Processing equipment for seafood processing

A technology for processing equipment and seafood, applied in the processing of crustaceans, shrimp/lobster processing, applications, etc., can solve food safety problems, dust and debris, unclean cleaning, etc., to achieve high production efficiency and easy transportation and fine cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

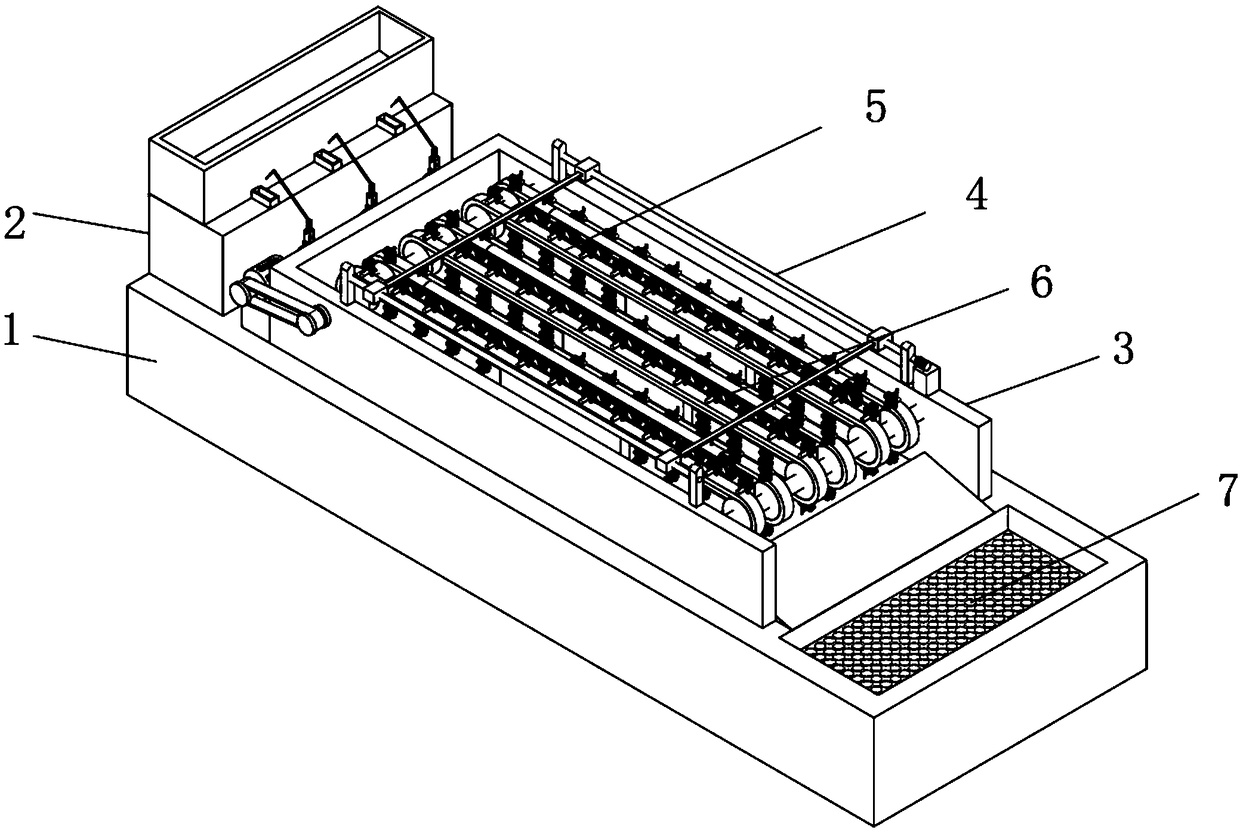

[0056] Example as Figure 1-2 , a processing equipment for seafood processing, comprising a base 1, a washing device 2, a box body 3, a back rubbing device 4, a conveying and clamping device 5, a laparotomy device 6, and a draining device 7, characterized in that: The top side of the base 1 is fixed with a flushing device 2, and one side of the flushing device 2 is provided with a box body 3, and the box body 3 is fixedly connected with the base 1, and three groups of conveying clamps are equidistantly arranged in the box body 3 device 5, and the bottom of each conveying and clamping device 5 is correspondingly provided with an abdominal washing device 6, and the abdominal washing device 6 is fixed on the bottom of the casing 3, and a back rubbing device 4 is provided above the conveying and clamping device 5, and the back rubbing The device 4 is fixed on the top of the box body 3, and the two ends of the three groups of conveying and gripping devices 5 are symmetrically provi...

