Processing equipment of large-radius arc surface on rib wood of piano

A processing equipment and large-radius technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of processed products, high labor intensity, low efficiency, etc., and achieve reduced labor intensity and improved surface processing quality Lifting, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

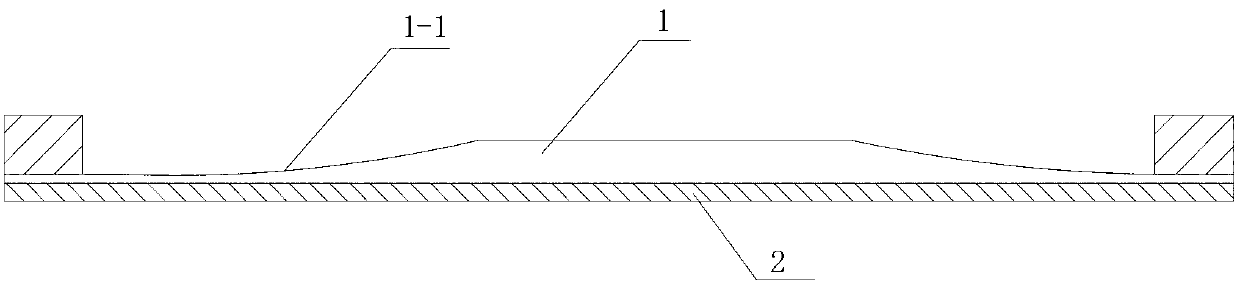

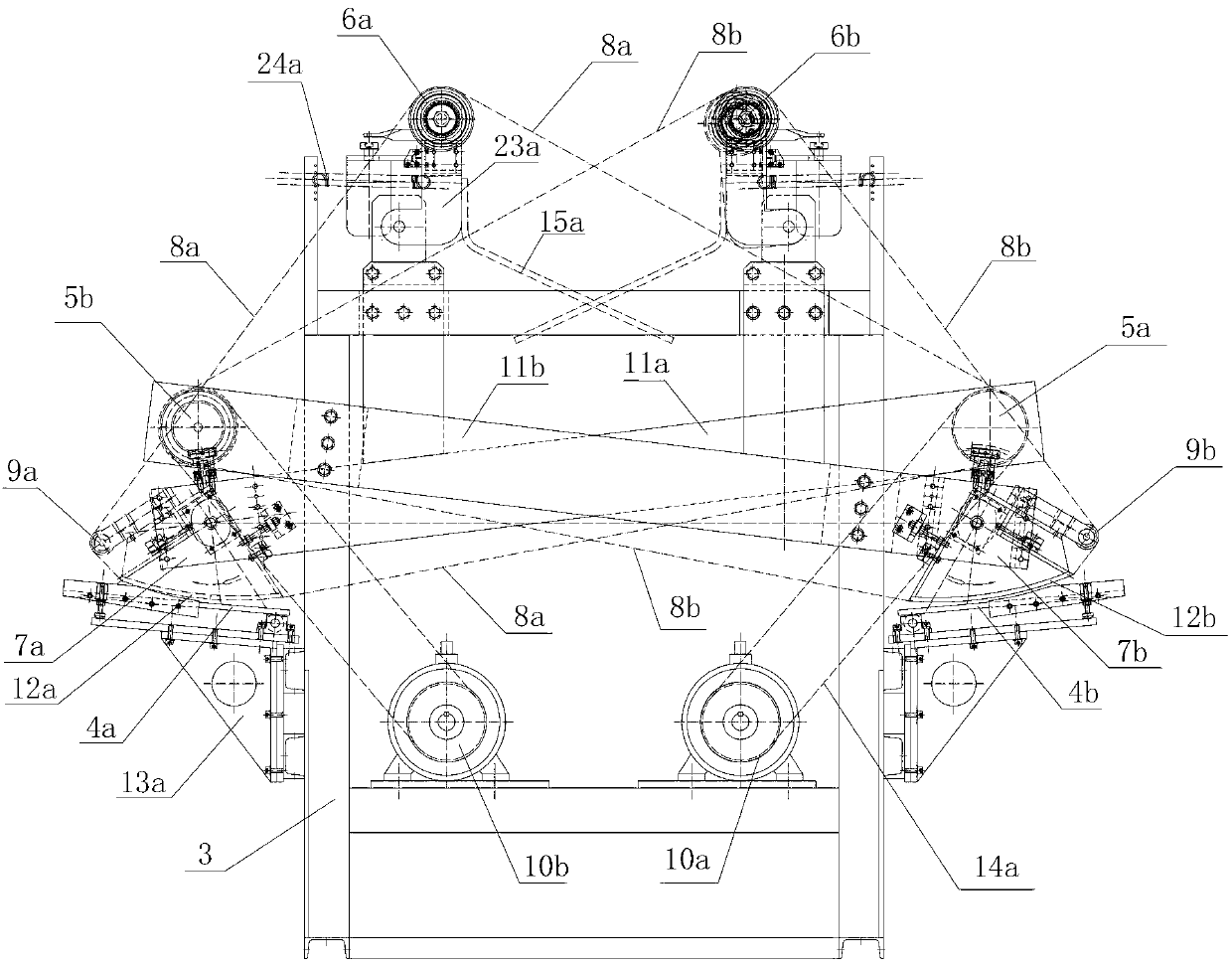

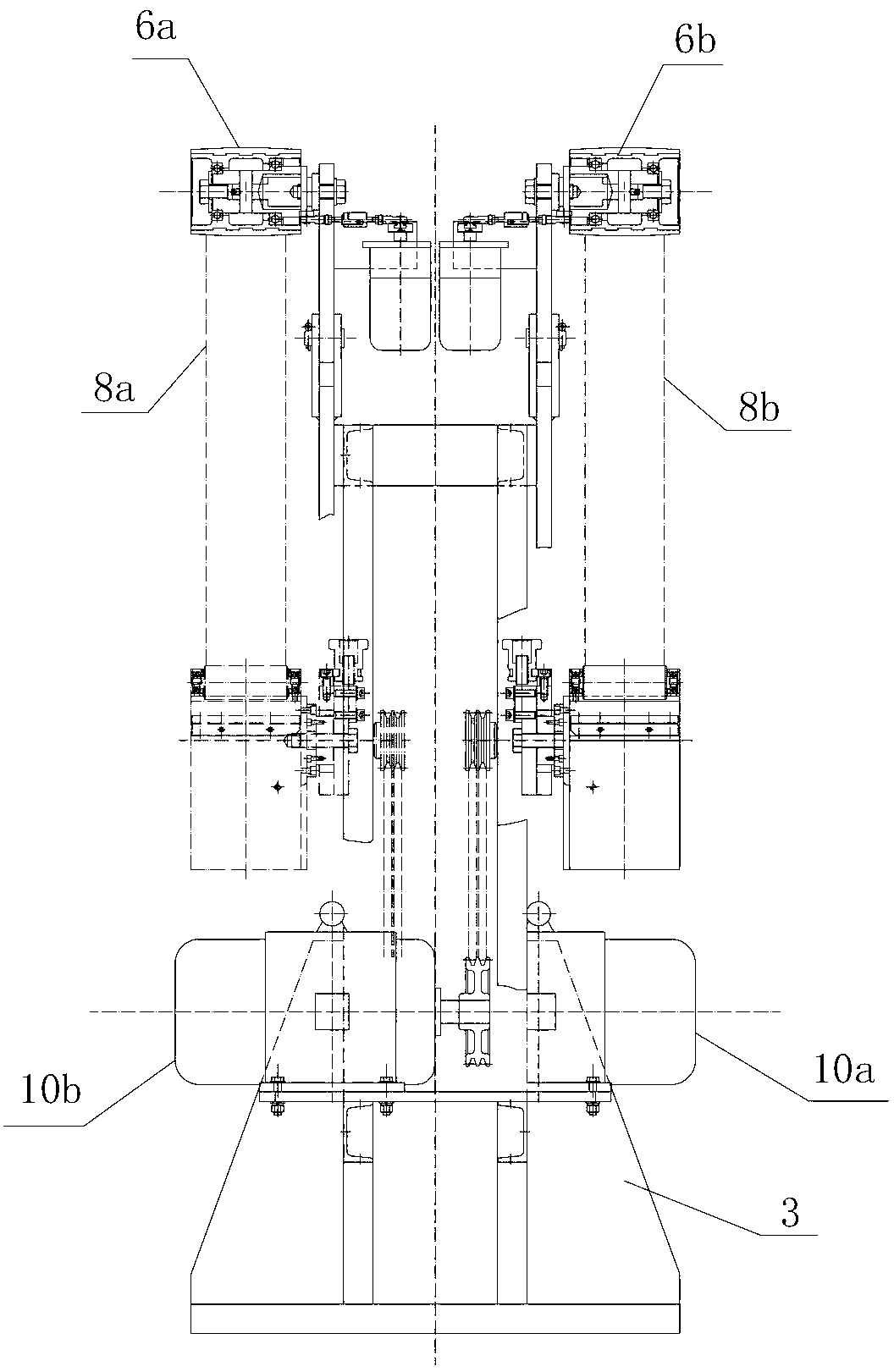

[0029] see Figure 2 ~ Figure 4 , the processing equipment of the large-radius arc surface on the piano rib of the present embodiment includes a frame 3 and two sets of processing assemblies, the two sets of processing assemblies are identical in composition, and the first set of processing assemblies is taken as an example below for a detailed description. The first set of processing components includes a workbench 4a, a power wheel 5a, a tension wheel 6a, a profiling grinding head 7a, an abrasive belt 8a, and a power unit 10a, wherein the power unit 10a is connected to the power wheel 5a, and the profiling The grinding head 7a is fixed on the frame 3, and the profiling grinding head 7a has an arc-shaped surface; the abrasive belt 8a is formed around the arc-shaped surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com