High oil-water ratiooil base drilling fluid system

An oil-based drilling and oil-water ratio technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high pollution degree, poor anti-pollution ability, high cost, etc., and achieve increased economic benefits and high demulsification voltage , the effect of moderate activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in further detail below using specific examples. The features in can be combined with each other.

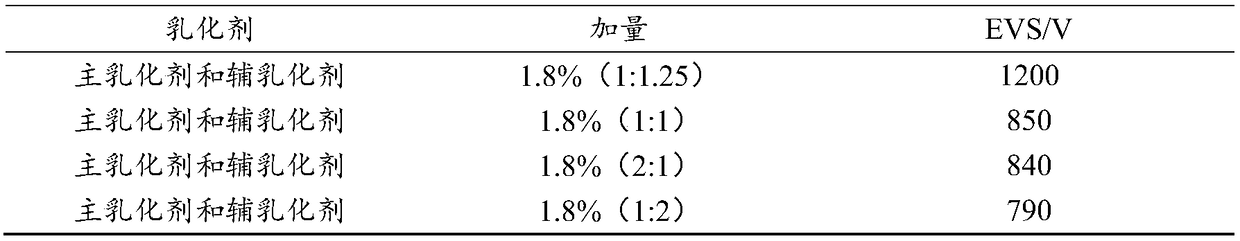

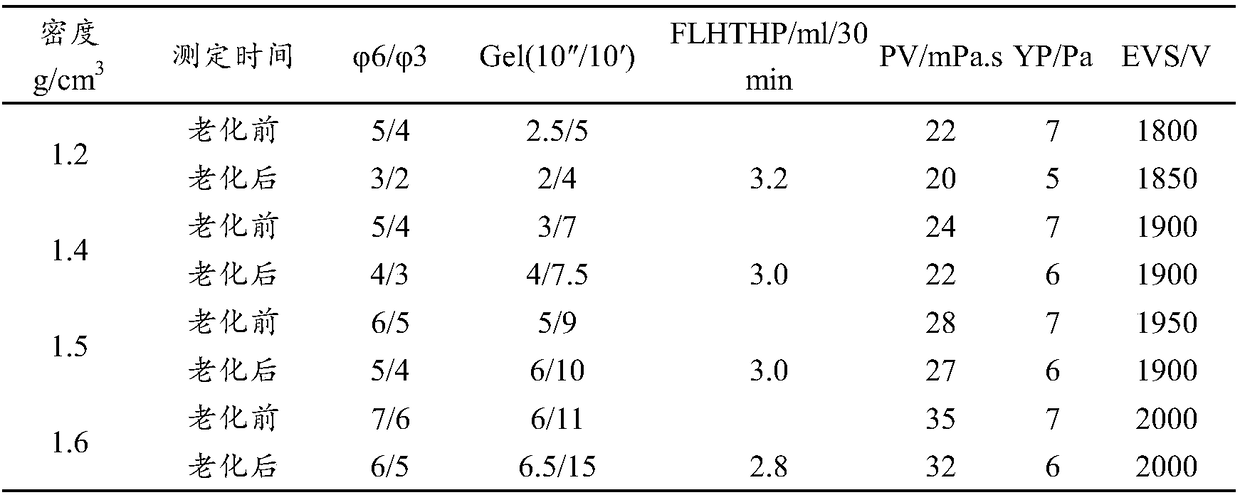

[0017] A high oil-water ratio oil-based drilling fluid system provided by an embodiment of the present invention includes 90-95 volume parts of base oil and 5-10 volume parts of water phase, and 0.8-1.8 weight percent of the total volume of base oil and water phase primary emulsifier, 1.0-2.0 weight percent secondary emulsifier, 1.2-1.5 weight percent wetting agent, 2.0-3.0 weight percent organic soil, 3.0-4.0 weight percent calcium oxide, 3.5-4.5 weight percent emulsifying Plugging material, 1-1.5 weight percent asphalt-type sealing material, 2.0-2.5 weight percent calcium chloride brine. The co-emulsifier is composed of an organic acid amide surfactant and a cationic emulsifier, and the weight ratio of the organic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com