Differential lock

A differential lock and differential gear technology, which is applied in the field of automobile driving, can solve the problems of short service life of the differential lock, troublesome replacement and high use cost, and achieve the effects of reducing the use cost, simple structure and not easy to damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

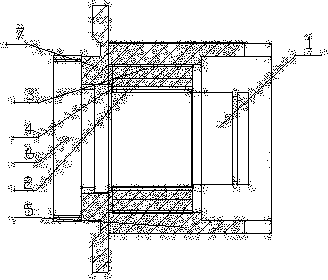

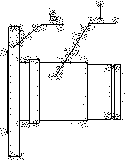

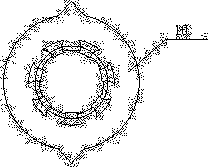

[0031] refer to Figures 1~5 , The differential lock of the present invention includes a differential lock shaft 1 , a brake seat 2 , a bearing fixing seat 3 , a bearing 4 and a housing 5 . The brake seat 2 is cylindrical, which can cooperate with the differential lock shaft 1, and the outer casing is also cylindrical, which can cooperate with the bearing fixing seat 3.

[0032] One end surface of the brake seat 2 is connected with a symmetrically arranged brake block 7, and the brake block 7 can rotate around the axis of the end. The brake blocks 7 are connected together by an elastic member 8, and the elastic member 8 is preferably a spring member. One end of the differential lock shaft 1 is provided with a fixed seat 6 , the brake seat 2 is sleeved and connected to the differential lock shaft 1 , and one side of the brake block 7 is in clearance fit with the fixed seat 6 . The bearing 4 is arranged in the bearing fixing seat 3 , the bearing 4 is sleeved and connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com