Anhydrous coolant and preparation method thereof

A technology of water cooling and propylene glycol, which is applied in the field of engine coolant, can solve the problems of destroying propylene glycol, small hidden dangers and big failures, and leakage of cooling system, so as to reduce the formation of bubbles, prevent deterioration and sourness, and reduce air resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An anhydrous cooling liquid, which is composed of the following raw materials: pharmaceutical grade 1,2 propylene glycol 1000kg, sodium benzoate 2.5kg, borax 1.6kg, sodium nitrite 1.5kg, triethanolamine 1.5kg, benzotriazole 0.3kg, Tributyl phosphate 0.1kg, sucrose octaacetate 6kg, food grade pigment 0.01kg.

[0022] During preparation, heat 1000kg of pharmaceutical grade 1,2 propylene glycol to 40°C with a heating and stirring tank, then add 2.5kg of sodium benzoate, 1.6kg of borax, 1.5kg of sodium nitrite, 1.5kg of triethanolamine, 0.3kg of benzotriazole, Add 0.1kg of tributyl phosphate, 6kg of sucrose octaacetate, and 0.01kg of food-grade pigment into a heating and stirring tank and stir, and keep at 40°C until completely dissolved to obtain anhydrous cooling liquid, which is filled and stored.

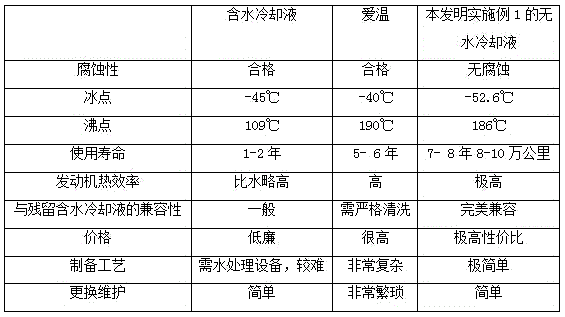

[0023] After inspection, the anhydrous cooling liquid prepared in this example has a final density (20°C) of 1035kg / m3, a freezing point of -52.6°C, a boiling point of 186°C,...

Embodiment 2

[0025] An anhydrous cooling liquid, which is composed of the following raw materials: pharmaceutical grade 1,2 propylene glycol 1000kg, sodium benzoate 2.4kg, borax 1.7kg, sodium nitrite 1.4kg, triethanolamine 1.6kg, benzotriazole 0.2kg, Tributyl phosphate 0.15kg, sucrose octaacetate 5kg, food grade pigment 0.011kg.

[0026] During preparation, take 300kg of propylene glycol and add it into the heating tube and heat it to 40°C, slowly add 2.4kg of sodium benzoate, 1.7kg of borax, 1.4kg of sodium nitrite, 1.6kg of triethanolamine, 0.2kg of benzotriazole, 0.15kg of Tributyl phosphate, 5kg sucrose octaacetate, 0.011kg food-grade pigment, stir evenly without precipitation, then add the remaining 700kg propylene glycol, keep heating at 40°C and stir until completely dissolved to obtain anhydrous cooling liquid, fill and store.

[0027] After inspection, the anhydrous cooling liquid prepared in this example has a final density (20°C) of 1035kg / m3, a freezing point of -52.6°C, a boil...

Embodiment 3

[0029] An anhydrous cooling liquid composed of the following raw materials: pharmaceutical grade 1,2 propylene glycol 1000kg, sodium benzoate 2.6kg, borax 1.5kg, sodium nitrite 1.6kg, triethanolamine 1.4kg, benzotriazole 0.4kg, Tributyl phosphate 0.05kg, sucrose octaacetate 7kg, food grade pigment 0.009kg.

[0030] When preparing, take 200kg propylene glycol, add 2.6kg sodium benzoate, 1.5kg borax, 1.6kg sodium nitrite, 1.4kg triethanolamine, 0.4kg benzotriazole, 0.05kg tributyl phosphate, 7kg sucrose octaacetate, 0.009 kg of food-grade pigment, stir until it becomes fluid, then add the above-mentioned fluid raw materials to the remaining 800kg of propylene glycol that has been heated to 40°C, keep heating at 40°C and stir until it is completely dissolved to obtain an anhydrous cooling liquid, fill and store .

[0031] After inspection, the anhydrous cooling liquid prepared in this example has a final density (20°C) of 1035kg / m3, a freezing point of -52.6°C, a boiling point of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com