilizationPrevent dispersalPhotography auxillary processesProcess efficiency improvementCeriumIon-exchange membranes

The present invention is one electrolytic process of reducing Yb, enriching Tu and Lu, and oxidizing Ce simultaneously. The electrolytic process reduces Yb into bivalent Yb ion in the cathode chamber so as to separate out Yb from the enriched Yb, Tu and Lu; oxidizes Ce into four-valent ion so as to separate out Ce. The electrolytic equipment has cathode of metal mercury or amalgam, anode of inert metal, anion exchange membrane to separate the anode chamber from the cathode chamber, cathode solution of sulfuric acid solution of pH 0.1-4.0 with enriched Yb, Tu and Lu, and anode solution of sulfuric acid solution of acidity 0.01-3.0 mol / L with enriched Ce. The present invention has low production cost, best utilization of electrolytic current and other advantages.

Owner:北京方正稀土科技研究所有限公司 +2

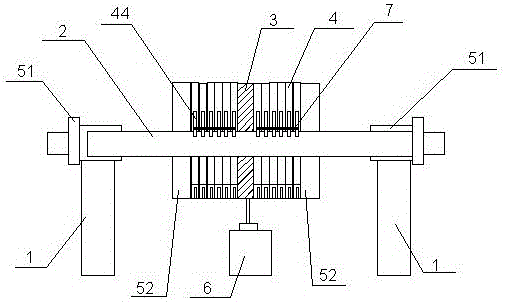

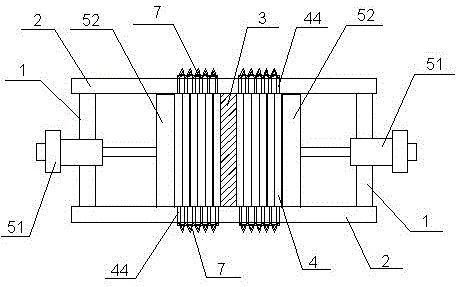

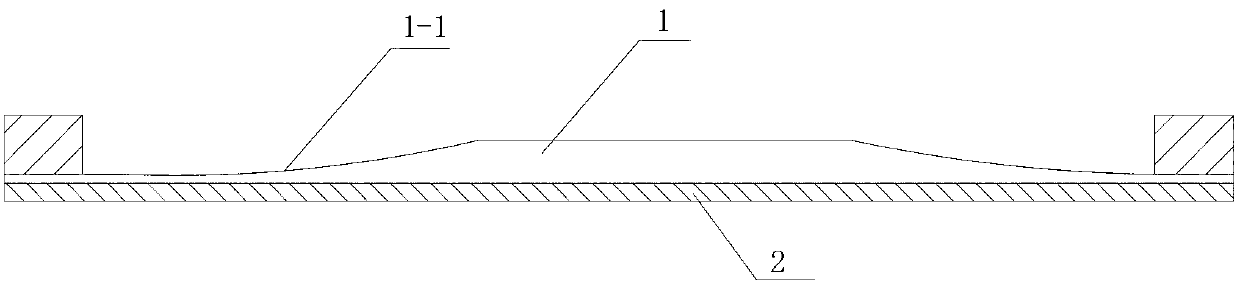

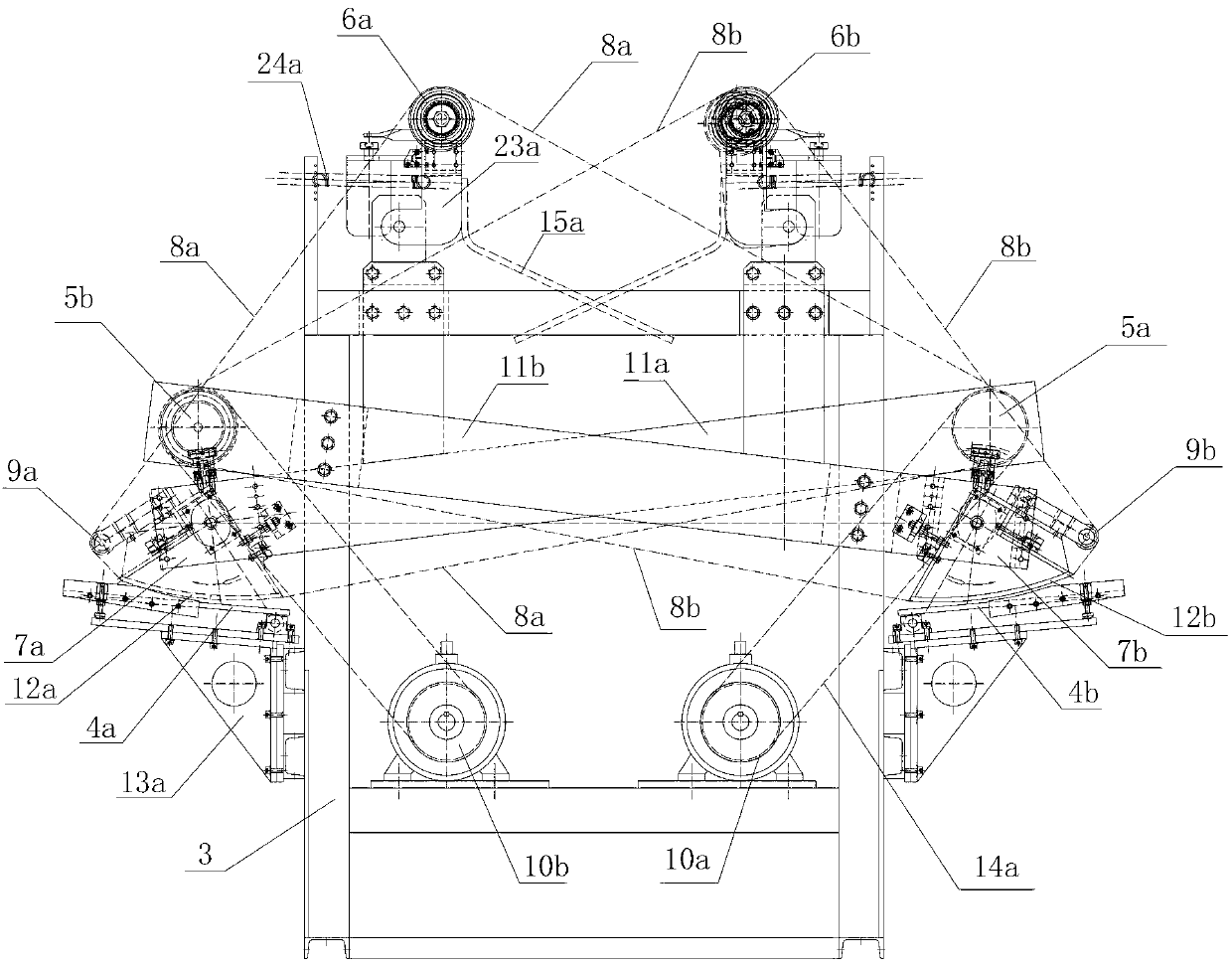

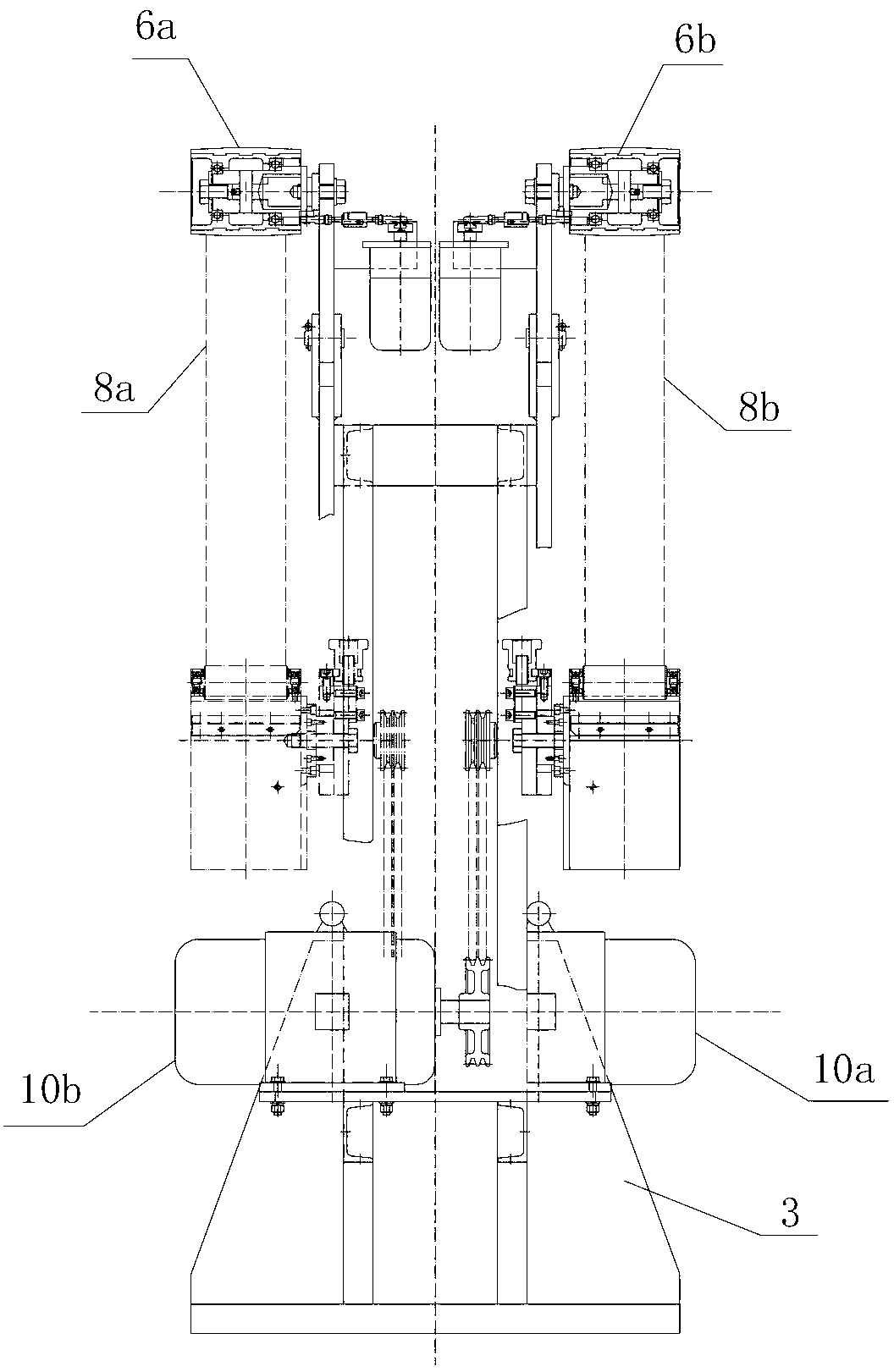

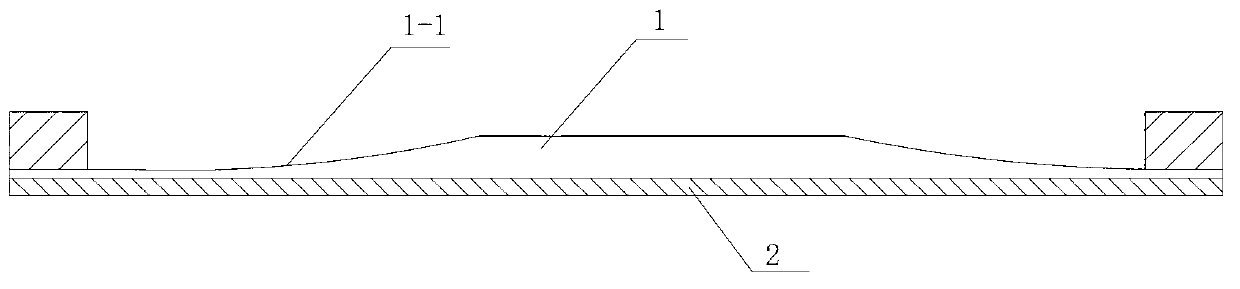

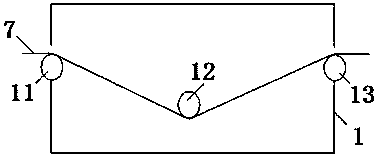

Processing equipment of large-radius arc surface on rib wood of piano

ActiveCN103341815AImprove work efficiencyReduce labor intensityBelt grinding machinesPianoMechanical engineering

The invention discloses processing equipment of a large-radius arc surface on a rib wood of a piano. The processing equipment comprises a rack, a working platform, a power wheel, a tensioning wheel, a profiling grinding head, a grinding belt and a power device, wherein the power device is connected with the power wheel; the profiling grinding head is fixed on the rack and is provided with an arc-shaped surface; the grinding belt surrounds on the power wheel, the tensioning wheel and the profiling grinding head to form a closed triangle; a processing space for allowing the end part of the rib wood to be pushed in during processing is formed between the profiling grinding head and the working platform; and the outer diameter of the grinding belt positioned on the arc-shaped surface of the profiling grinding head is equal to the radius of the large-radius arc surface on the rib wood. The processing equipment disclosed by the invention has the advantages of high working efficiency, high accuracy and low labor intensity.

