System and method for detecting cracks of fasteners of high-speed rails and subways

A detection system and fastener technology, which are used in railway car body parts, railway vehicle shape measuring instruments, transportation and packaging, etc., can solve the problem of inability to detect whether there are cracks in fasteners, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

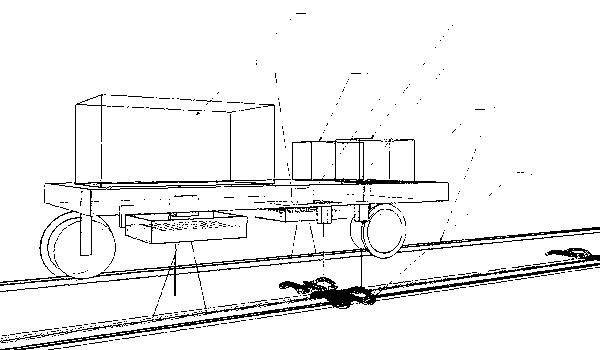

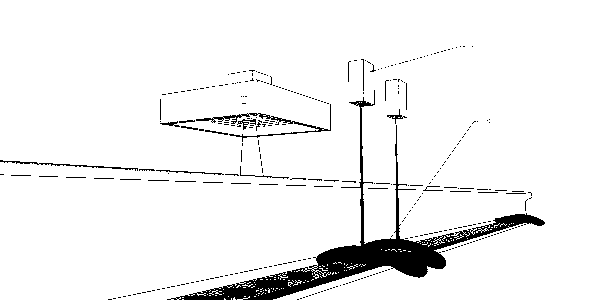

[0047] Such as figure 1 As shown, the present invention includes a trigger system, an image acquisition system, an image processing system and a circuit system. The trigger system includes: two photoelectric triggers1,2;

[0048] The image acquisition system includes: camera 3 and LED light source 4;

[0049] The image processing system includes: an image acquisition card and an industrial computer 6;

[0050] The circuit system includes: wires connecting various parts, a storage battery 5 and a signal processing device 7 .

[0051] Such as figure 1 As shown, the trolley is divided into front and rear sections along the direction of the rail. The image acquisition system and trigger system of the front part and the rear part are symmetrical with the rail as the axis, so only the first half of the trolley can explain the structure here. The photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com