Novel chamber type pressure filter

A box-type filter press, a new type of technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as incomplete solid-liquid separation, blockage of filter cloth mesh, and reduced work efficiency, so as to reduce labor costs and maintenance costs, convenient filter cake discharge, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

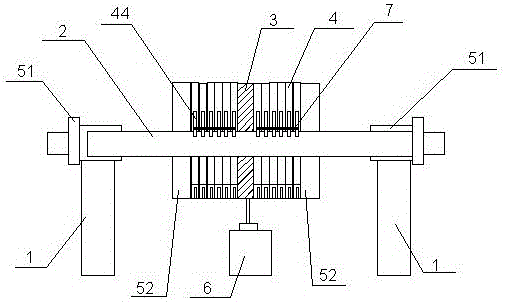

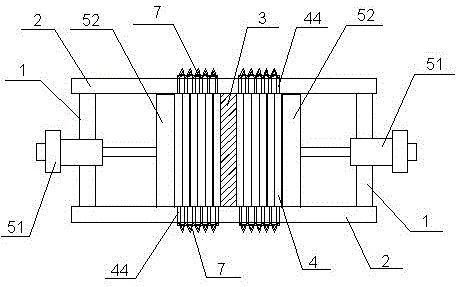

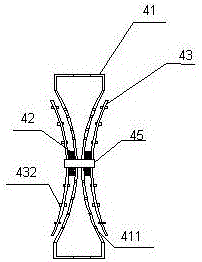

[0020] As shown in the figure, a new box filter press according to the present invention includes a bracket 1, two beams 2, a thrust plate 3, a filter unit 4, a pressing device 5, a feed pump 6 and a tie rod device 7 , two beams 2 are arranged parallel to each other on the support 1, the front and rear ends of the thrust plate 3 are respectively fixed in the middle of the two beams 2, and the bottom of the thrust plate 3 is provided with a feed port, The left and right side walls are provided with a discharge port, the feed pump 6 is connected to the feed port of the thrust plate 3, and the left and right sides of the thrust plate 3 are respectively provided with several The filter unit 4 parallel to the plate 3 is connected by a pull rod device 7 between several filter units 4, and the left and right ends of the support 1 are respectively provided with a pressing device 5, and the pressing device 5 includes a hydraulic structure 51 and a pusher Plate 52, the hydraulic structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com