Owner:PEARL RIVER PIANO GROUP

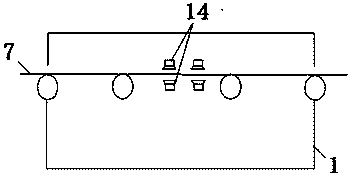

Processing equipment of medium-radius arc surface on rib wood of piano

ActiveCN103341814AImprove work efficiencyReduce labor intensityBelt grinding machinesPianoEngineering

The invention discloses processing equipment of a medium-radius arc surface on a rib wood of a piano. The processing equipment comprises a rack, a working platform, a power wheel, a tensioning wheel, a rotatable profiling wheel, a grinding belt and a power device, wherein the power device is connected with the power wheel; the profiling wheel is fixed on the rack; the grinding belt surrounds on the power wheel, the tensioning wheel and the profiling grinding head to form a closed triangle; a processing space for allowing the end part of the rib wood to be pushed in during processing is formed between the profiling grinding head and the working platform; and the outer diameter of the grinding belt positioned on the profiling wheel is equal to the radius of the medium-radius arc surface on the rib wood. The processing equipment disclosed by the invention has the advantages of high working efficiency, high accuracy and low labor intensity.

Owner:PEARL RIVER PIANO GROUP

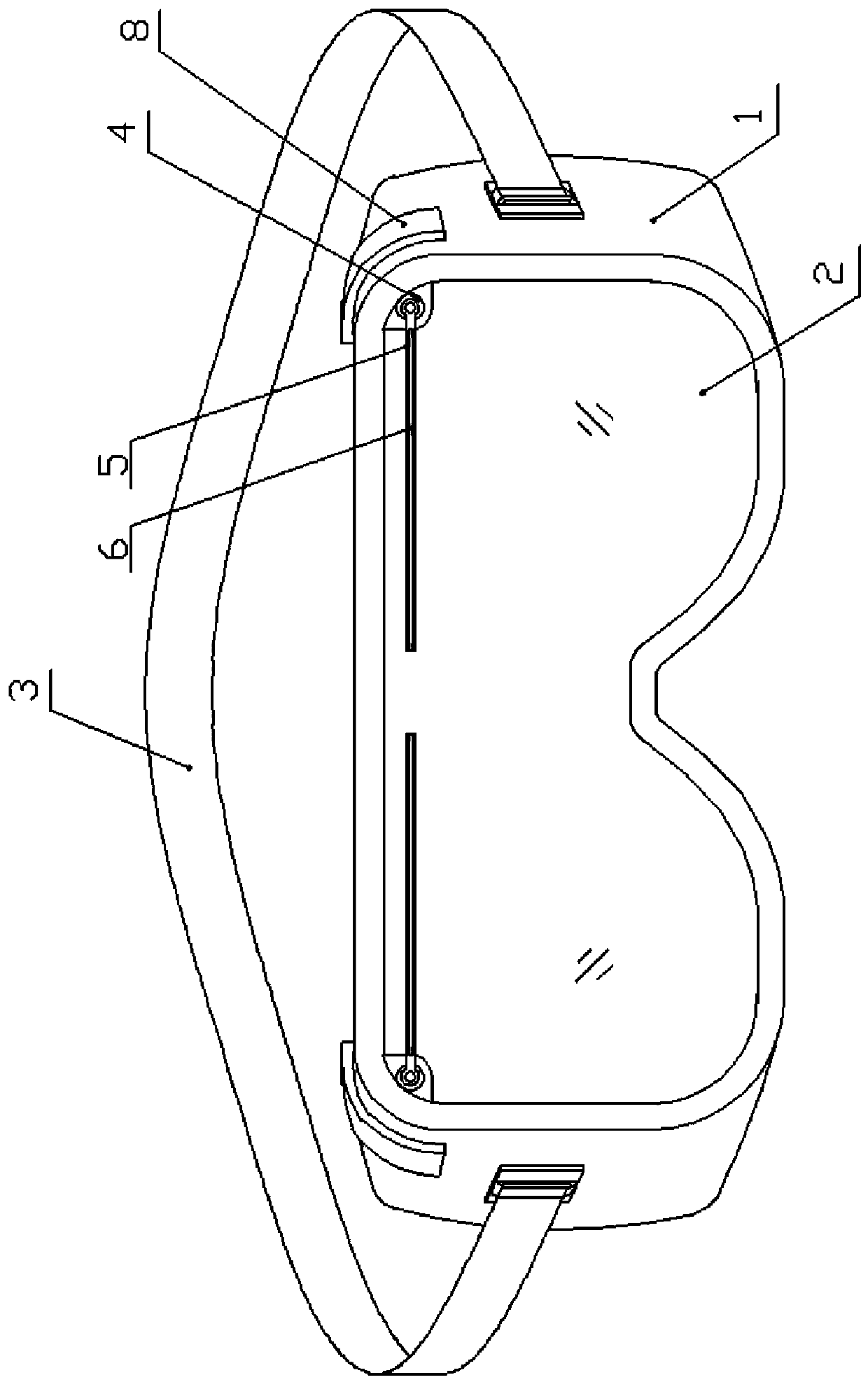

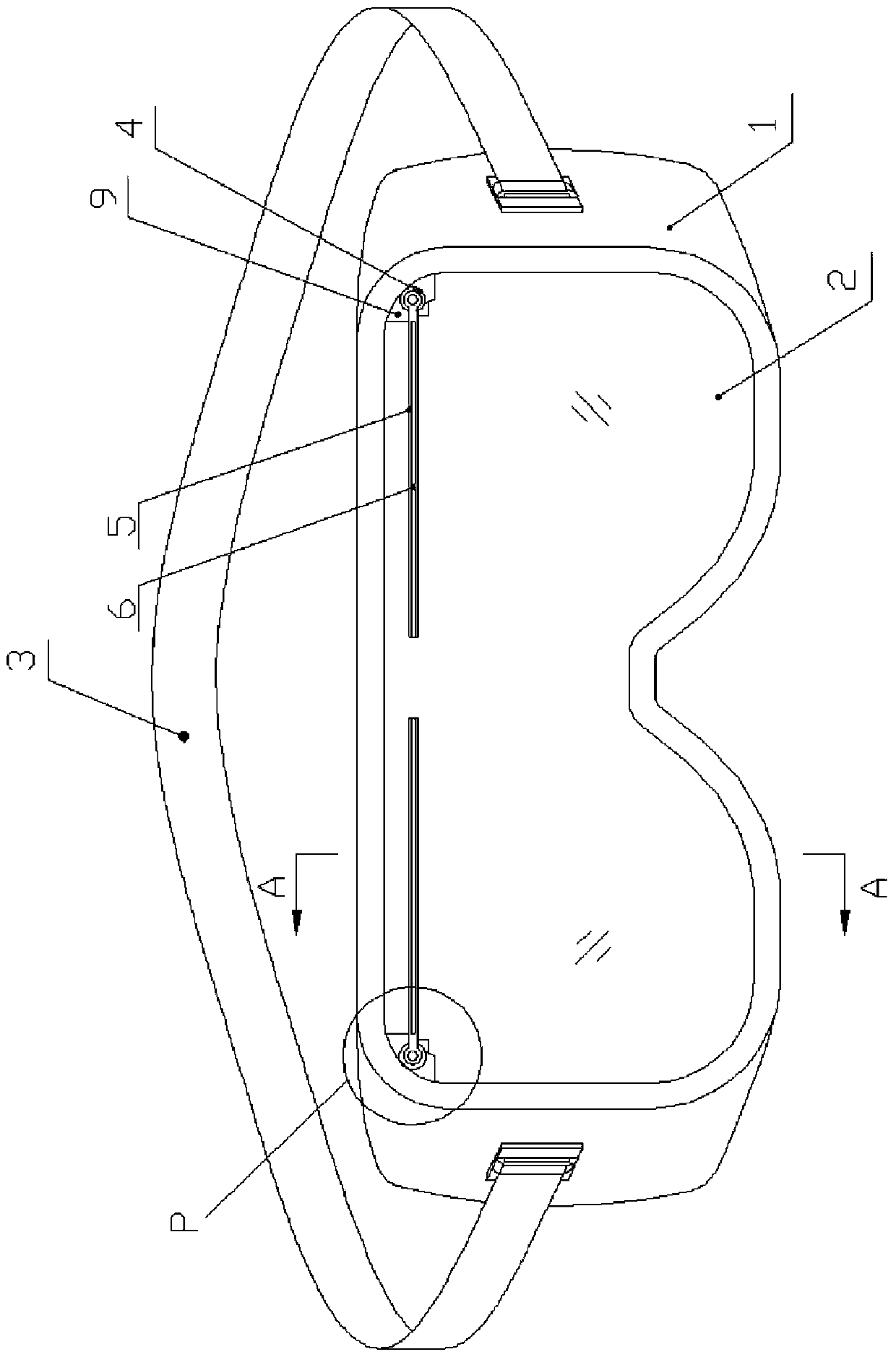

Demisting goggles

PendingCN111123558AGuaranteed clarityEasy to operateNon-optical adjunctsOptical partsProtective glassesEngineering

The invention discloses demisting goggles. The glasses comprise protective glasses frames, lenses and fixing bands, and two-way micro motors are fixedly mounted on the inner walls of the upper cornersof the two sides of the protective glasses frame respectively; demisting brushes are respectively arranged on rotating shafts of the two-way micro motors, the fixed ends of the demisting brushes arefixedly connected with the rotating shafts, the free ends of the demisting brushes are parallel to the mirror surface of the lens and extend along the mirror surface, scrapers fixed on the demisting brushes are in contact with the inner side of the lens, and a control box is arranged on the two-way micro motors. The pair of demisting goggles is worn on the head of a medical worker; medical staff can be protected from being infected due to contact between eyes and external germs; and the medical staff can remove fog water generated on the inner sides of lenses of the goggles at regular time bythe scraping pieces on the demisting brushes without taking down the goggles, clear sight is obtained through the transparent lenses, fine operation is carried out, accidental injury accidents are avoided, and the infection probability of the medical staff is greatly reduced.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

