Simultaneous process of electroreducing ytterbium and oxidizing cerium

An electrolysis method and cerium oxide technology, which are applied in the improvement of process efficiency, instruments, optics, etc., can solve the problems of not considering the utilization of cathode electric energy, short process flow, non-compliance, etc., and achieve easy control, simple process, and avoidance of consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

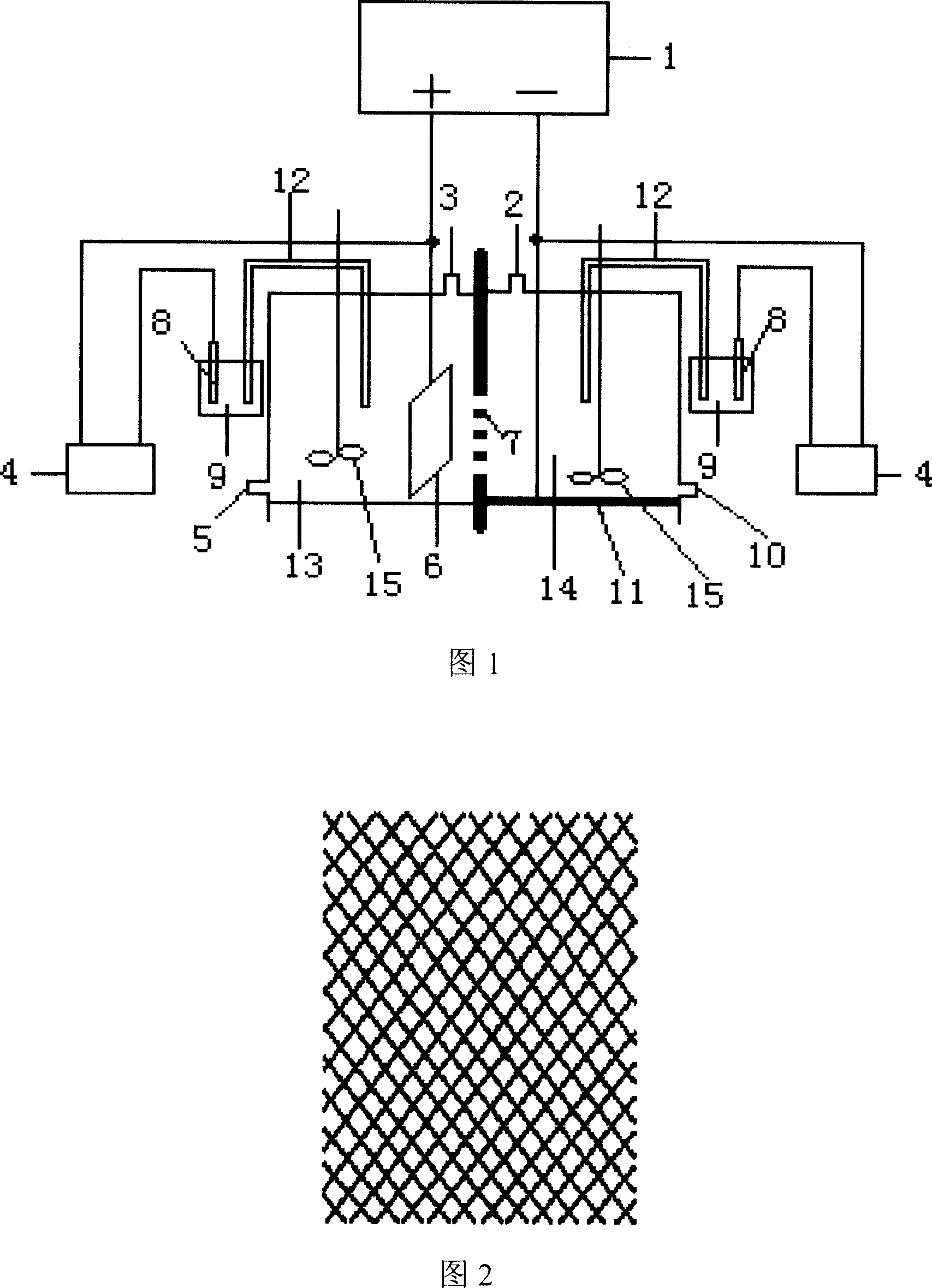

Method used

Image

Examples

Embodiment Construction

[0026] A. Preparation of cathode solution: add water to the carbonate of thulium, ytterbium, and lutetium concentrates, and then dissolve them with sulfuric acid to prepare a sulfuric acid solution of a mixture of thulium, ytterbium, and lutetium, with a concentration of 0.1965mol / L. Adjust the solution The pH is 0.60;

[0027] B. Preparation of anode solution: After adding cerium-rich carbonate to water for slurry adjustment, dissolve it with sulfuric acid to prepare a cerium carbonate solution with a concentration of 0.2758mol / L and Ce / REO of 61.11%, [H + ] is 2.0mol / L;

[0028] C. get 1000ml thulium ytterbium lutetium sulfuric acid solution and 1000ml cerium sulfate solution respectively, drop into electrolyzer cathode chamber 14 and anode chamber 13;

[0029] D. Electrolysis: the negative electrode is metallic mercury, and the anode is a diamond-shaped reticular ruthenium-iridium-titanium alloy. Under the situation of 20° C., start the stirring device 15 of the negative e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com