Embodiment 2

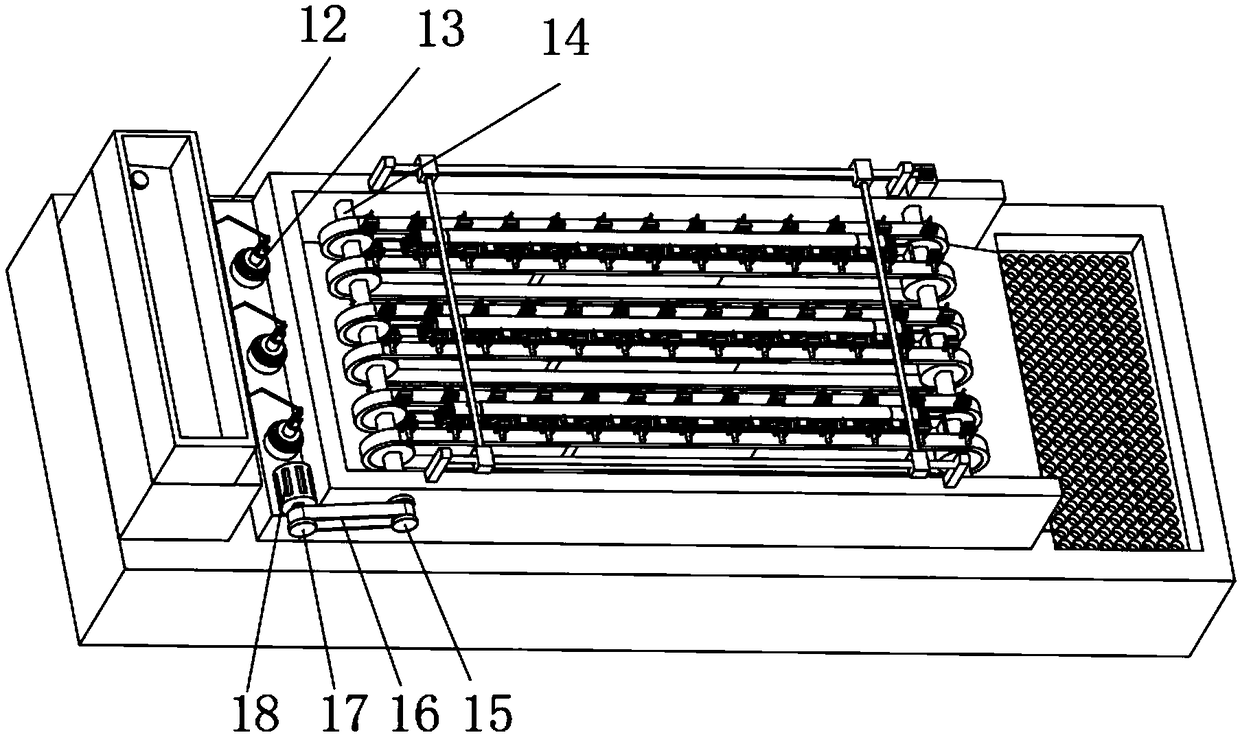

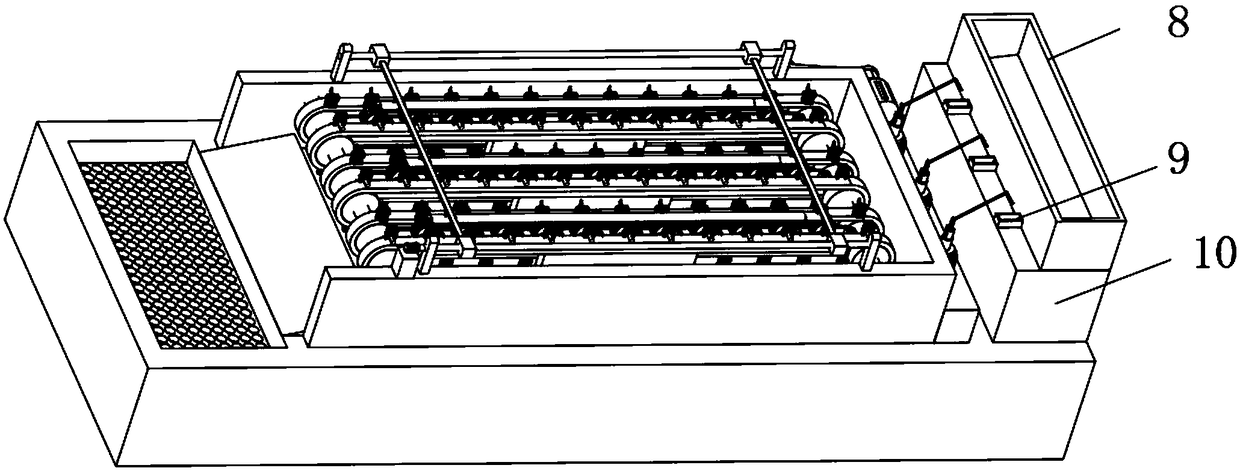

[0057] Example two such as Figure 3-4 The flushing device 2 includes a flushing tank 8, a lobster outlet 9, a water storage tank 10 and a drain valve 11, the water storage tank 10 is fixed on the top of the base 1, and the top of the water storage tank 10 is fixedly connected to the flushing tank 8, and the One side of the flushing box 8 is equidistantly provided with three lobster outlets 9, and the bottom of the flushing box 8 is provided with a drain valve 11.

Embodiment 3

[0058] Embodiment three such as Figure 4 , the back rubbing device 4 includes a support block 19, a second motor 20, a support column 21, a first connection block 22, a screw mandrel 23, a support rod 24, a back rub cleaning mechanism 25, a slide bar 51, a second connection block 52 , the support block 19 is fixed on the top of the box wall on one side of the box body 3, the top of the support block 19 is fixed with the second motor 20, and the top of the box wall on both sides of the box body 3 is symmetrically fixed with four supports column 21, and the top of the two sides of the box wall are respectively provided with a screw 23 and a slide bar 51, the screw 23 is movably connected with two support columns 21 located on the same side of the top of the box wall of the box body 3 through bearings, the first The output ends of the two motors 20 are fixedly connected to one end of the screw rod 23, and the two ends of the slide rod 51 are fixedly connected to two support colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com