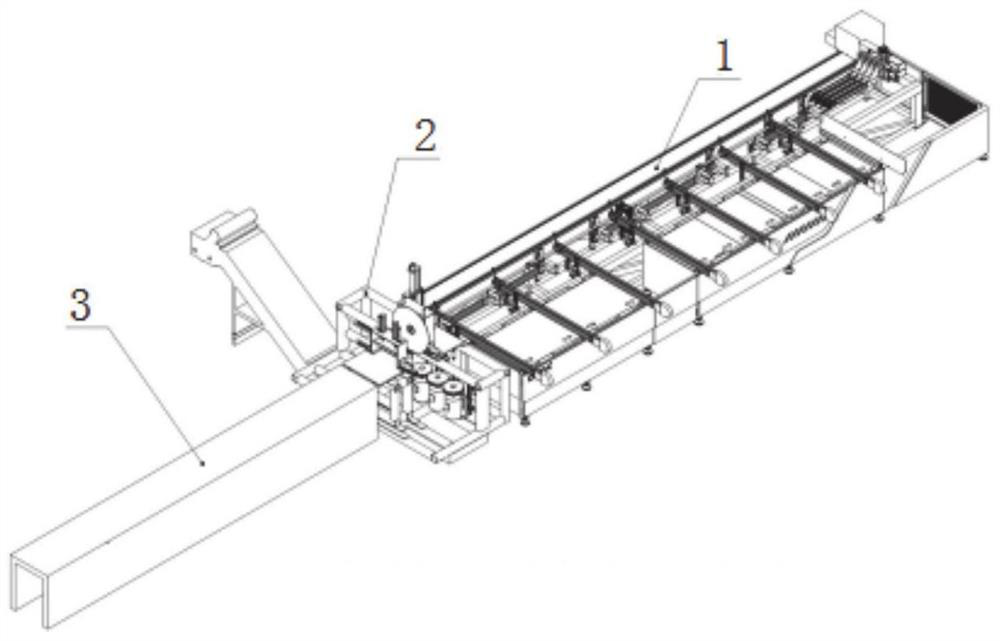

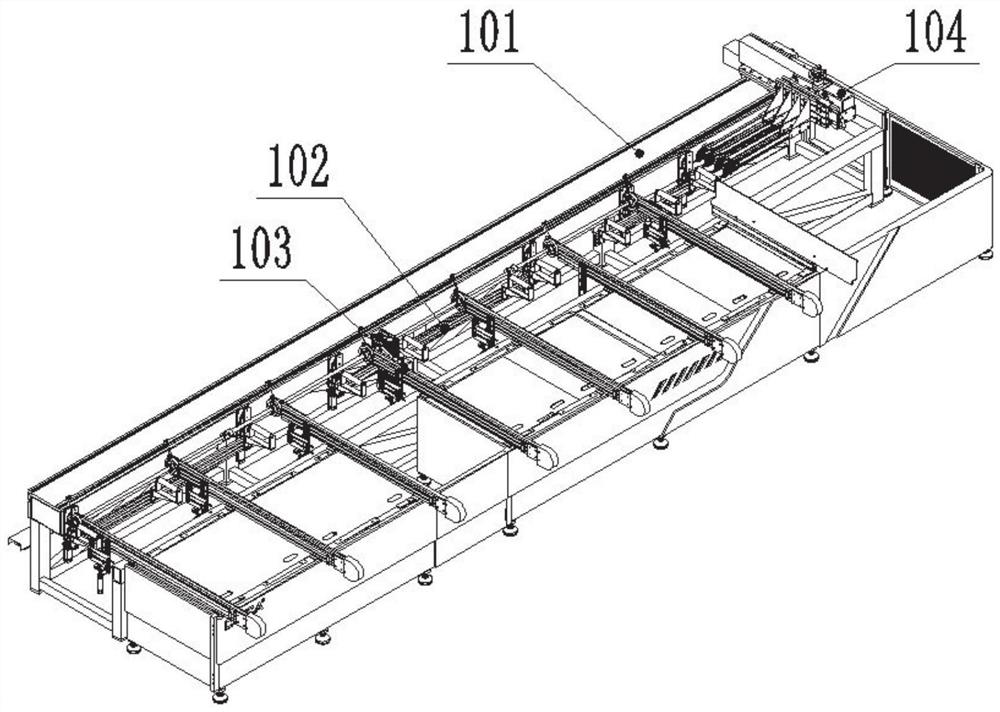

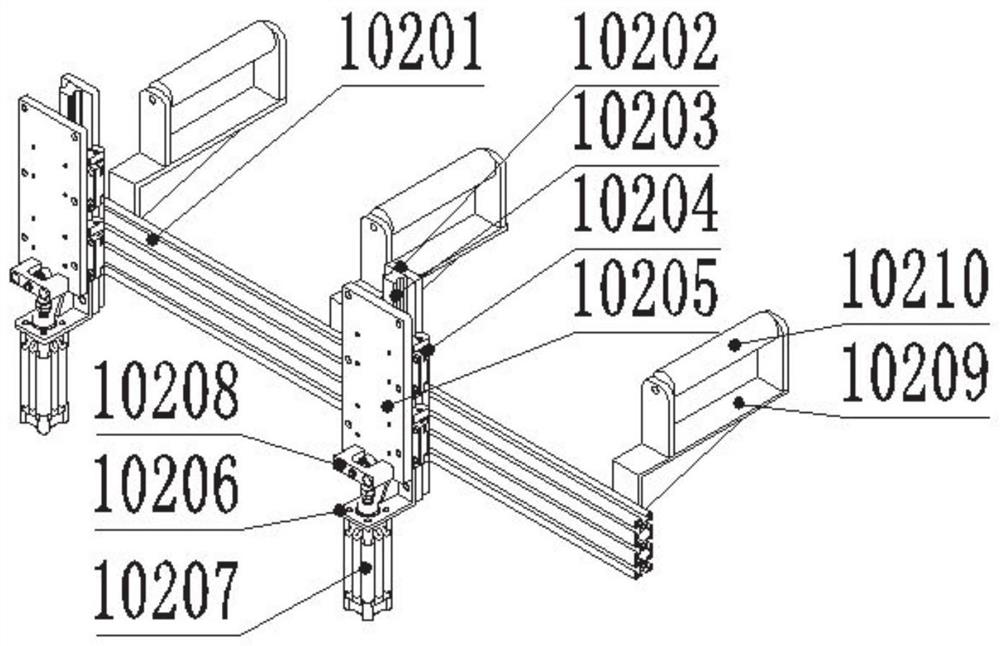

Numerical control profile end surface milling center

PendingCN113305577ARealize automatic feeding processGap can be adjustedWork clamping meansOther manufacturing equipments/toolsNumerical controlStructural engineering

The invention discloses a numerical control profile end surface milling center, comprising a feeding section, a sawing section and a discharging section. The feeding section comprises a feeding frame; a conveying mechanism is installed in the feeding frame; a plurality of supporting mechanisms are arranged on one side of the conveying mechanism at intervals; a feeding claw mechanism is slidably connected to the inner wall of the feeding frame; the conveying mechanism is used for conveying a profile to the position above the supporting mechanism; the feeding claw mechanism is used for clamping the profile and is matched with the supporting mechanism to convey the profile to the sawing section; the sawing section comprises a sawing frame; a sawing part and a pressing part are sequentially mounted on the sawing frame; and the sawing part is used for cutting the profile pressed by the pressing part; the milling part is installed below the sawing part; and under the action of the feeding claw mechanism, the milling part can machine an end surface formed by sawing the profile; and the discharging section is used for outputting the profile processed by the milling part. According to the invention, automatic feeding can be achieved, a plurality of profiles can be machined at a time, double surfaces can be machined at a time, the profiles do not need to be manually turned around, and the profile machining efficiency is improved.

Owner:JINAN CGMA CNC MACHINERY CO LTD

A fully-automatic continuous kinematic viscosity measuring device

PendingCN107894375AHigh degree of automationContinuous operationFlow propertiesSolenoid valveCapillary Tubing

The invention relates to a fully-automatic continuous kinematic viscosity measuring device. A rotary motor is controlled by an MCU to drive a set testing oil cup to rotate to a fixed position and to rise to a pointed height. Through cooperation of a plurality of solenoid valves, an oil sample is sucked up by a vacuum pump to a viscometer. During analysis, NTC sensors are adopted to detect whetherthe oil sample flows through bulbs or not so as to calculate a test result. After a test is finished, the residual oil sample is sucked into a waste liquid bottle through the vacuum pump, then a balance tube and a capillary tube of the viscometer are cleaned under cooperation of the vacuum pump and an air compressor, the current testing oil cup is blow-dried by the air compressor after the cleaning liquid is sucked to the waste liquid bottle, the system completes all actions, and analysis testing for a next testing oil cup is started. Dark opaque oil samples can be measured, the viscosity measuring range is broadened, and oil sample preheating time is shortened to one third of conventional oil sample preheating time. The device can continuously measure a plurality of oil samples, and integrates automatic constant temperature, sample sucking, cleaning, draining and blow-drying, thus greatly saving sample preparation time, and saving testing test oil samples and the cleaning liquid.

Owner:SHANGHAI SHENKAI GASOLINEEUM INSTR +1

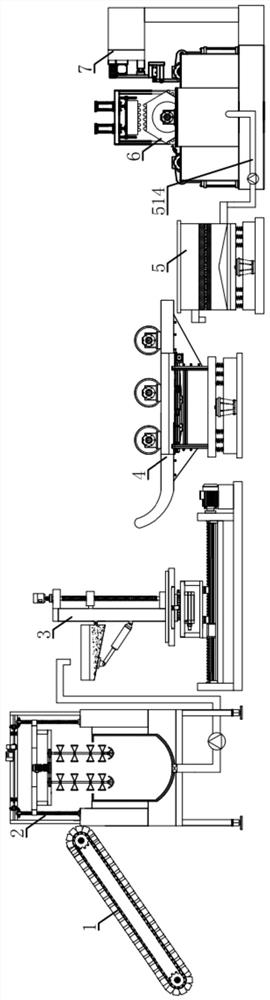

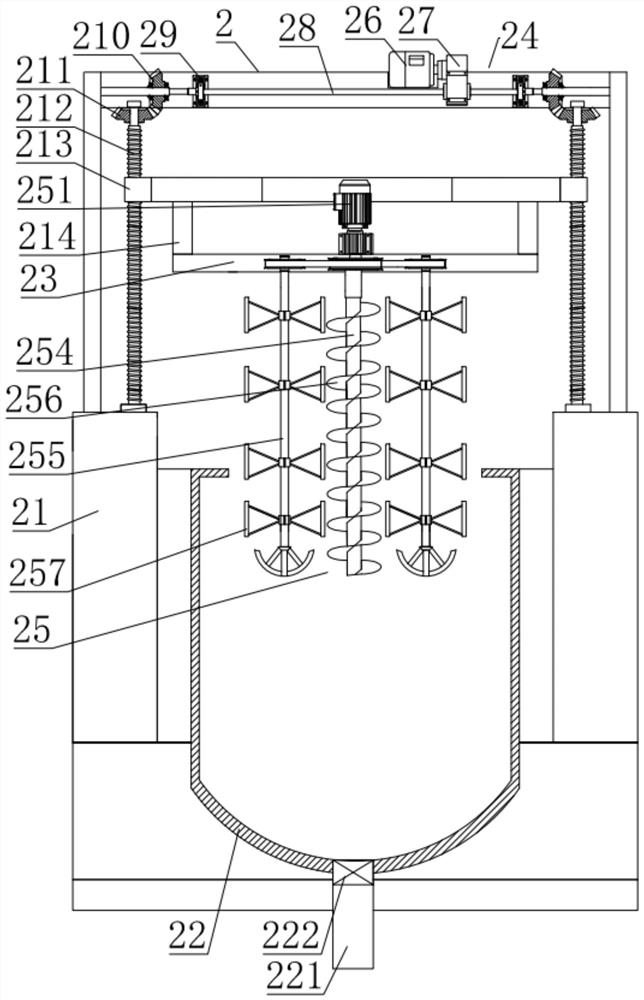

Multi-circulation type automatic paper pulp impurity screening device and working method thereof

