Fluorescence intensity ratio temperature measurement method based on fluorescence spectral line broadening mechanism

A fluorescence intensity ratio and fluorescence spectrum line technology, applied in the field of fluorescence intensity ratio temperature measurement, can solve the problems of low temperature measurement sensitivity and temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

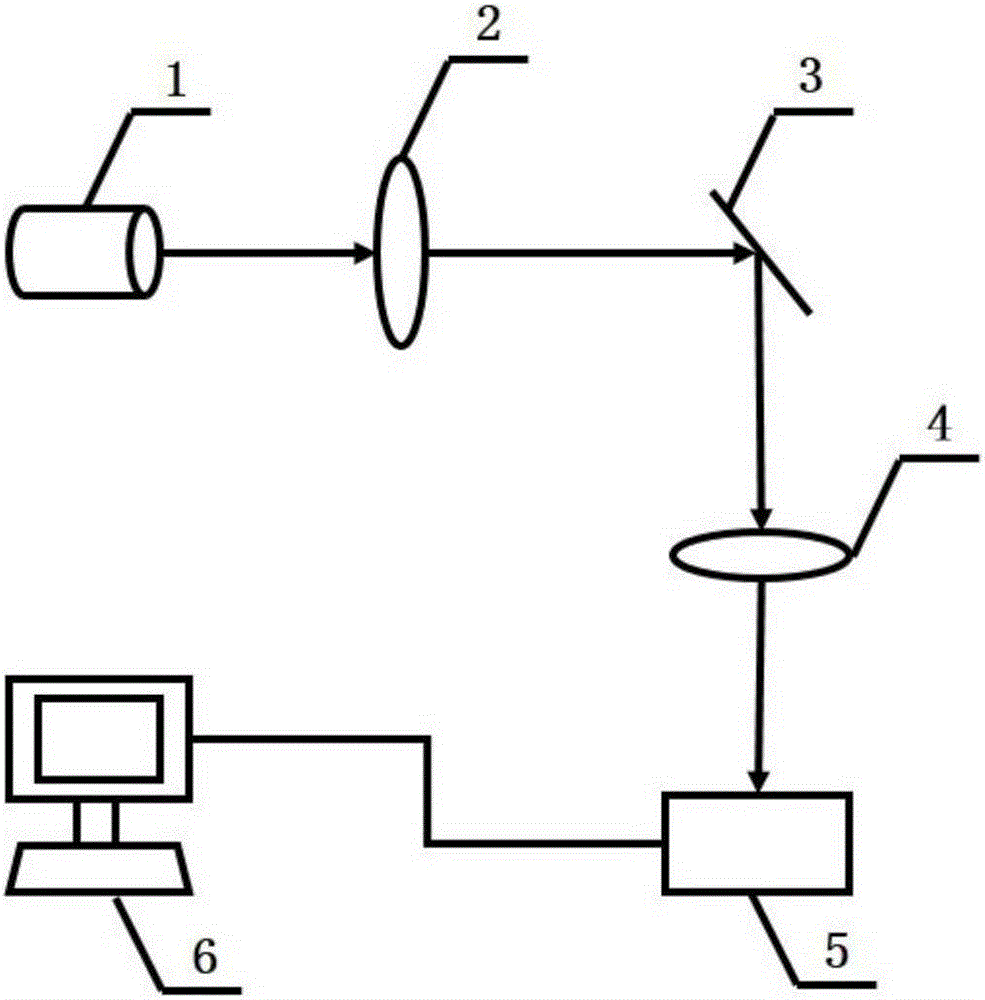

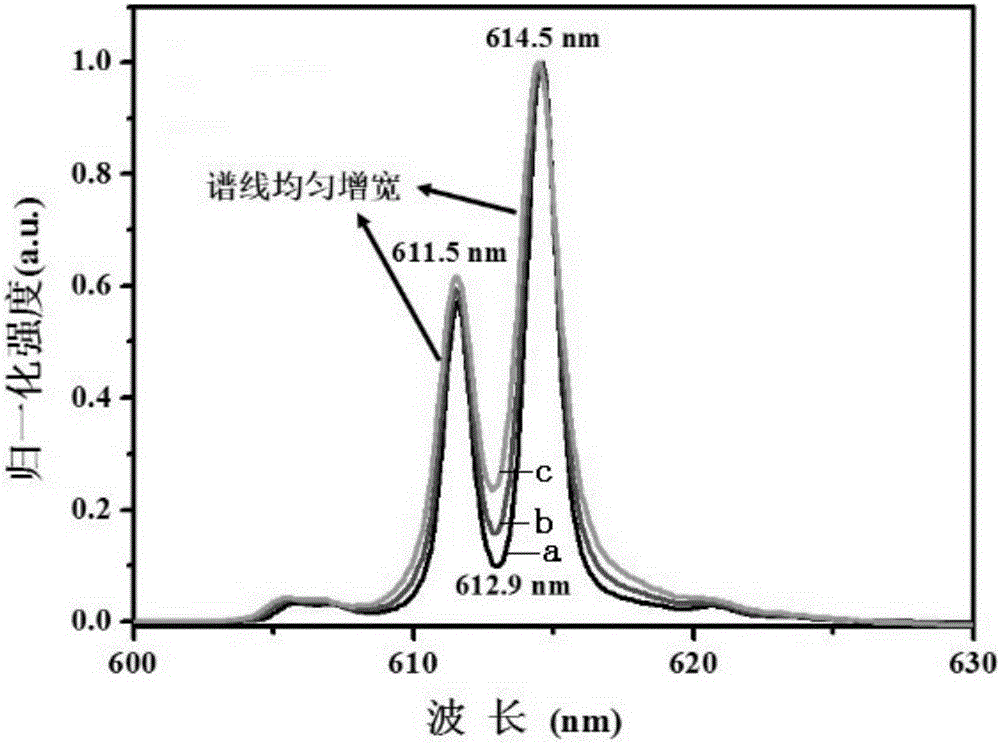

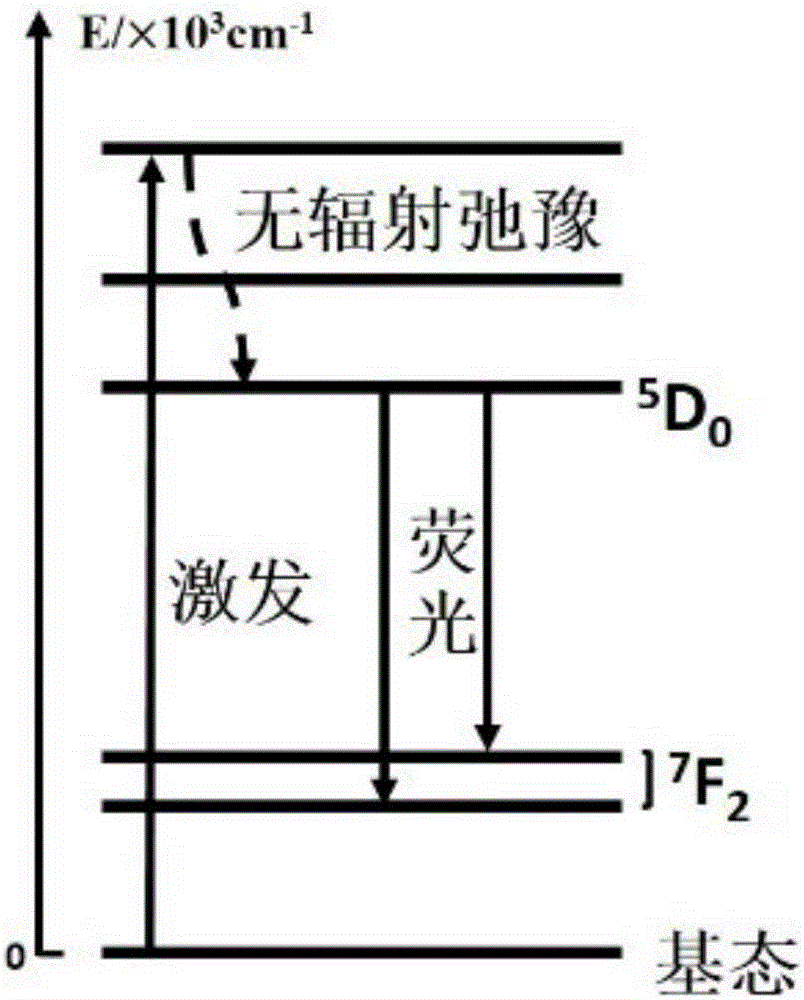

[0014] Specific Embodiment 1: In this embodiment, a fluorescence intensity ratio temperature measurement method based on the fluorescence spectral line broadening mechanism is carried out according to the following steps: 1. The near-ultraviolet light emitted by the 405nm light-emitting diode is converged and irradiated to Eu 3+ On the doped temperature-sensitive material, Eu 3+ The fluorescence emitted by the doped temperature-sensitive material is converged into the imaging spectrometer through another convex lens; the fluorescence collected by the imaging spectrometer has two fluorescence peaks, the fluorescence peaks are 611.5nm and 614.5nm respectively, and the two fluorescence peaks overlap to form a valley; 2. Connect the imaging spectrometer to the computer, and the computer performs analysis and processing, calculates and records the variation of the fluorescence intensity ratio between the valley value and the fluorescence peak A with the calibration temperature, and ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Eu 3+ Doped temperature-sensitive material is Eu 3+ :CaWO 4 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the two fluorescence peaks in step 1 both come from the same transition from one upper energy level to two adjacent lower energy levels. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com