Integrated type one-operator jade machining device and method

A processing device and integrated technology, applied in grinding devices, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of frequent replacement, rapid abrasive failure, low processing efficiency, etc., saving manpower and material resources, and achieving scientific structure. , the effect of high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

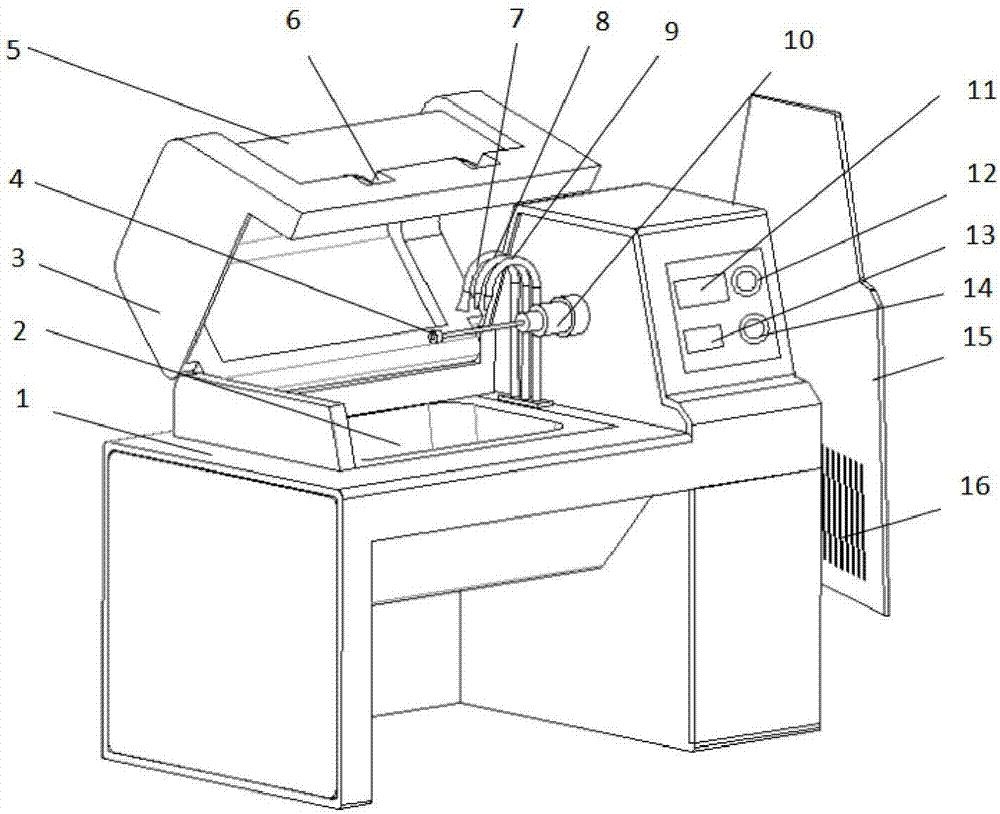

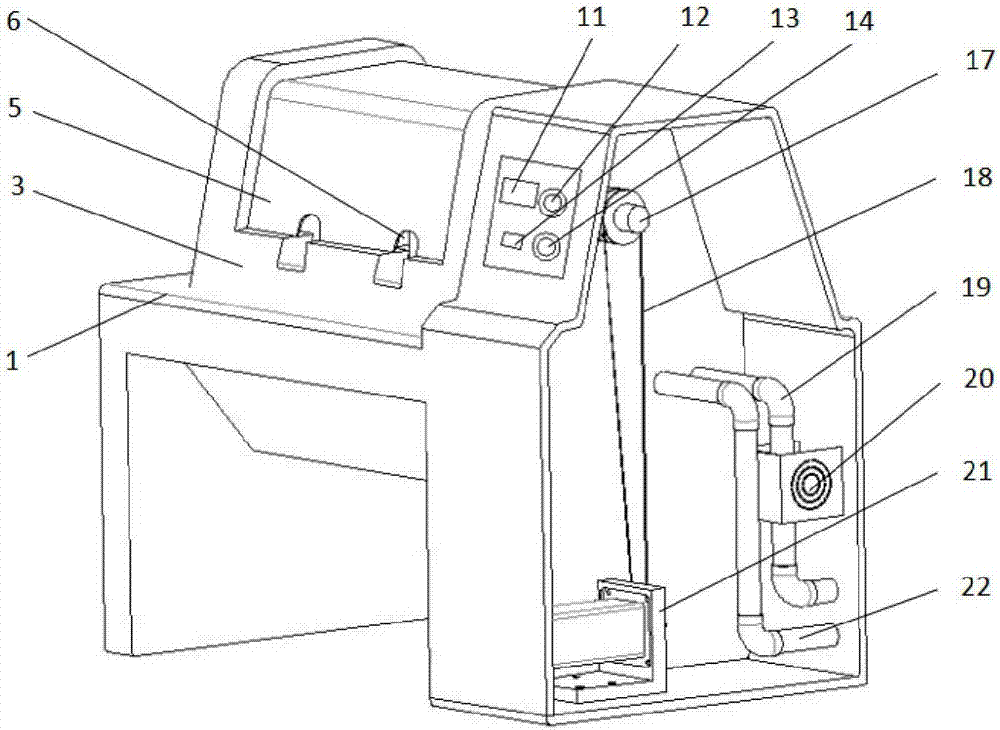

[0032] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0033] An integrated single-person jade processing device, including a working table 1, a protective cover 3, a grinding device, a power system, an operating light, a dust collector 7, and a polishing liquid nozzle 9; a water tank 2 and a water tank 2 are arranged in the middle of the working table 1 There are operating lights, dust suction device 7 and polishing liquid nozzle 9 on the side, the grinding device is arranged directly above the water tank 2, and the power system provides power for the grinding device; the protective cover 3 is hinged on the work surface 1, and the protective cover 3 Fasten it on the work surface 1, and cover the operation lamp, the vacuum device 7, the polishing liquid nozzle 9 and the grinding device in the protective cover 3.

[0034] A transparent observation window 5 is provided in the middle of the protective cover 3 , and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com