InactiveCN113073491AReasonable structural designHigh degree of automationPaper material treatmentFiberPaperboard

The invention discloses a multi-circulation type automatic paper pulp impurity screening device and a working method, wherein a waste paperboard feeding magnetic separation conveying belt, a paper pulp stirring unit, a paper pulp transferring unit, a paper pulp impurity screening unit, a paper pulp vibration screening unit, a paper pulp forming unit and a paper pulp discharging unit are sequentially arranged according to production procedures. According to the invention, the multi-circulation type automatic paper pulp impurity screening device is reasonable in structure and design, high in automation degree, high in working efficiency and flexible in application; heavy metal impurities and other light impurities are separated and filtered through the waste paperboard feeding magnetic separation conveying belt, so that the filtering effect is improved, and metal scrap iron is removed from slurry while the slurry is conveyed through the conveying belt; and two-stage screening is formed through the paper pulp impurity screening unit and the paper pulp vibration screening unit, so that dust or large fiber impurities in the paper pulp can be completely removed.

Owner:徐州利华环保科技有限公司

Copper strip surface passivation device

InactiveCN104005017ARealize online passivation treatmentImprove passivation efficiencyMetallic material coating processesProduction lineCopper tape

The invention discloses a copper strip surface passivation device comprising a passivation tank and a passivation solution arranged in the passivation tank, wherein one side of the passivation tank is provided with an inlet for feeding a copper strip, and the other side of the passivation tank is provided with an outlet for discharging a passivated copper strip; and a structure for enabling the copper strip to be in contact with the passivation solution is arranged between the inlet and the outlet in the passivation tank. The device can be used for realizing online passivation treatment, and passivation operation can be continuously carried out if only the copper strip on a production line passes through the passivation tank, so that the passivation efficiency is high; the passivation solution in the passivation tank is circularly filtered through a filter to remove copper powder and other particles entering from the surface of the copper strip to the passivation solution in a passivation process, so that the purity of the passivation solution is ensured, and furthermore, the passivation quality is ensured; and in addition, the passivation solution does not need to be replaced frequently, so that the passivation efficiency is increased, and the cost is reduced.

Owner:ANHUI YONGJIE COPPER

Spectacular fishpond water disinfection powder and preparation method thereof

InactiveCN105211136AReasonable formulaSimple preparation processBiocideDisinfectantsChlorine dioxideToxic material

A spectacular fishpond water disinfection powder relates to the technical field of aquaculture, and is made from the following raw materials: 30-40 parts of chlorine dioxide solution, 15-25 parts of hydrogen peroxide solution, 10-20 parts of didodecyl dimethyl dibenzyltinoammonium chloride, 8-10 parts of polyhydroxy polyene polyamine, 2-4 parts of dodecyl triphenyl phosphorus chloride, 3-5 parts of Salvia miltiorrhiza, 2-4 parts of radix angelicae tuhuo, 3-5 parts of Chinese alpine rush, 2-4 parts of saponin, 3-5 parts of folium artemisiae argyi, 2-4 parts of Angelica dahurica, 2-4 parts of patchouli, 1-3 parts of rhizoma kaempferiae, 1-3 parts of Chinese angelica, 2-4 parts of Lysimachia fortunei, 1-3 parts of hibiscus, 1-3 parts of Ranunculus japonucus and 2-4 parts of Carpesium abrotanoides L.. The invention has the beneficial effects that the disinfection powder prepared by the invention has reasonable formula, simple preparation process, potent bactericidal effect on cultured fish, and small content of toxic substances in water, ensures the normal survival of spectacular fish and does not require frequently replacement of water, and is convenient and simple.

Owner:蚌埠龙达农业专业合作社

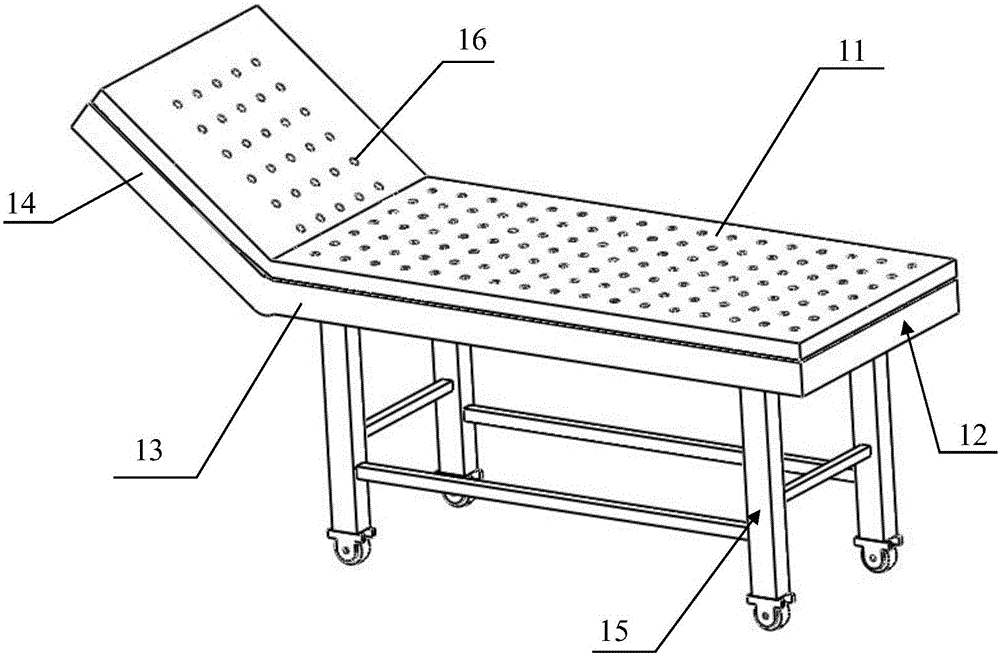

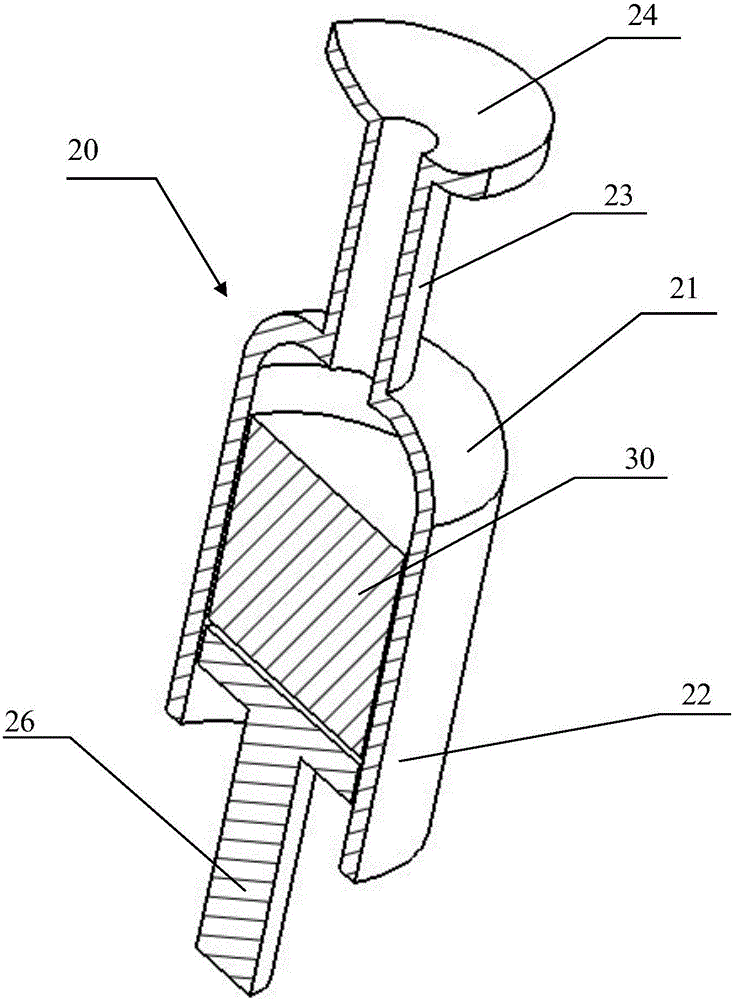

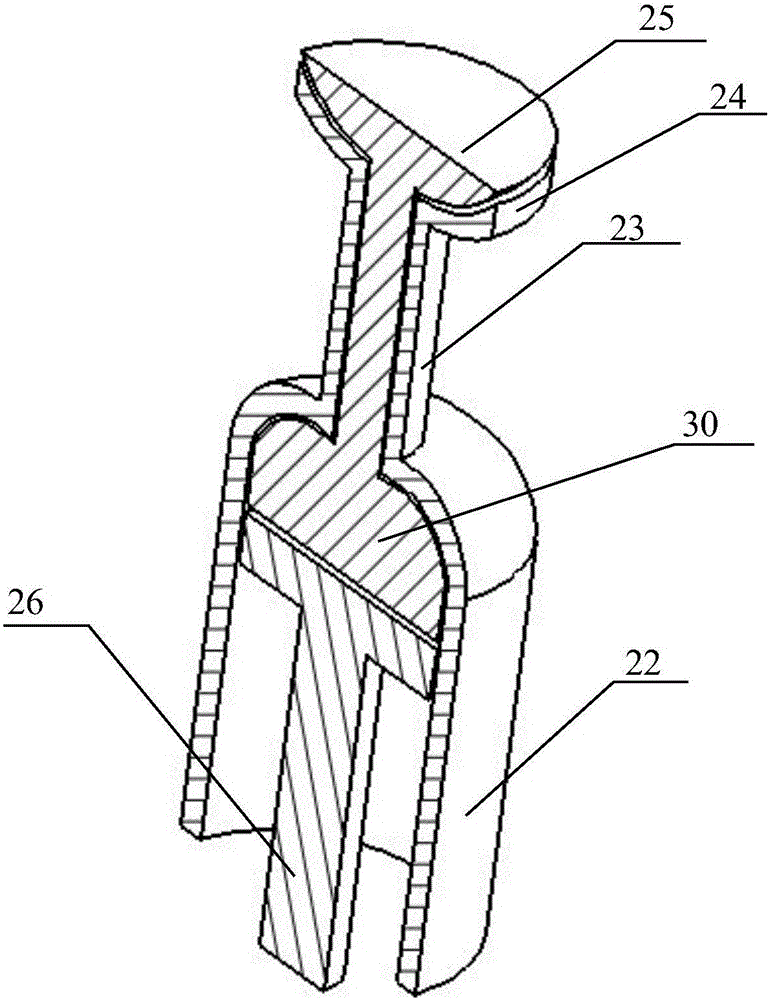

Myoelectricity detection stretcher and myoelectricity detection method

ActiveCN105708454AEasy extension and retraction controlsEasy to stick outDiagnostic recording/measuringSensorsPistonIndium

The invention provides a myoelectricity detection stretcher and a myoelectricity detection method. The myoelectricity detection stretcher comprises a support plate and a cushion, wherein the cushion is provided with a plurality of first electrode holes, and the support plate is provided with second electrode holes corresponding to the first electrode holes; an electrode is arranged in each second electrode hole, and each electrode comprises an electrode sleeve, a piston arranged in the electrode sleeve as well as a liquid metal arranged in a cavity formed by the electrode sleeve and the piston; each electrode sleeve comprises a drum part, a neck part and an opening part which are sequentially communicated, and the opening part is in the shape of a horn; the melting point of each liquid metal is 40-50 DEG C, and the liquid metal comprises 7-8 parts by weight of gallium and 2-3 parts by weight of indium; and heating wires are arranged in each piston, and during detection, after the piston is heated by the heating wires and the liquid metal is molten, the piston pushes the liquid metal to the opening part to form a detection electrode head. Because myoelectricity electrodes are added into the stretcher, in the process of conveying a patient by using the stretcher, the myoelectricity detection can be carried out on the patient.

