A fully-automatic continuous kinematic viscosity measuring device

A kinematic viscosity and fully automatic technology, which is applied in the field of analytical instruments, can solve the problems of unfavorable determination of dark opaque oil samples, long warm-up time, shortened measurement range, etc., to expand the scope of use of the instrument, high degree of automation, and expanded test range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

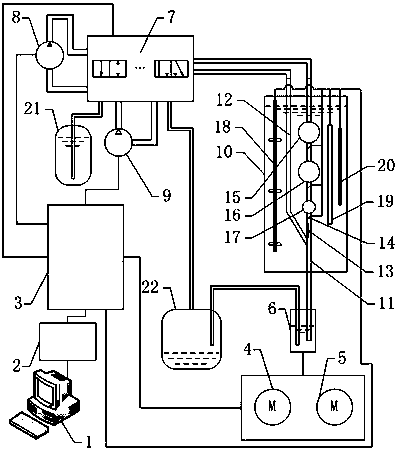

[0034] Combine the following Figure 1 ~ Figure 2 , the present invention will be further elaborated by specifying a preferred specific embodiment.

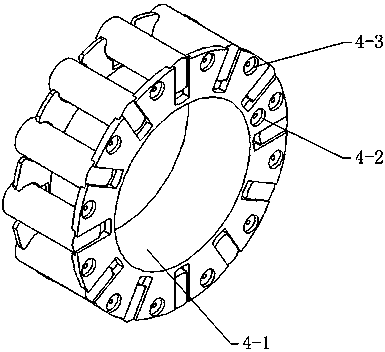

[0035] like figure 1 As shown, it is the fully automatic continuous operation kinematic viscosity measuring device provided by the present invention, including host computer 1, TCP to serial port server 2, MCU control system 3, rotating motor module 4, lifting motor module 5, test oil cup 6, Electromagnetic valve assembly 7, vacuum pump 8, air compressor 9, oil bath 10, viscometer 11, stirring device 18, heating rod 19, temperature sensor 20, cleaning bottle 21 and waste liquid bottle 22.

[0036] Wherein, the viscometer 11 includes a balance tube 12 , a capillary tube 13 , an NTC sensor 14 , an upper bulb 15 , a middle bulb 16 , and a lower bulb 17 . The upper bulb 15 acts as a buffer and protector, the middle bulb 16 is used for testing oil samples with lower viscosity values, and the lower bulb 17 can test oil samples with h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com