Multi-circulation type automatic paper pulp impurity screening device and working method thereof

A technology of multiple circulation and screening devices, used in textiles and papermaking, fiber raw material processing, etc., can solve problems such as affecting product quality and difficult to remove impurities in pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

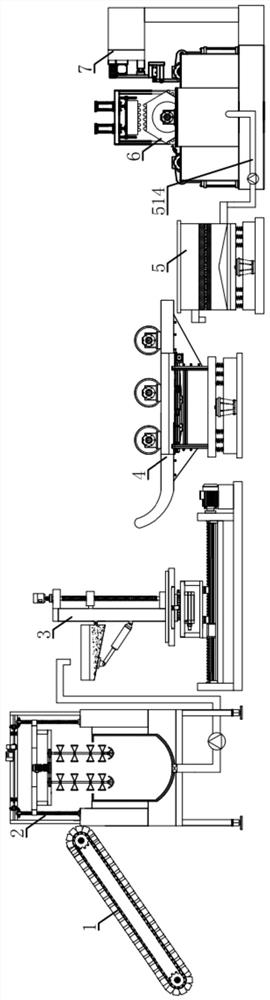

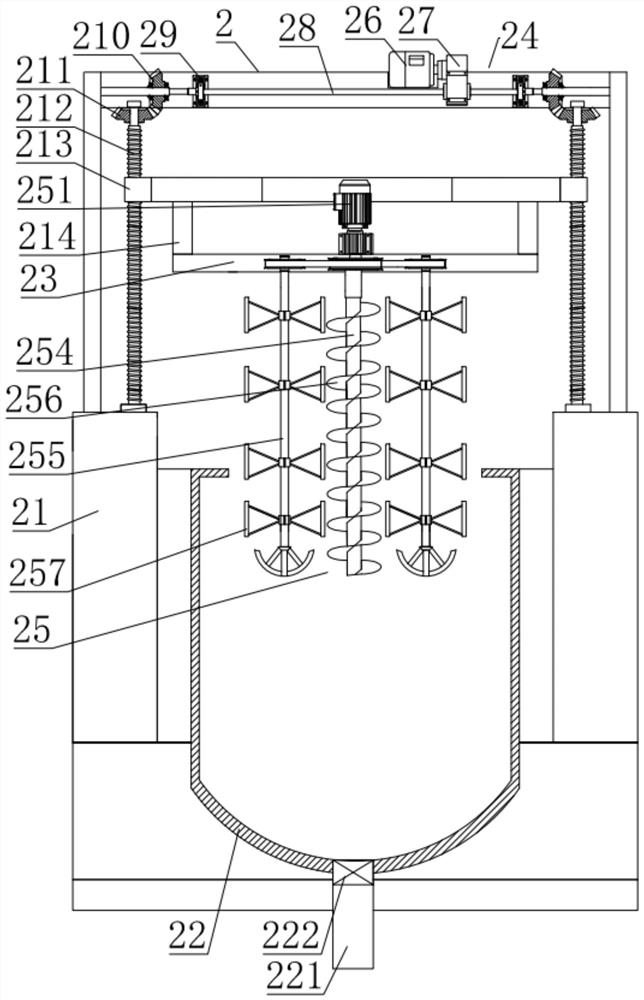

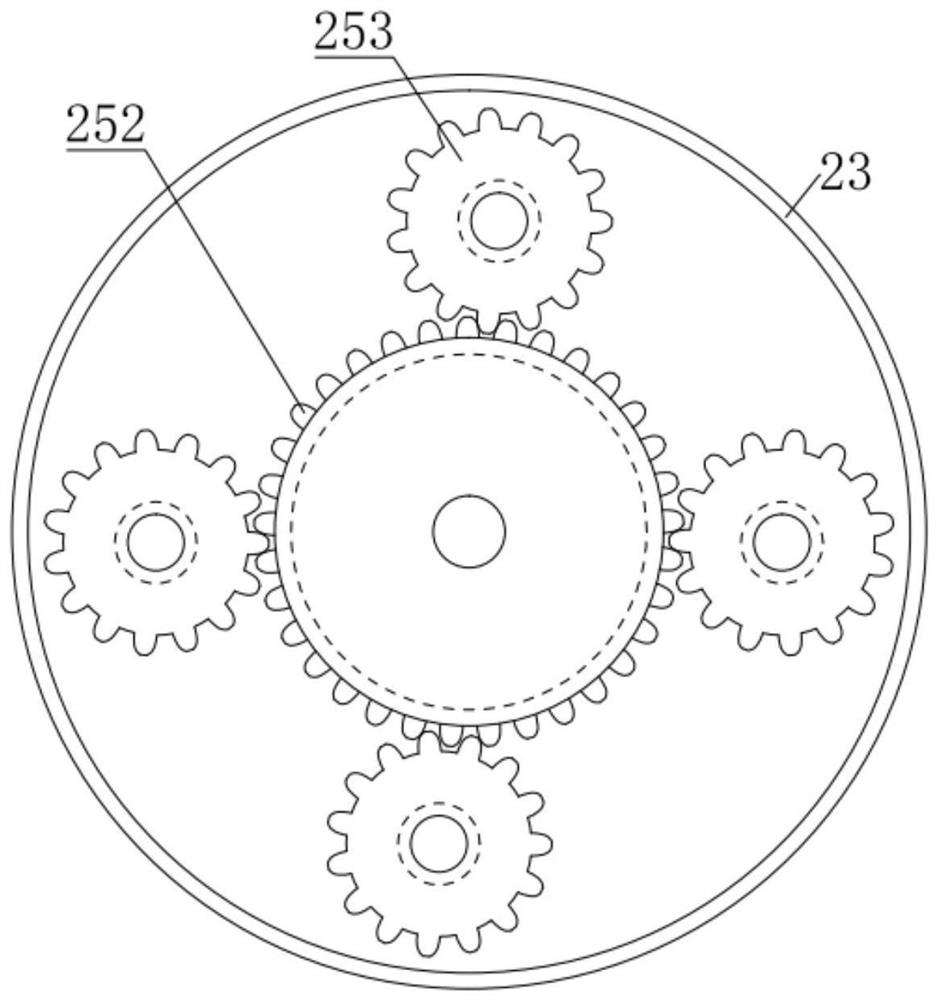

[0046] Such as figure 1 The shown multi-cycle automatic pulp impurity screening device includes a waste cardboard feeding magnetic separation conveyor belt 1, a pulp stirring unit 2, a pulp transfer unit 3, a pulp impurity screening unit 4, a pulp vibration screening unit 5, a pulp forming unit 6 and Pulp unloading unit 7, the waste cardboard feeding magnetic separation conveyor belt 1, pulp stirring unit 2, pulp transfer unit 3, pulp impurity screening unit 4, pulp vibration screening unit 5, pulp forming unit 6 and pulp unloading unit 7 Set up in sequence according to the production process, the waste cardboard feeding magnetic separation conveyor belt 1 transports the waste cardboard to the pulp stirring unit 2, and the pulp stirring unit 2 is continuously filled with solvent liquid and waste cardboard, and the pulp stirring unit 2 can be Stirring of pulp, the pulp transfer unit 3 can transport the pulp in the pulp stirring unit 2 to the pulp impurity screening unit 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com