Owner:SUZHOU HAISHEN JOINT MEDICAL DEVICES CO LTD

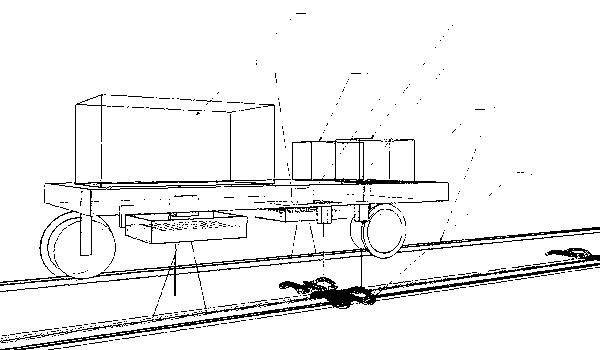

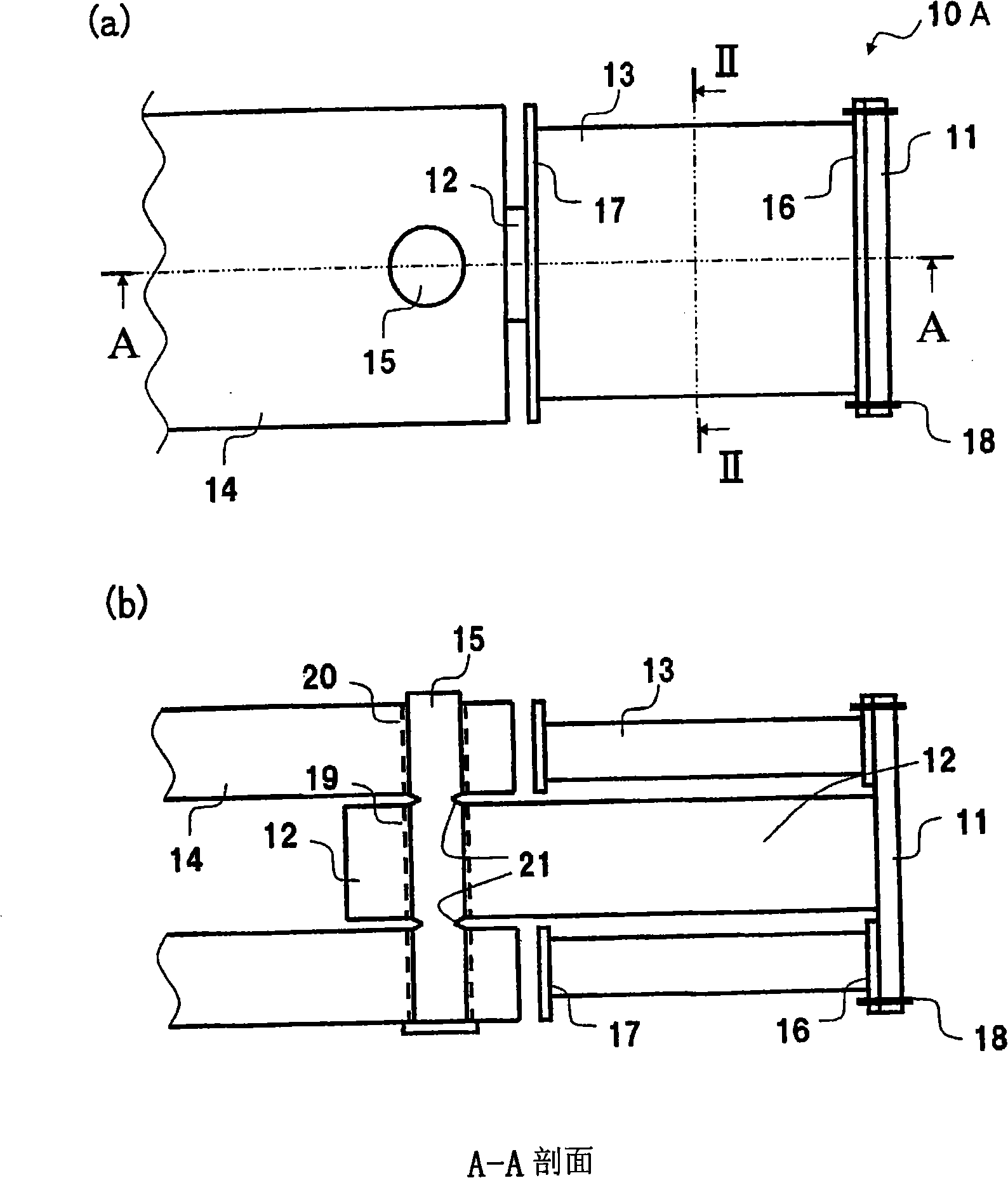

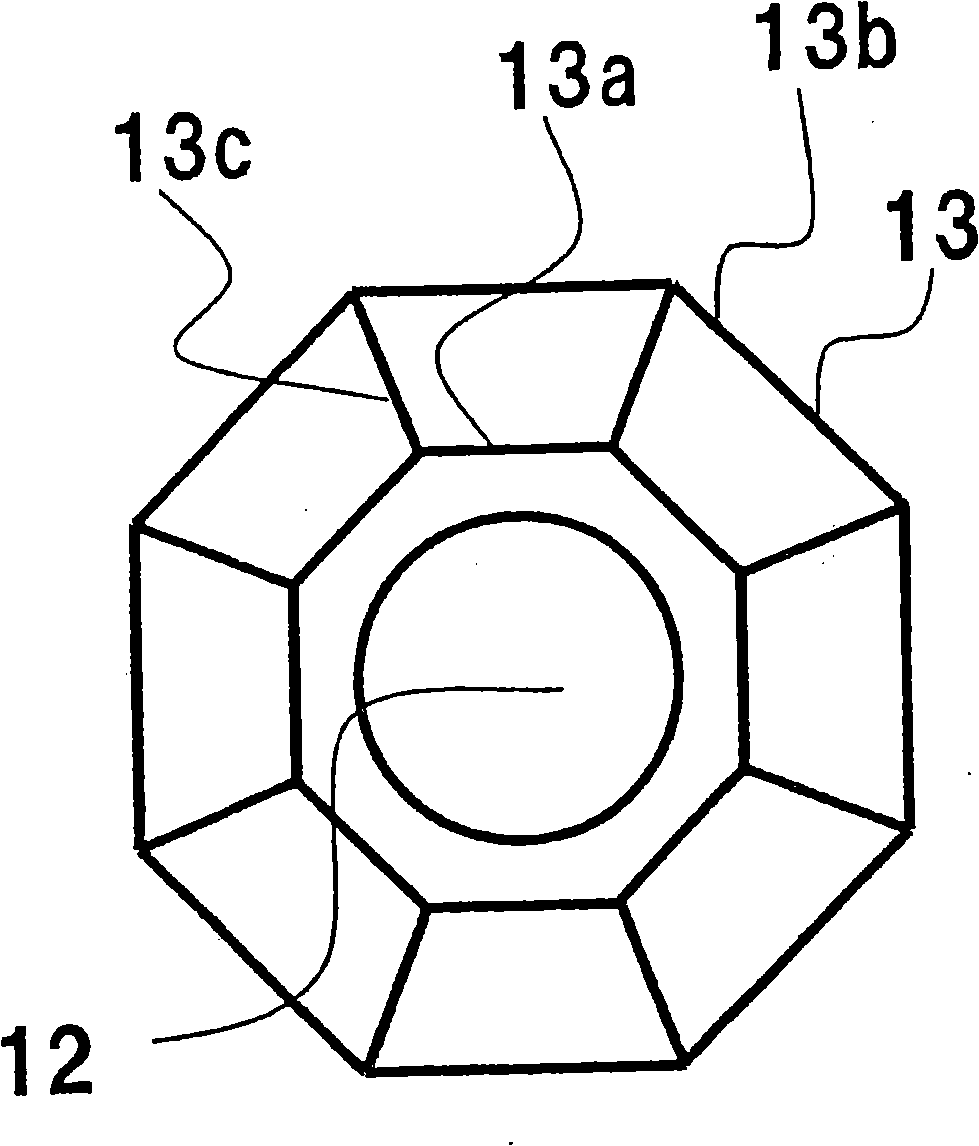

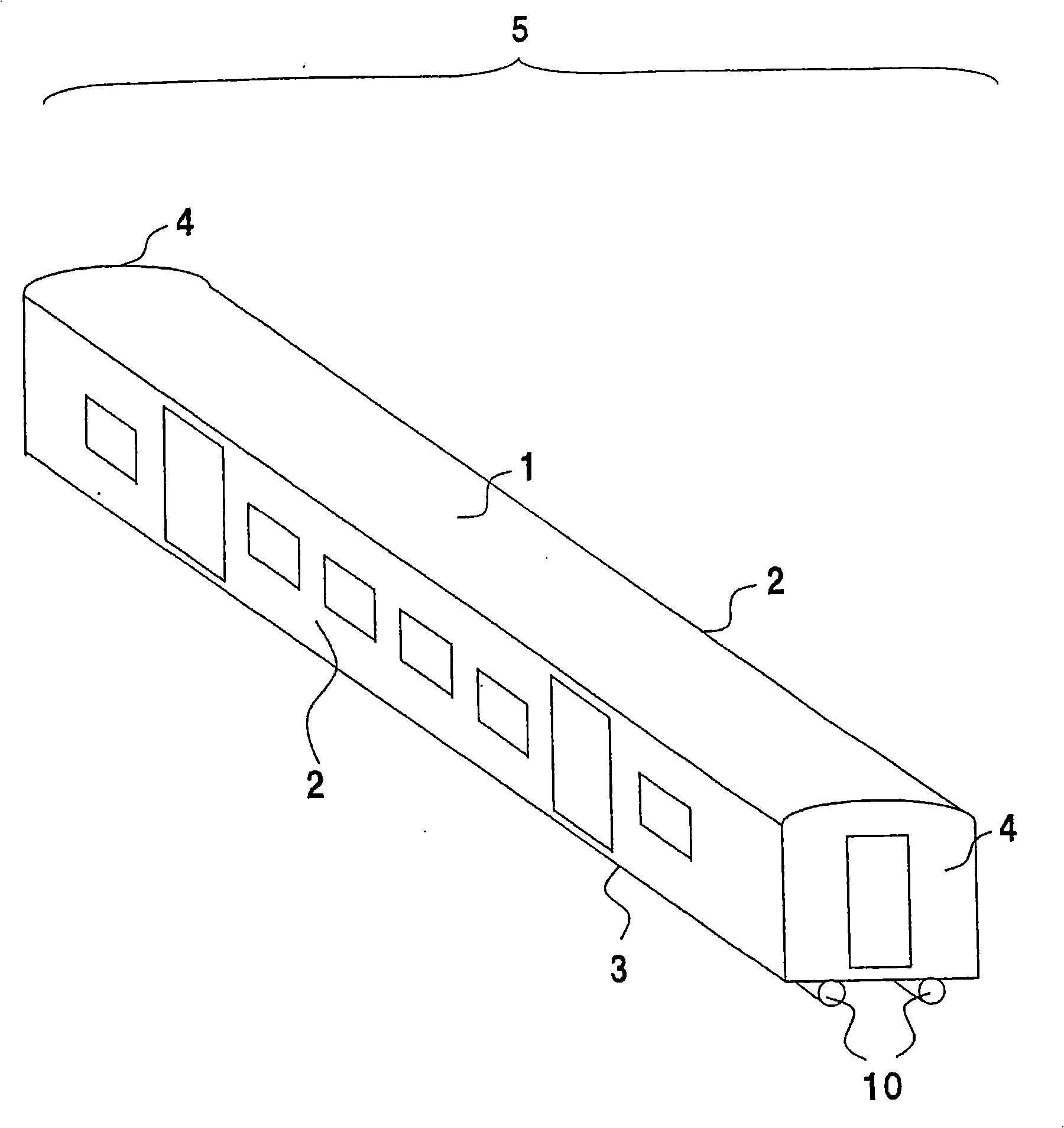

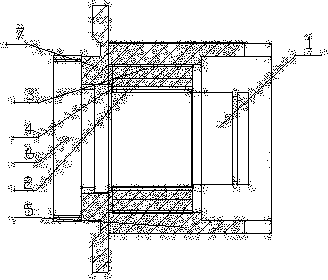

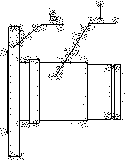

Transportation device

ActiveCN101274634ADo not change frequentlyBuffer carsRailway wheel guards/bumpersEngineeringShock absorber

The invention provides a shock absorbing structure capable of turning the function of the shock absorber on and off according to the level of shock during collision, thereby reducing the frequency of replacing shock absorbers. On a rear surface of a load operating unit 11 constituting a shock absorbing device 10 A are attached a load transmitting shaft 12 and a shock absorber 13. The load transmitting shaft 12 is passed through the center of the shock absorber and is connected to a supporting unit 14 via a pin 15 that extends toward the radial direction. The rear end of the shock absorber 13 faces the supporting unit 14 with a clearance therebetween. The pin 15 has notched grooves 21 formed thereto. When small load is applied, the load is transmitted from the load operating unit 11 through the load transmitting shaft 12 , the pin 15 and the supporting unit 14 to the main body, so that the load is not applied on the shock absorber 13 . When large load is applied, the pin 15 breaks from where the notched grooves 21 are formed, by which the surface of the closing plate 17 collides against the supporting unit 14 , so that the load is transmitted to the shock absorber 13 and the shock is absorbed effectively.

Owner:HITACHI LTD

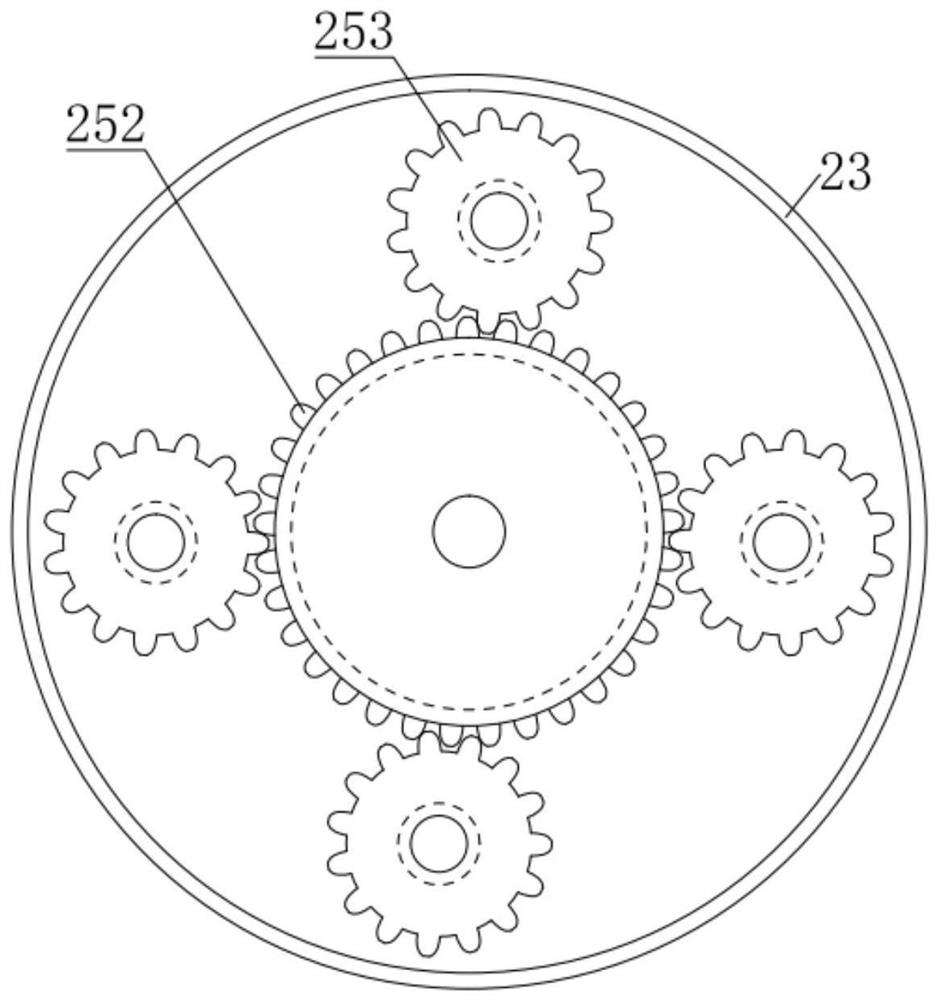

Differential lock

InactiveCN103742622ASimple structureNot easy to damageDifferential gearingsElastic componentEngineering

Owner:优必胜(福建)机械工业有限公司

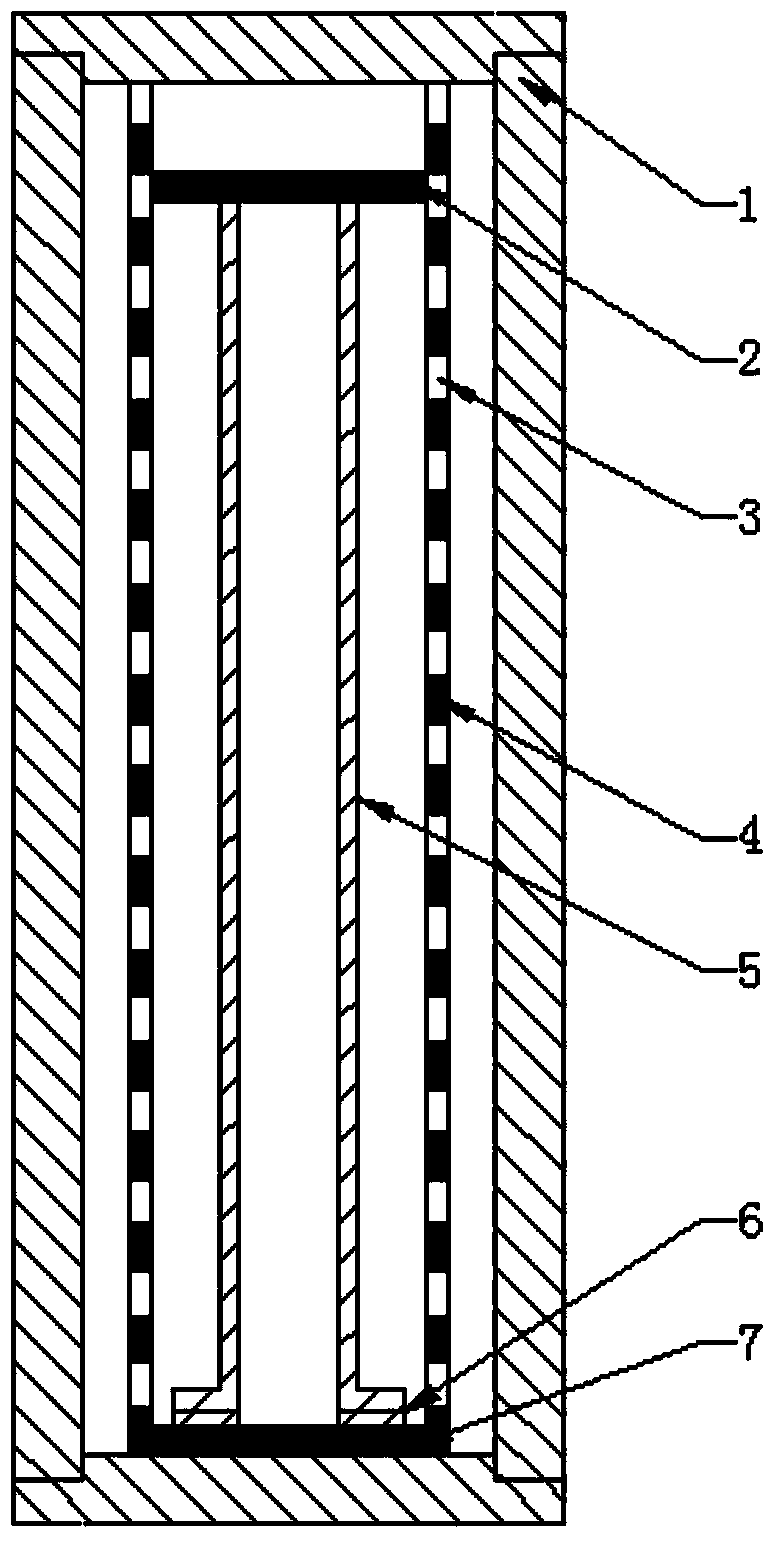

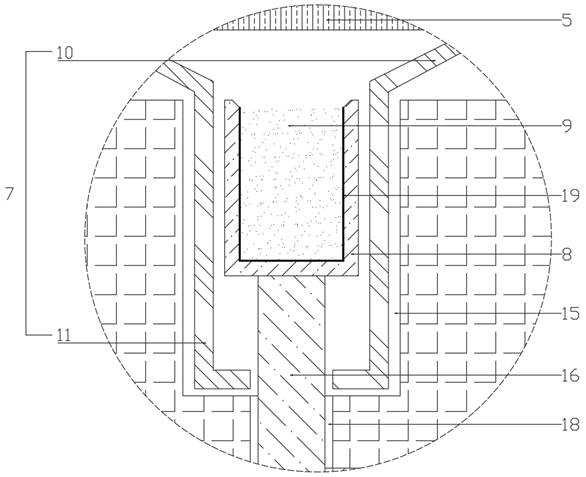

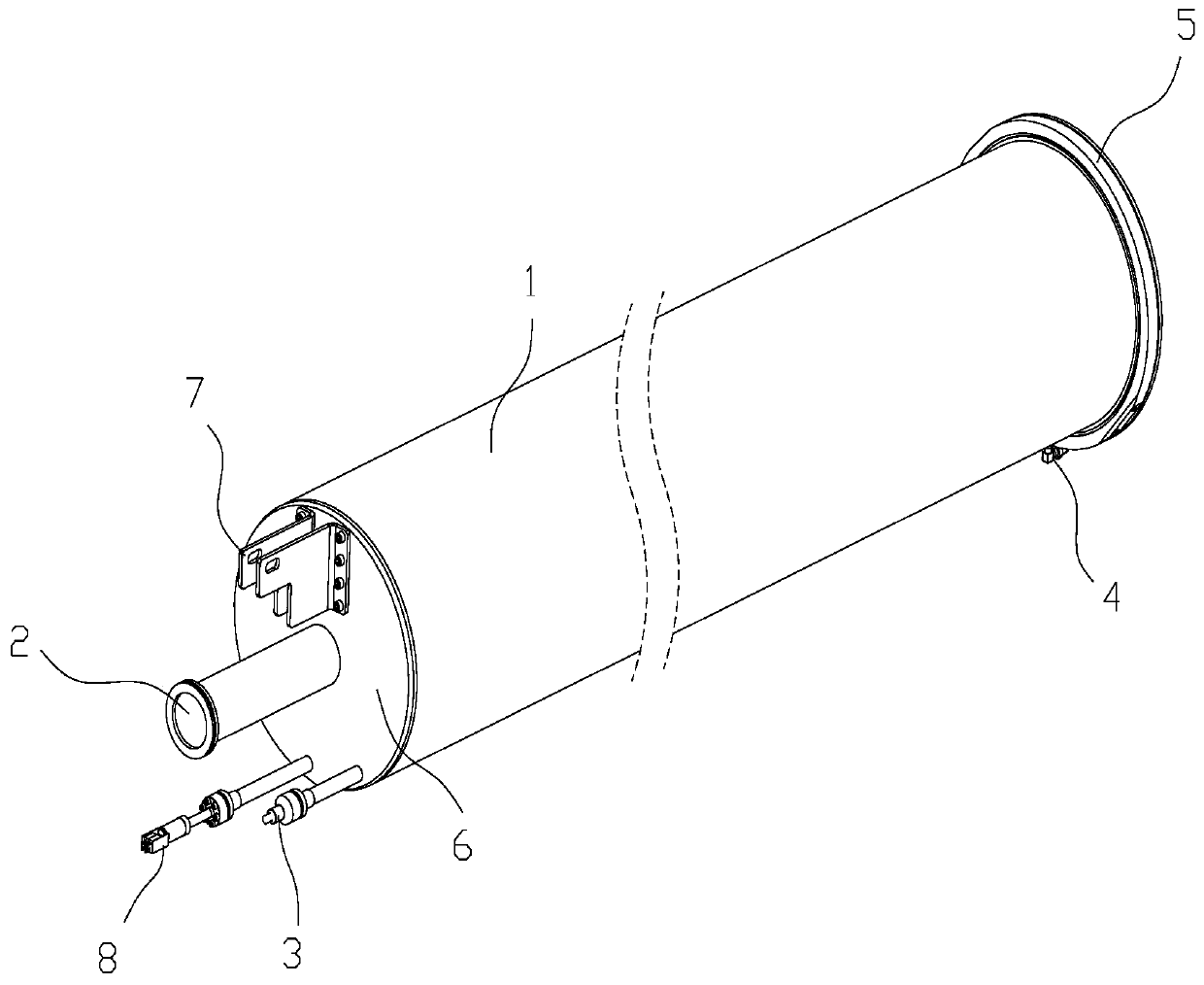

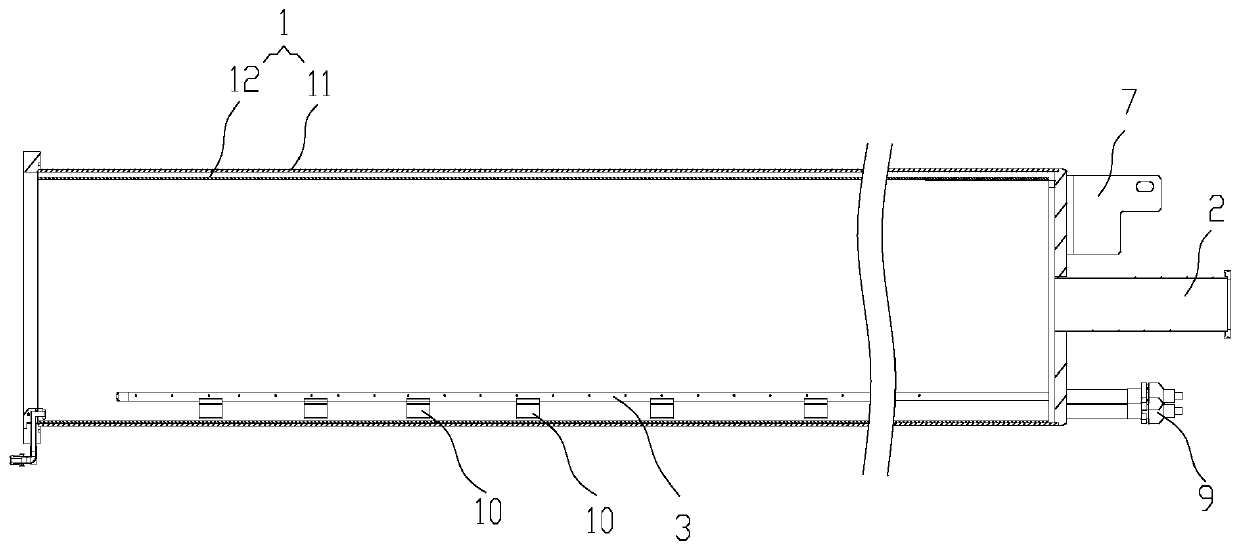

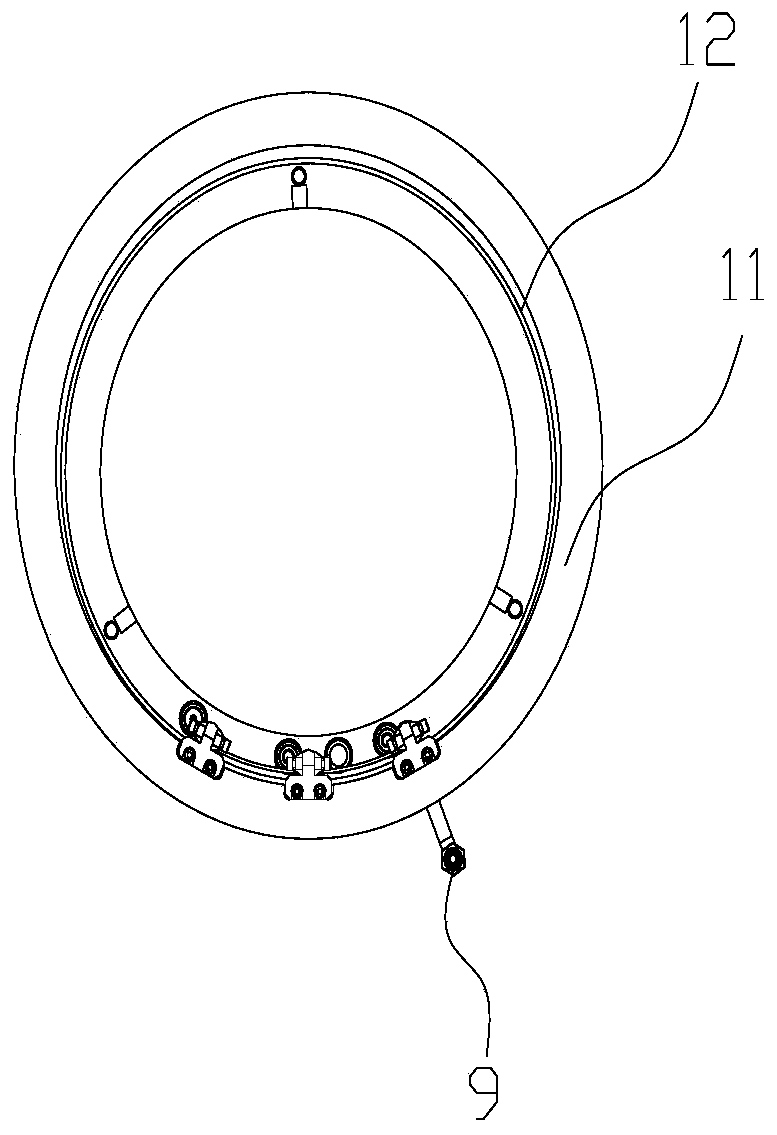

LPCVD double material vacuum reaction chamber

PendingCN111074239ASpread widely and evenlyImprove uniformityChemical vapor deposition coatingEngineeringSilicon thin film

The invention discloses an LPCVD double material vacuum reaction chamber, which comprises a reaction chamber, an air inlet assembly and an air outlet pipe; and the air inlet assembly is connected withan external air source, the reaction chamber comprises an outer cavity and an inner cavity arranged in the outer cavity, the air inlet assembly comprises one or more left air inlet pipes and one or more right air inlet pipes, an air inlet of each left air inlet pipe is arranged at the end portion of the reaction chamber in the length direction, an air inlet of each right air inlet pipe is arranged at the other end of the reaction chamber in the length direction, and a plurality of air outlets are correspondingly arranged on the left air inlet pipes and the right air inlet pipes. According tothe LPCVD double material vacuum reaction chamber, the two ends of the reaction chamber correspondingly has air inlet pipes for gas diffusion, thus gas in the reaction chamber is widely and evenly distributed, air outlet is stable, the uniformity and process quality of a silicon thin film are improved, and the excellent rate of a product is improved; the vacuum reaction chamber adopts a double-layer structure, the vacuum performance is excellent, the impact resistance is high, the strength of the overall reaction chamber is improved, and the service life is prolonged.

Owner:赛姆柯(苏州)智能科技有限公司

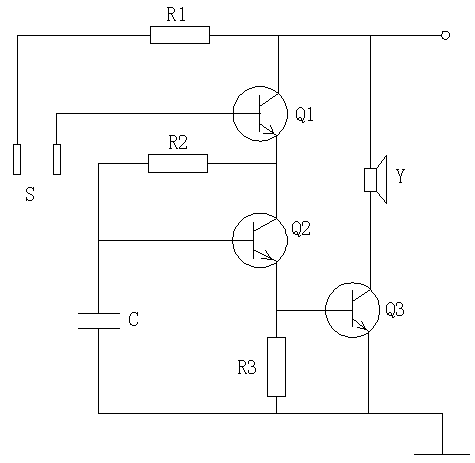

Water level alarm capable of continuously working for long time

The invention discloses a water level alarm capable of continuously working for a long time. The water level alarm comprises a triode Q1, a triode Q2, a triode Q3, a resistor R1, a resistor R2, a resistor R3, a capacitor C, a loudspeaker Y, a power supply and two probes S, wherein a collector electrode of the triode Q1 is connected with an anode of the power supply; an emitting electrode of the triode Q1 is connected with a collector electrode of the triode Q2; an emitting electrode of the triode Q2 is connected to a base electrode of the triode Q3; an emitting electrode of the triode Q3 is grounded; one of the probes is connected to a base electrode of the triode Q1; the other probe S is serially connected with the resistor R1 and then is connected to the anode of the power supply; one end of the resistor R2 is connected to the emitting electrode of the triode Q1; the other end of the resistor R2 is connected to a base electrode of the triode Q2; one end of the capacitor C is also connected with the base electrode of the triode Q2; and the other end of the capacitor C is grounded. By the structure, current consumed by a circuit is quite low, a battery is not required to be changed frequently, and the water level alarm can work for a long time.

Owner:CHENGDU ZHONGSHAN SCI & TECH

Spinning thread dyeing equipment capable of switching colors

InactiveCN112726063ASwitch in real timeFast color fixTextile treatment machine partsLiquid/gas/vapor removalEngineeringColor changes

The invention relates to the related field of spinning equipment, in particular to spinning thread dyeing equipment capable of switching colors. The spinning thread dyeing equipment comprises a machine body and a groove formed in the machine body and provided with openings in the upper side and the right side. A color changing groove located in the left side of the groove is formed in the machine body, and the color changing groove is provided with an opening in the upper left side; and a color changing device is arranged in the color changing groove, the color changing device can provide different dyeing for threads when the equipment runs, and a first transmission cavity located on the lower side of the groove is formed in the machine body. According to the spinning thread dyeing equipment capable of switching the colors, in the process of producing clothes, feeding threads are switched in real time according to the required color, and the threads are dyed in different colors; and the dyed threads are subjected to rapid color fixing operation through a drying mechanism in the equipment, so that the production efficiency is greatly improved, thread coils do not need to be frequently replaced, and the production cost is saved to a certain extent.

Owner:杭州莎婷服饰有限公司

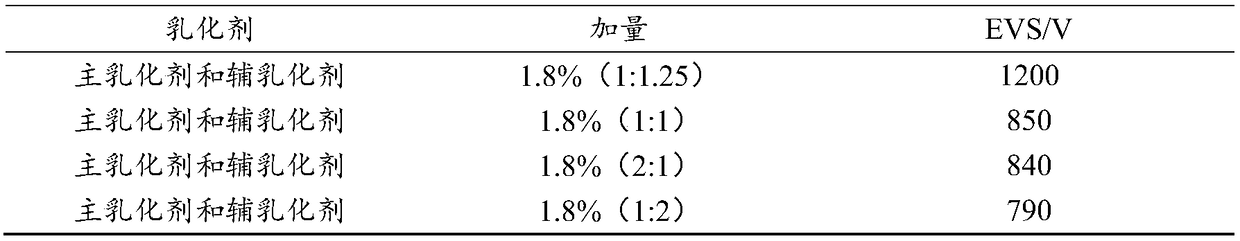

High oil-water ratiooil base drilling fluid system

The invention discloses a high oil-water ratiooil base drilling fluid system. The system is prepared from, by volume, 90-95 parts of base oil and 5-10 parts of an aqueous phase, and further comprisesa primary emulsifier, an auxiliary emulsifier, a wetting agent, organic soil, calcium oxide, an emulsifying sealing material, a keritesealing material and calcium chloride brine, wherein the weight ofthe primary emulsifieris equal to 0.8-1.8% of the overall weight of the base oil and the aqueous phase, the auxiliary emulsifier1.0-2.0%, the wetting agent 1.2-1.5%, the organic soil 2.0-3.0%, the calcium oxide 3.0-4.0%, the emulsifying sealing material 3.5-4.5%, the keritesealing material 1-1.5% and the calcium chloride brine 2.0-2.5%. The high oil-water ratiooil base drilling fluid system is low in ECD value, has good emulsion stability, low rheological property and good well wall flushing capability, facilitates borehole cleaning, cost saving of drilling fluid and maintenance of on-site performanceof the drilling fluid, effectively reduces the risk of well leakage, and can avoid rheological propertyrise caused by drilling a stratum in which the moisture content is high.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Polyurethane coating technique of knitting gloves

InactiveCN101283842AImprove wear resistanceExtended service lifeFibre treatmentGlovesSolventChemistry

The invention relates to a polyurethane applying process of knitted gloves, which comprises following steps: heating knitted cotton gloves to 80 to 100 DEG C; applying polyurethane material to the knitted cotton gloves; curing for 30 to 40 min; and vulcanizing twice at 90 to 110 DEG C for 16 to 24 h. The cotton gloves with polyurethane coating can substitute for cotton gloves with rubber coating, and have the advantages of high wear resistance, oil resistance, solvent resistance, weak acid and alkali resistance, long service life, saved cost, infrequent replacement, and economic practicality.

Owner:许甫民

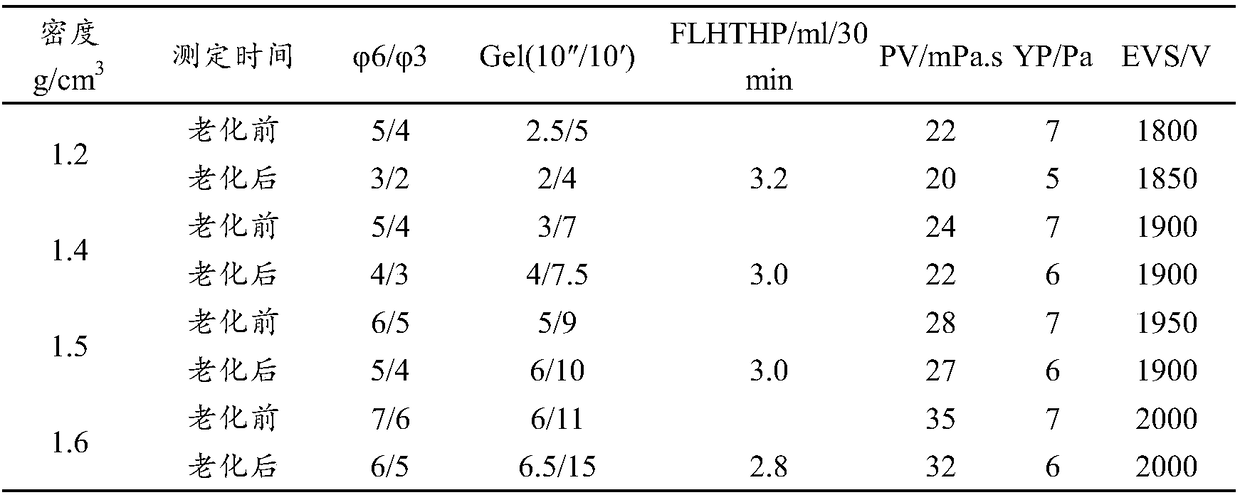

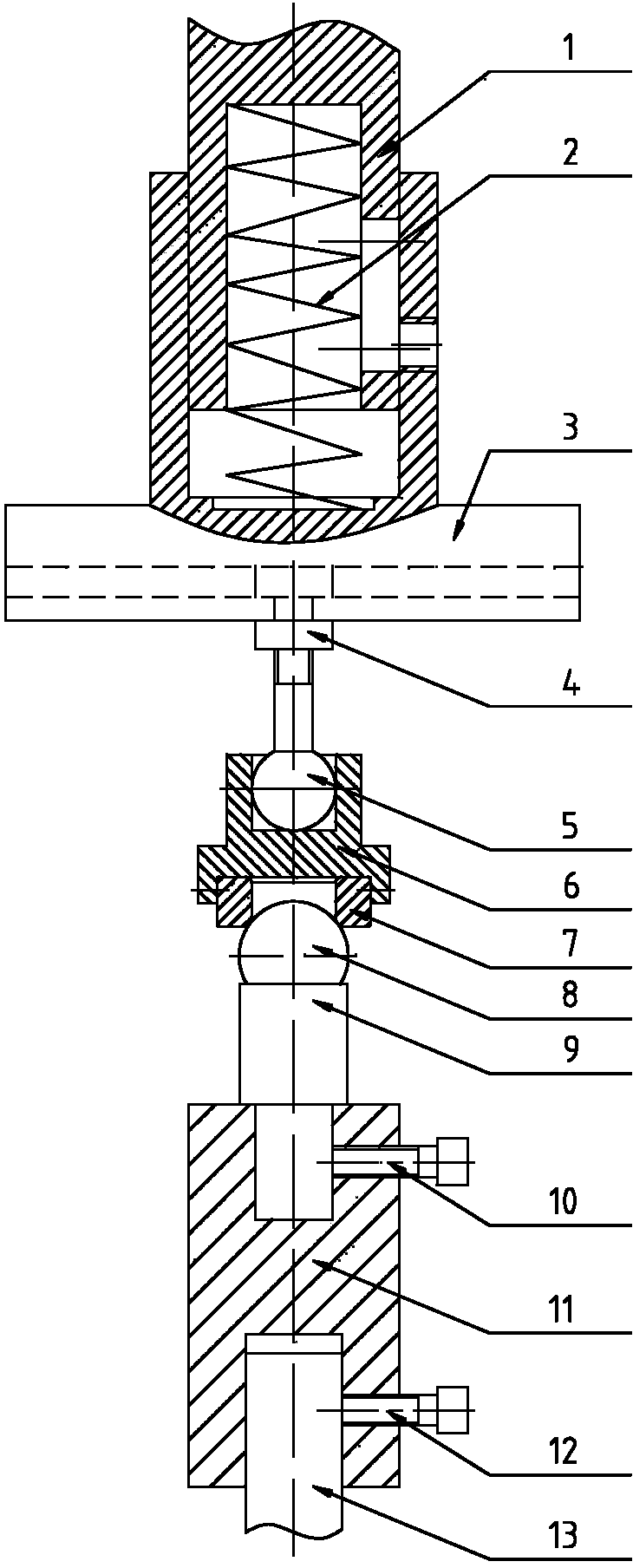

Grinding device and grinding method of oil well pump valve seat

ActiveCN104249280AReduce labor loadEven by forceSeat surface grinding machinesLapping machinesElectric machineryEngineering

The invention provides a grinding device and a grinding method of an oil well pump valve seat. The grinding device is composed of two large parts, namely an upper grinding part and a lower grinding part, wherein the upper grinding part is internally provided with a spring; an upper grinding head and a valve seat are mounted in a valve seat clamping sleeve. The grinding method comprises the following steps: the upper grinding part and the lower grinding part are connected with a motor to drive the valve seat to move up and down; grinding pressure is applied between the valve seat and a lower grinding head of the lower grinding part by using the spring, and the valve seat is ground. By adopting the grinding device and the grinding method, at least two valve seats can be ground in one step, and each valve seat is independently controlled by one set of the independent valve seat grinding device. The grinding efficiency of the valve seat is improved, the labor load of an operator is reduced, and the grinding yield of the valve seat is high; the grinding device and the grinding method are particularly suitable for a petroleum drilling and production industry.

Owner:ZIGONG CEMENTED CARBIDE CORP

Processing equipment for seafood processing

ActiveCN109287724AIncrease productivityAccurate grippingShrimp/lobster processingEngineeringProduct processing

The invention discloses processing equipment for seafood processing. The processing equipment comprises a base, a flushing device, a box body, a back scrubbing device, conveying and clamping devices,abdomen cleaning devices and a draining device, wherein the flushing device is fixed to one side of the top of the base; the box body is arranged at one side of the flushing device, and the box body is fixedly connected with the base; three groups of the conveying and clamping devices are equidistantly arranged in the box body; one abdomen scrubbing device is correspondingly arranged below each conveying and clamping device; the back scrubbing device is arranged above the conveying and clamping devices, and the back scrubbing device is fixed at the top of the box body. According to the processing equipment disclosed by the invention, the problems of low efficiency of traditional manual brushing and cleaning as well as uncleanness of conventional machine washing are solved, the cleaning efficiency is high, the cleaning effect is good, environmental protection and sanitation are achieved.

Owner:江西佰嘉实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com